Intelligent manufacturing production-line for refractory bricks

A technology for intelligent manufacturing and refractory bricks, applied in the field of refractory brick manufacturing, can solve the problems that the degree of automation of the refractory brick production line needs to be further improved, and the production process needs to be further optimized, so as to reduce the expenses for accidents and occupational diseases, reduce the risk of safe production, and solve the problem of recruitment. difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

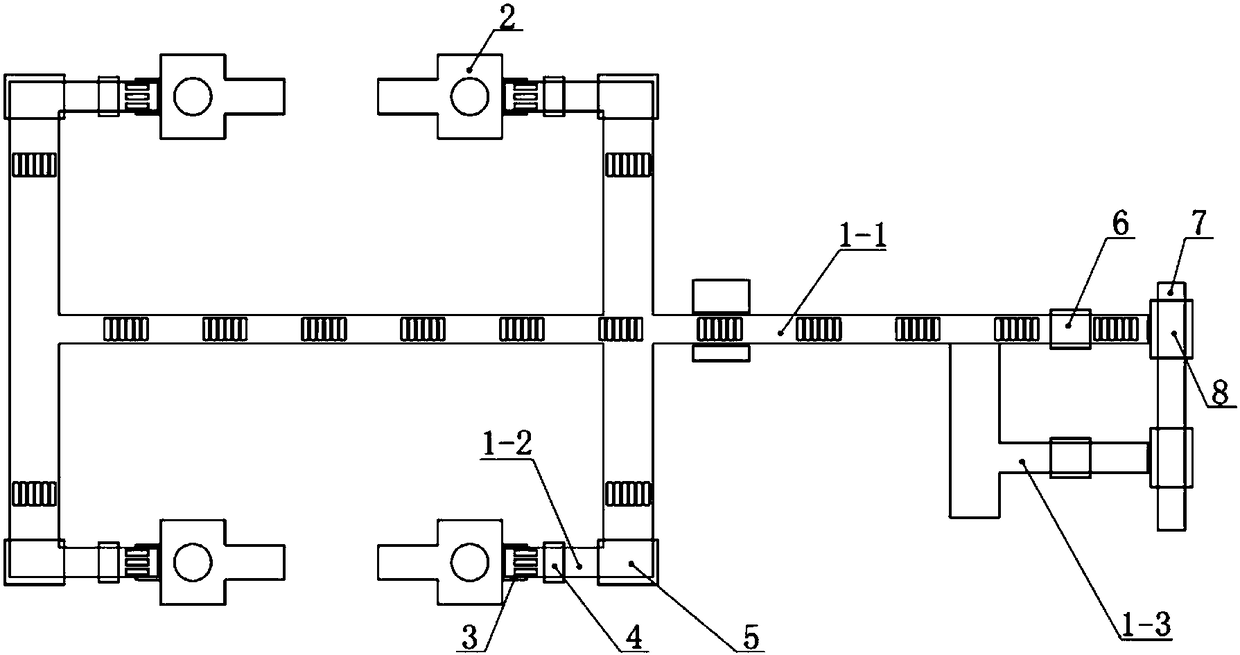

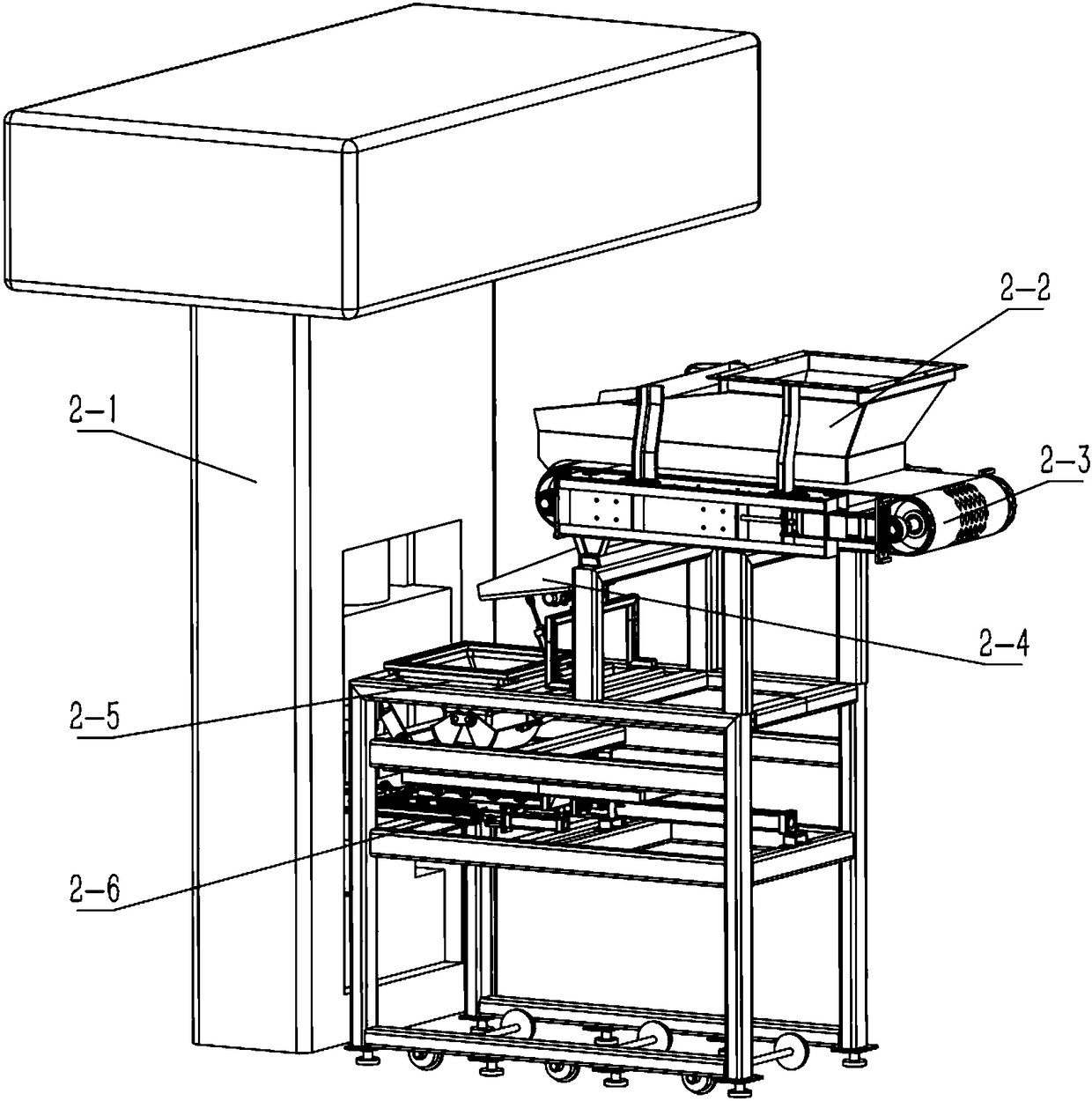

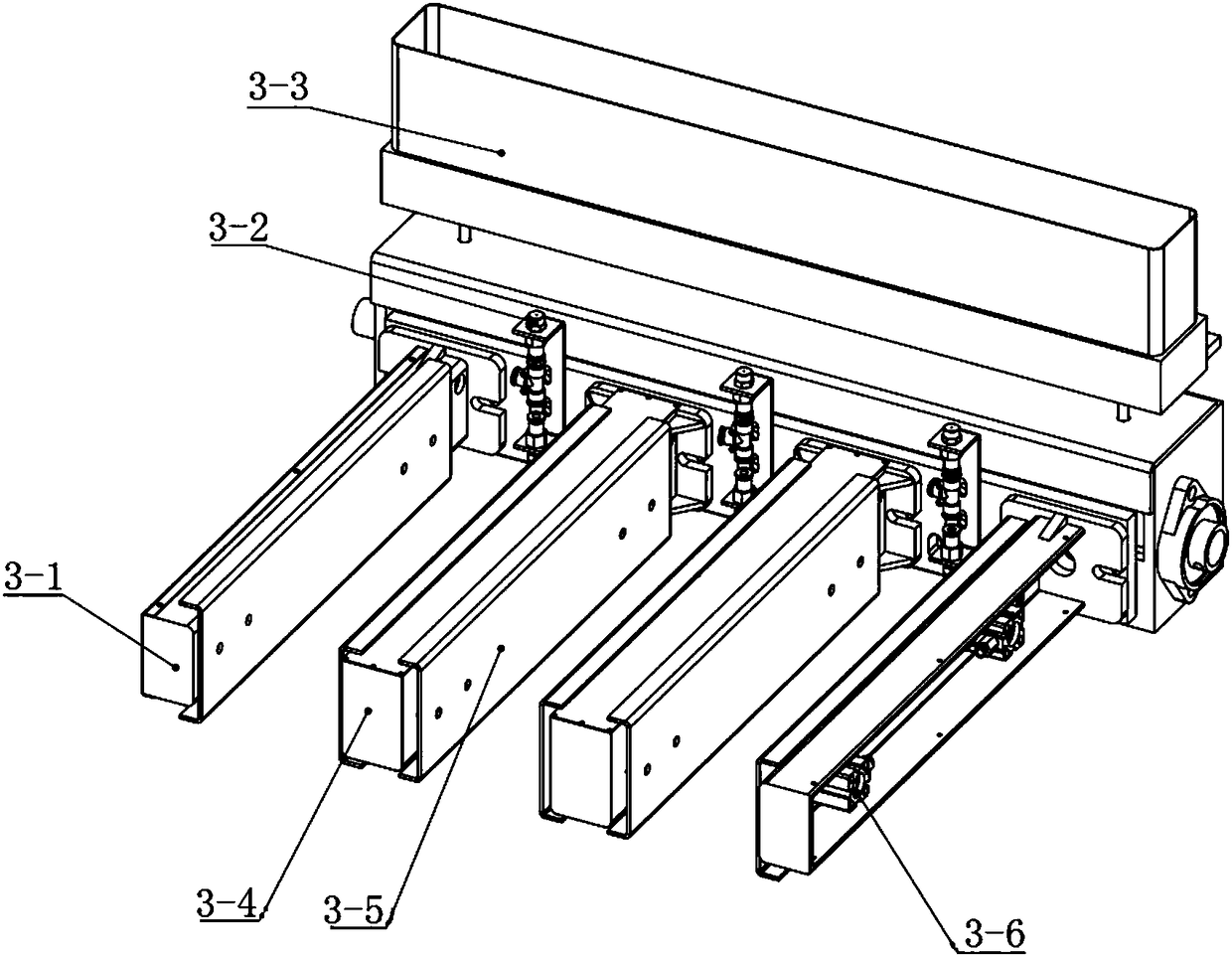

[0071] combine figure 1 As shown, a refractory brick intelligent manufacturing production line in this embodiment includes an intelligent control system, a conveying line, an automatic cloth pressing brick device 2, an automatic brick clamping manipulator 3, a visual inspection device 4, an automatic line shifting device 5, and an automatic stacking device. Device 6 and transfer car drive device 7. The conveying line includes a main flow line 1-1 and a front auxiliary line 1-2. The main flow line 1-1 is an upper and lower double-layer horizontal circulation conveying line. To the end of the main flow line 1-1, the lower layer is used to return the empty flow transfer plate to each front sub-line 1-2, and the junction of the front sub-line 1-2 and the main line 1-1 is also installed for the front The circulation plate filled with bricks on the auxiliary assembly line 1-2 is transported to the upper layer of the main flow line 1-1, and the empty flow plate returned from the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com