Pneumatic type waste zip-top can extrusion forming and recycling equipment for environmental protection

A technology for extrusion molding and recycling equipment, applied in the direction of presses, manufacturing tools, etc., can solve the problems of poor extrusion effect, manual collection of materials, etc., and achieve good extrusion molding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

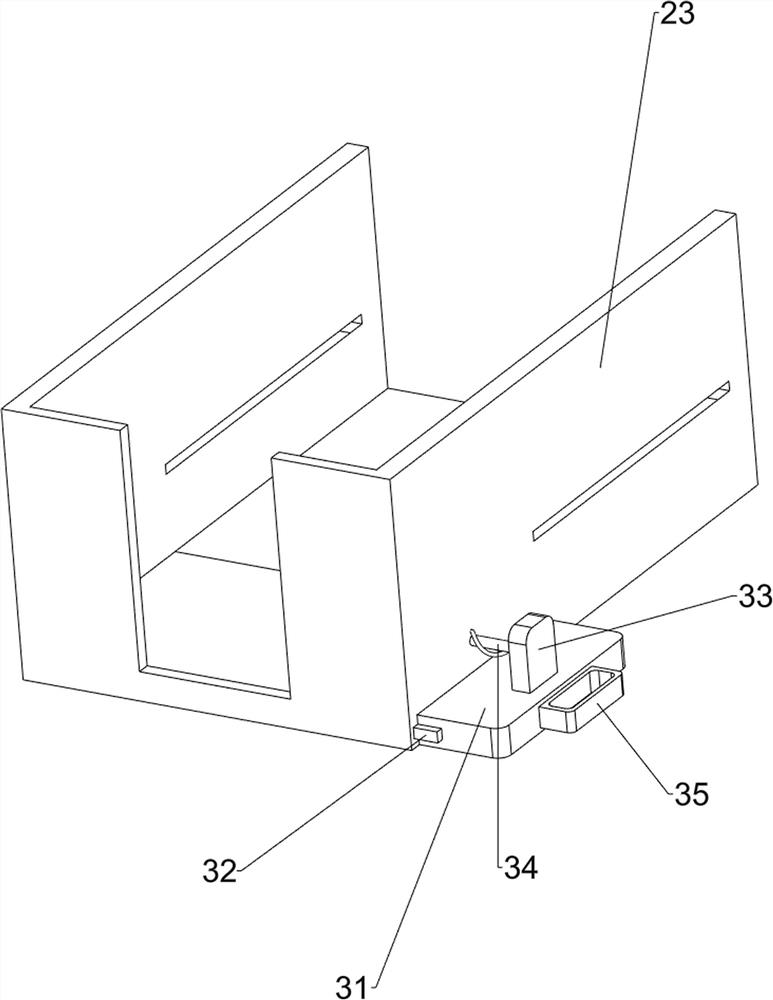

[0062] A pneumatic recycling equipment for extruding waste cans for environmental protection, such as figure 1 As shown, it includes a base 1 , a compression mechanism 2 and a feeding mechanism 3 , the left side of the base 1 is provided with a compression mechanism 2 , and the lower rear side of the compression mechanism 2 is provided with a feeding mechanism 3 .

[0063] When people want to squeeze and recycle waste cans, they can use this environmentally friendly pneumatic recovery equipment. First, put the cans in the compression mechanism 2, then start the compression mechanism 2, and the compression mechanism 2 will squeeze the cans, and then send Pull the unloading mechanism 3 to the left to make the extruded pop cans fall downwards, close the compression mechanism 2 after completing the above actions, push back the unloading mechanism 3 to the right, and repeat the above steps to recycle the pop cans again.

Embodiment 2

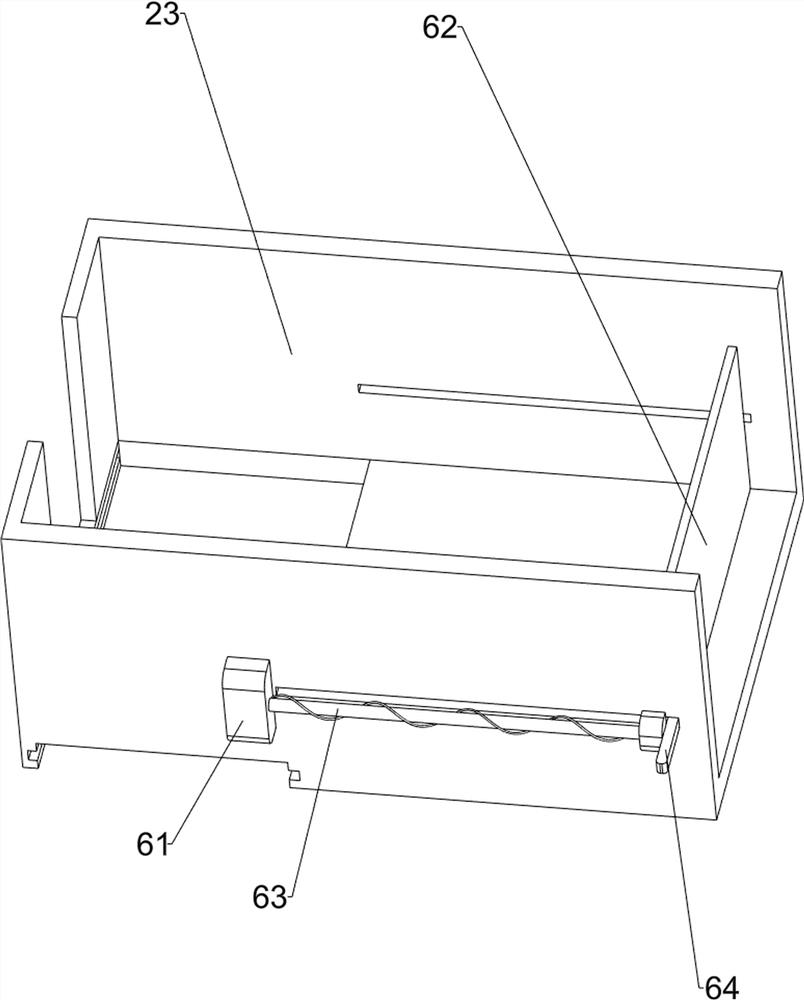

[0065] On the basis of Example 1, such as figure 2 with image 3 As shown, the compression mechanism 2 includes a cylinder 21, a push rod 22, an extruding table 23 and an extruding plate 24. The cylinder 21 is installed on the left side of the upper front part of the base 1, and the output shaft of the cylinder 21 is provided with a push rod 22. An extruding table 23 is provided at the left rear portion of the seat 1, and an extruding plate 24 is provided at the rear end of the push rod 22, and the extruding plate 24 is slidably connected with the extruding table 23.

[0066]People put the pop cans to be extruded into the extrusion table 23, open the cylinder 21, the cylinder 21 stretches and pushes the push rod 22 backwards, thereby pushing the extrusion plate 24 backwards, and the extrusion plate 24 pushes the pop cans backwards, and the pop cans are Clamped between the inner wall on the rear side of the extrusion table 23 and the extrusion plate 24, the effect of extrudin...

Embodiment 3

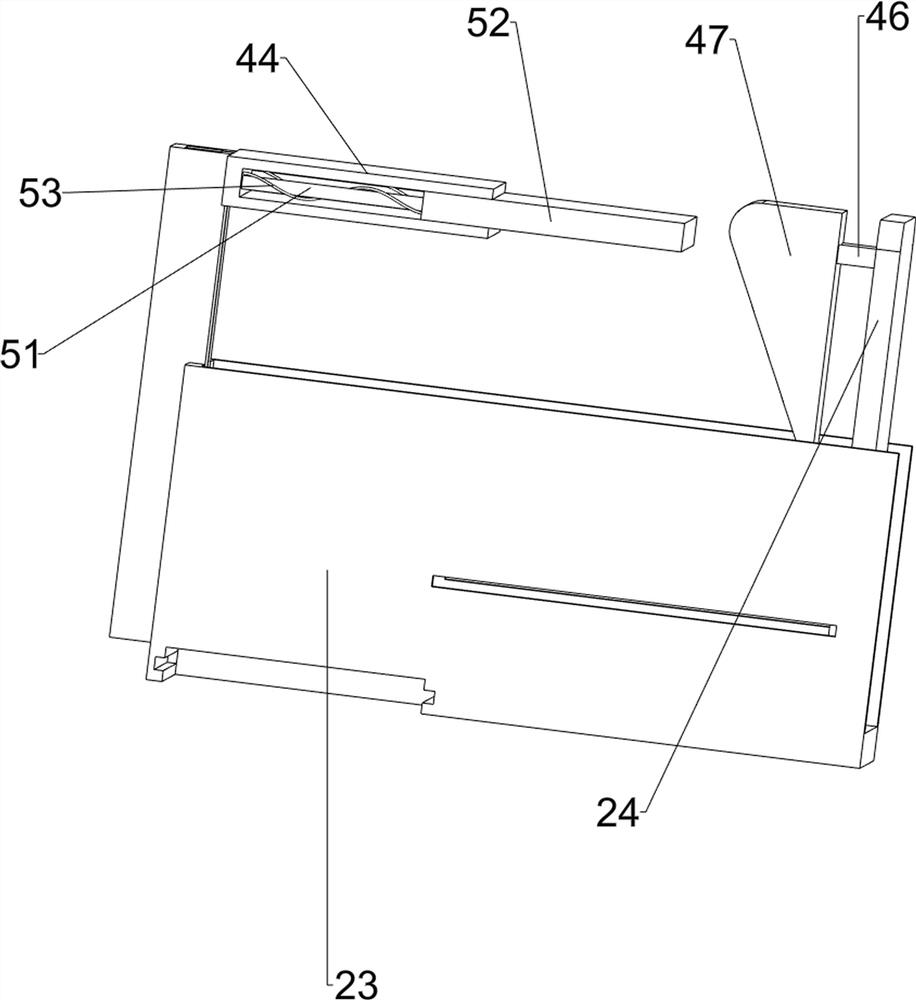

[0070] On the basis of Example 2, such as Figure 4 to Figure 7 As shown, it also includes a pressing mechanism 4, and the pressing mechanism 4 includes a first connecting rod 41, a column sleeve 42, a second slider 43, a lower pressing plate 44, a second telescopic assembly 45, a second connecting rod 46 and a first connecting rod 46. A wedge-shaped block 47, the left and right sides of the rear of the extrusion table 23 are provided with a first connecting rod 41, the top of the first connecting rod 41 is provided with a column sleeve 42, and the inner side of the extrusion table 23 is slidingly provided with a second slider 43. A second telescopic assembly 45 is connected to the column sleeve 42. A lower pressing plate 44 is connected between the bottom ends of the two second telescopic assemblies 45. The lower pressing plate 44 is connected with the second slider 43. Both sides are provided with second connecting rods 46 , and a first wedge-shaped block 47 is connected bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com