Building material strength detection device

A technology for strength detection and building materials, applied in measuring devices, using stable tension/pressure to test material strength, analyzing materials, etc., can solve the problem of unable to realize the storage of samples after automatic push detection and automatic replacement of samples continuously Detection, low detection efficiency and other problems, to achieve the effect of saving labor costs, realizing automatic feeding, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

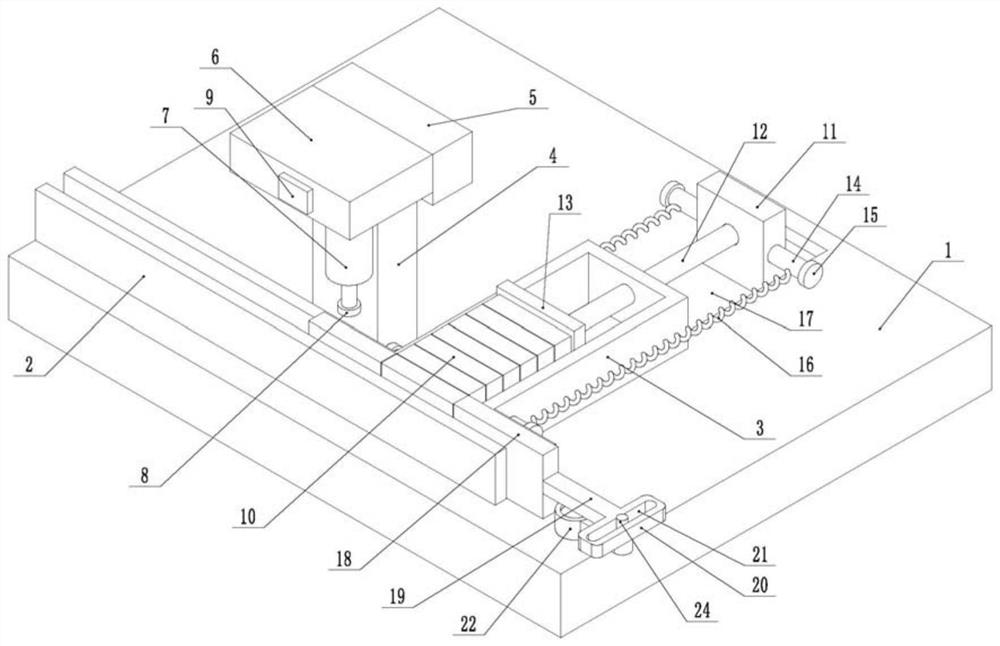

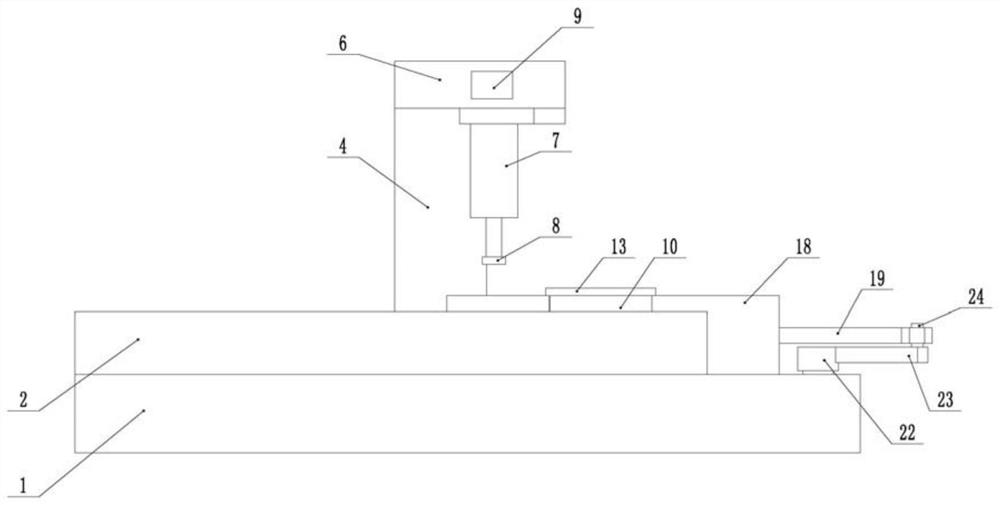

[0035] The embodiment is basically as attached figure 1 Shown: a device for testing the strength of building materials, including a support plate 1 having a rectangular parallelepiped structure, and a detection unit for detecting a sample 10 is provided on the support plate 1 .

[0036] Two guide plates 2 arranged parallel to each other are connected to the support plate 1, and a moving channel is formed between the two guide plates 2. In this embodiment, the two guide plates 2 are welded and fixed with the support plate 1, and the two guide plates 2 The distance between them is 1 cm larger than the width of the sample 10, so that the sample 10 can slide smoothly in the moving channel, and at the same time, the distance between the guide plate 2 and the sample 10 is small, and the sample 10 is not easy to be deflected.

[0037]The support plate 1 is also provided with a storage frame 3 vertically arranged with the guide plate 2, the storage frame 3 is a rectangular frame struc...

Embodiment 2

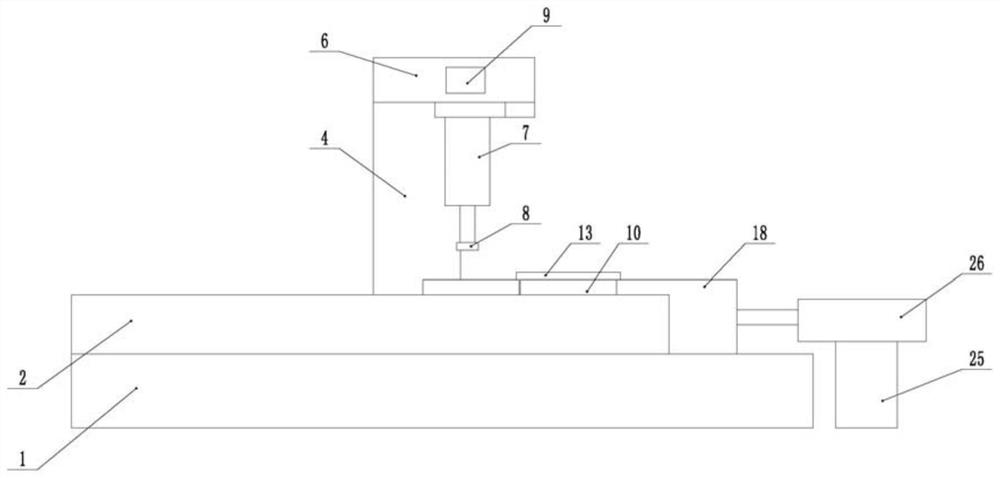

[0048] Such as image 3 As shown, a building material strength detection device differs from Embodiment 1 in that the drive unit in this embodiment includes a cylinder 26, the right side of the support plate 1 is provided with a support 25, and the cylinder body of the cylinder 26 and the support The seat 25 is fixedly connected by bolts, and the output shaft of the cylinder 26 is fixedly connected with the slide plate 18 .

[0049] When in use, the telescopic movement of the output shaft of the drive cylinder 26 drives the reciprocating sliding motion of the slide plate 18, and then the slide plate 18 pushes the sample 10 in the moving channel to the detection unit for detection. The structure in this embodiment is simple and easy to install .

Embodiment 3

[0051] A building material strength detection device, the difference from Embodiment 1 is that in this embodiment, the motor is electrically connected with a time relay (not shown in the figure).

[0052] In this embodiment, the setting of the time relay can control the delayed rotation of the motor. When the slide plate 18 pushes the sample 10 to the detection unit for detection, the time for delaying the reverse rotation of the motor is controlled by setting the time relay in advance. In this embodiment, the motor The time for delaying the reverse rotation is greater than the time for the detection unit to detect the sample 10. When the detection unit finishes detecting the sample 10, the output shaft of the hydraulic cylinder 7 moves upward to make the test head 8 away from the sample 10, and the motor rotates in reverse, thereby Returning the slide plate 18 to the initial position prepares for pushing the sample 10 to the detection unit next time. Such an arrangement can k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com