Portable vacuum cup screen printing device

A convenient, cup silk technology, applied in screen printing machines, printing machines, printing machines, etc., can solve the problems of easy arm pain, poor screen printing effect, and low screen printing efficiency, and achieve the effect of convenient and unified collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

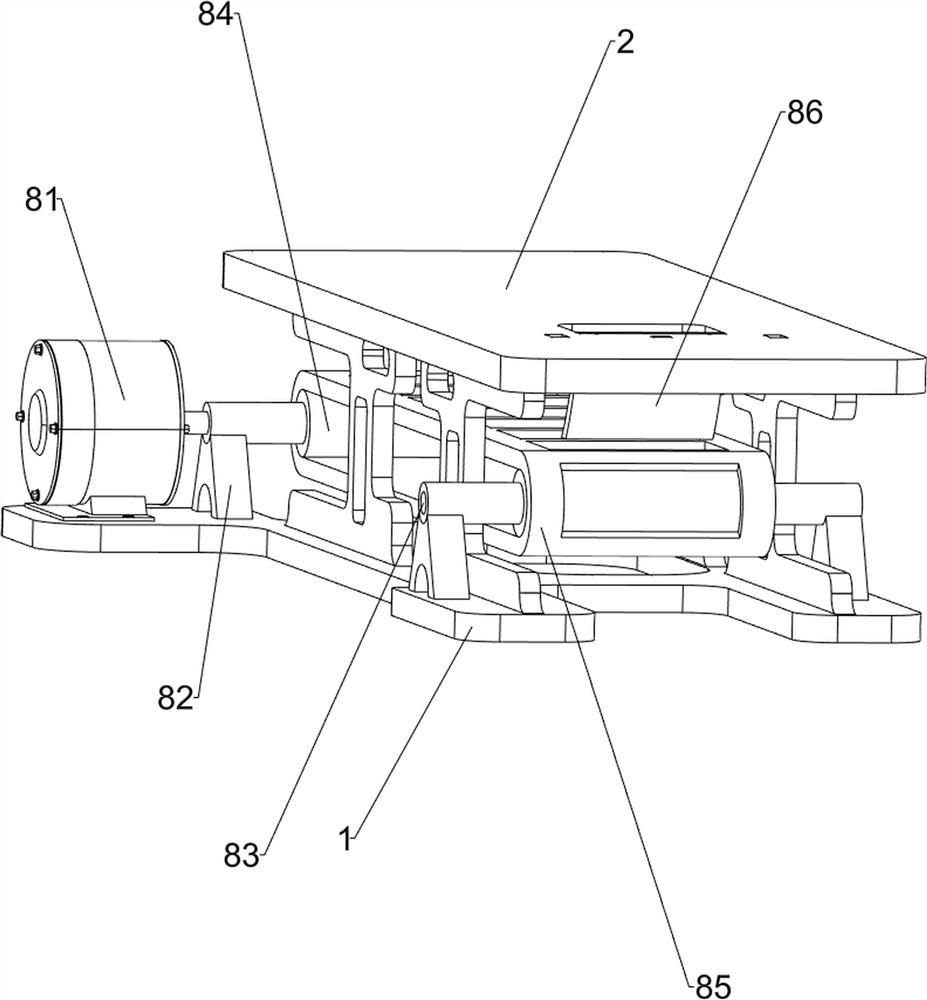

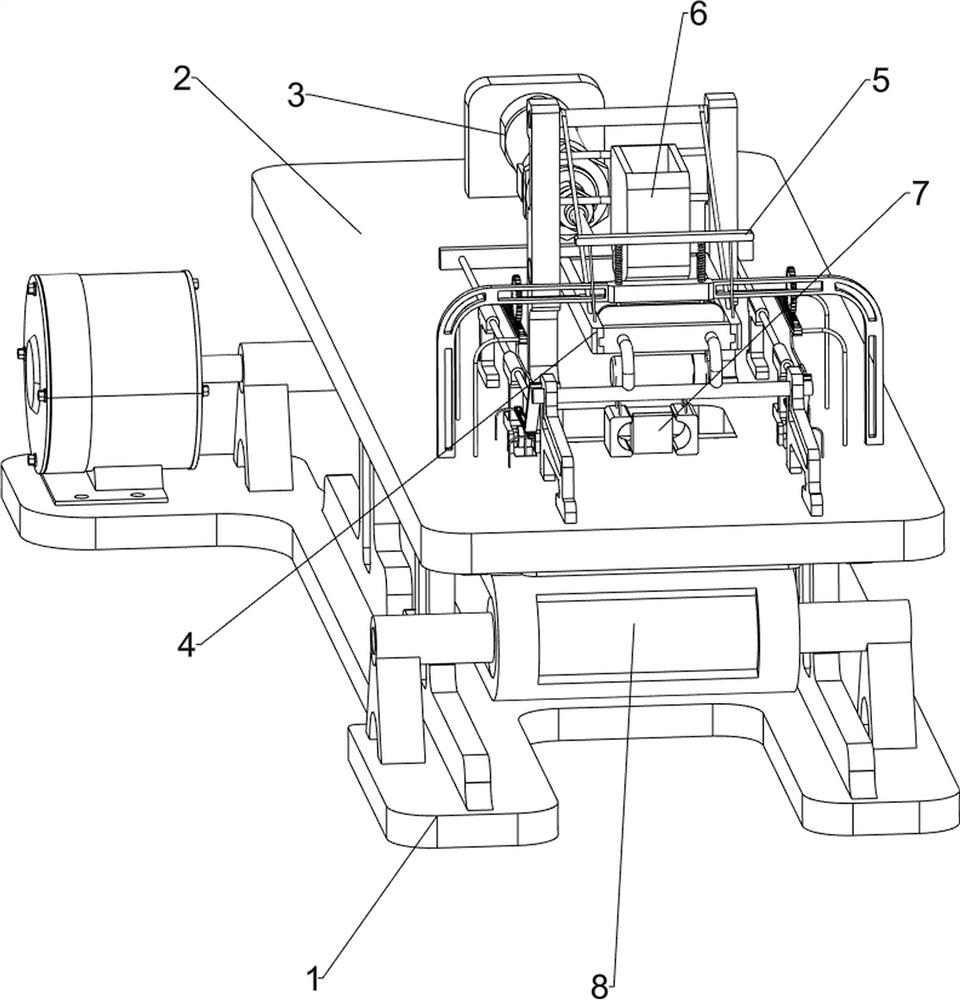

[0029] A portable thermos cup silk screen device, such as figure 1 As shown, it includes a base 1, a placement plate 2, a cylinder 3, a silk screen mechanism 4, and a mud scraping mechanism 5. The base 1 is provided with a placement plate 2, the rear side of the top of the placement plate 2 is equipped with a cylinder 3, and the front side of the top of the placement plate 2 A silk screen mechanism 4 is provided, and the silk screen mechanism 4 is connected with the cylinder 3 .

[0030] When people need to screen-print pictures and texts on the thermos cup, they can use this screen printing device. First, people place the thermos cup and the ink pad to be silk-screened on the corresponding positions of the silk screen mechanism 4, and then open the cylinder 3, which drives the screen with the graphics. The silk screen printing mechanism 4 in the text rotates to contact with the thermos cup, and the operation of the silk screen printing mechanism 4 drives the mud scraping mech...

Embodiment 2

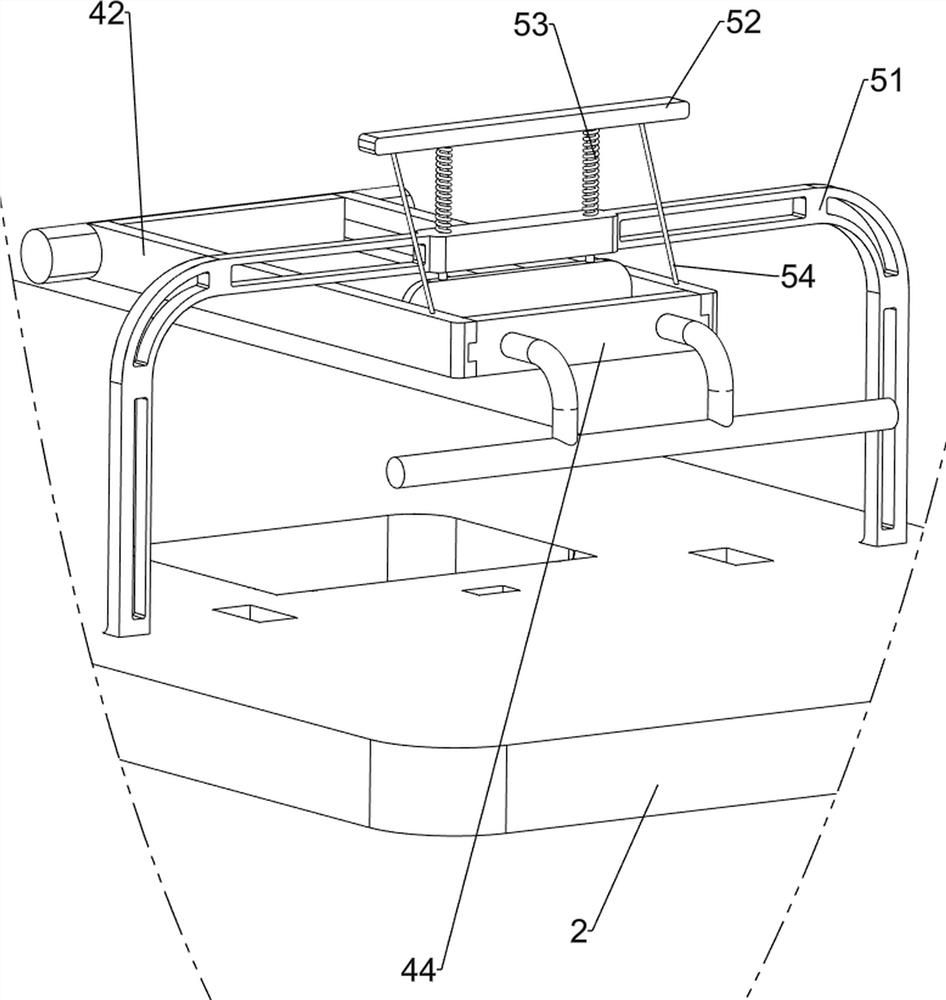

[0032] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 and Figure 5As shown, the screen printing mechanism 4 includes a support rod 41, a support frame 42, a first elastic pull cord 43, a screen printing frame 44, a sliding fixing plate 45, a handle 451, a first guide sleeve 46, a push rod 47, a support block 48 and a sliding The fixed wheel device 49, the front side of the top of the placement plate 2 is provided with a support rod 41, the middle part of the support rod 41 is rotatably provided with a support frame 42, and the left and right sides between the support rod 41 top and the support frame 42 front are connected with a first elastic Stay cord 43, sliding type is provided with silk screen frame 44 in the supporting frame 42, and the left and right sides of the upper front side of the placement plate 2 are all provided with sliding fixed plate 45, and two sliding fixed plates 45 tops are slidingly connected with handle 451, and handle 451 is con...

Embodiment 3

[0037] On the basis of Example 2, such as Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 Shown, also comprise mud adding mechanism 6, support bar 41 top, support frame 42 front left and right sides and place plate 2 upper front part left and right sides are provided with mud adding mechanism 6, mud adding mechanism 6 includes mud adding frame 61, the second guide sleeve 62, the first rotating shaft 63, the gear 64, the column sleeve 65, the baffle plate 66, the torsion spring 67, the first guide block 68, the band rack slide block 69, the band column wedge block 610 and the second compression Spring 611, support rod 41 tops are provided with mud adding frame 61, and support frame 42 front, left and right sides are all provided with second guide bushing 62, the first rotating shaft 63 that is connected with rotation between two second guide bushings 62, the second A rotating shaft 63 left and right ends are all provided with gear 64, and mud adding frame 61 bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com