Power converter

A technology for power converters and shells, which is applied to circuits, electrical components, contact parts, etc., can solve problems such as cutting corners, safety hazards, and structural design errors, and achieve the effects of reducing use costs, reducing safety hazards, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

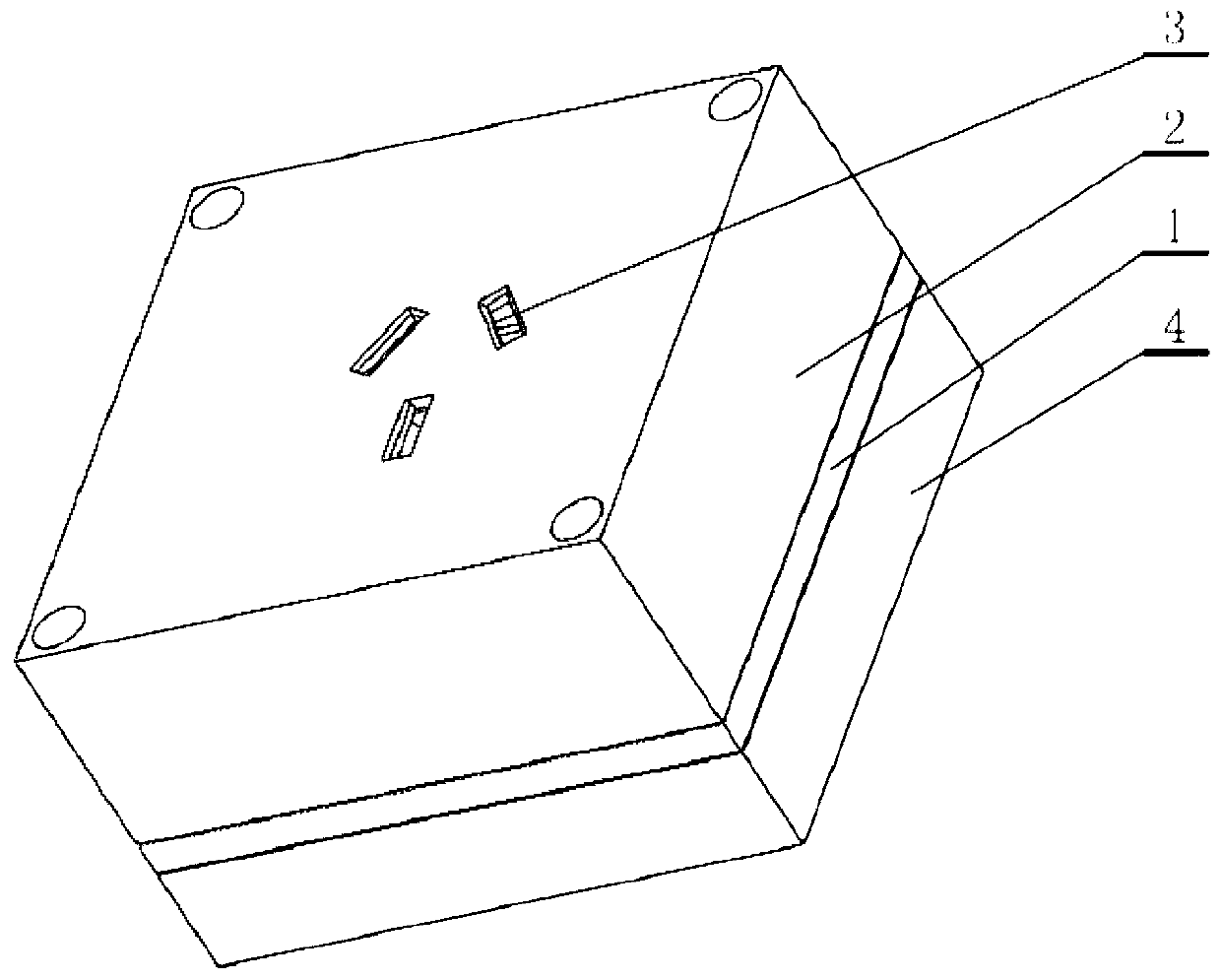

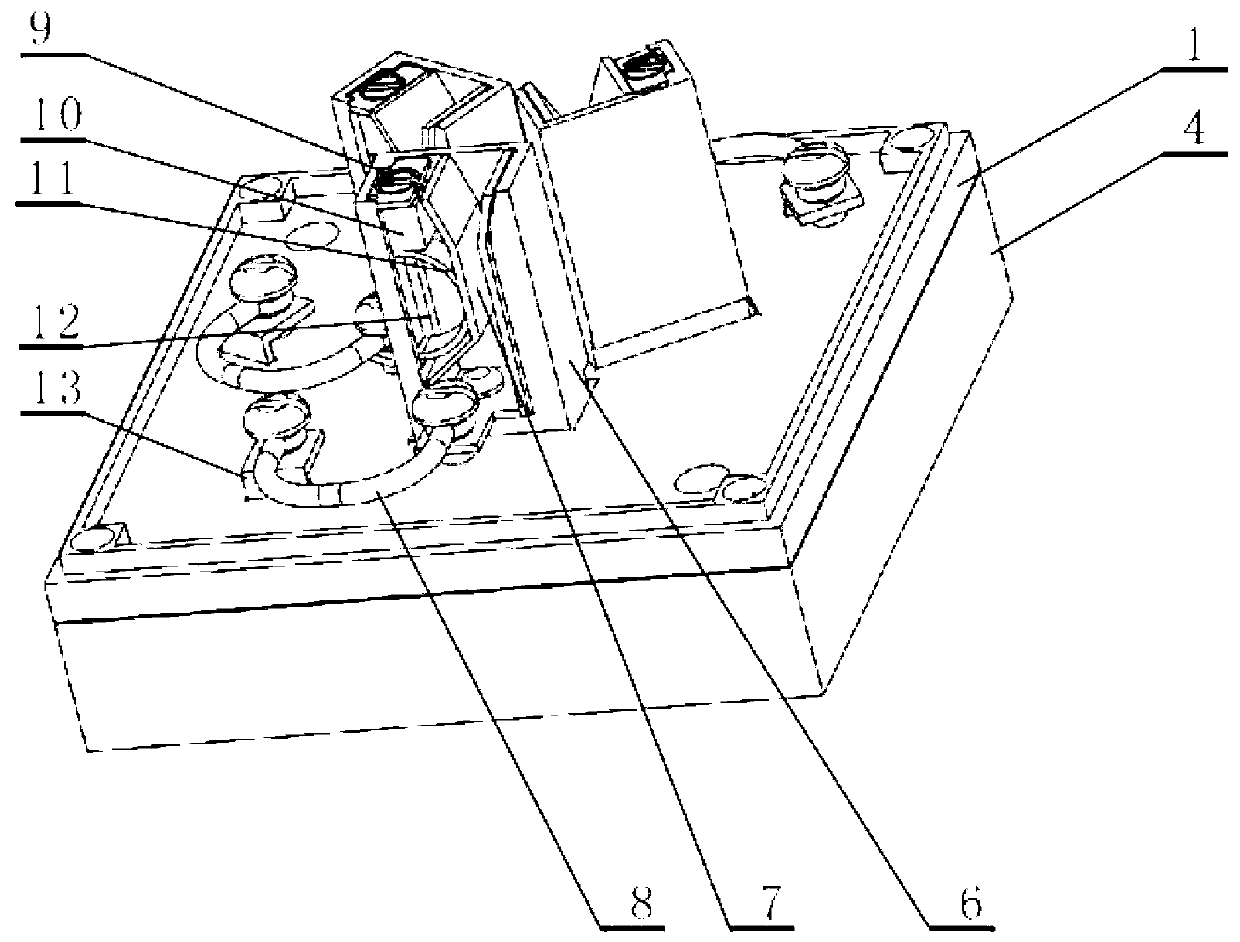

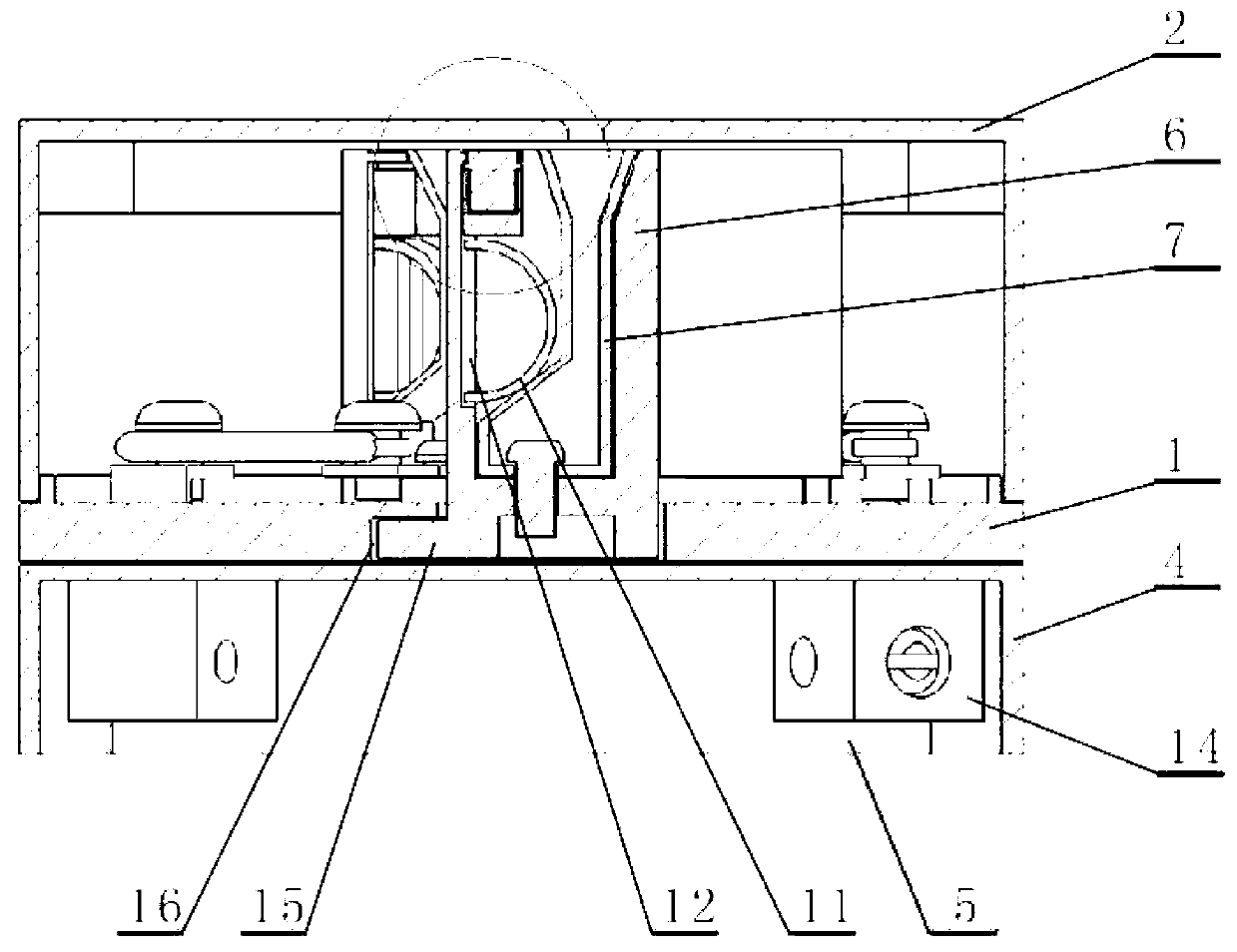

[0015] Such as Figure 1 to Figure 4 As shown, the power converter includes a middle case 1, and an upper case 2 and a lower case 4 installed in cooperation therewith. The middle case 1 is screwed to a bottom plate 5, and the terminal 14 passes through the middle case 1 and the bottom plate. 5. It is airtightly packaged in the lower case 4, and the connecting terminal 14 is reliably connected to the intermediate connecting terminal 13; figure 1 As shown, an insertion hole 3 is provided at the position corresponding to the socket on the upper housing 2 .

[0016] A chute 16 is provided between the middle housing 1 and the lower housing 4, and the sleeve bracket 6 is installed in the chute 16 through the slider 15, and the sleeve bracket 6 passes through the action of the slider 15 and the chute 16, With the change of the center distance error of the power plug blades,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com