Machine for processing and making ball-shaped food

A food processing and machine technology, which is applied in the field of food processing and production machines, can solve the problems of low hygienic coefficient, poor appearance of meatballs, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

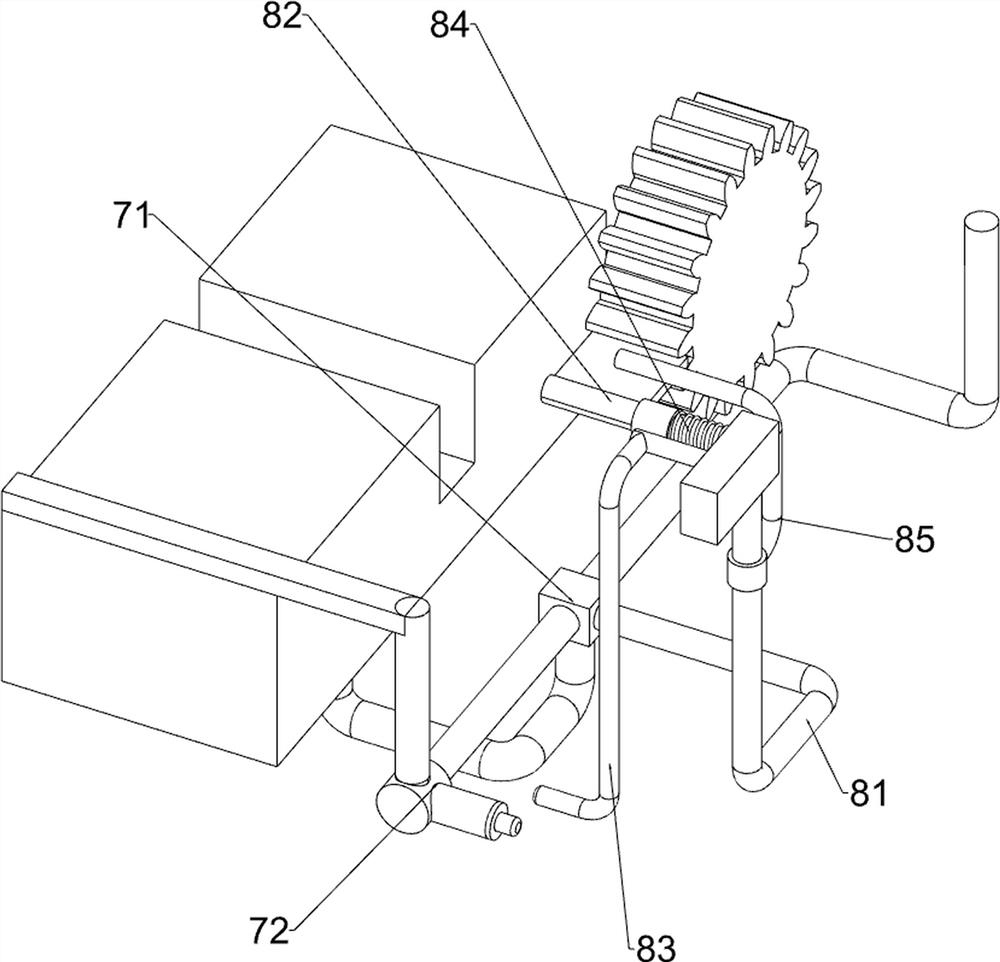

[0069] A kind of machine that is used for the processing and making of meatball-shaped food, such as figure 1 As shown, it includes a support rod 1, a first fixed column 2, a second fixed column 3 and a blanking mechanism 4. The column 3 and the left side of the support rod 1 are provided with a blanking mechanism 4 .

[0070]When people need to make a kind of meatball-shaped food, they can use this food processing machine. First, put the food raw materials into the feeding mechanism 4, then open the feeding mechanism 4 to start feeding, and then let go of the feeding and close the feeding after the feeding is completed. Mechanism 4, thereby stops blanking, finally manual assistance makes blanking mechanism 4 be processed and shaped into ball shape, if need to make this ball food again next time, repeat above-mentioned steps and get final product.

Embodiment 2

[0072] On the basis of Example 1, such as figure 2 As shown, the blanking mechanism 4 includes a placement platform 41, a first fixed rod 42, a blanking tube 43, a material storage frame 44, a switch material rod 45 and a first spring 46, and the left side of the support rod 1 is provided with a placement platform 41. , the upper left side of the support rod 1 is provided with a first fixed rod 42, the top of the first fixed rod 42 is provided with a feeding pipe 43, the rear end of the feeding pipe 43 is provided with a storage frame 44, and the front side of the feeding pipe 43 is slidingly arranged. There is a switch material rod 45, a first spring 46 is wound around the switch material rod 45, and the rear end of the first spring 46 is connected with the feeding pipe 43.

[0073] People put food raw materials into the material storage frame 44, place the lower half of the mold making on the front side of the placement table 41, put the upper half of the mold making on the...

Embodiment 3

[0075] On the basis of Example 2, such as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 with Figure 9 As shown, it also includes a left and right intermittent plate release mechanism 5, the first fixed column 2 is provided with a left and right intermittent plate release mechanism 5, and the left and right intermittent plate release mechanism 5 includes a first sliding sleeve 51, a pusher plate 52, a first tooth Bar 53, the second spring 54, the first charging frame 55, the support column 56, the second fixed rod 57, the first spur gear 58, the motor 59, the missing gear 510, the second sliding sleeve 511, the rack bar 512, the second Three springs 513, material bearing push plate 514, second charging frame 515, lifting plate 516 and the fourth spring 517, the left side on the first fixed column 2 is provided with the first charging frame 55, the first charging frame 55 right The lower part of the wall is provided with a first sliding sleeve 51, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com