Garbage pyrolysis treatment equipment

A technology of pyrolysis and waste, which is applied in the direction of grain processing, heating, special form of dry distillation, etc., can solve the problems of low pyrolysis efficiency, environmental pollution, extensive treatment methods, etc., and achieve the effect of high feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

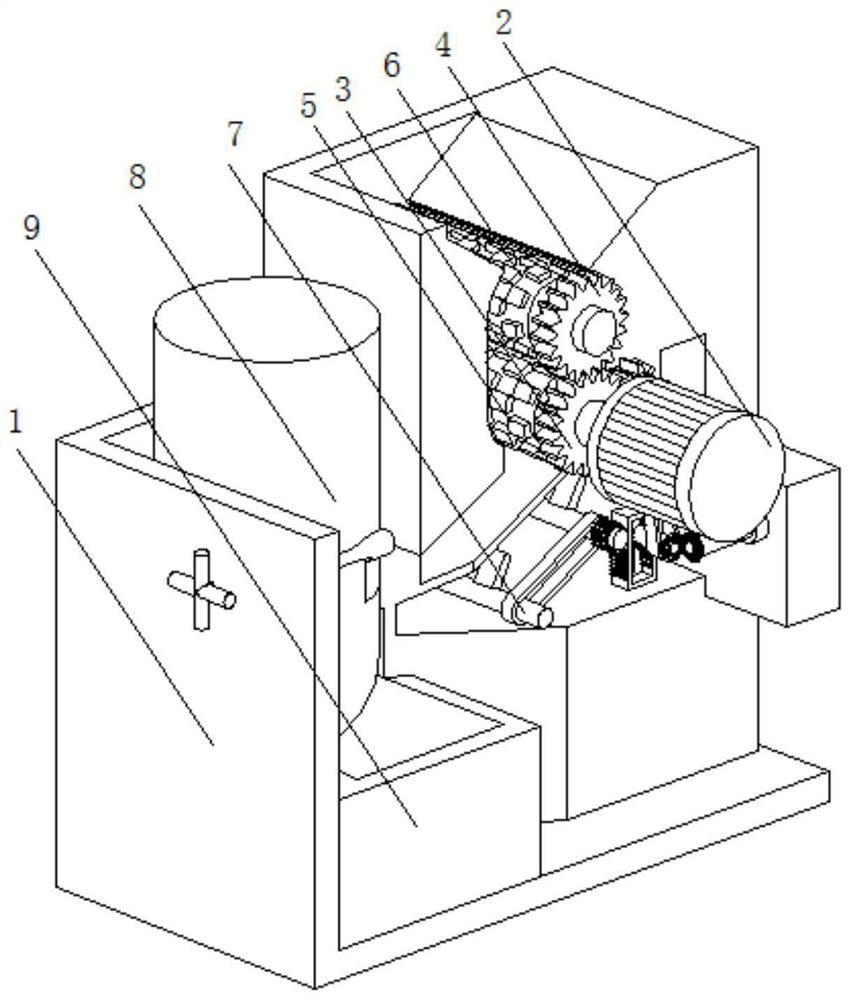

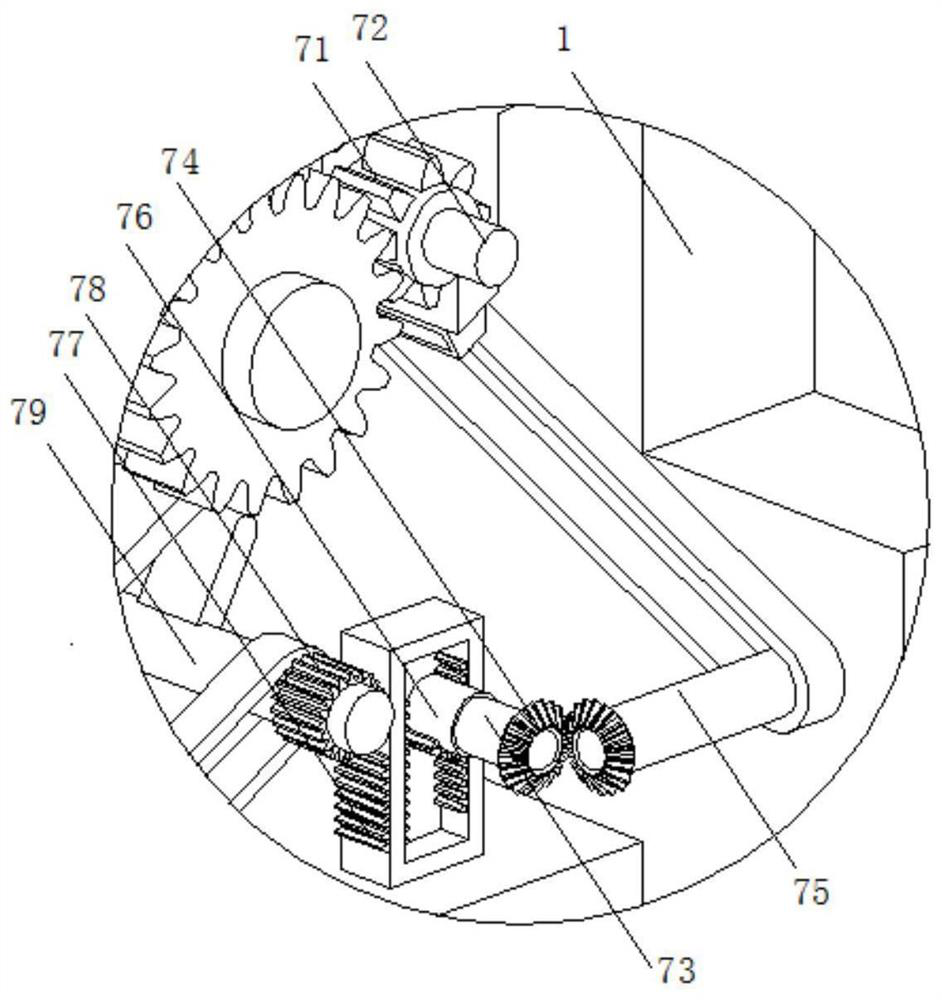

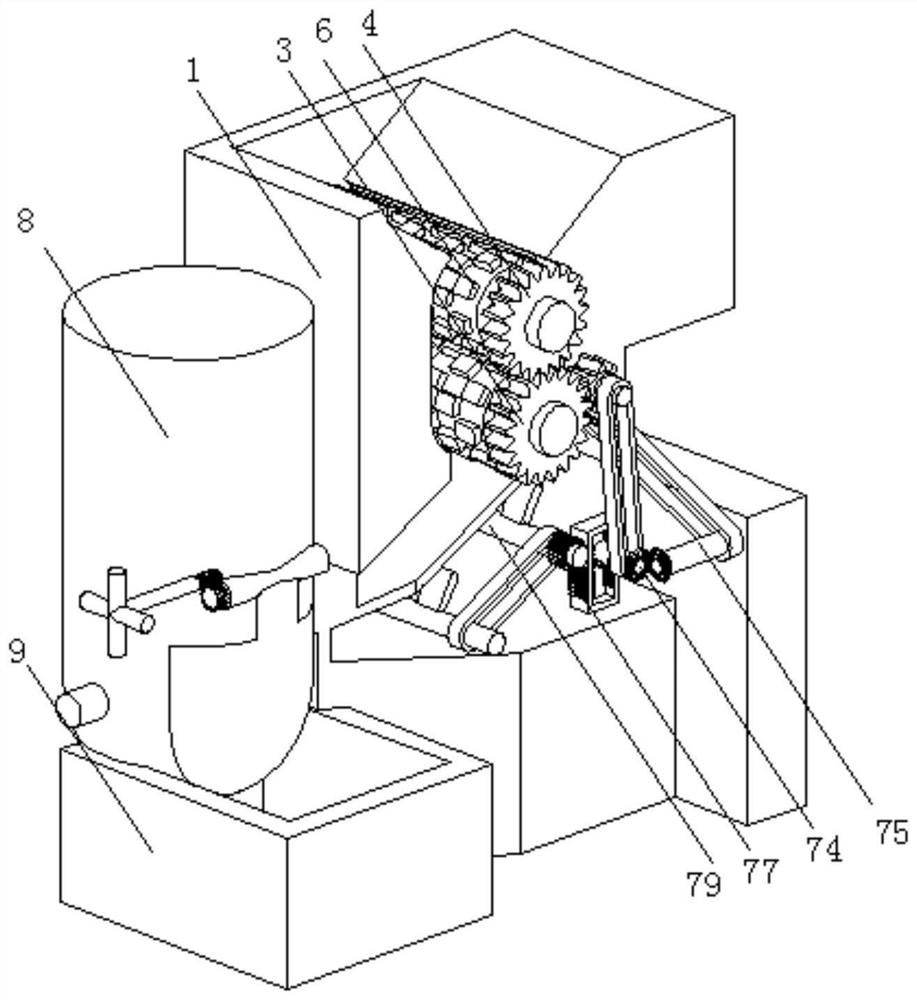

[0031] A kind of garbage pyrolysis treatment equipment, such as Figure 1-Figure 5 As shown, the body 1 is included, the inside of the body 1 is connected with a power motor 2 by bolts, the output shaft of the power motor 2 is clamped with a driving gear 3, the surface of the driving gear 3 is meshed with a driven gear 4, and the driving gear 3 and the driven gear 4 The inside of the body is welded with a large crushing roller 5 and a small crushing roller 6 respectively, the surface of the driving gear 3 is provided with an auxiliary unloading mechanism 7, the inside of the body 1 is provided with an auxiliary disinfection discharge mechanism 8, and the body 1 is located at the auxiliary disinfection discharge mechanism 8 The bottom of the card is connected with waste collection box 9.

[0032]By arranging the waste collection box 9 to be located directly below the auxiliary disinfection discharge mechanism 8, the effect of being convenient to the centralized treatment of the...

Embodiment 2

[0043] Such as Figure 6-7 As shown, on the basis of Embodiment 1, in this embodiment, the auxiliary disinfection discharge mechanism 8 includes a high-temperature disinfection isolation bin 81 and a stirring motor 84, and the surface of the high-temperature disinfection isolation bin 81 is fixedly installed with the inside of the body 1, and the high-temperature disinfection isolation bin 81 is fixedly installed inside the body 1. The internal rotation of the disinfection isolation bin 81 is connected with a stirring rod 82, the surface of the stirring rod 82 is welded with a stirring dislocation plate 83, the inner rotation of the high temperature disinfection isolation bin 81 is connected with a shaft rod 85, and the surface of the shaft rod 85 is welded with an isolation bin door 86, The left end of the shaft rod 85 is welded with a switch worm gear 87 , the surface of the switch worm gear 87 is engaged with a twisting worm 88 , and the left end of the twisting worm 88 is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com