Automatically-assembled high-precision laser welding equipment

A technology of laser laser and welding equipment, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of insufficient accuracy, affecting the quality of mobile phone production, etc., to improve the efficiency of welding, improve the scope of use, guarantee The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

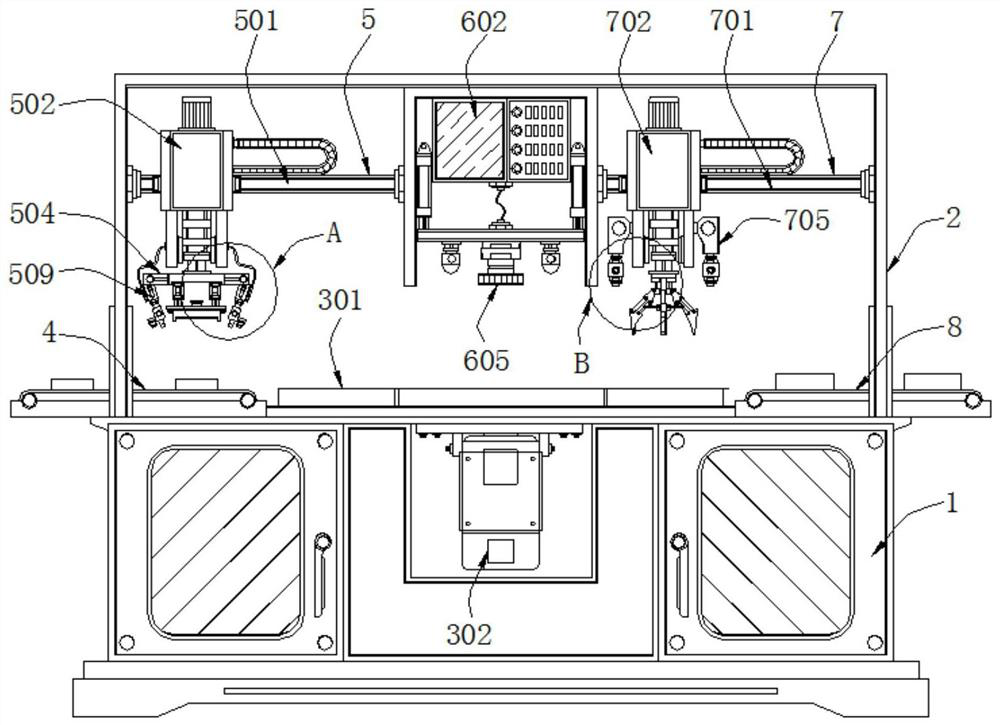

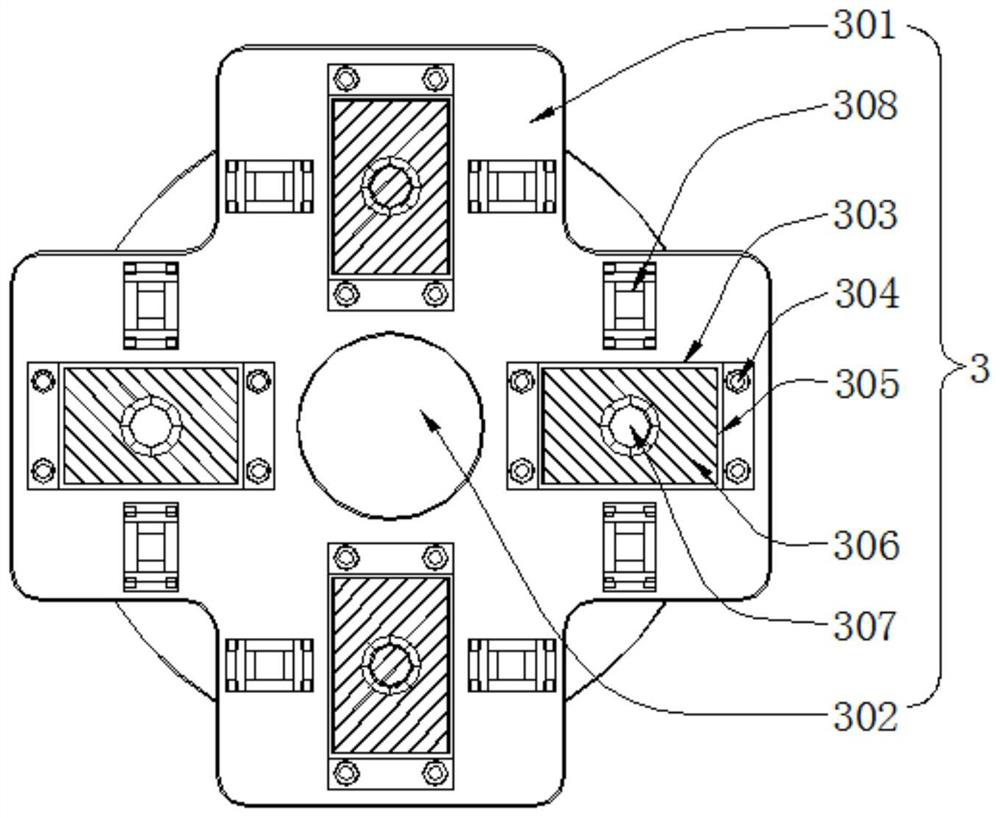

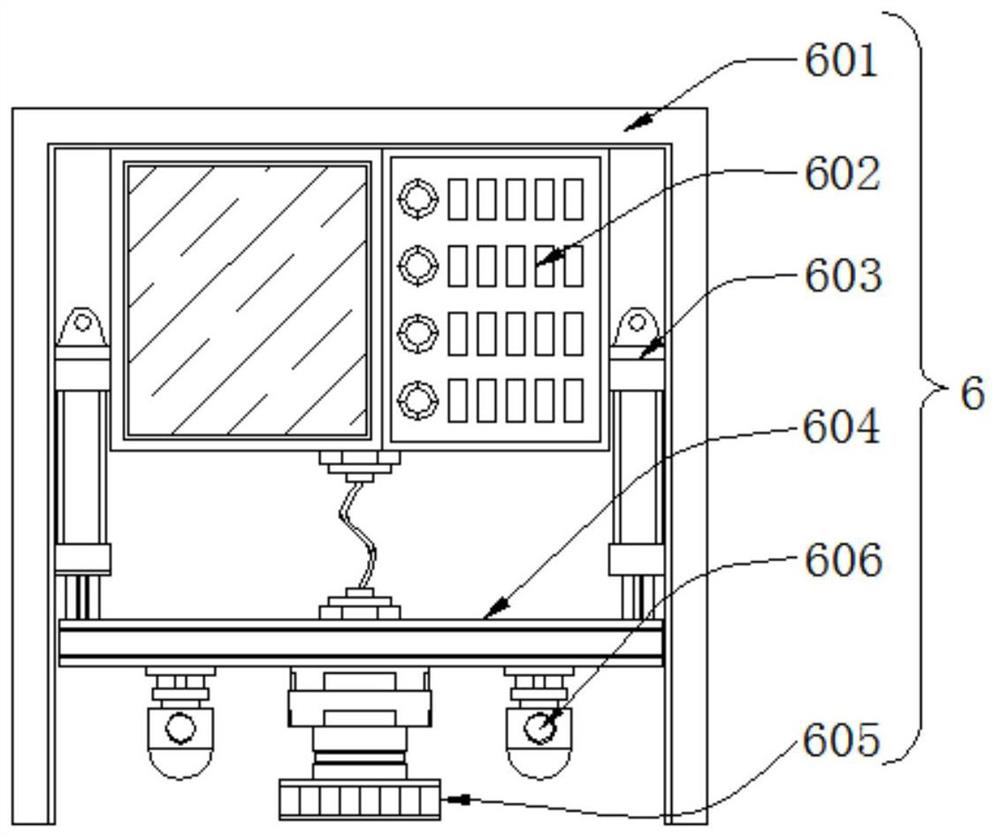

[0027] see Figure 1-5 , the present invention provides a technical solution: an automatic assembly of high-precision laser laser welding equipment, including a bearing base 1 and a welding assembly 5, the upper end of the bearing base 1 is provided with a placement frame 2 near the edge, and the upper end of the bearing base 1 The center position is provided with a transfer assembly 3 for the transfer of the mobile phone case, the upper left middle of the bearing seat 1 is provided with an accessory conveyor belt 4, and the welding assembly 5 for metal parts welding is provided on the inner left side of the placement frame 2, and the welding Assembly 5 includes a first cross rail 501, a first X-axis driving block 502, a welding cylinder 503, a connecting block 504, a driving cylinder 505, a connecting flange block 506, an adsorption clamping block 507, fastening bolts 508 and a laser welding head 509 The upper end of the first horizontal rail 501 is connected with the first X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com