Patents

Literature

40results about How to "Case to prevent scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

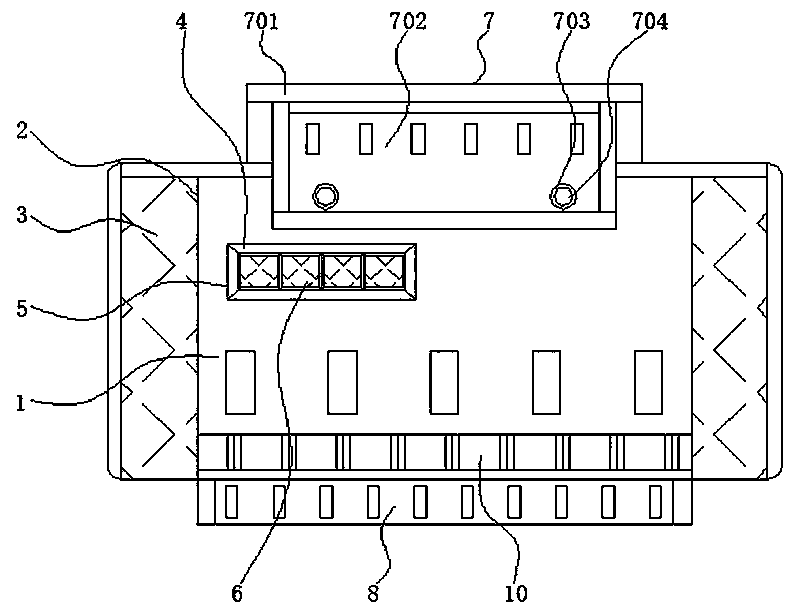

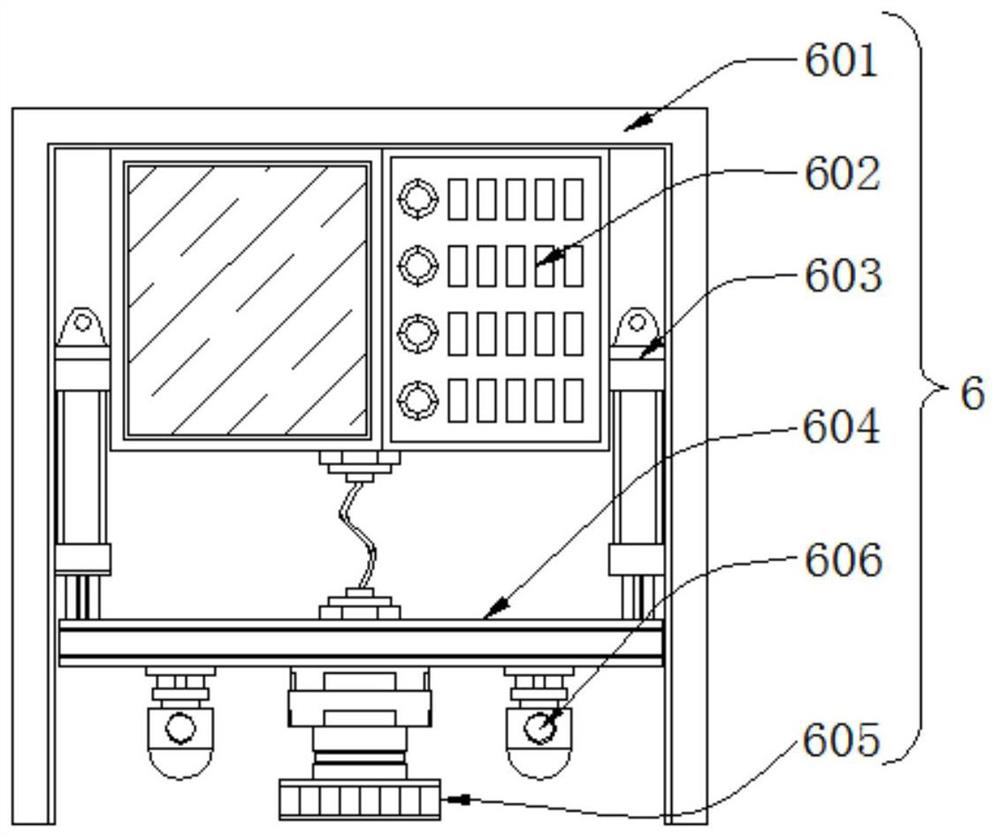

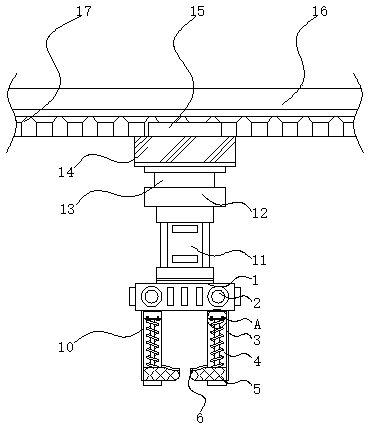

A detection device capable of performing multi-angle insertion for multi-group detection for computer hardware

InactiveCN109726065AIncrease frictionImprove securityError detection/correctionMotherboardComputer engineering

The invention discloses a detection device capable of performing multi-angle insertion for multi-group detection for computer hardware, and relates to the technical field of computer hardware detection, in particular to a detection device capable of performing multi-angle insertion for multi-group detection for computer hardware. The detection device capable of achieving multi-angle insertion formulti-group detection for computer hardware comprises a front plate, a display screen and a baffle; the display screen is arranged on the surface of the front end of the front plate, the baffle is distributed at the bottom end of the front plate, and a rubber sleeve is attached to the surface of the left end of the front plate. The detection device capable of being inserted from multiple angles for multi-group detection for computer hardware Has a first connecting port, a second connecting port and s third connecting port, so that the device can be inserted into a computer at multiple angles,so that multiple groups of detection can be carried out on computer hardware, and the problem that an existing detection device can only detect a computer mainboard and cannot be connected with otherhardware of the computer through other connecting ports for detection is solved.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

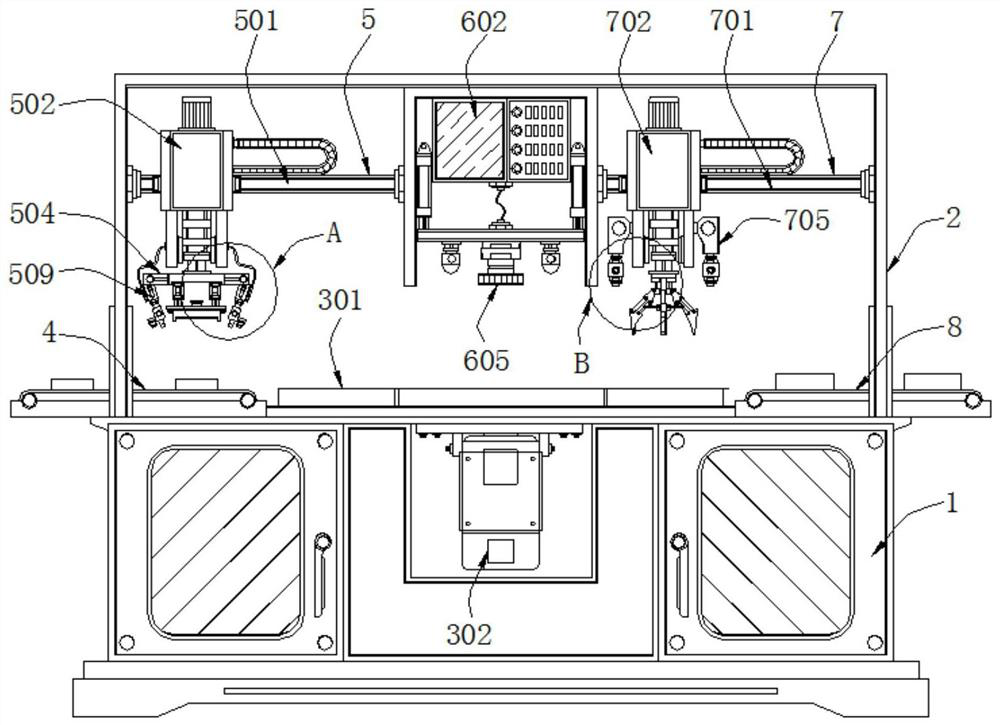

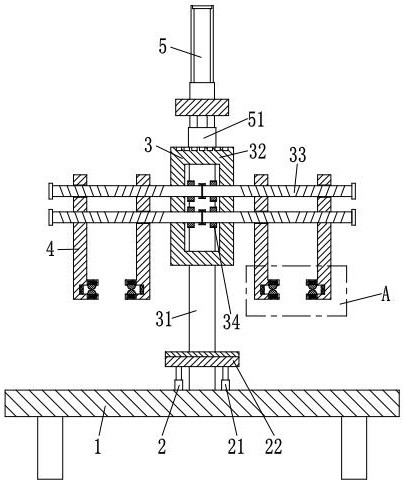

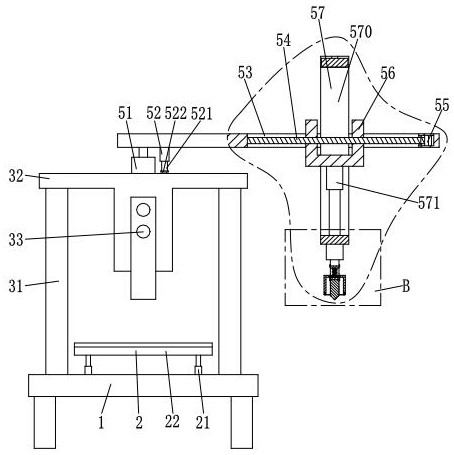

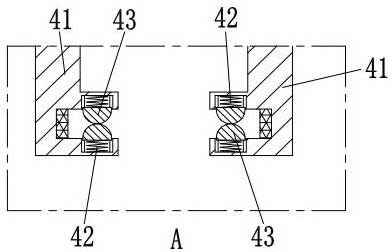

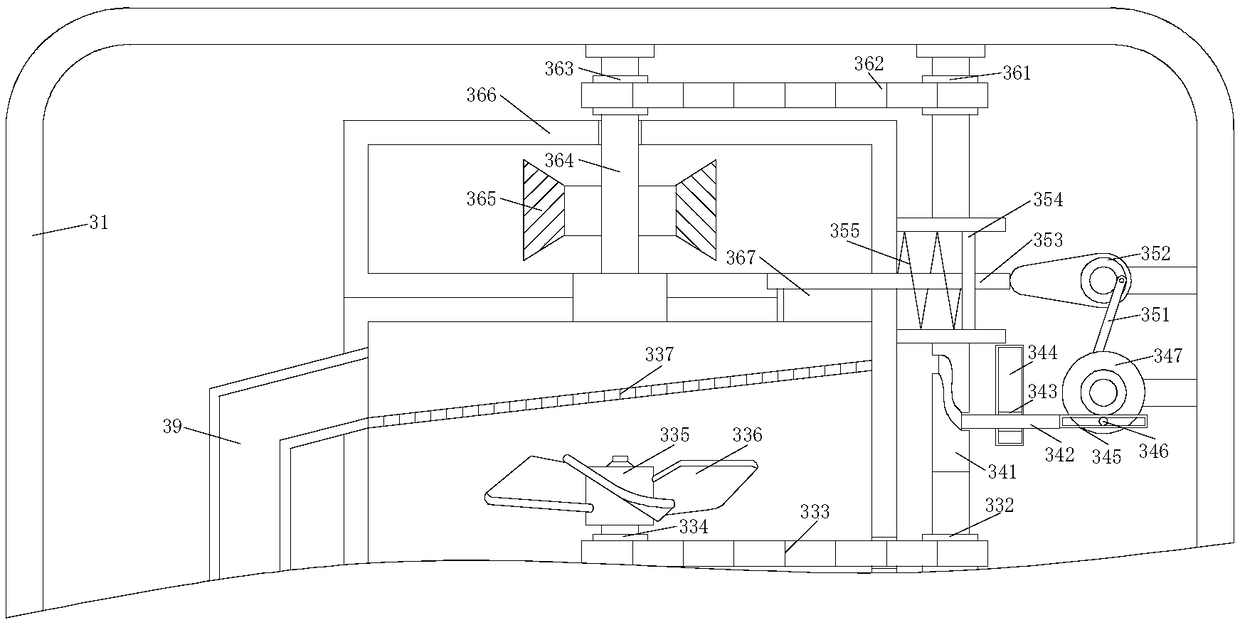

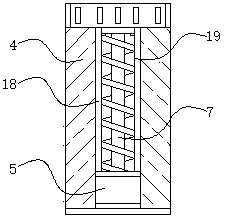

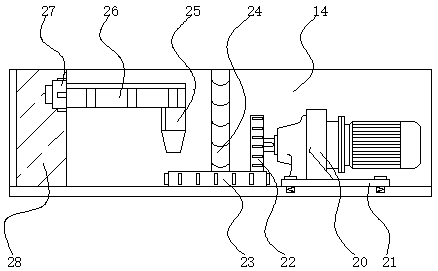

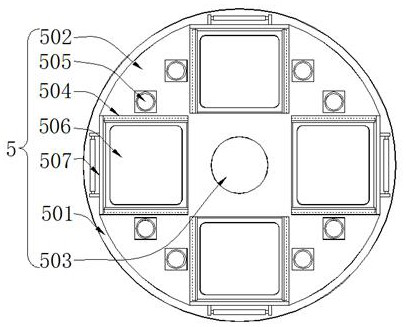

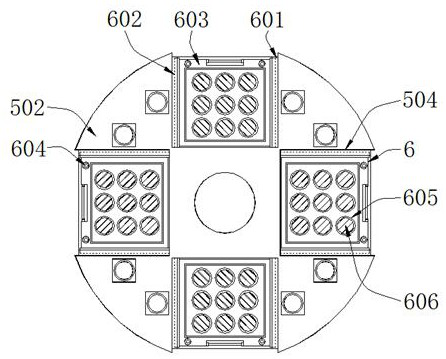

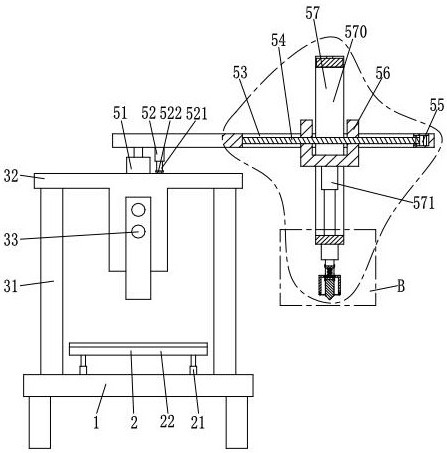

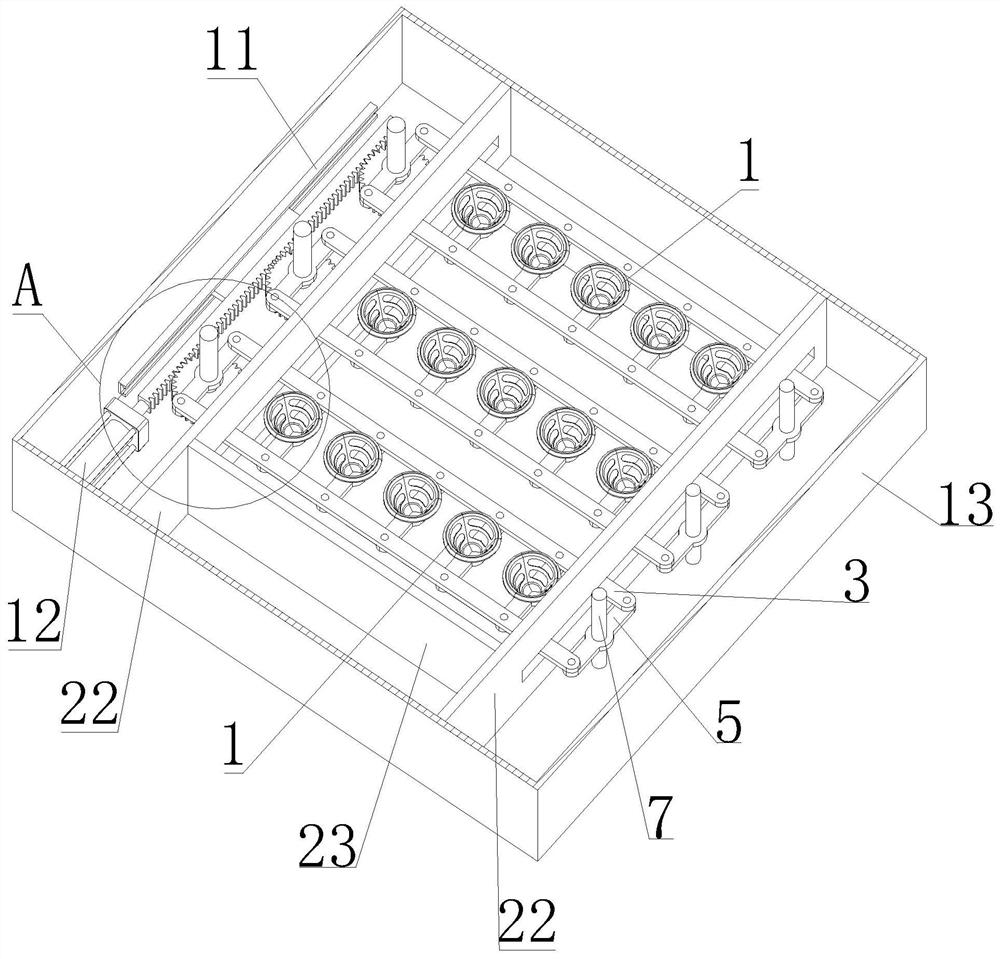

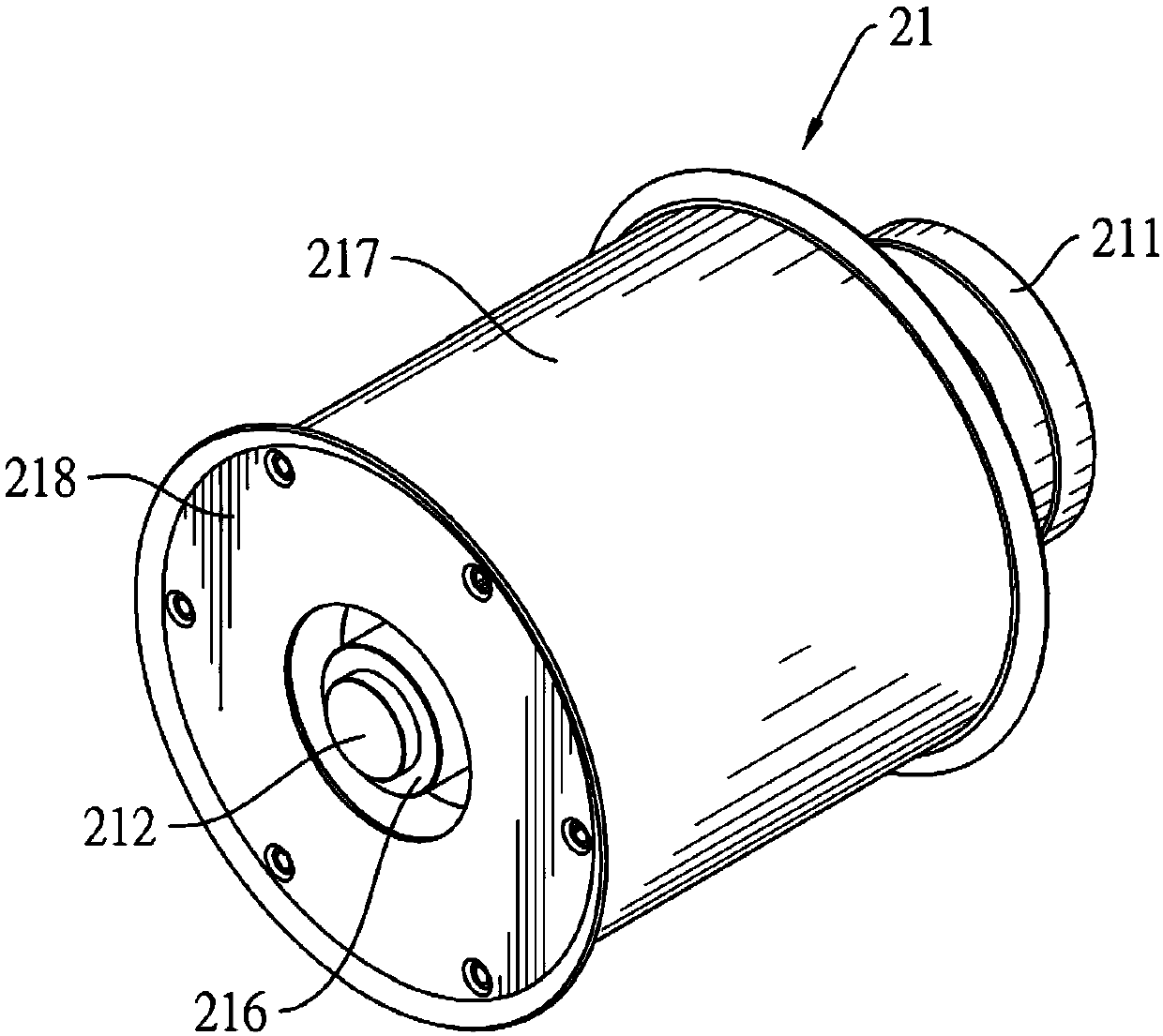

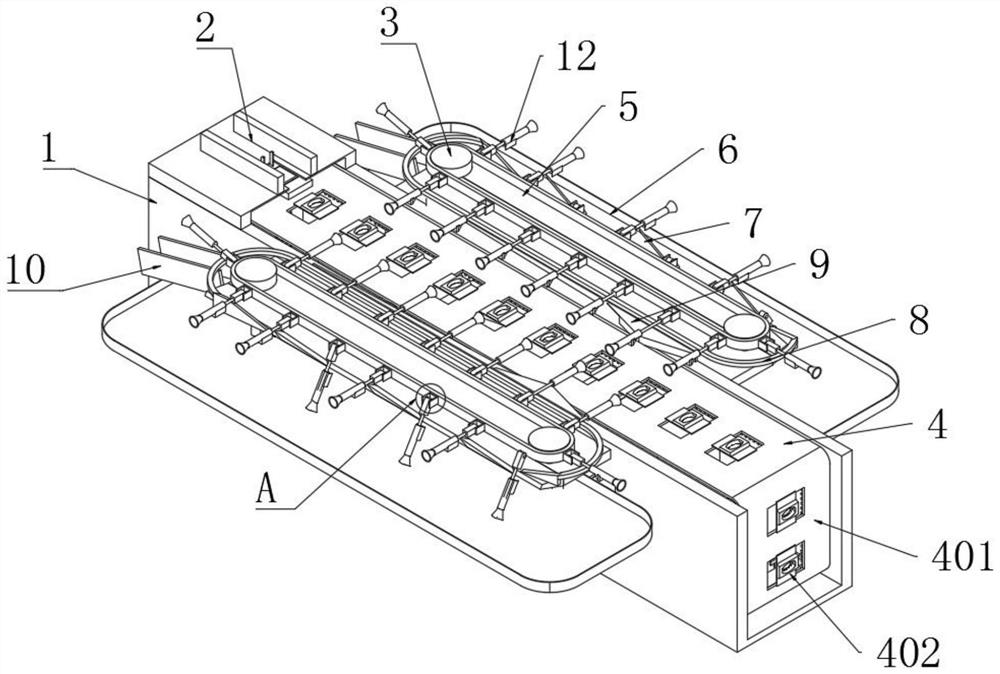

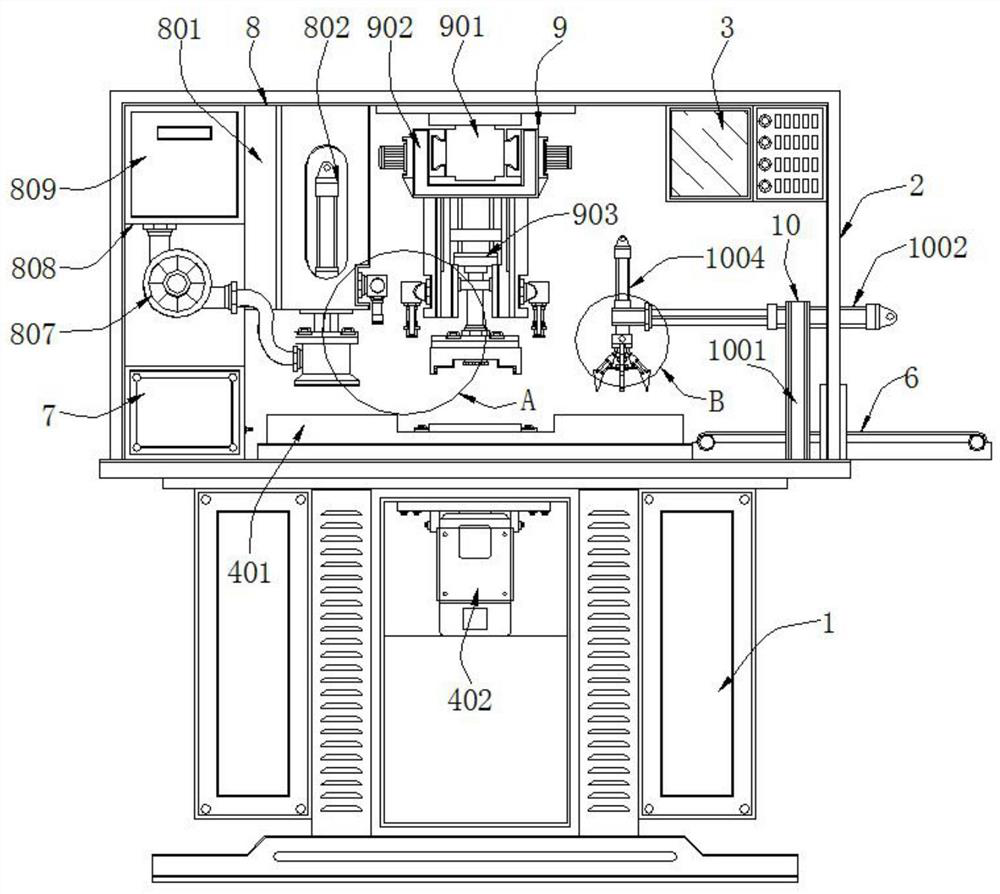

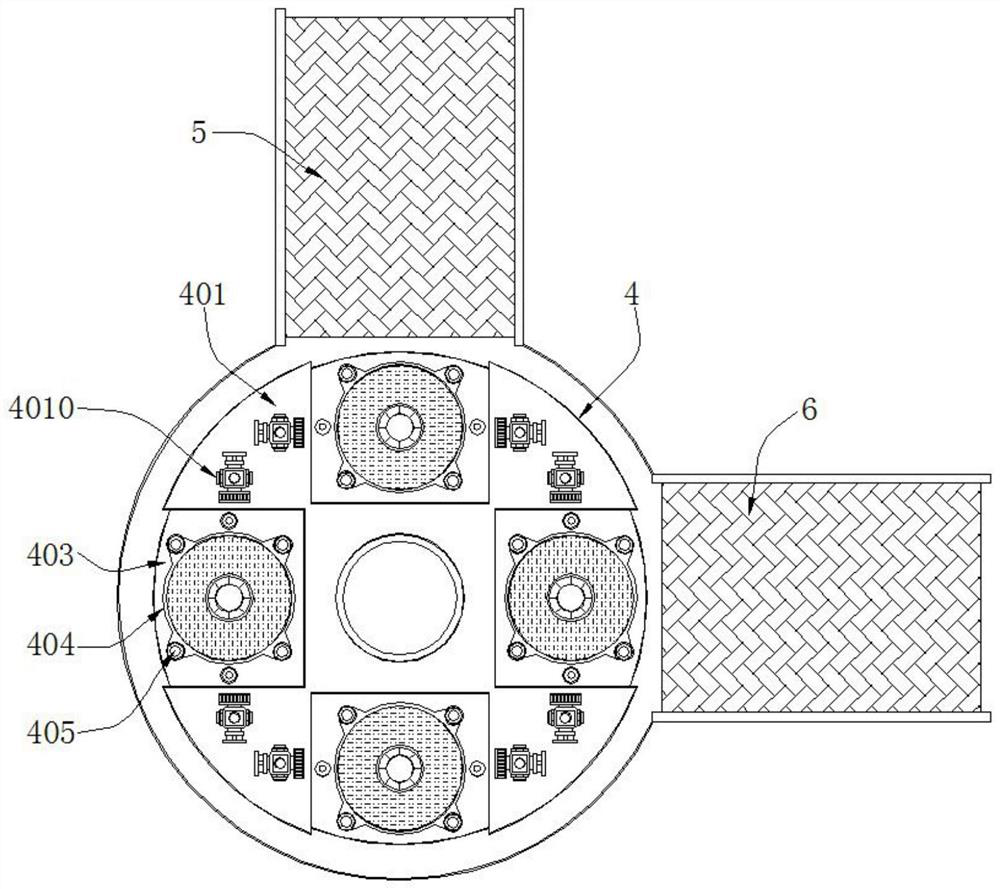

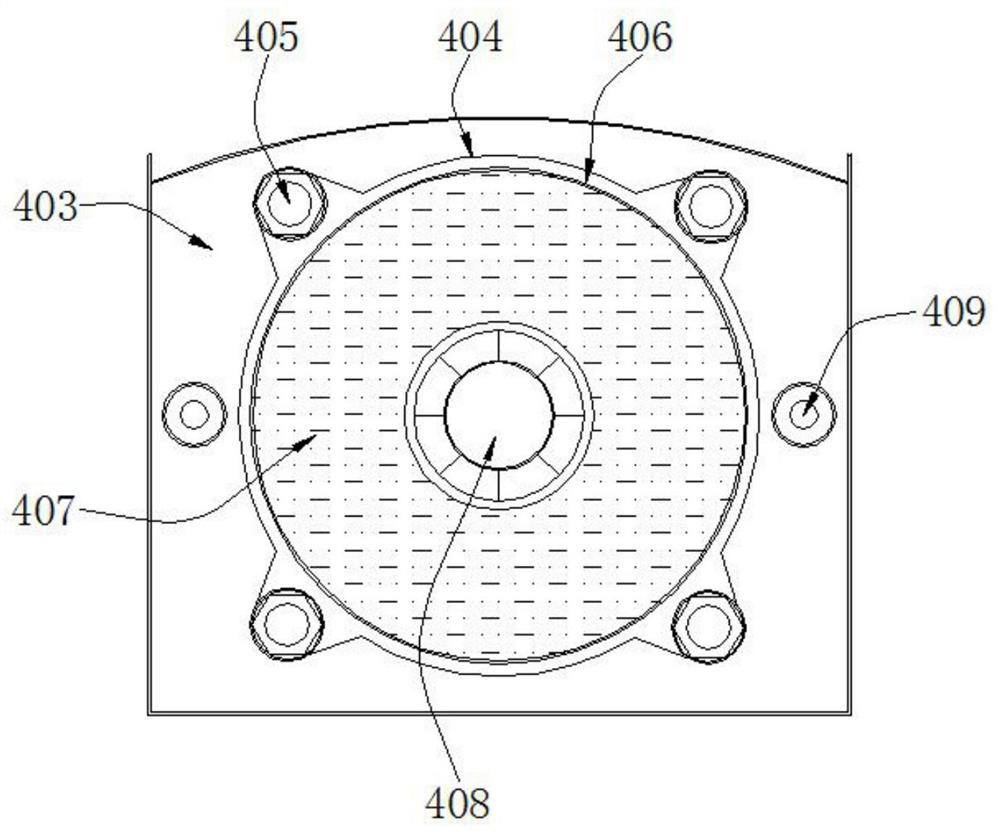

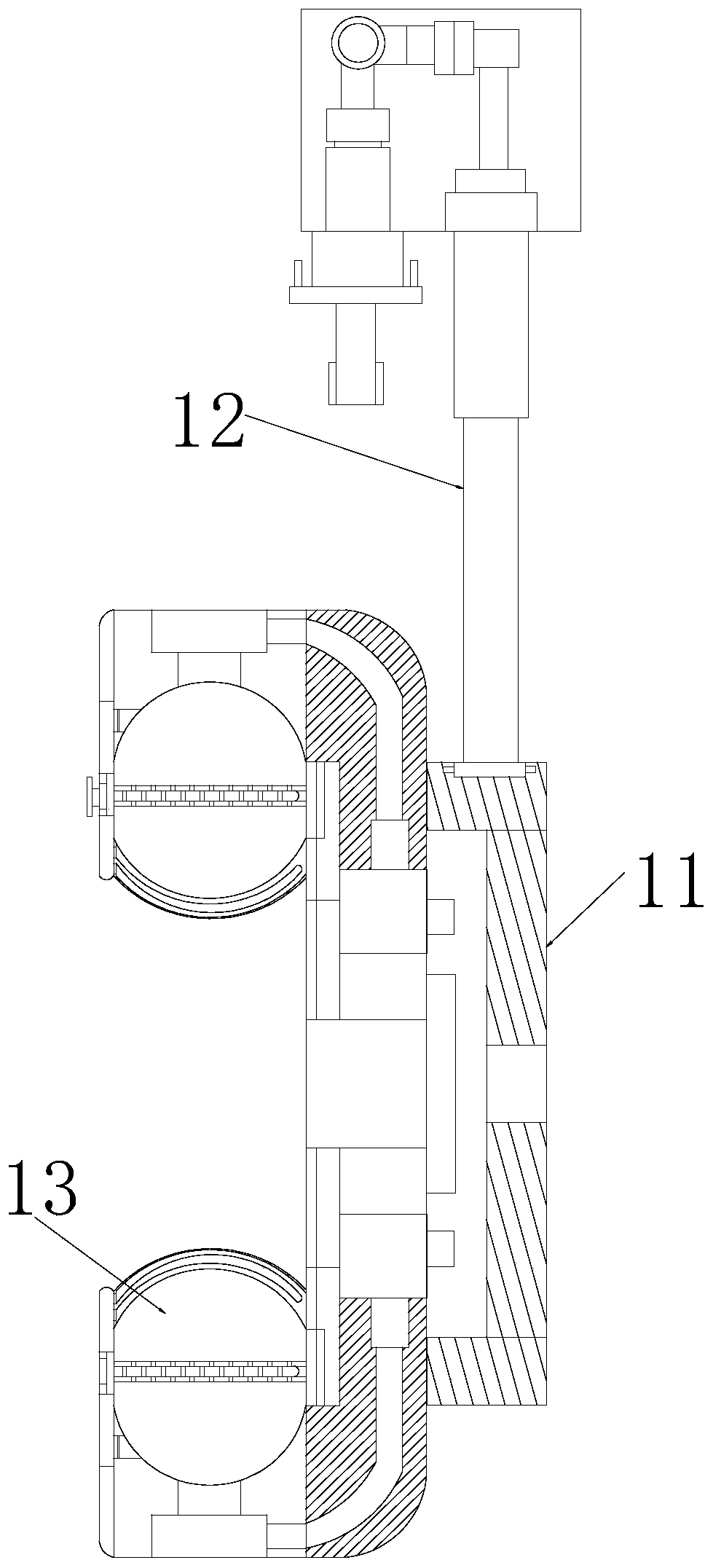

Automatically-assembled high-precision laser welding equipment

ActiveCN113751873ARealize automatic continuous welding workGuarantee welding qualityLaser beam welding apparatusMobile phoneLaser soldering

The invention discloses automatically-assembled high-precision laser welding equipment, and relates to the technical field of mobile phone automatic assembly. The automatically-assembled high-precision laser welding equipment comprises a bearing seat and a welding assembly, a placement frame is arranged at the position, close to the edge, of the upper end of the bearing seat, a transfer assembly used for transferring a mobile phone shell is arranged at the center position of the upper end of the bearing seat, an accessory conveying belt is arranged in the middle of the left side of the upper end of the bearing seat, and the welding assembly used for metal part welding is arranged on the left side in the placement frame. By means of adsorption clamping blocks and connecting flange blocks which are distributed in parallel, the precision of adsorbing and clamping small metal parts conveyed at the upper end of the accessory conveying belt through the adsorption clamping blocks is guaranteed, the adsorption clamping blocks connected with the connecting flange blocks through fastening bolts are conveniently matched with the replacement progress of bearing blocks for corresponding replacement, so as to ensure the actual using effect of the welding equipment. The exposed area of the small metal parts is larger in an adsorption clamping mode, welding work can be conveniently conducted on the small metal parts through a laser welding head, and the welding precision is improved.

Owner:苏州派富特智能制造科技有限公司

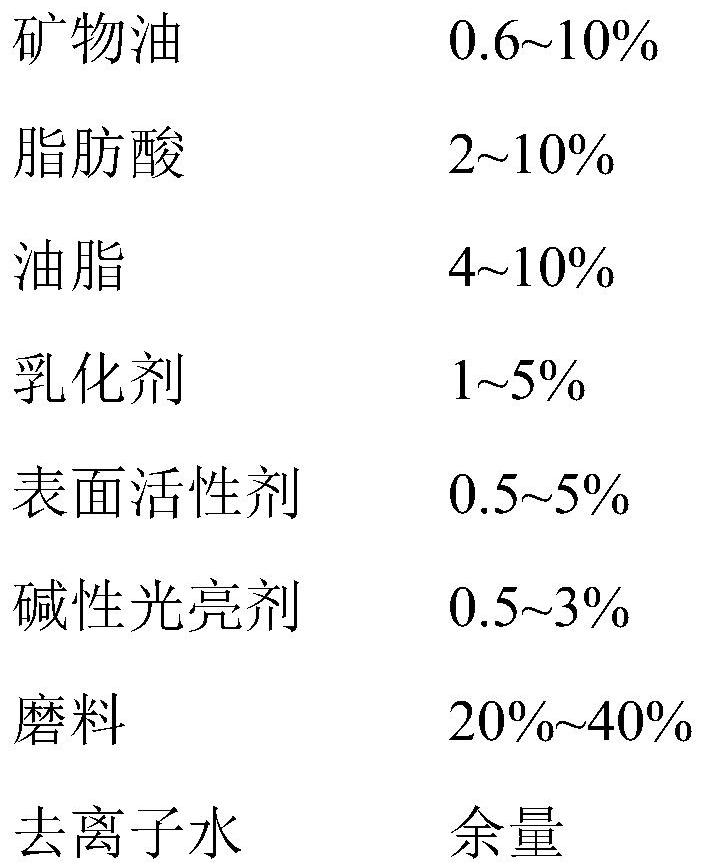

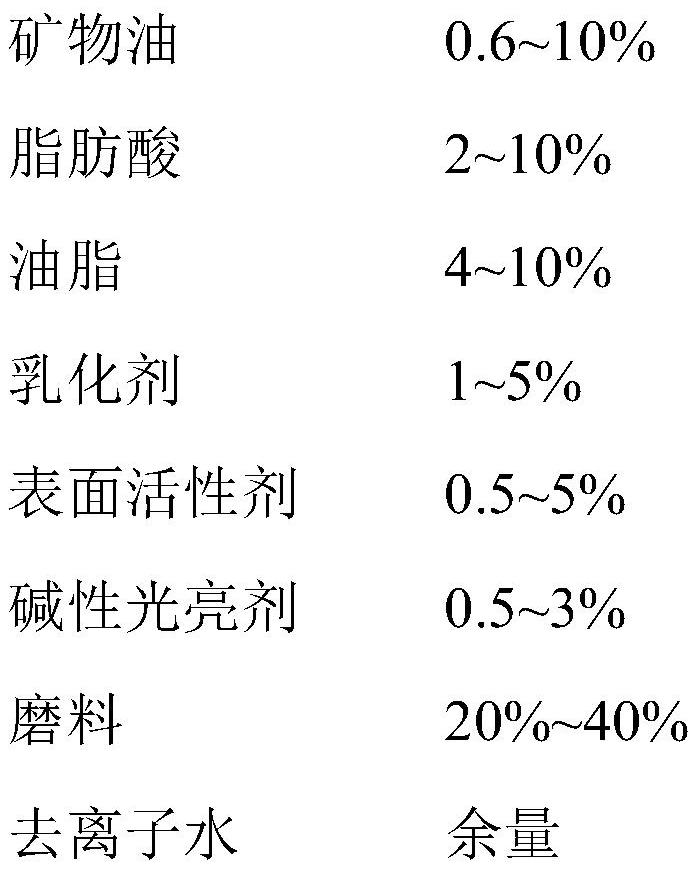

Aluminum alloy liquid fine polishing wax and preparation method thereof

PendingCN114163931AAvoid corrosionCase to prevent scratchesPolishing compositions with abrasivesLubricant compositionProcess equipmentEmulsion

The invention relates to the technical field of liquid polishing wax, in particular to aluminum alloy liquid fine polishing wax and a preparation method thereof, and the aluminum alloy liquid fine polishing wax comprises the following components: mineral oil, fatty acid, grease, an emulsifier, a surfactant, an alkaline brightener and an abrasive. The aluminum alloy liquid fine polishing wax is high in polishing efficiency and good in surface effect. The preparation method of the aluminum alloy liquid fine polishing wax comprises the following steps that under the stirring condition, water, the alkaline brightener, the surfactant, the emulsifier and the abrasive are stirred to be completely dissolved, and a uniform mixed solution is obtained; and when the temperature of the mixed solution reaches 75 DEG C or above, adding mineral oil, grease and fatty acid, stirring to obtain an emulsion, continuously stirring for continuous emulsification, and stopping stirring and heating to obtain the aluminum alloy liquid fine polishing wax. The preparation method of the aluminum alloy liquid fine polishing wax is low in process equipment investment, simple and convenient in process operation, and capable of producing the high-quality and high-stability aluminum alloy liquid fine polishing wax.

Owner:SHENZHEN PARDANG TECH

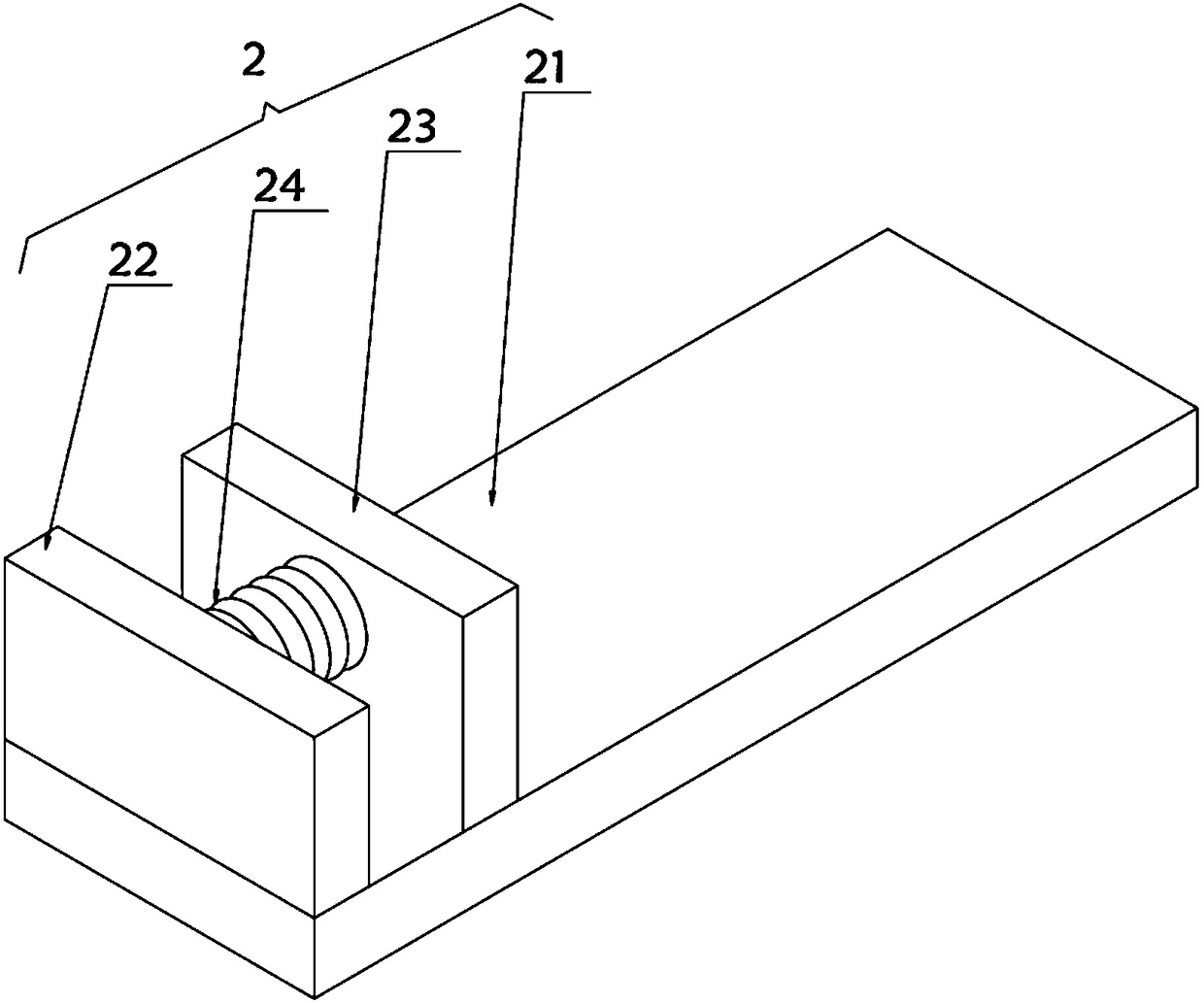

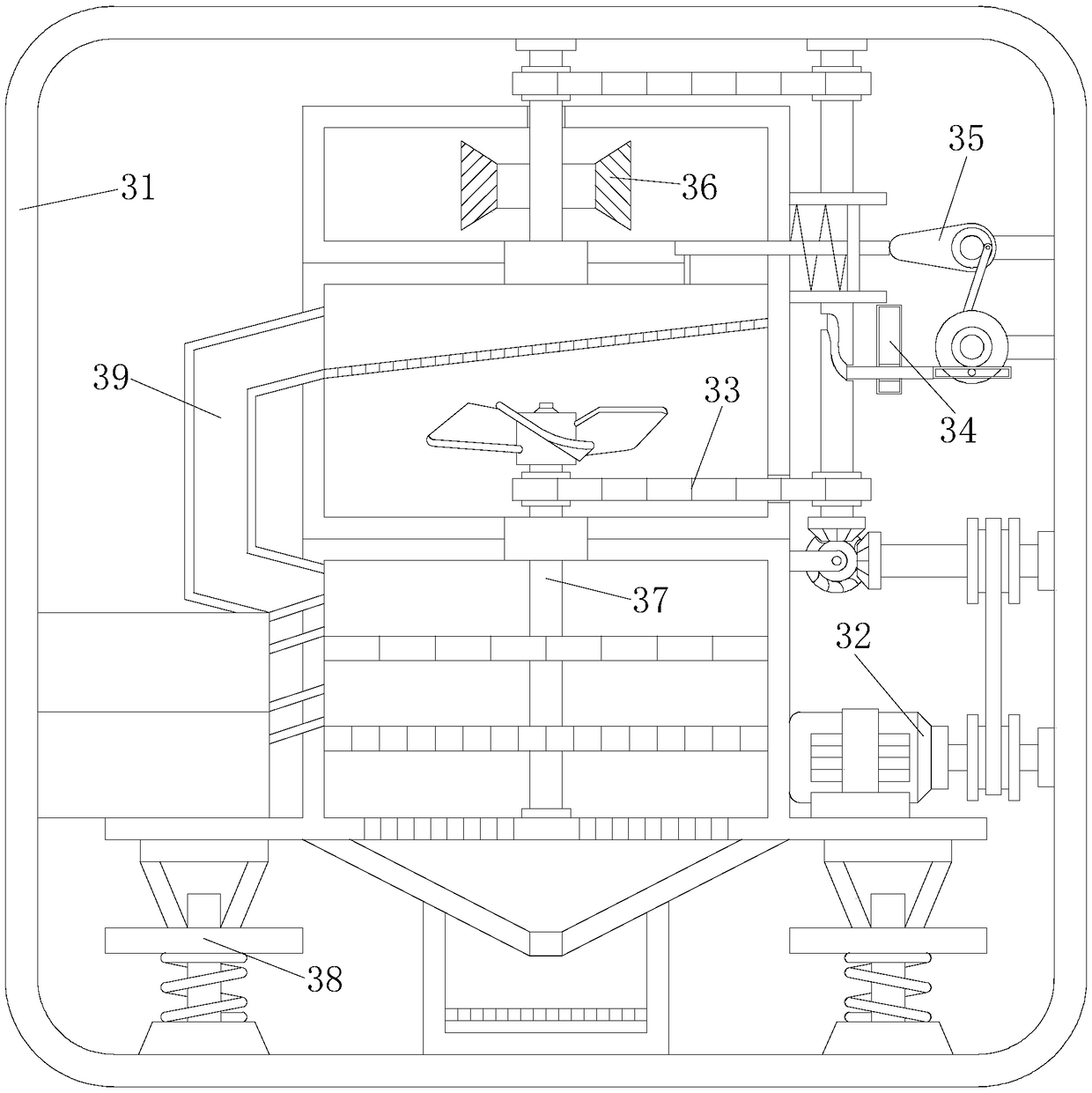

Abrasive cloth wheel polishing machine for double-sided curve grinding and polishing method of abrasive cloth wheel polishing machine

The invention discloses an abrasive cloth wheel polishing machine for double-sided curve grinding. The abrasive cloth wheel polishing machine comprises a workbench, a protective cover, two discharging grooves and a collecting groove; the protective cover is fixed to the upper end face of the workbench, and noise reduction plates are installed on the two sides of an inner cavity of the protective cover in an embedded mode respectively; the two discharging grooves are formed in the surface of the workbench; and the collecting groove is placed at the lower end of the workbench and is oppositely connected with output ends of the discharging grooves. According to the polishing machine, a polishing yarn wheel can be always kept attached to a through groove through a pull ring installed in a kidney groove, when the through groove is connected to the surface of a workpiece in a sleeving mode, the polishing yarn wheel can be always kept in the state of being attached to the curved surface workpiece, and therefore the irregular curved surface can be polished; and the mode that a manipulator or a hydraulic rod needs to be received to drive the position of a polishing disc is changed, the manufacturing cost is low, the surface is accurately polished, meanwhile, a cleaning brush in a connecting pipe can clean the surface of the curved surface workpiece, accumulated impurities are prevented from affecting the polishing efficiency, and the situation of scratching in the polishing process is prevented.

Owner:盐城市锐克斯研磨科技有限公司

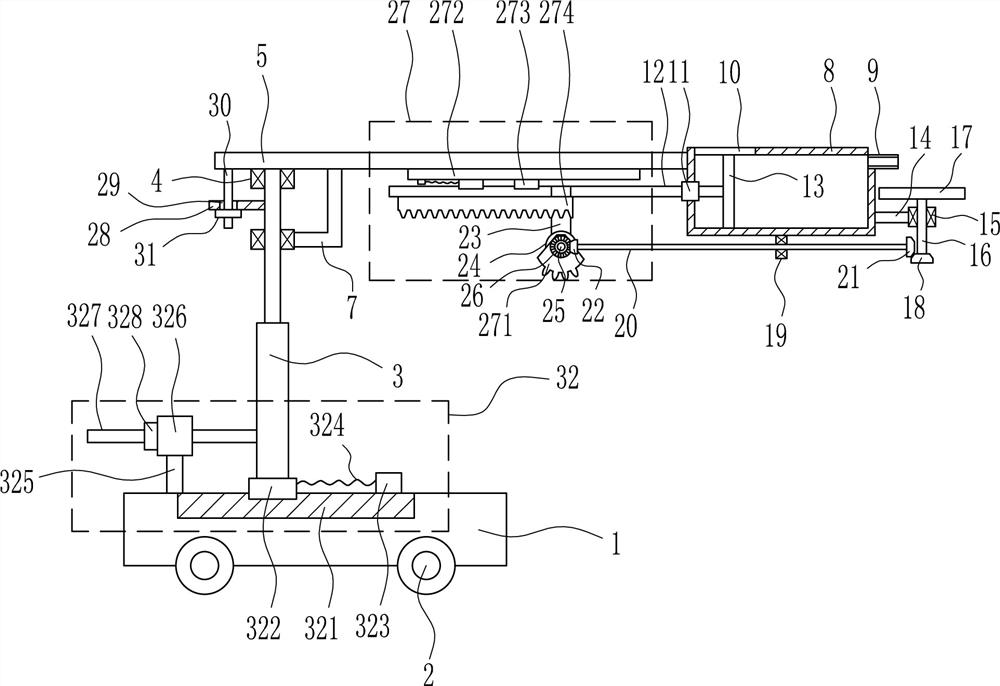

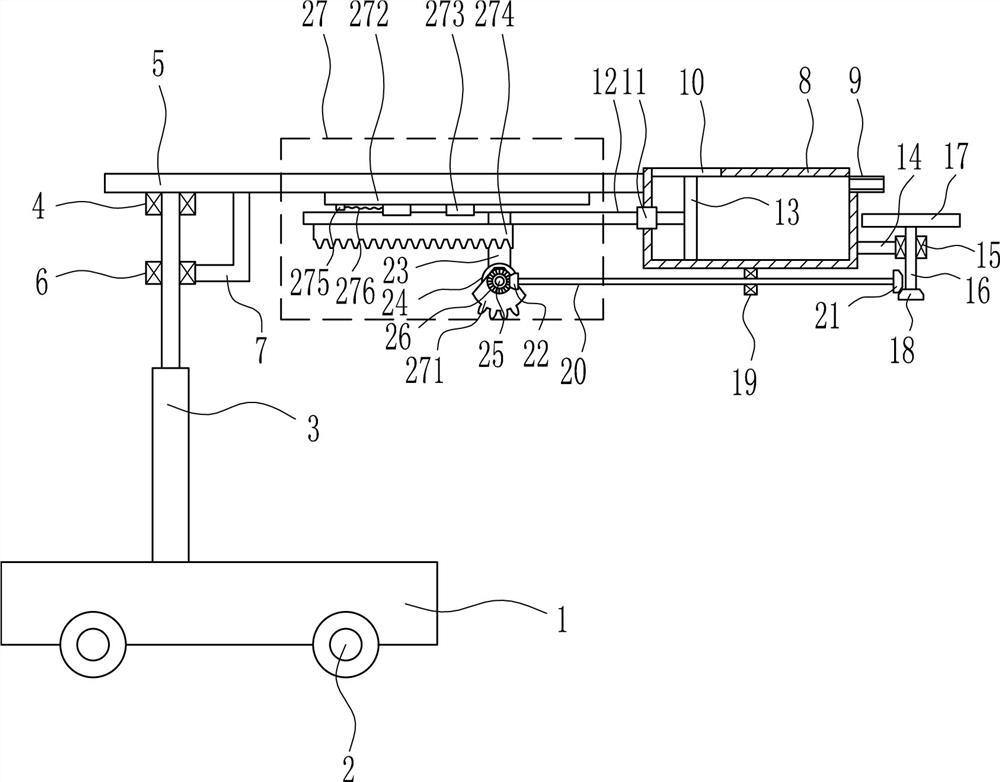

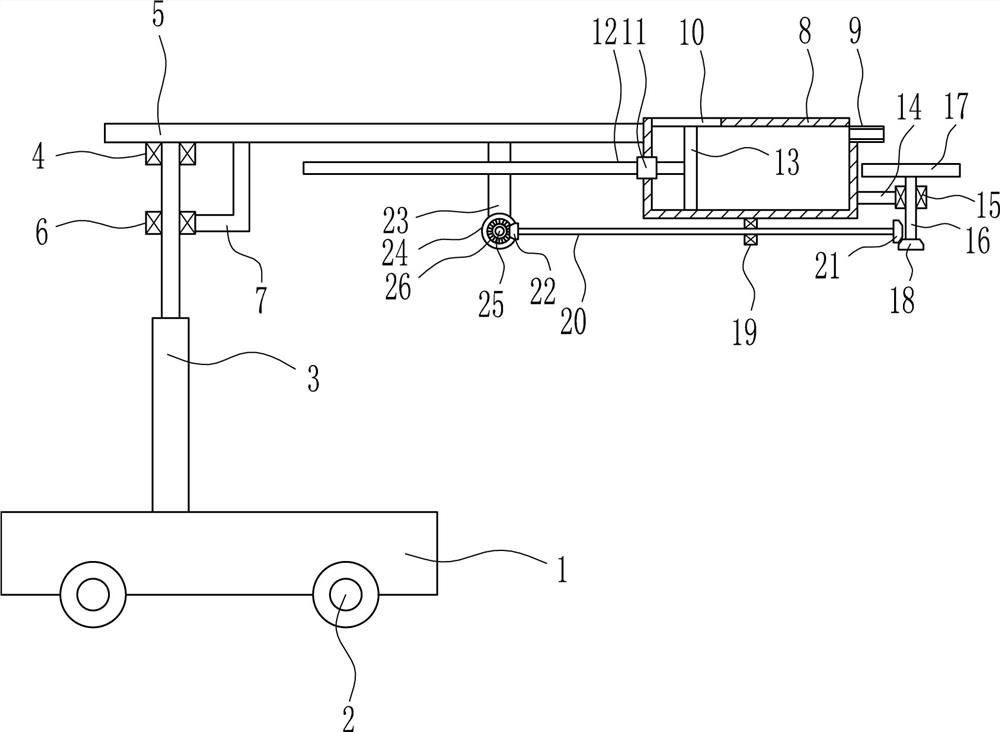

Lubricating oil smearing equipment for electromechanical products

The invention relates to lubricating oil smearing equipment and in particular relates to mechanical and electrical product lubricating oil smearing equipment. The invention aims at providing the mechanical and electrical product lubricating oil smearing equipment which is used for conveniently smearing lubricating oil and does not injure hands. According to the technical scheme, the mechanical andelectrical product lubricating oil smearing equipment comprises a bottom plate, wheels, an air cylinder, a first bearing seat, a first connection rod, a second bearing seat and the like, wherein thewheels are mounted at the bottom of the bottom plate; the air cylinder is arranged at the left side of the top of the bottom plate; the second bearing seat is arranged at the upper part of the air cylinder; an L-shaped supporting rod is connected with the right side of the second bearing seat; the top of the L-shaped supporting rod is connected with the first connection rod. According to the mechanical and electrical product lubricating oil smearing equipment, sponge rotates and the lubricating oil can be smeared on mechanical and electrical products; the lubricating oil does not need to be smeared by hands through the equipment; a condition that the hands of a user are scratched by parts of the mechanical and electrical products when the lubricating oil is smeared is prevented from occurring; the user pulls a piston toward the left side to return back the right side of a through hole through a guide rod, so that the lubricating oil remained in a cylinder can be protected and is convenient for next-time utilization.

Owner:滨州高新区国有资本投资运营有限公司

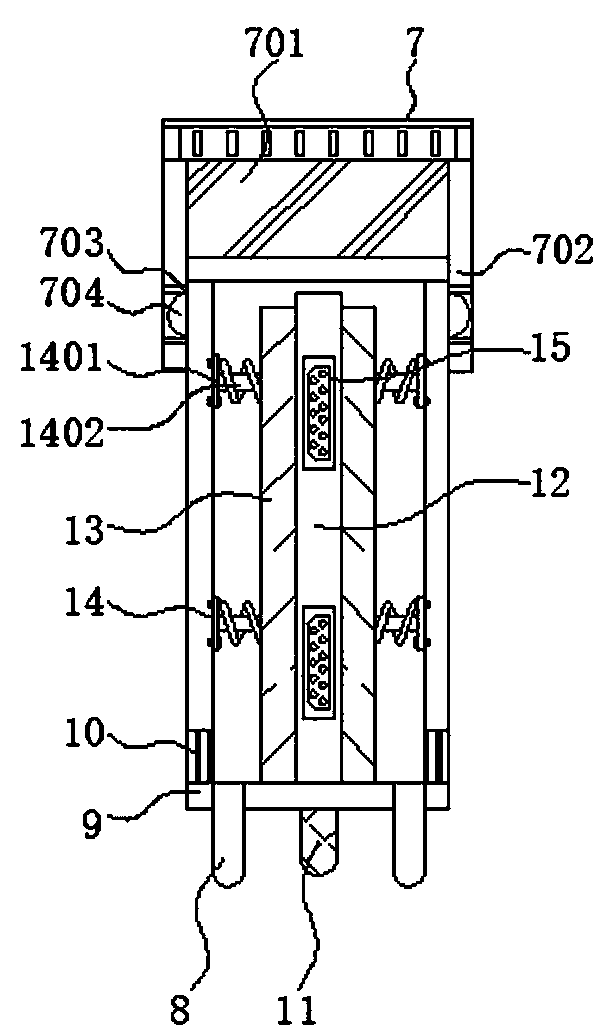

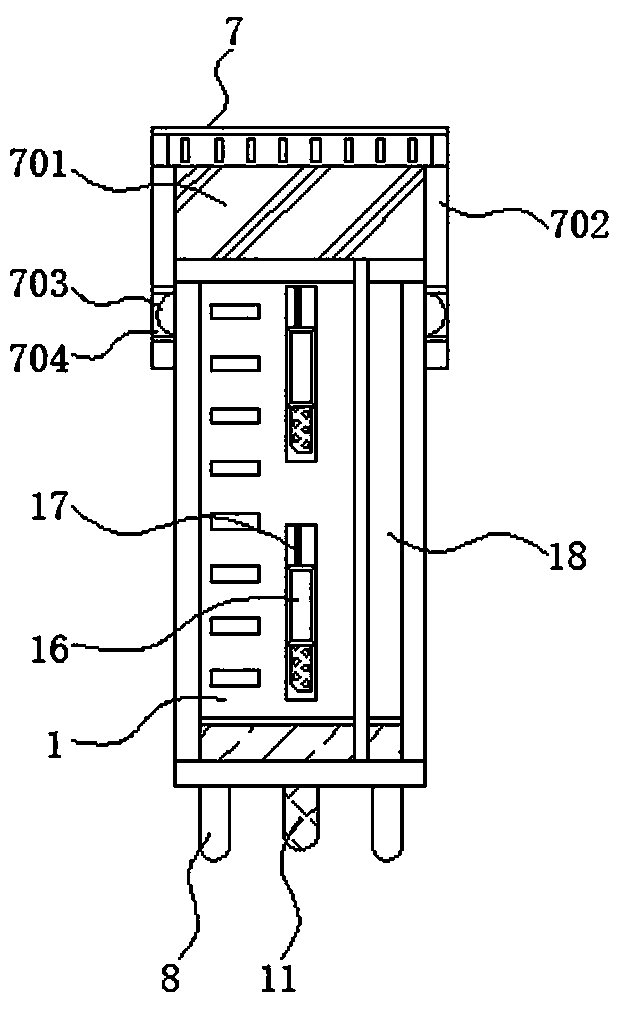

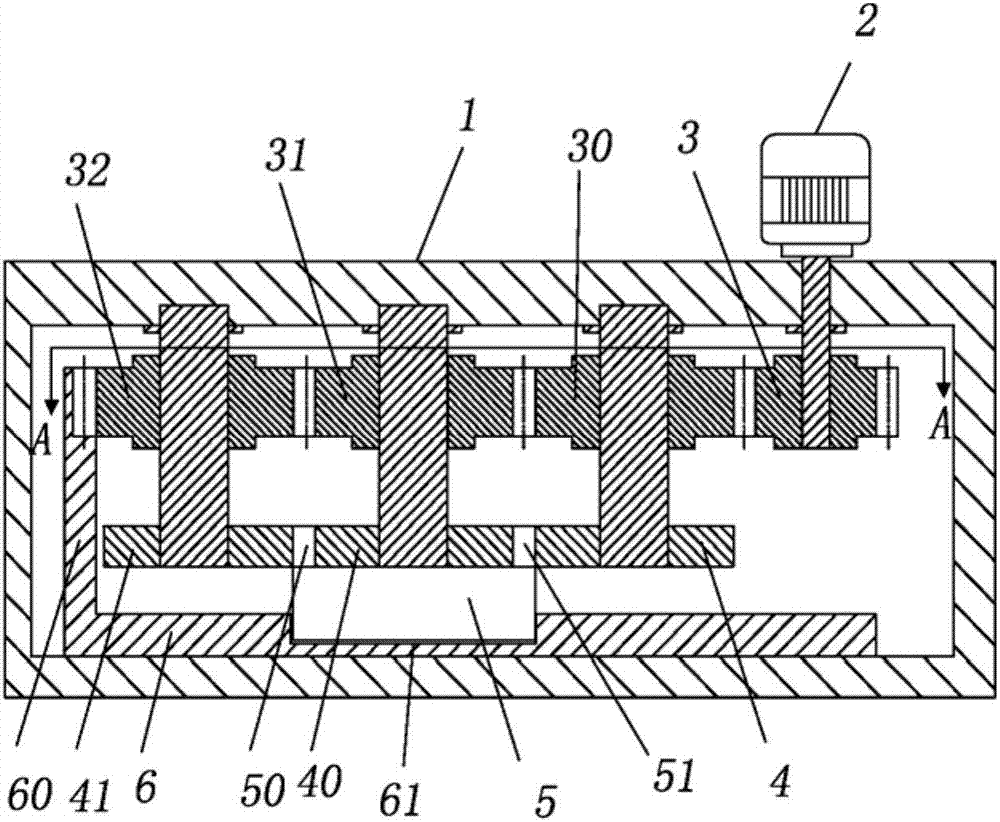

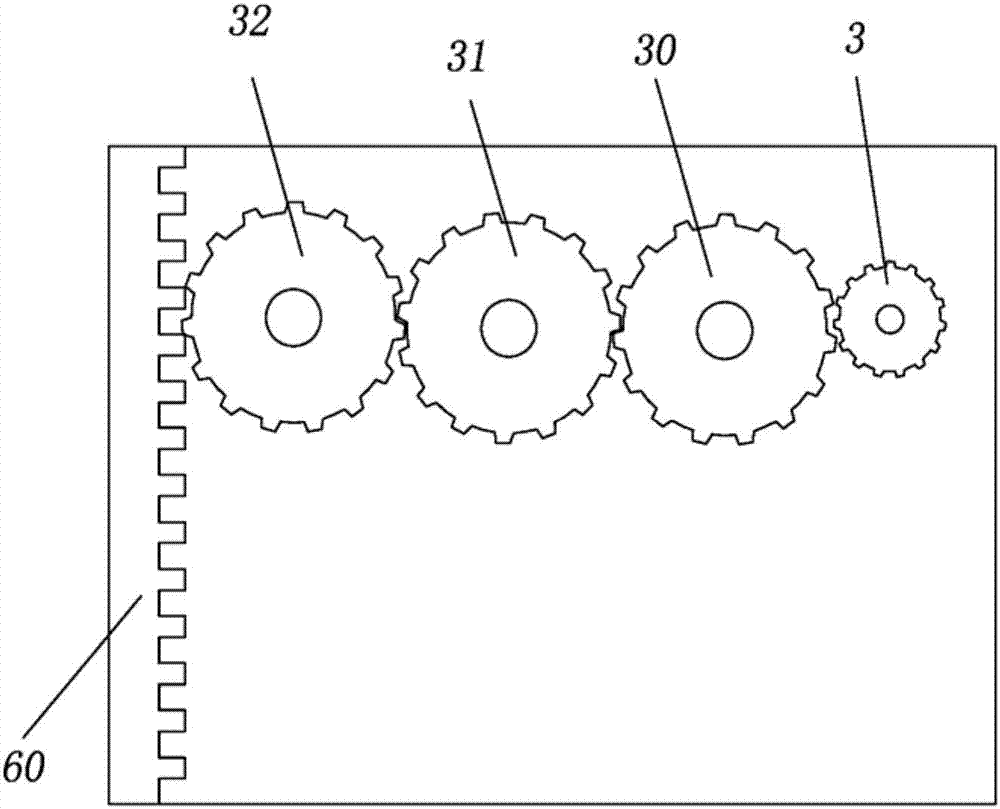

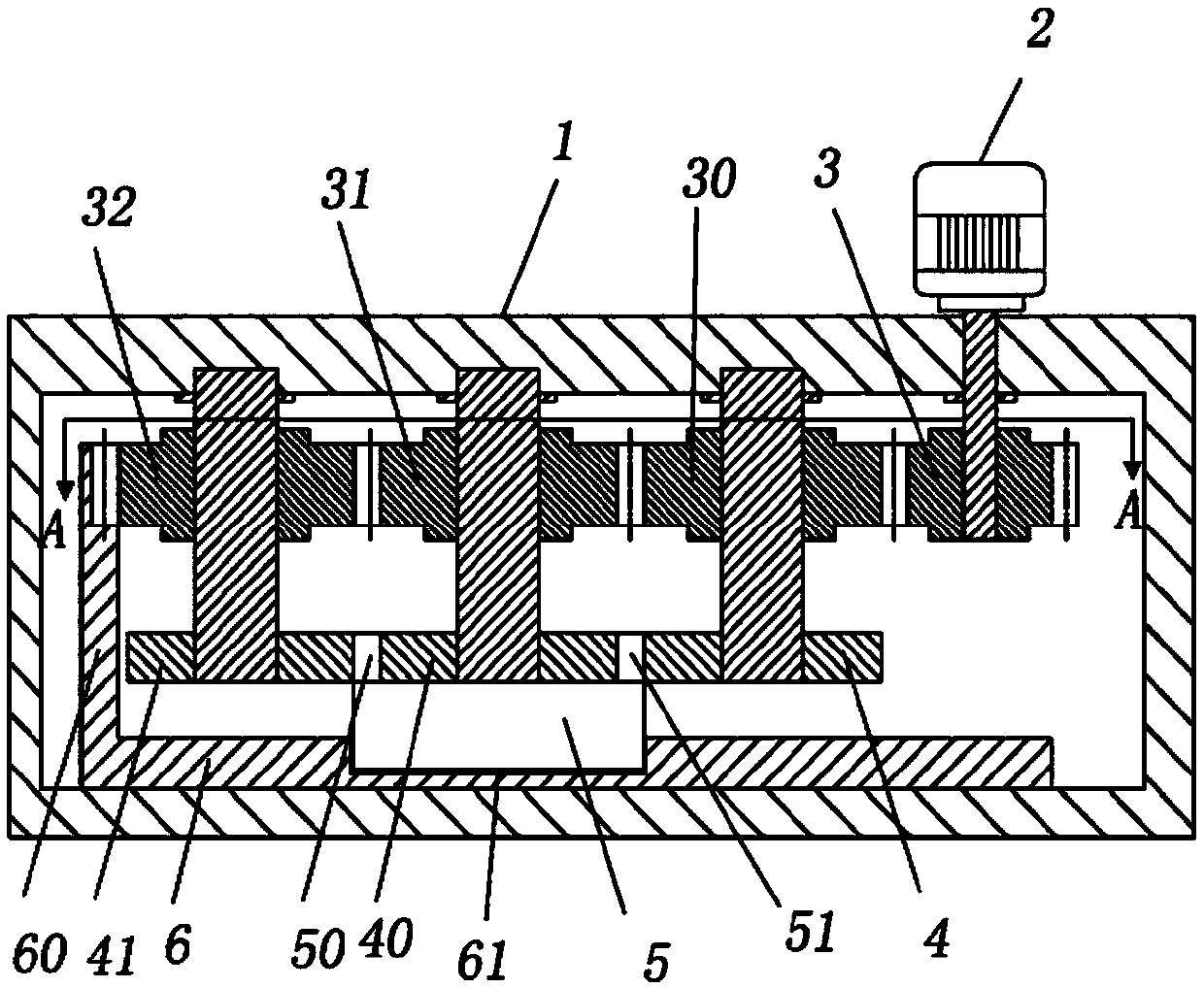

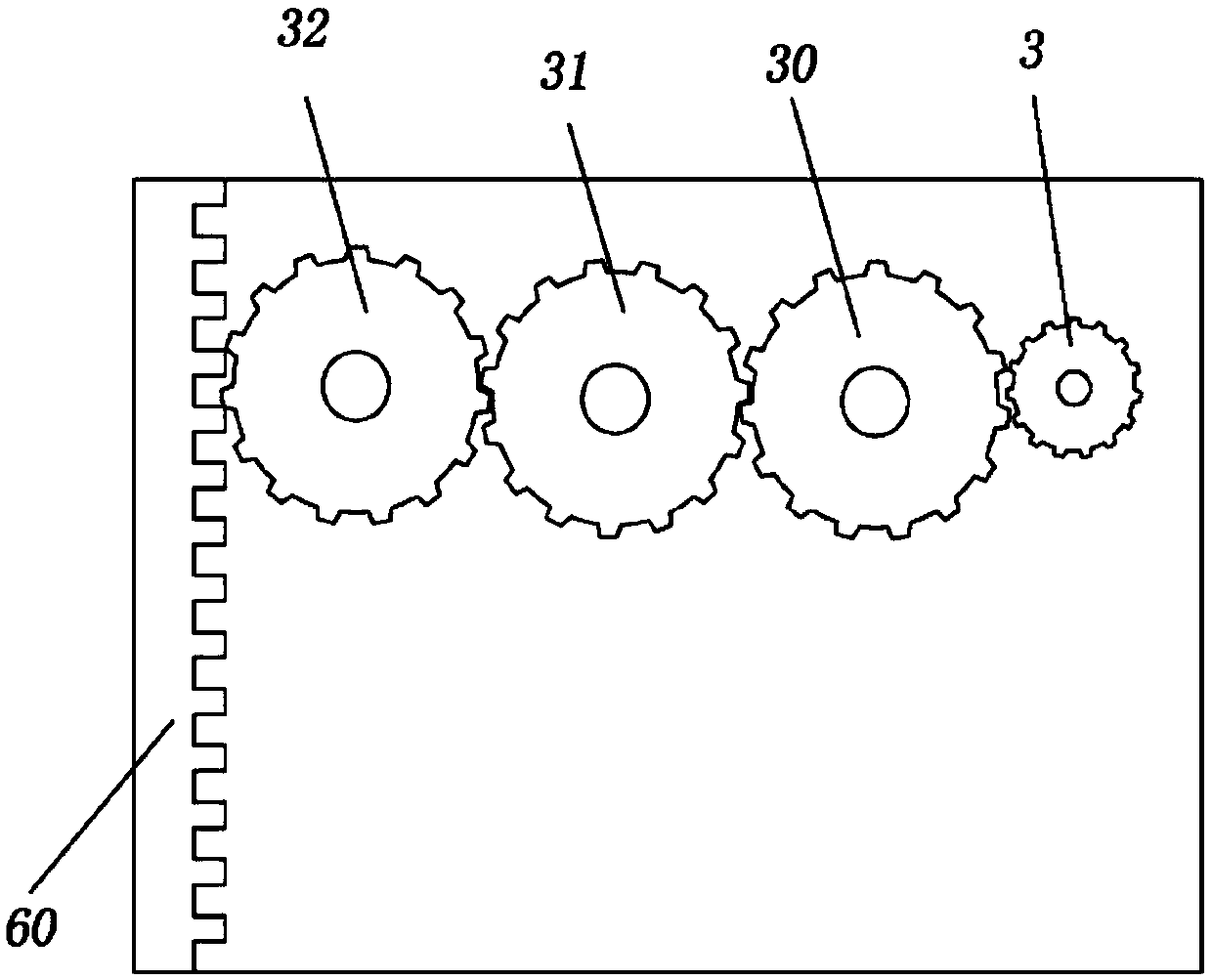

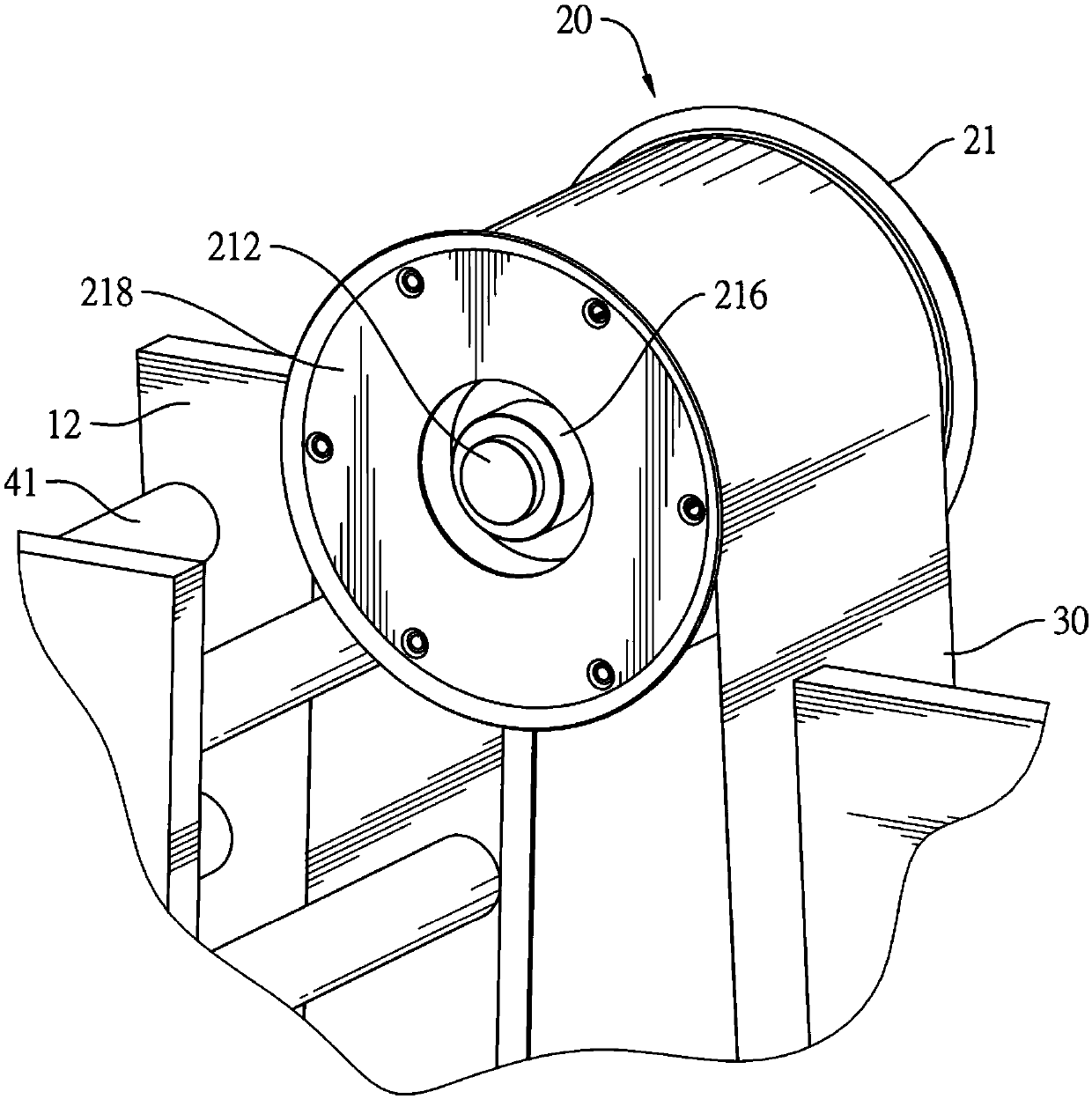

Manufacturing equipment of electronic components

ActiveCN107876661AEven vertical conditionAvoid damageTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureTransformerTransfer mechanism

The invention belongs to the technical field of electronic components and particularly relates to manufacturing equipment of electronic components. The manufacturing equipment comprises a rack, a motor, a power mechanism, a straightening mechanism and a transferring mechanism, the power mechanism comprises a transmission gear, a right gear, a center gear and a left gear which are engaged sequentially, and an output shaft of the motor is connected with the transmission gear. The straightening mechanism comprises a right squeezing wheel, a center squeezing wheel and a left squeezing wheel, and the transferring mechanism comprises a limiting strip and a supporting plate for supporting a transformer. One end of the limiting strip is connected with the supporting plate, engaged teeth are arranged at the other end of the limiting strip, the limiting strip is engaged with the left gear through the engaged teeth, and the supporting plate and a support are slidably connected. By adopting the technical scheme, the situation that in straightening, pins are pulled out or scratched, or soldering tin is damaged can be effectively prevented, meanwhile the straightening efficiency is improved, andthe labor intensity is reduced.

Owner:威海市多益电子有限公司

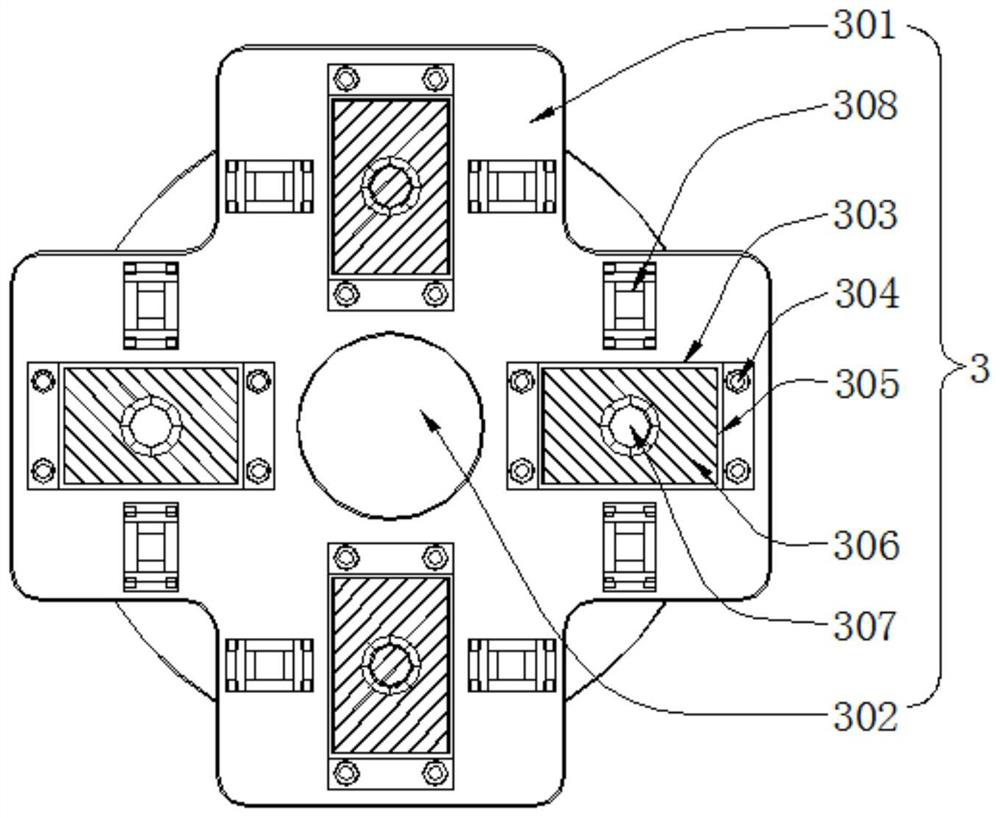

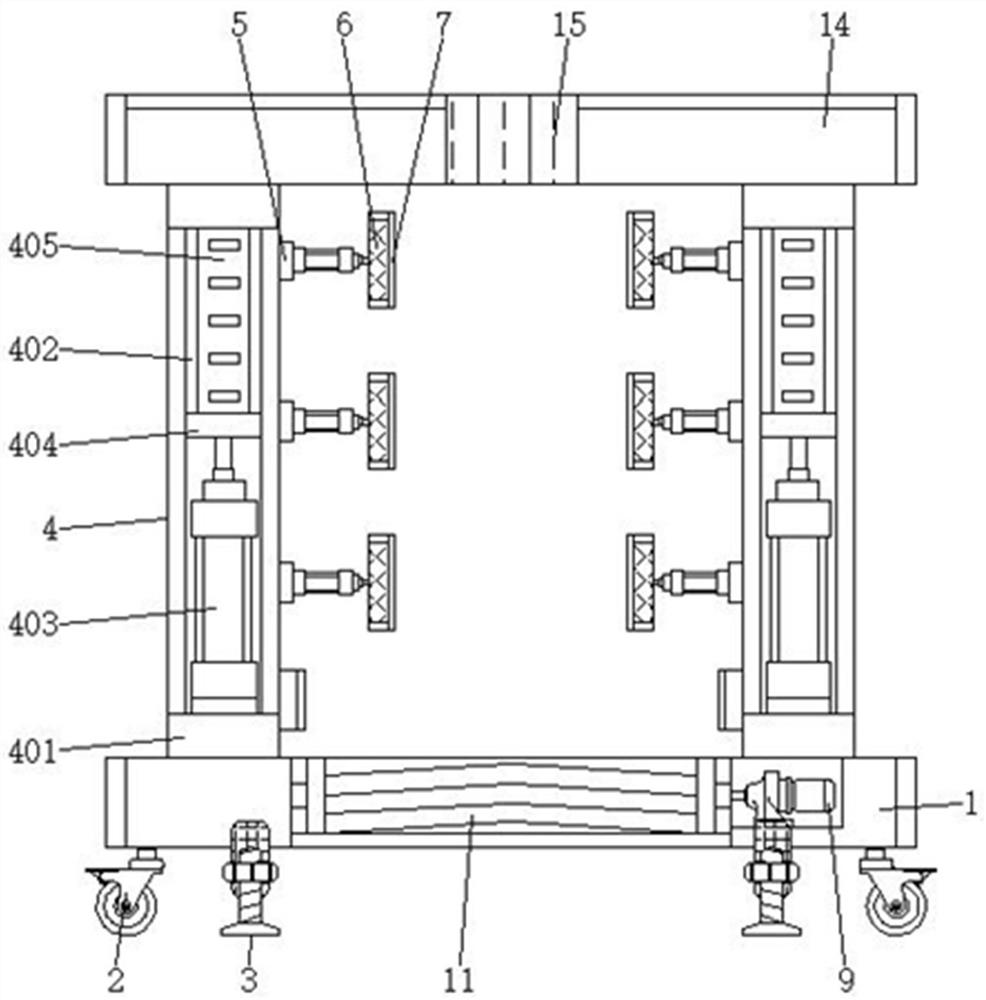

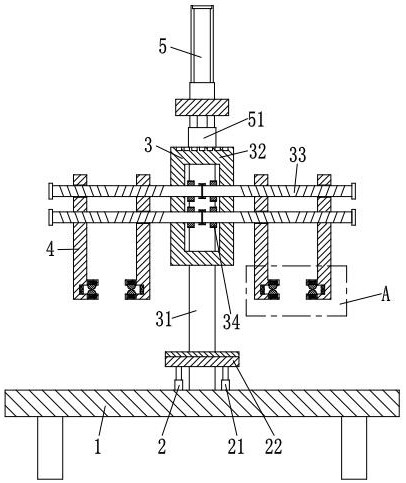

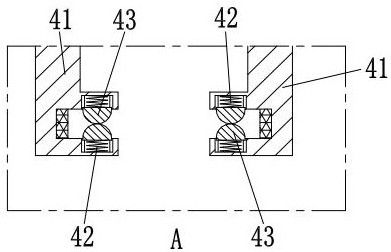

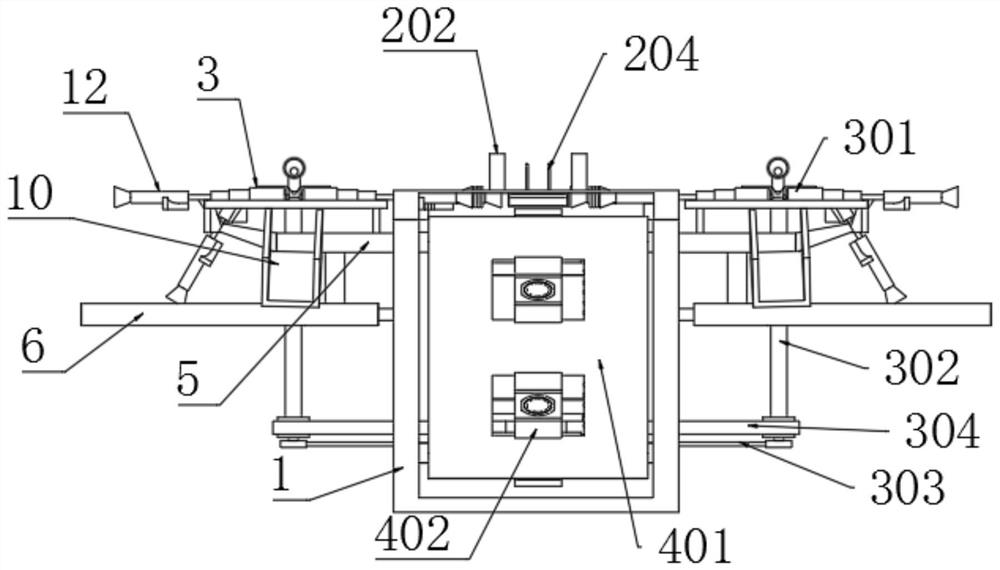

New energy automobile rear suspension auxiliary frame connecting piece drilling machining machine

ActiveCN113275627AGuaranteed structural qualityCase to prevent scratchesWork clamping meansFeeding apparatusVehicle framePunching

The invention relates to the field of automobile part machining, in particular to a new energy automobile rear suspension auxiliary frame connecting piece drilling machining machine which comprises a supporting frame, an auxiliary device, a supporting device, a fixing device and a drilling device. According to the new energy automobile rear suspension auxiliary frame connecting piece drilling machining machine, the problems that in an existing full-frame type rear suspension auxiliary frame connecting piece punching process, the position of a punching device cannot be conveniently adjusted to conduct drilling machining on full-frame type auxiliary frames of various sizes, the fixing position of a fixing device is difficult to adjust to conduct stable clamping and fixing on the full-frame type auxiliary frames of various sizes, and a large amount of scrap iron is likely to be splashed in the process of punching the full-frame type auxiliary frames through an existing punching device, so that on one hand, the splashed scrap iron is likely to hurt people, and on the other hand, the splashed scrap iron enables workers to clean a working site and recycle the scrap iron inconveniently in the later period are solved.

Owner:江苏特塑新能源科技有限公司

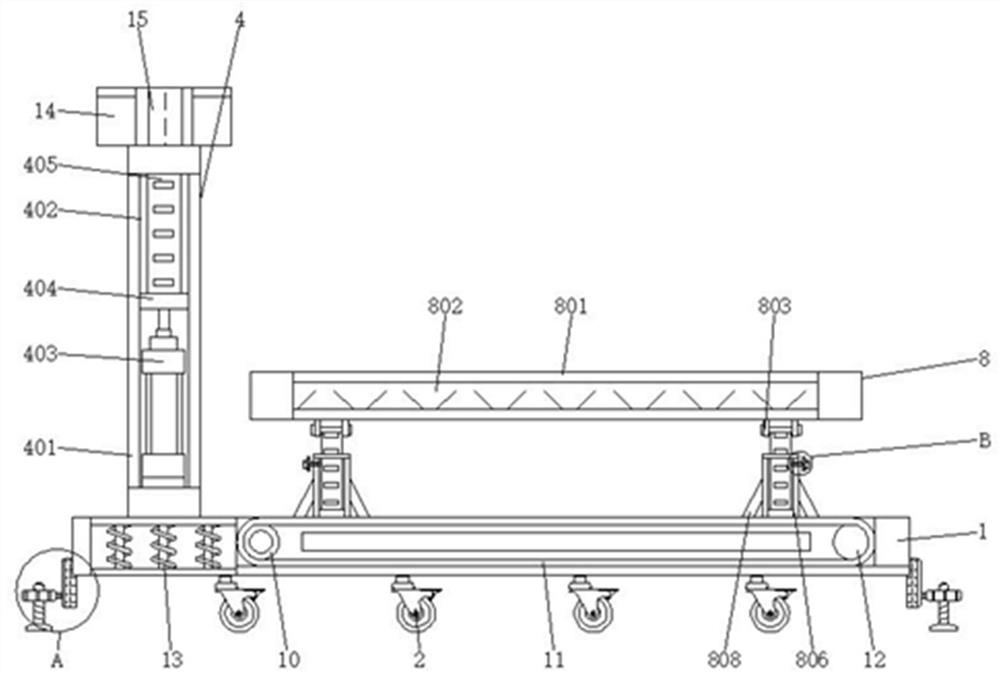

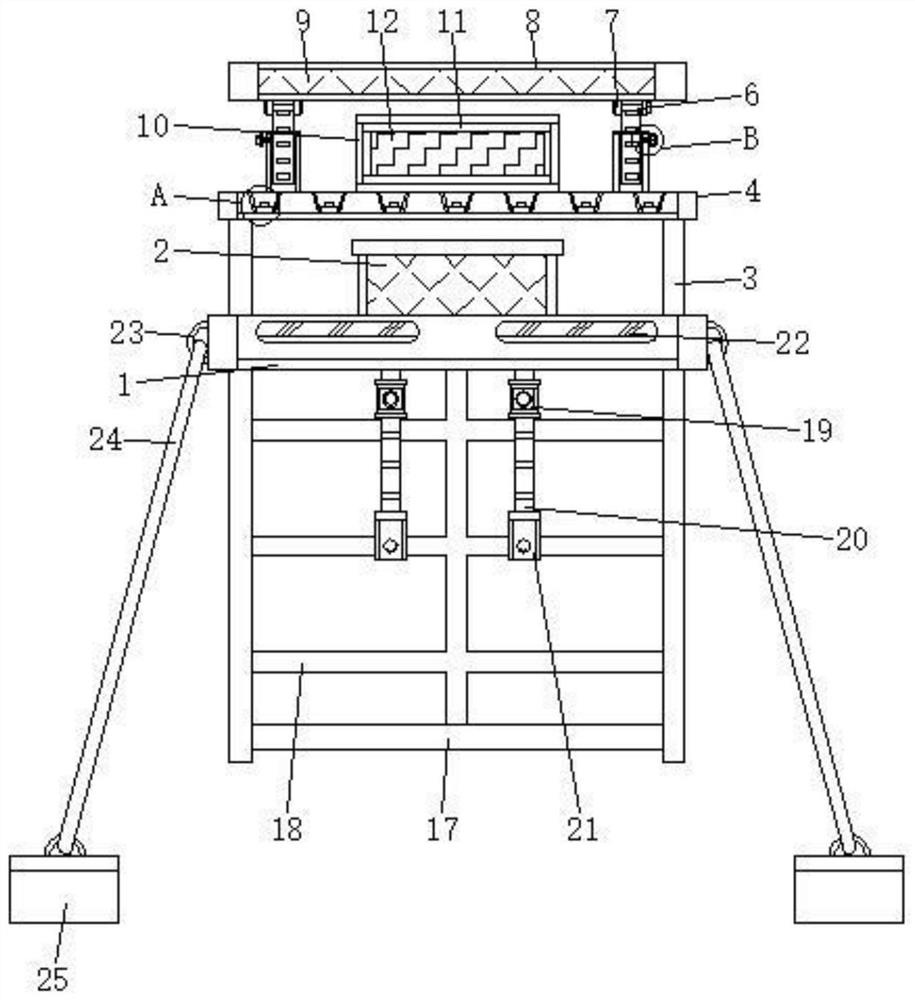

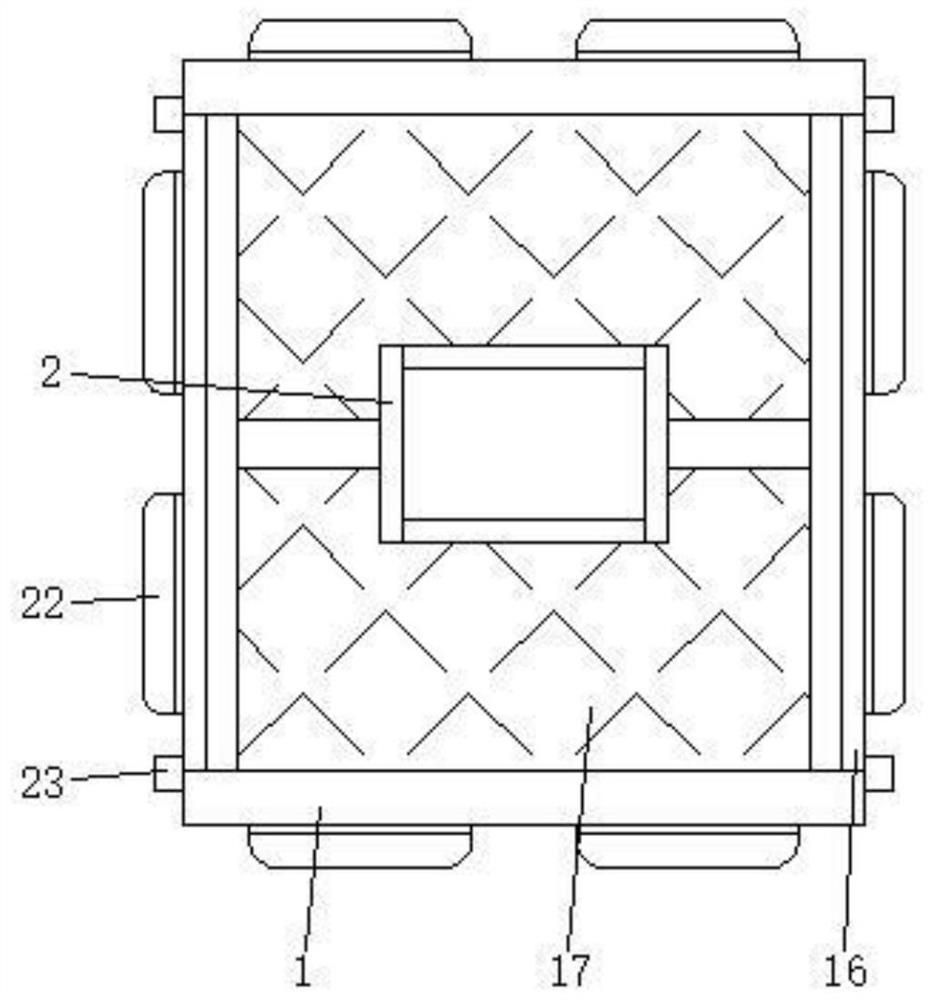

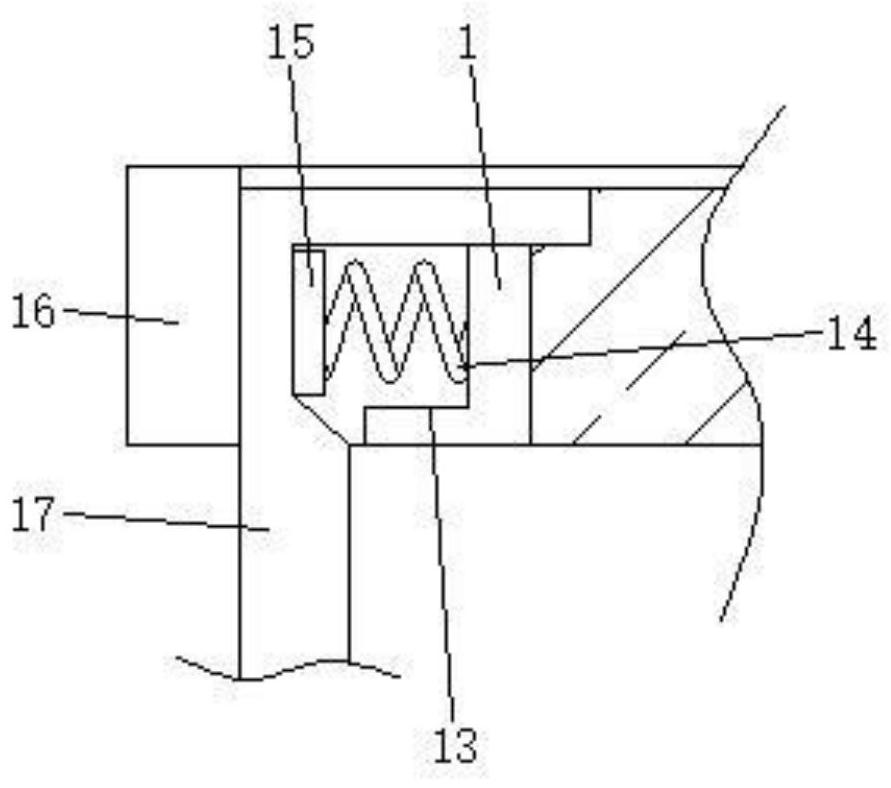

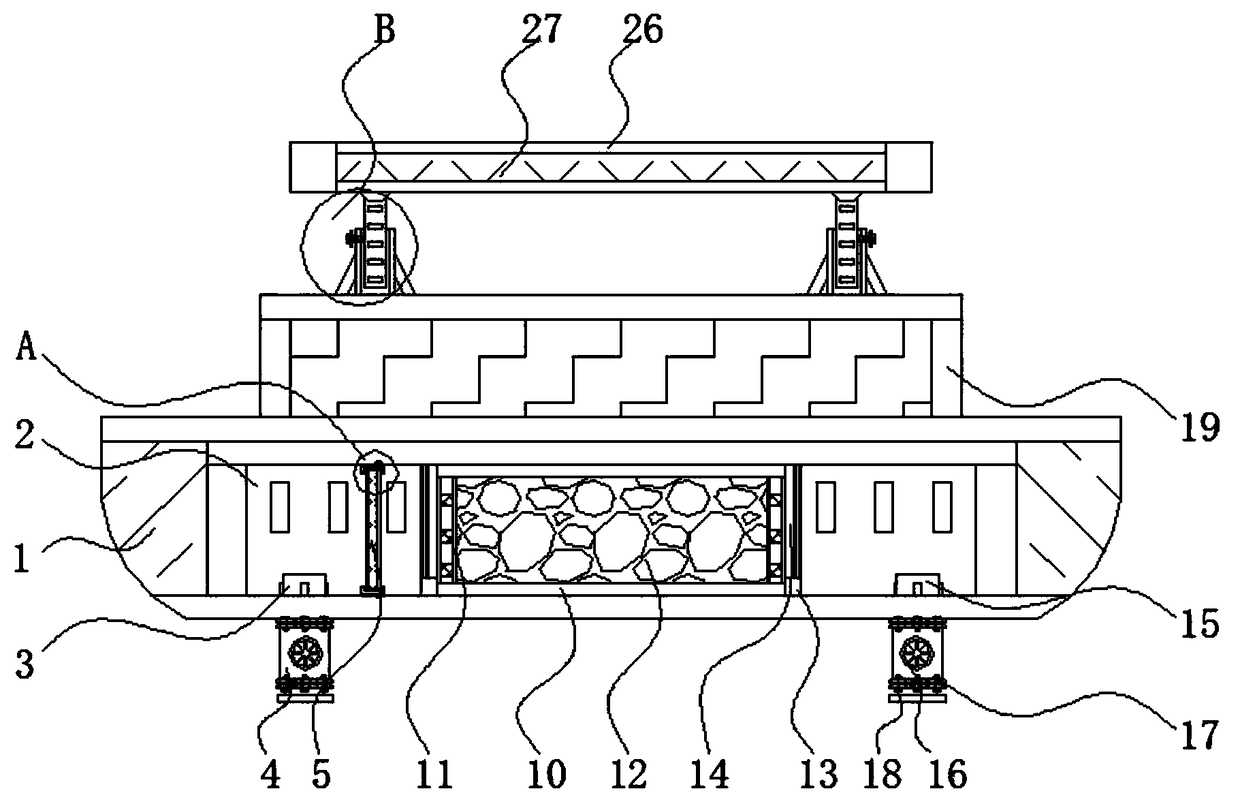

Steel beam vertical splicing auxiliary balancing device and using method thereof

InactiveCN112338489ACase to prevent scratchesExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryStructural engineering

The invention discloses a steel beam vertical splicing auxiliary balancing device and a using method thereof, and belongs to the field of steel beam machining. The steel beam vertical splicing auxiliary balancing device comprises a base, an adjusting mechanism and a clamping plate. Universal wheels are connected to the lower part of the base, and a supporting mechanism is arranged on the right sides of the universal wheels. A second hydraulic rod is connected to the right side of the adjusting mechanism, and the adjusting mechanism is located above the base. A rubber pad is fixed to the rightside of the clamping plate, and the clamping plate is located on the right side of the second hydraulic rod. A photovoltaic mechanism is arranged behind the adjusting mechanism, a motor is arranged inthe base, and a driving wheel is installed on the left side of the motor. The steel beam vertical splicing auxiliary balancing device is convenient to move, consumes less time and energy during movement, can adapt to the uneven ground during placement, is flexible in structure, can be adjusted according to the height of vertical steel beams, is high in functionality, can fully utilize resources in the nature, saves energy and protects the environment.

Owner:杜文贤

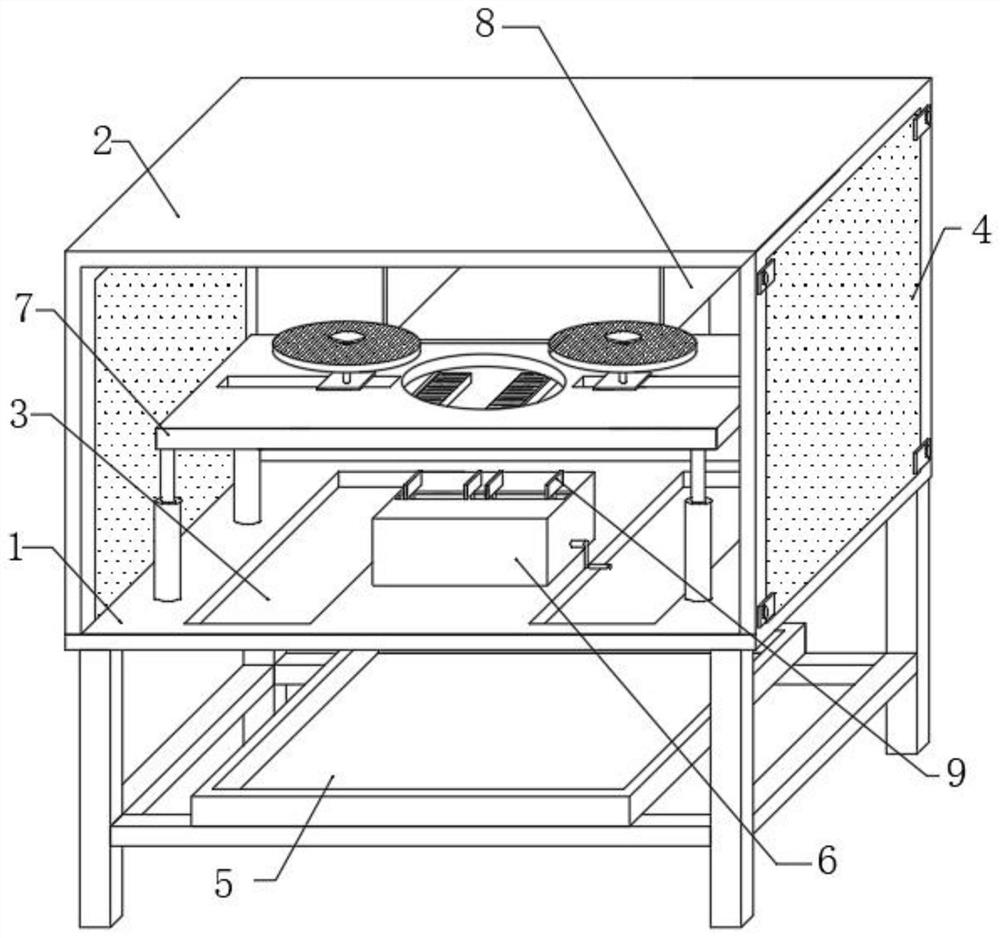

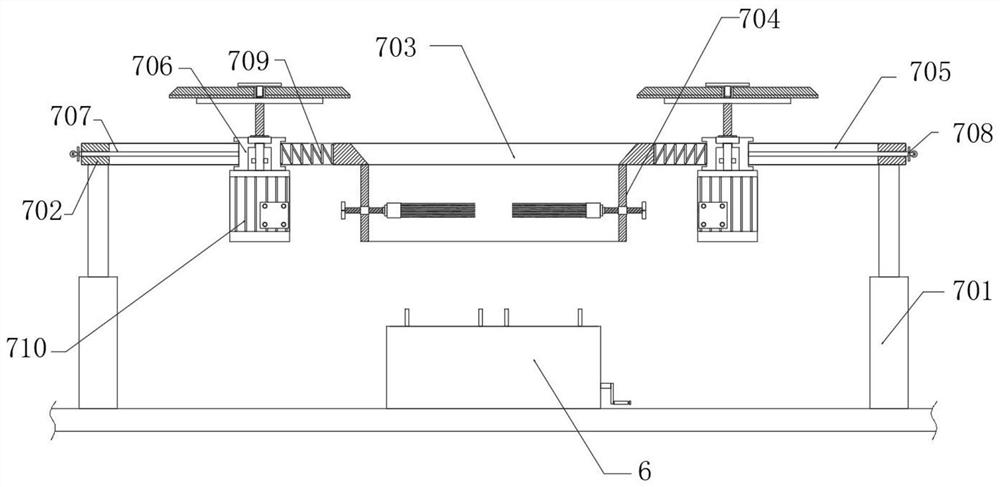

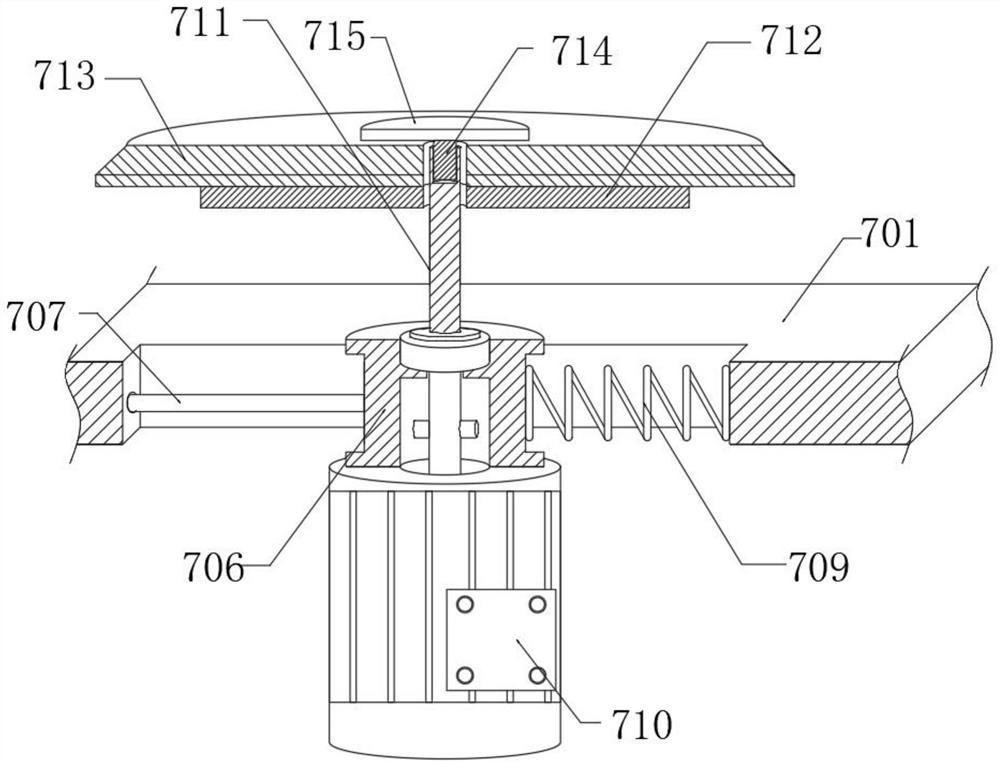

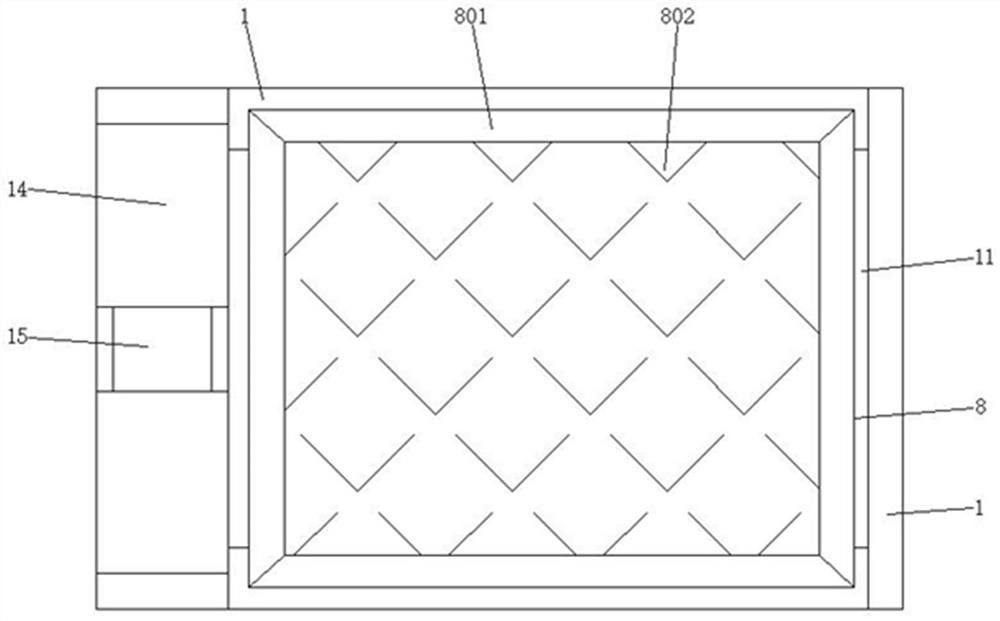

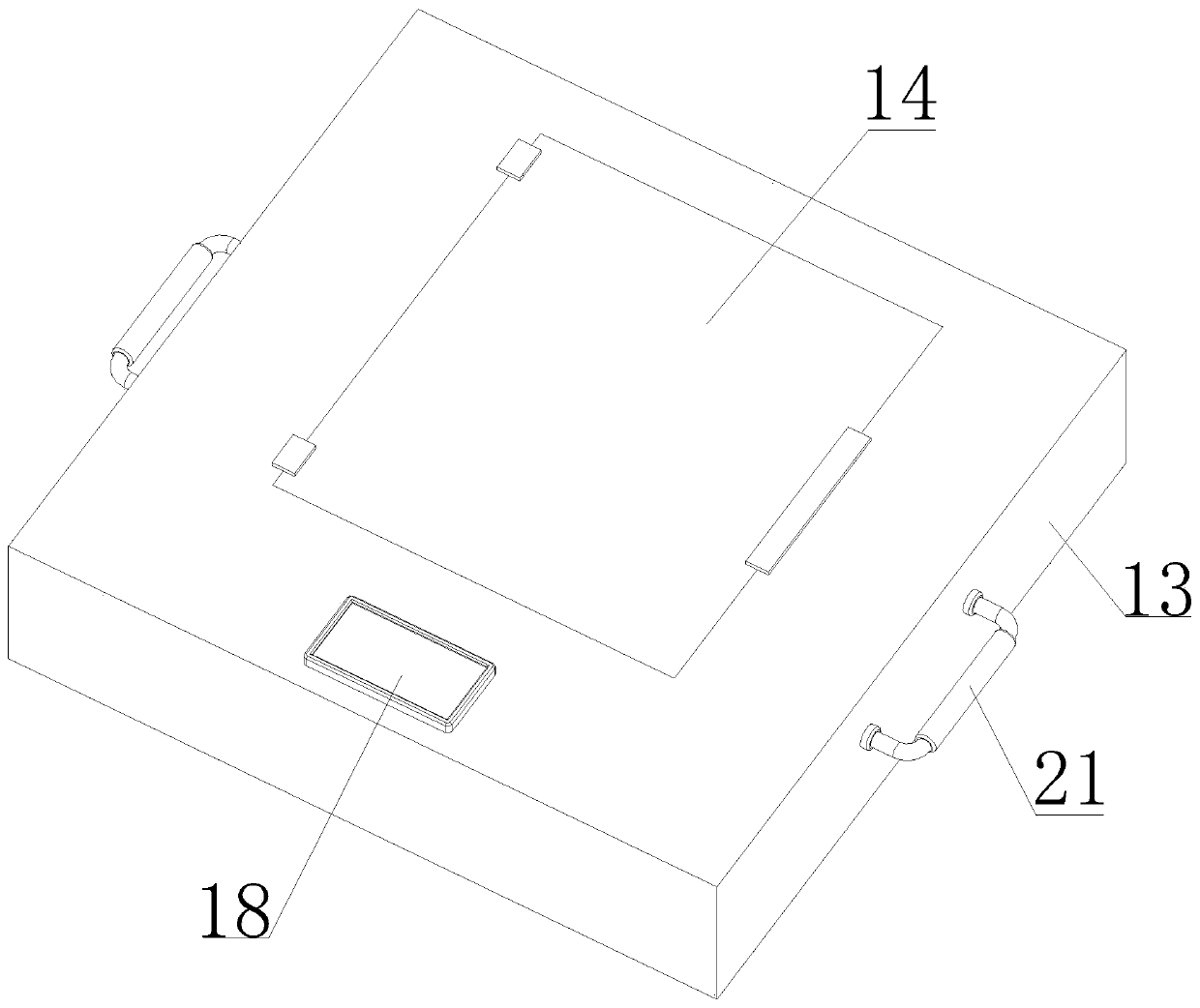

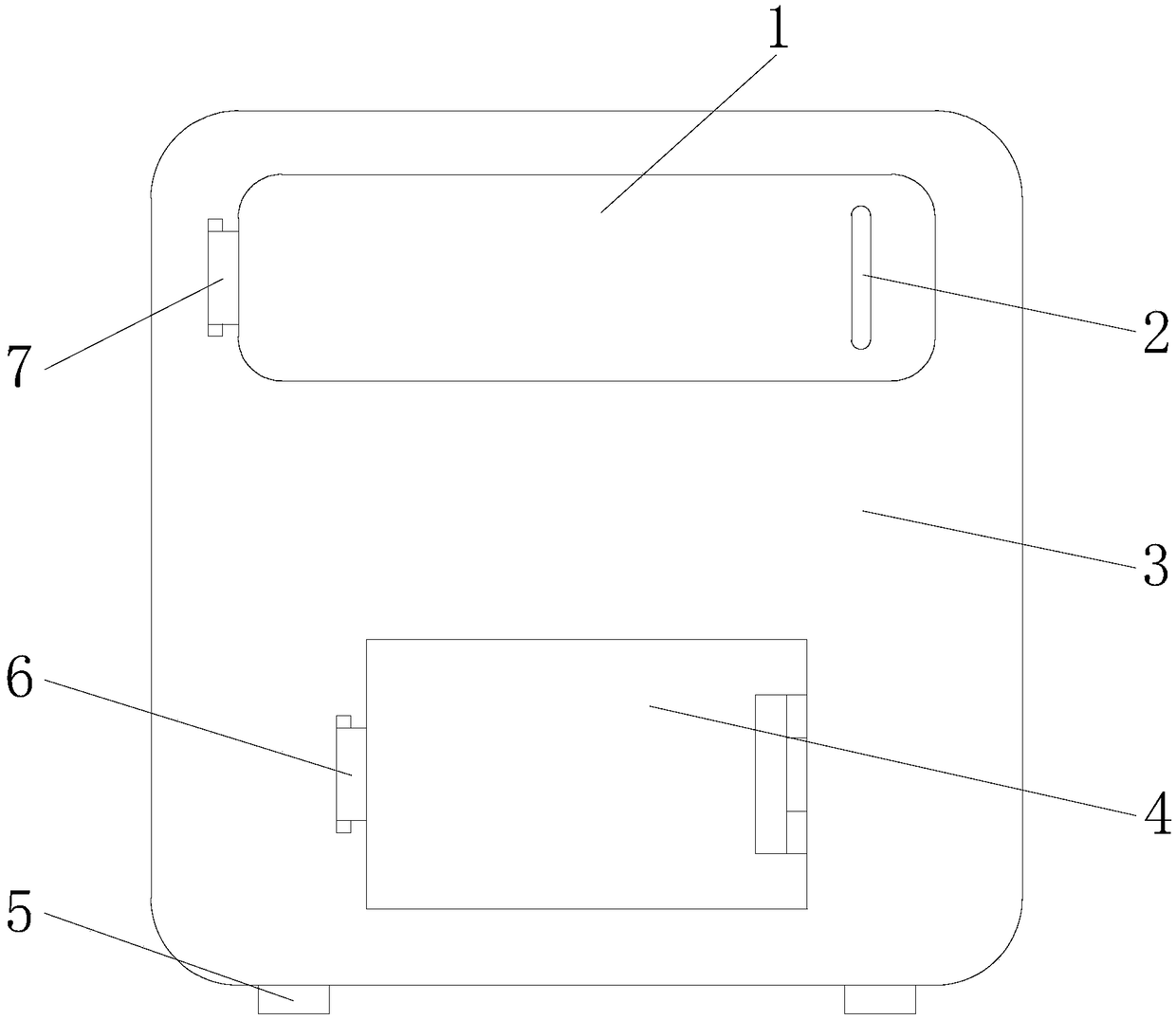

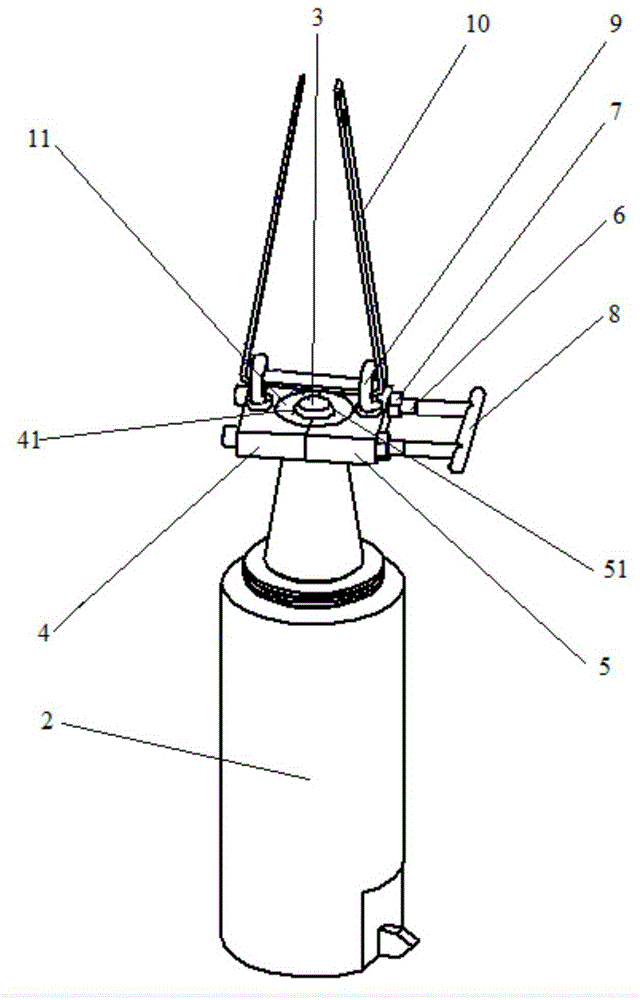

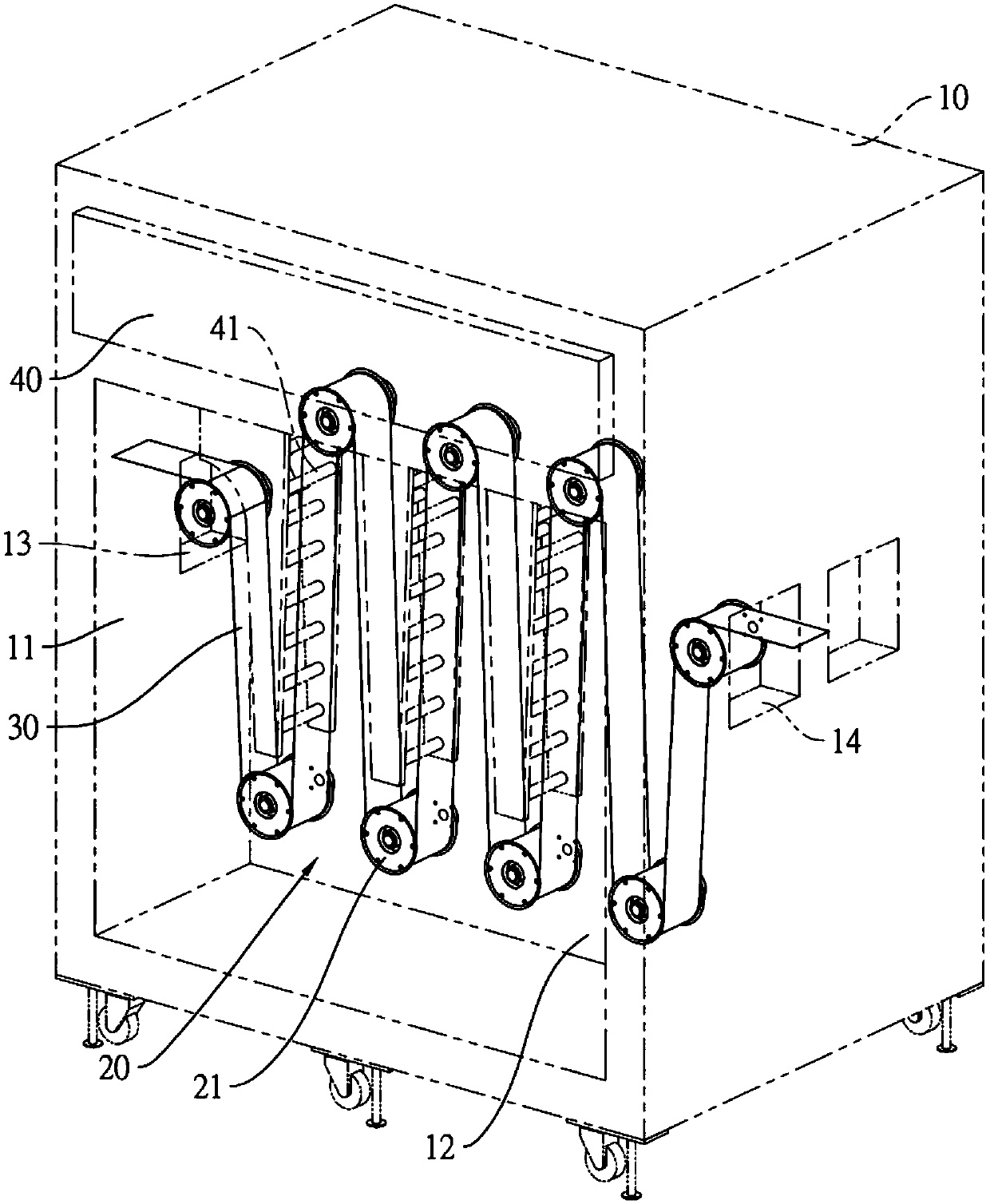

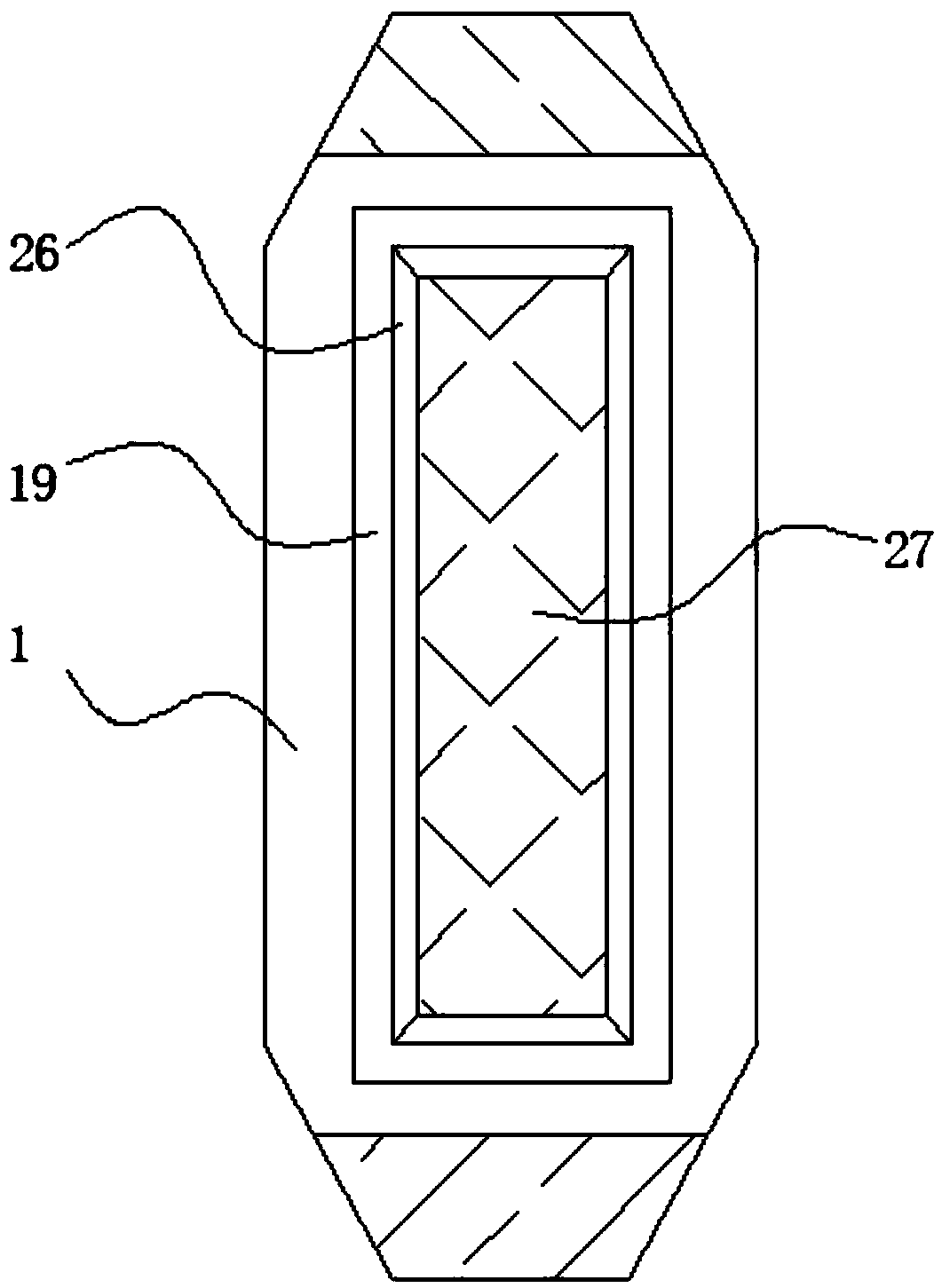

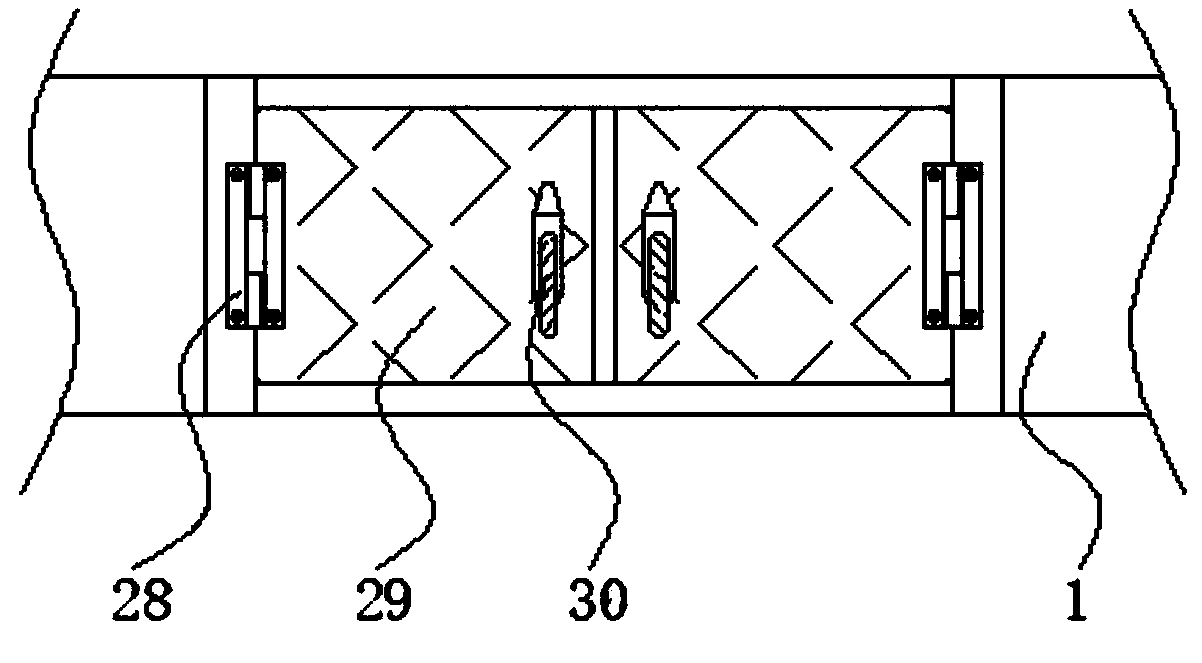

Intelligent box type incubator for wild geese

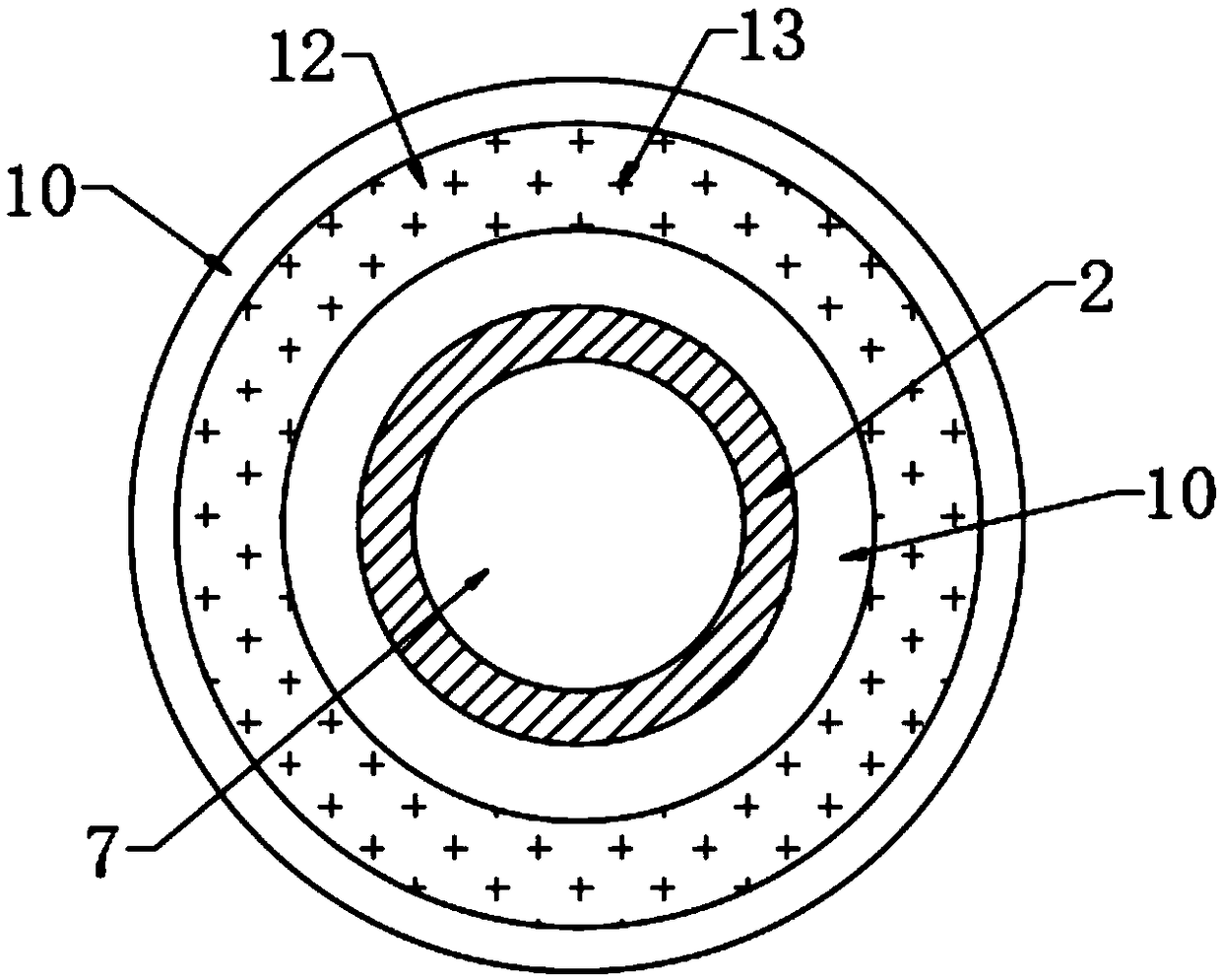

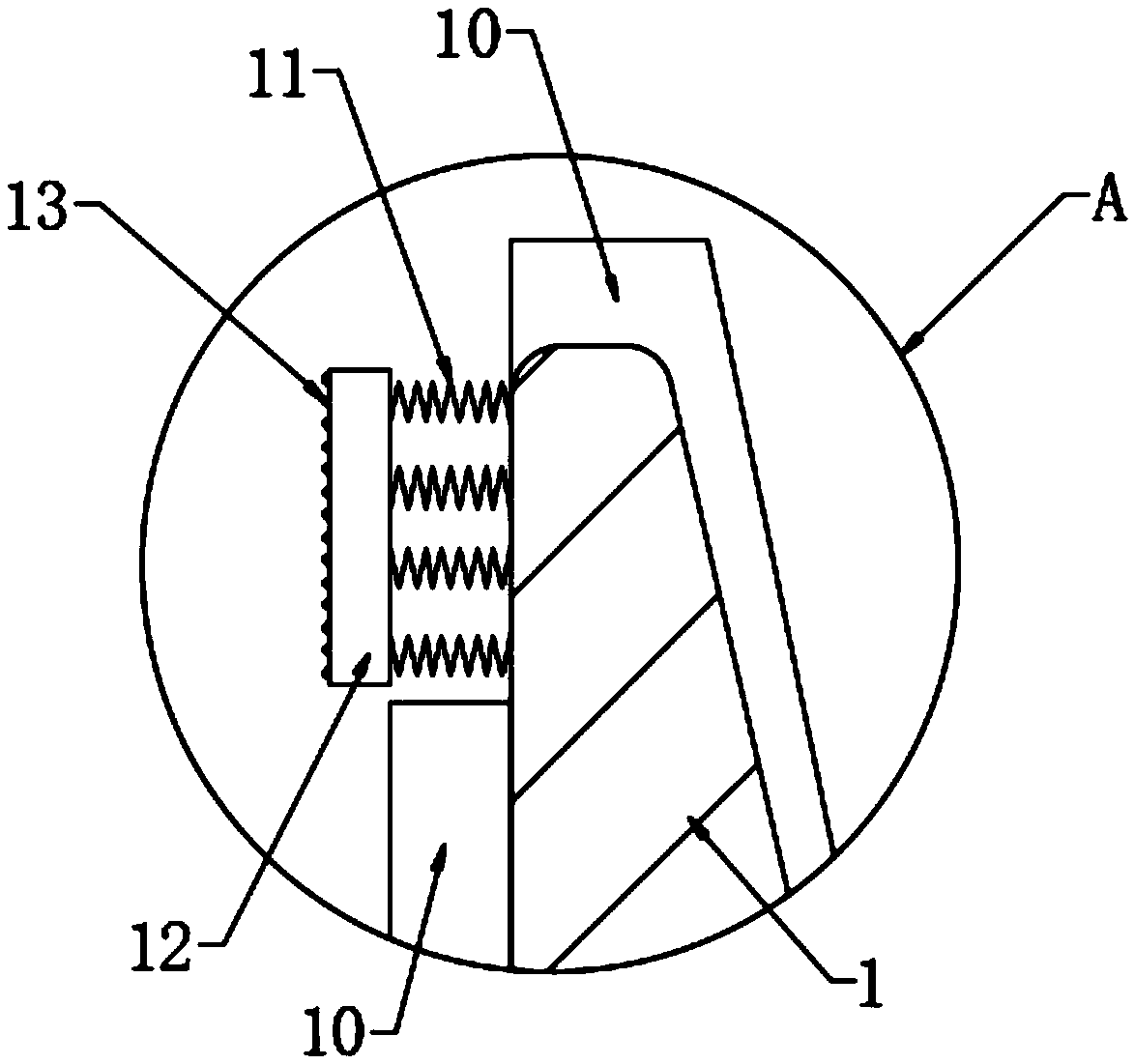

ActiveCN110810281AImplementation of egg turning processEvenly heatedPoultry incubationSimultaneous control of multiple variablesAnimal scienceZoology

An intelligent box type incubator for wild geese comprises egg frames, a plurality of placing tables, a connecting rod, a first connecting plate, a second connecting plate, a first rotating shaft, a second rotating shaft, a box body and a control panel; the first rotating shaft and the second rotating shaft are rotatably arranged on the inner surface of the box body; the first connecting plate isarranged on the first rotating shaft; the second connecting plate is arranged on the second rotating shaft; the first connecting plate and the second connecting plate are arranged side by side in thetransverse direction; two connecting rods are arranged side by side in the longitudinal direction, and two transverse ends of each connecting rod are respectively rotatably connected with the first connecting plate and the second connecting plate to form a parallelogram mechanism; the egg frames are placed on the tops of the placing tables; the placing tables are parallel to the first connecting plate, the placing tables are arranged side by side in the transverse direction, and the longitudinal two ends of the placing tables are respectively rotatably connected with the two connecting rods; and a box cover is arranged on the box body, and a driving mechanism for driving the first rotating shaft to rotate is arranged inside the box body. According to the intelligent box type incubator forthe wild geese, goose eggs can be turned over, so that the goose eggs are uniformly heated, and hatching is facilitated.

Owner:JIUJIANG POYAN CULTIVATION CO LTD

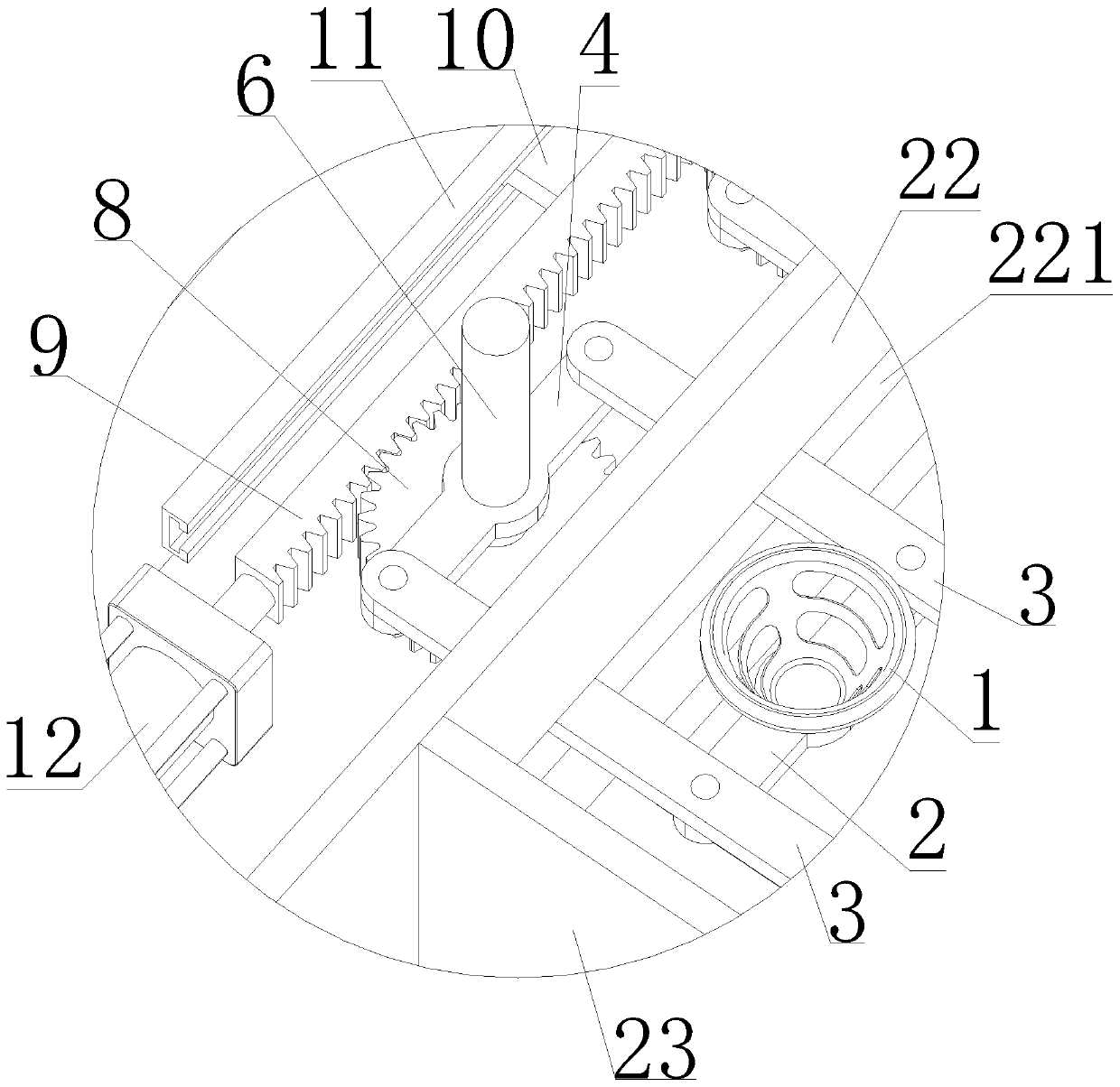

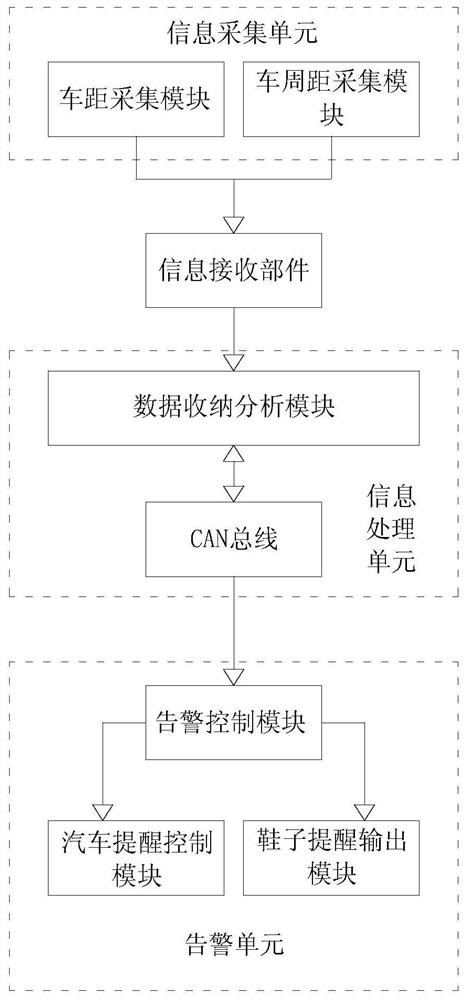

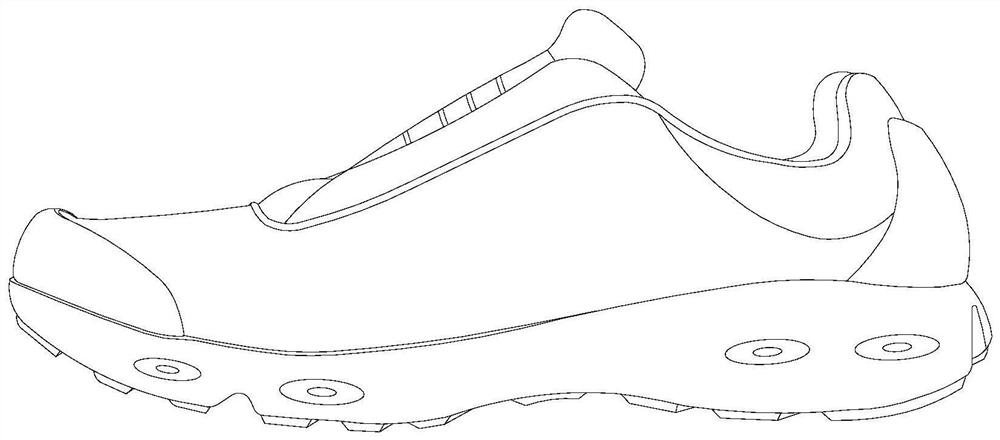

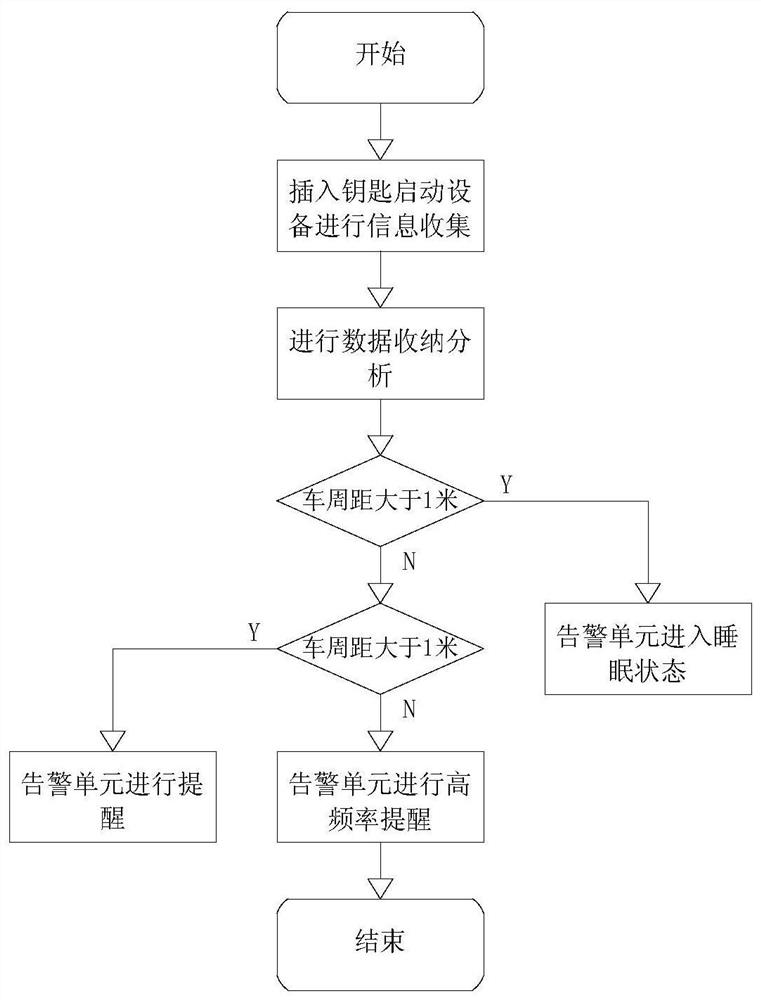

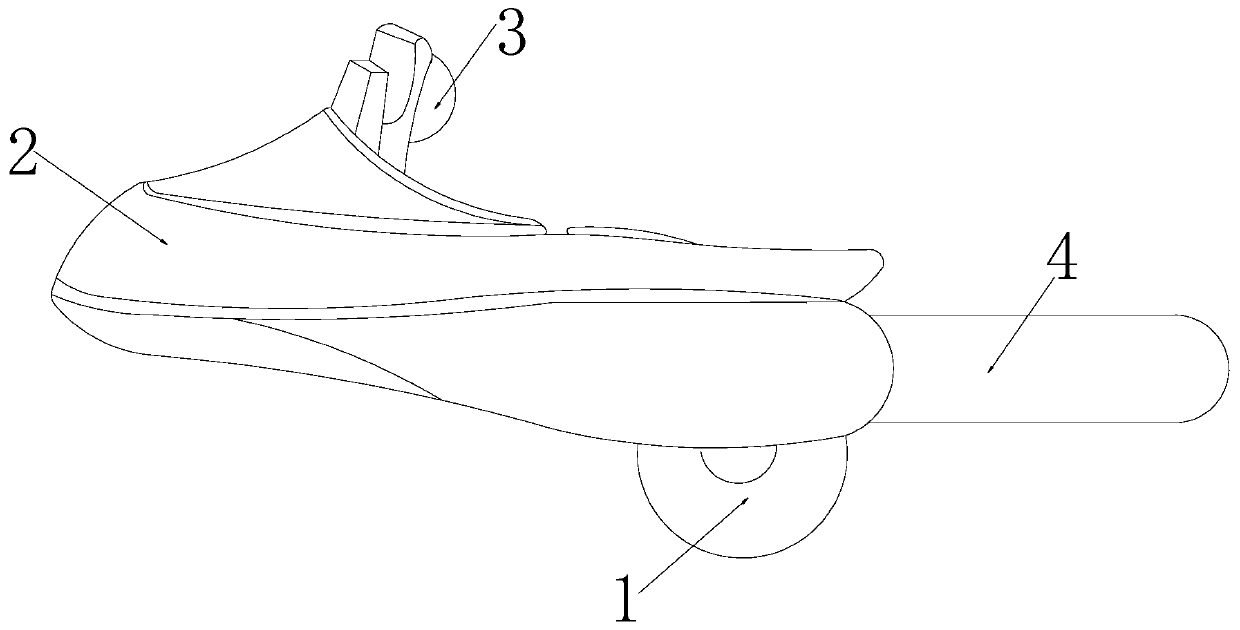

Pair of driving intelligent shoes based on automobile safety device and alarm method of driving intelligent shoes

InactiveCN112315107AImprove securityEasy to driveFootwearControl devicesDriver/operatorAutomobile safety

The invention discloses a pair of driving intelligent shoes based on an automobile safety device and an alarm method of the driving intelligent shoes, each intelligent shoe comprises an information receiving part, an information processing unit and an alarm unit, the information collecting unit comprises an automobile distance collecting module and an automobile circumference distance collecting module, the information processing unit comprises a data storage and analysis module and a CNA bus, the warning unit comprises a warning control module, an automobile reminding control module and a shoe reminding output module, a driving beginner can start and stop an automobile conveniently, the warning lamp, the loudspeaker and the shoe reminding output module of the warning unit remind the driving beginner to pay attention to the surrounding situation of the automobile, scratching is prevented, accidents caused by visual dead angles are prevented, and in the driving process, a driver is assisted in judging whether the vehicle is in the three-second interval or not, and the safety coefficient is increased.

Owner:向维智联(福建)科技有限公司

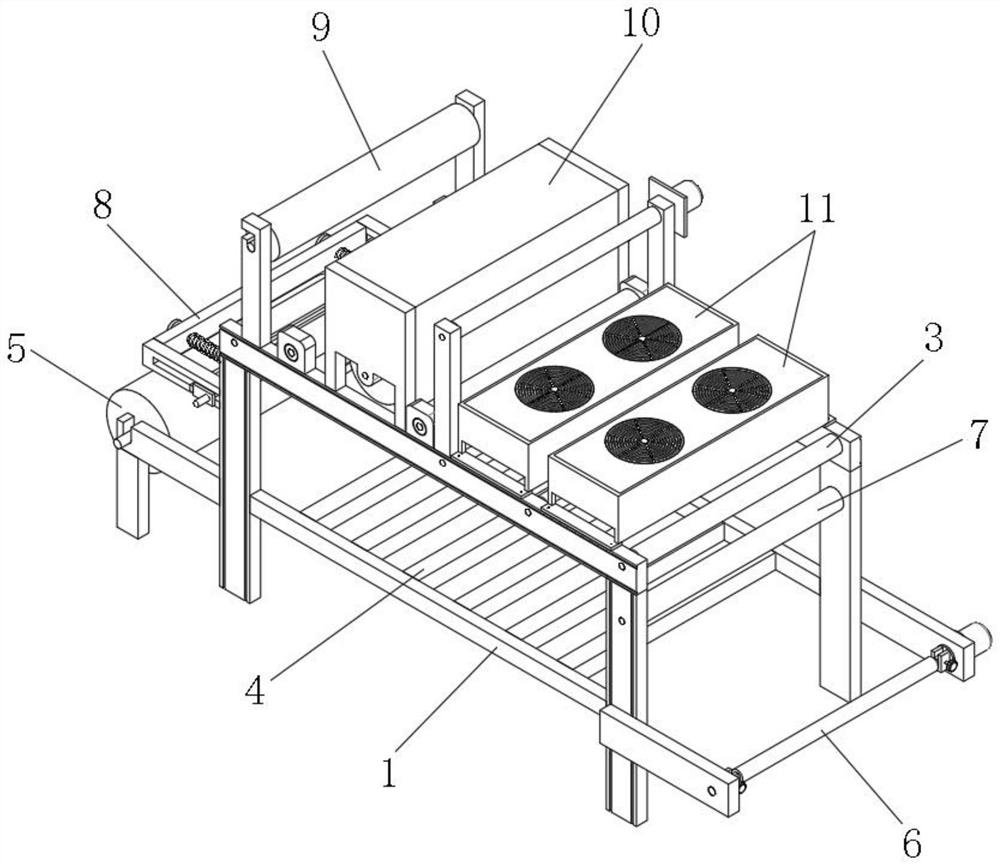

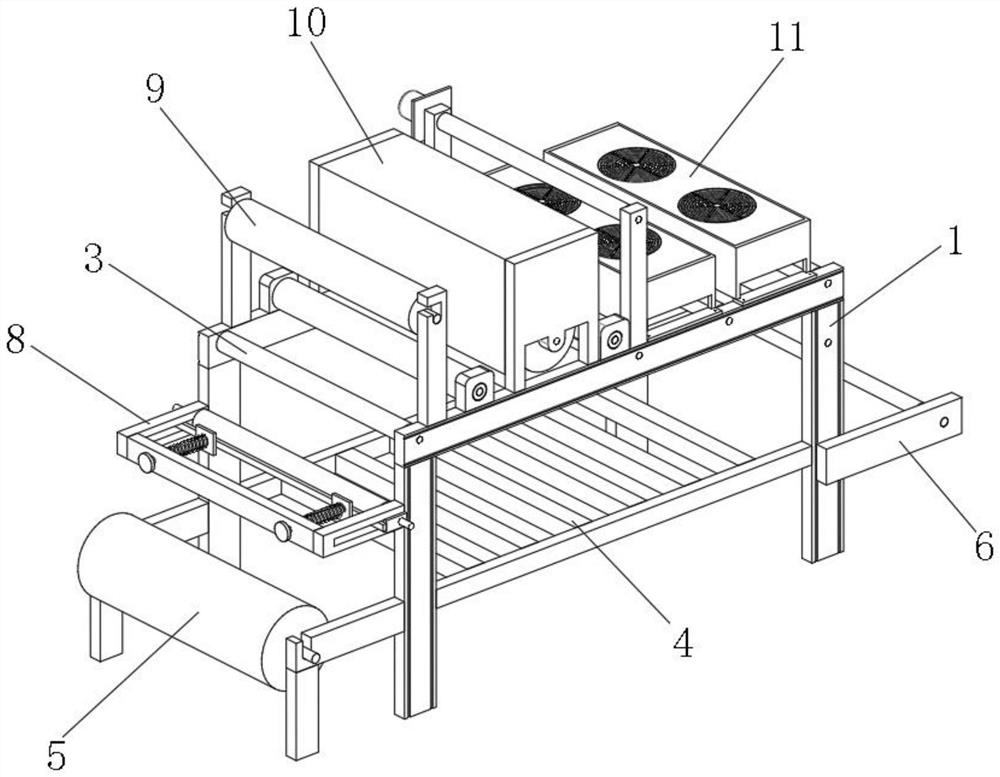

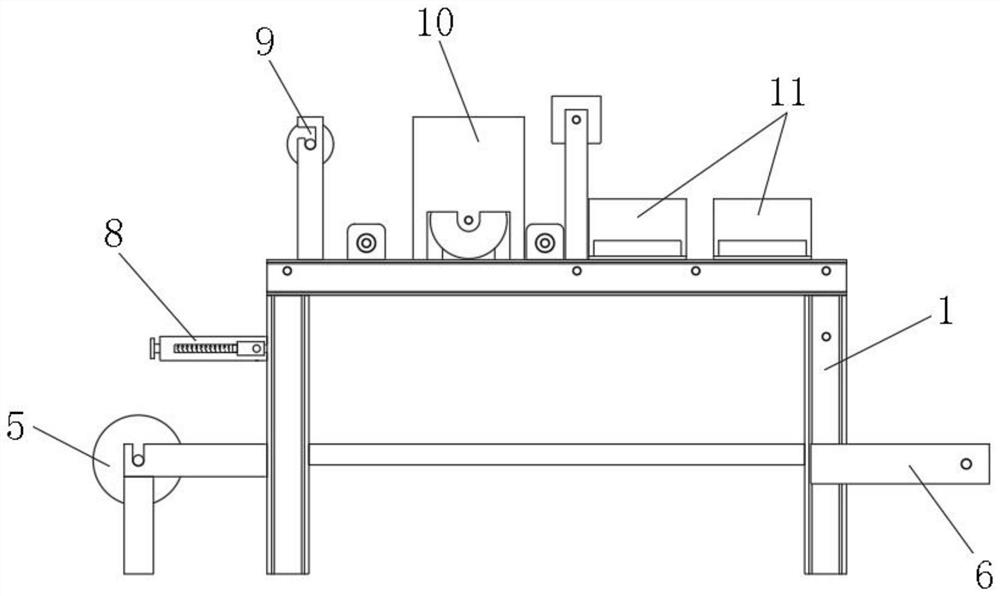

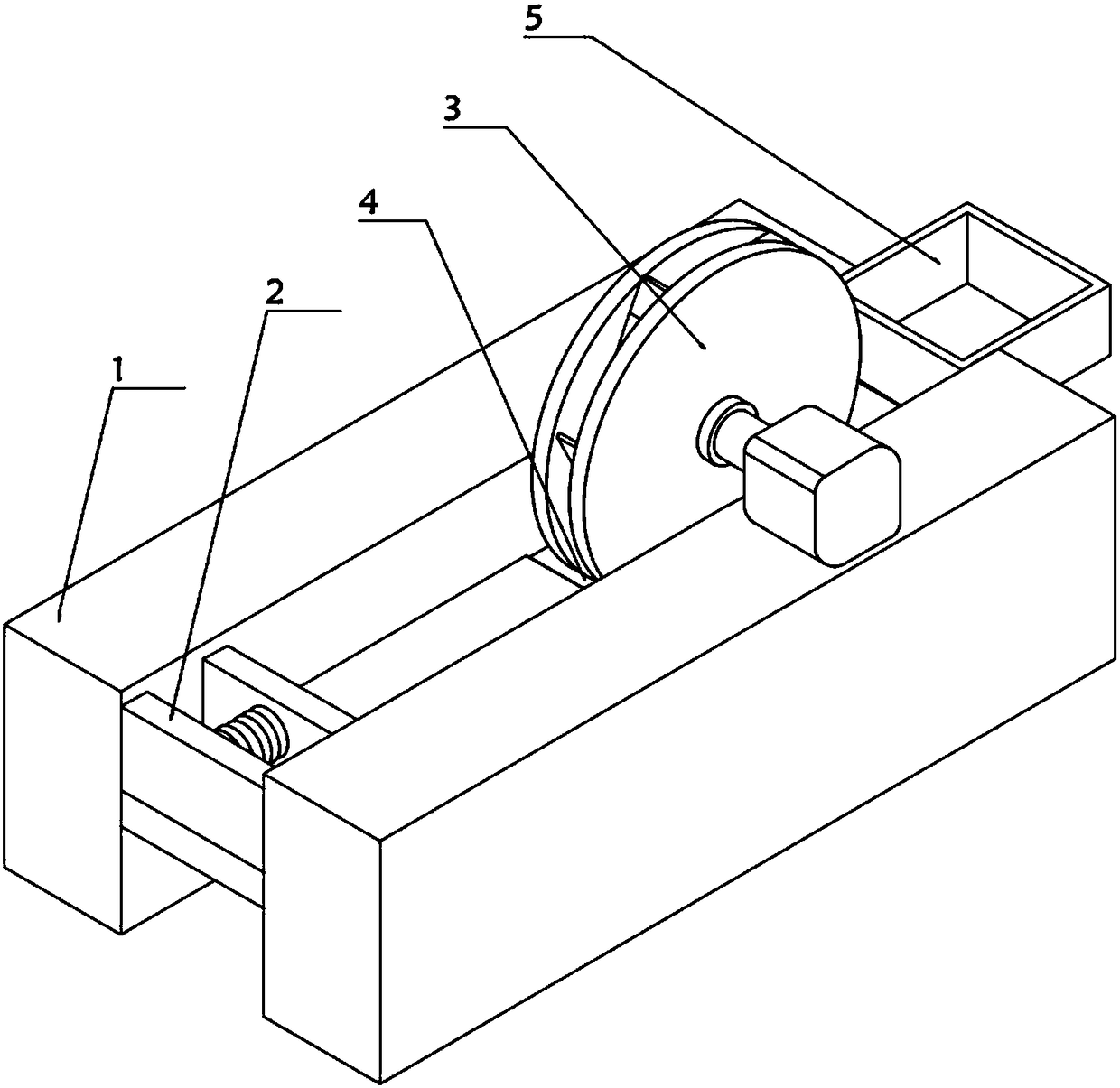

Digital printing heat transfer printing machine

PendingCN114684652ARapid heat dissipation and coolingCase to prevent scratchesTransfer printingPrinting press partsProcess engineeringDigital printing

The invention provides a digital printing heat transfer printing machine, and relates to the technical field of heat transfer printing. The digital printing thermal transfer printing machine comprises a fixed rack, one side of the center of the top of the fixed rack is fixedly connected with a thermal printing supporting plate, the top of the center of the fixed rack is rotationally connected with a plurality of conveying roller shafts, and the bottom of one end of the fixed rack is fixedly connected with a cloth roll feeding mechanism; the bottom of the other end of the fixed rack is fixedly connected with a cloth roll receiving mechanism, the center of the end, close to the cloth roll feeding mechanism, of the fixed rack is fixedly connected with an elastic extension mechanism, and a transfer printing film feeding and rolling mechanism is arranged on one side of the top of the fixed rack. Through the simple design of the cloth roll feeding mechanism, the cloth roll receiving mechanism, the elastic extension mechanism, the transfer printing film feeding and rolling mechanism, the hot-pressing roll printing mechanism and the cooling mechanism, normal heat transfer printing machining work can be completed, meanwhile, rapid heat dissipation and cooling can be conducted on cloth rolls after hot printing is completed, and the cloth rolls are prevented from being scratched in the subsequent rolling process.

Owner:厦门高准工贸有限公司

Frozen fish meat slicing device for aquaculture

The invention relates to the technical field of aquaculture, in particular to a frozen fish meat slicing device for aquaculture. The frozen fish meat slicing device comprises a supporting plate, a feeding mechanism mounted in the supporting plate and a cutting mechanism arranged on one side of the feeding mechanism. According to the frozen fish meat slicing device for the aquaculture disclosed bythe invention, a cutting plate is driven by a rotating shaft to rotate, the frozen fish meat is broken by scraping and is cut into slices by cutting knives located close to the frozen fish meat; the frozen fish meat slices slide into the surface of the feeding plate from the cutting knives by gravity; besides, feeding plates on one side of a finished product tank and the finished product tank areoblique; the frozen fish meat slices slide into the finished product tank from the feeding plates to be collected; the cutting knives located at one end of a water tank are soaked in a water tank, andimpurities on the surfaces of the cutting knives are cleaned; besides, resistance of the surfaces of the cutting knives is reduced, the cutting effect is improved, the situation that slicing, collecting and cleaning are performed on the same production line is facilitated, and the efficiency of slicing the frozen fish meat is improved.

Owner:开县泰旭农业综合开发有限公司

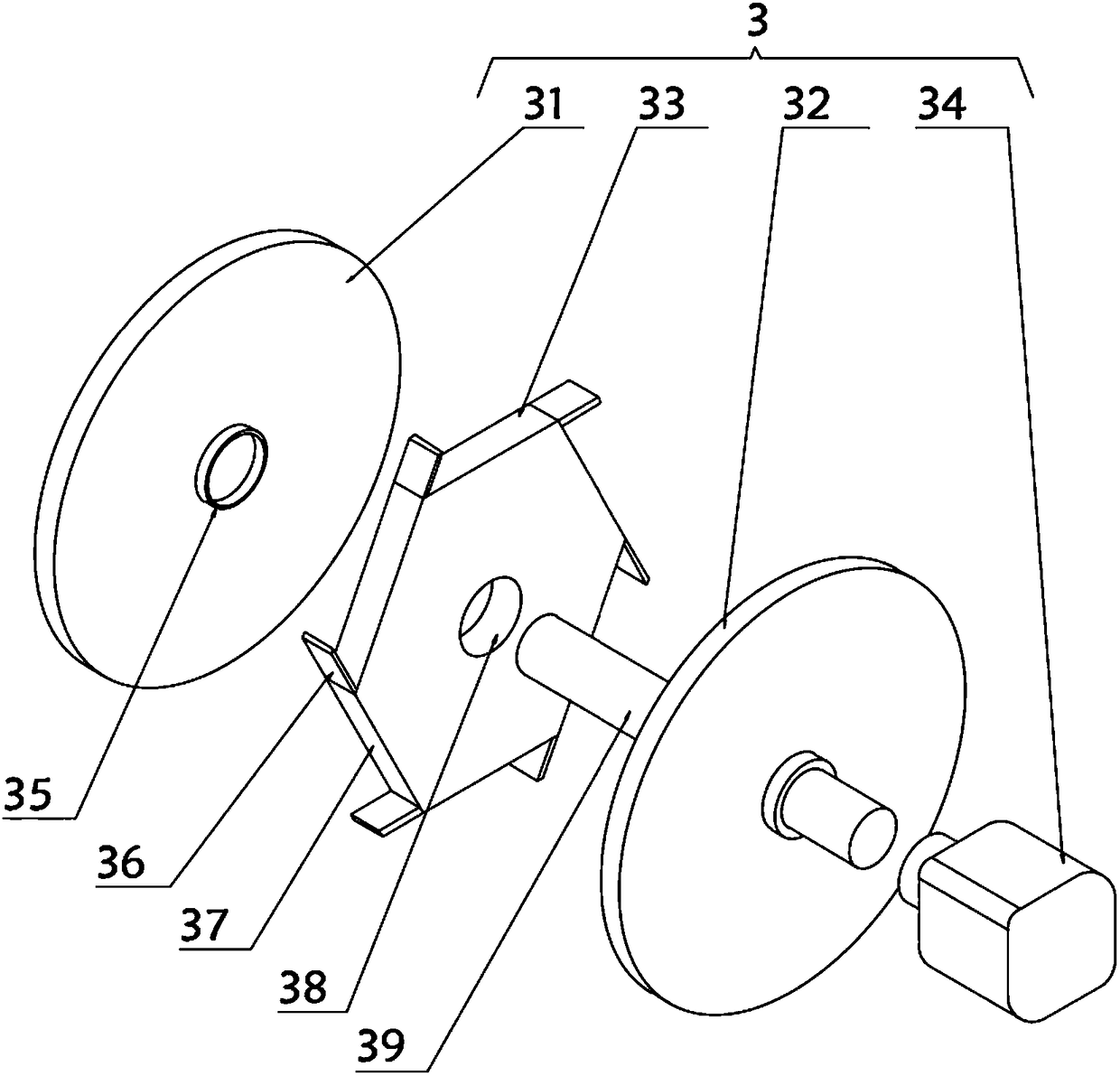

Gem screening device

The invention discloses a gem screening device. The gem screening device structurally comprises a feeding door, a handle, a screening main machine, a material taking door, rubber gaskets, a first hinge and a second hinge. The handle is welded to the right end of the front surface of the feeding door. The material taking door is arranged on the front surface of the lower end of the screening main machine. Through start of a power mechanism, a dust removal mechanism conducts dust removal on gems, impurities on the surfaces of the gems are removed through a cleaning mechanism, and therefore the cleanness of the gems is ensured. In the screening process, it is ensured that the impurities are discharged and cannot scratch the gems; and meanwhile, a multi-layer screening mechanism conducts multi-layer screening on the gems. Tiny storage boxes are used for conducting centralized collection on some tiny gems, it is ensured that the tiny gems can be screened out, and it is avoided that the tinygems are lost. Damping mechanisms weaken vibration generated in the work process of the multi-layer screening mechanism, and it is avoided that excessively large vibration of the gems causes scratches of the gems in the screening process.

Owner:FOSHAN XUNTUOAO TECH CO LTD

Deep sea cage culture device with quantitative range feeding function

PendingCN112568162AEasy to useEasy to collect the netClimate change adaptationPisciculture and aquariaEngineeringDeep sea

The invention belongs to the technical field of deep sea cage culture devices, and particularly relates to a deep sea cage culture device with a quantitative range feeding function. The deep sea cageculture device comprises a frame body, a lighting mechanism and a rotating shaft, a feed box is fixed above the frame body, an adjusting mechanism is connected above the lighting mechanism, and a connecting block is mounted at the left side of the rotating shaft; and an aluminum alloy outer frame is fixed to the upper portion of the connecting block, a mortar waterproof layer is installed in a protective shell, a groove is formed in the frame body, a reset spring is installed in the groove, a clamping plate is connected to the left side of the reset spring, a net body is arranged at the left side of the clamping plate, and an extension plate is fixed to the left side of the net body. The deep sea cage culture device with the quantitative range feeding function is conspicuous at night, doesnot need to use external tools for illumination when used at night, is convenient to use, can utilize natural resources, is energy-saving and environment-friendly, facilitates net drawing, and can automatically conducting quantitative range feeding of feed.

Owner:ZHEJIANG OCEAN UNIV

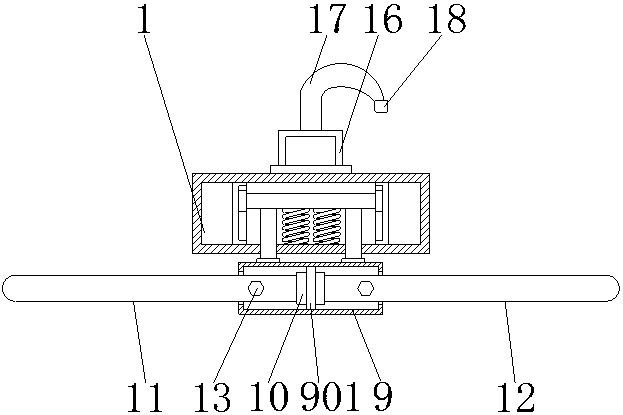

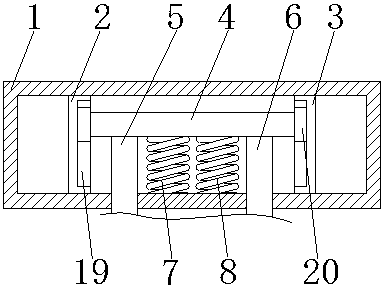

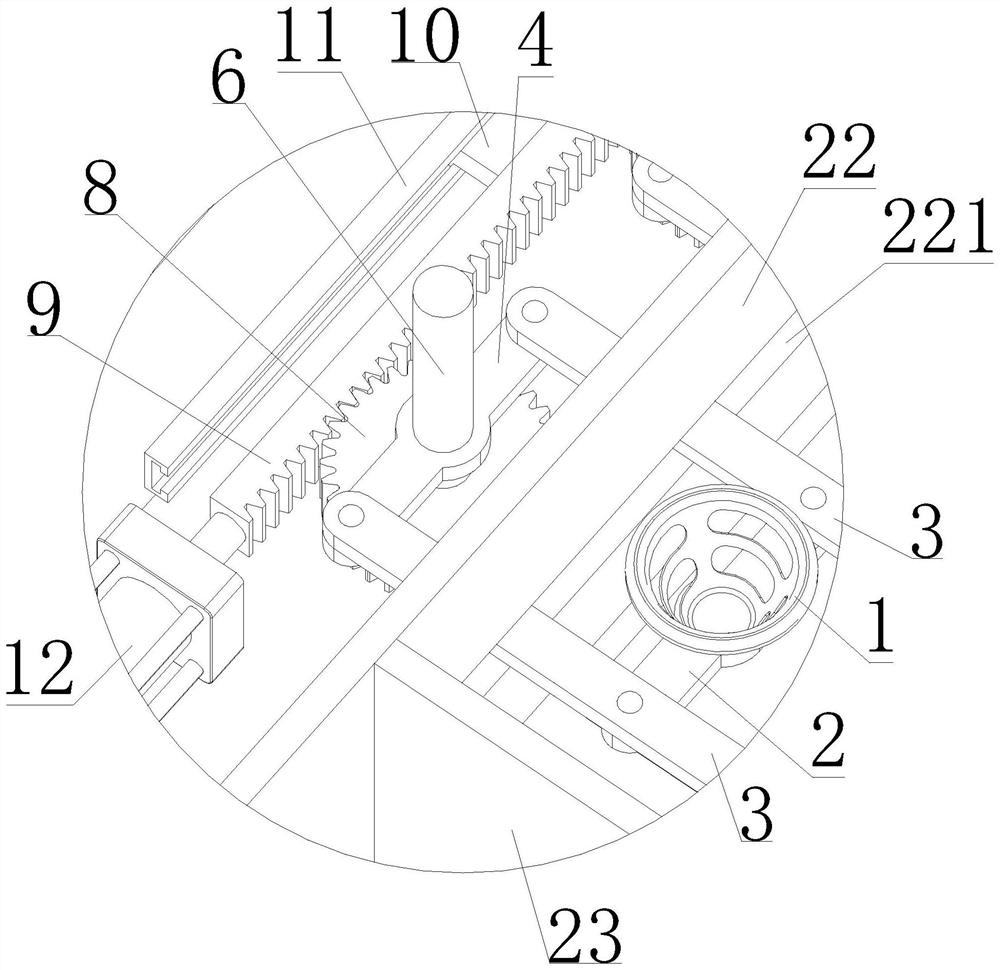

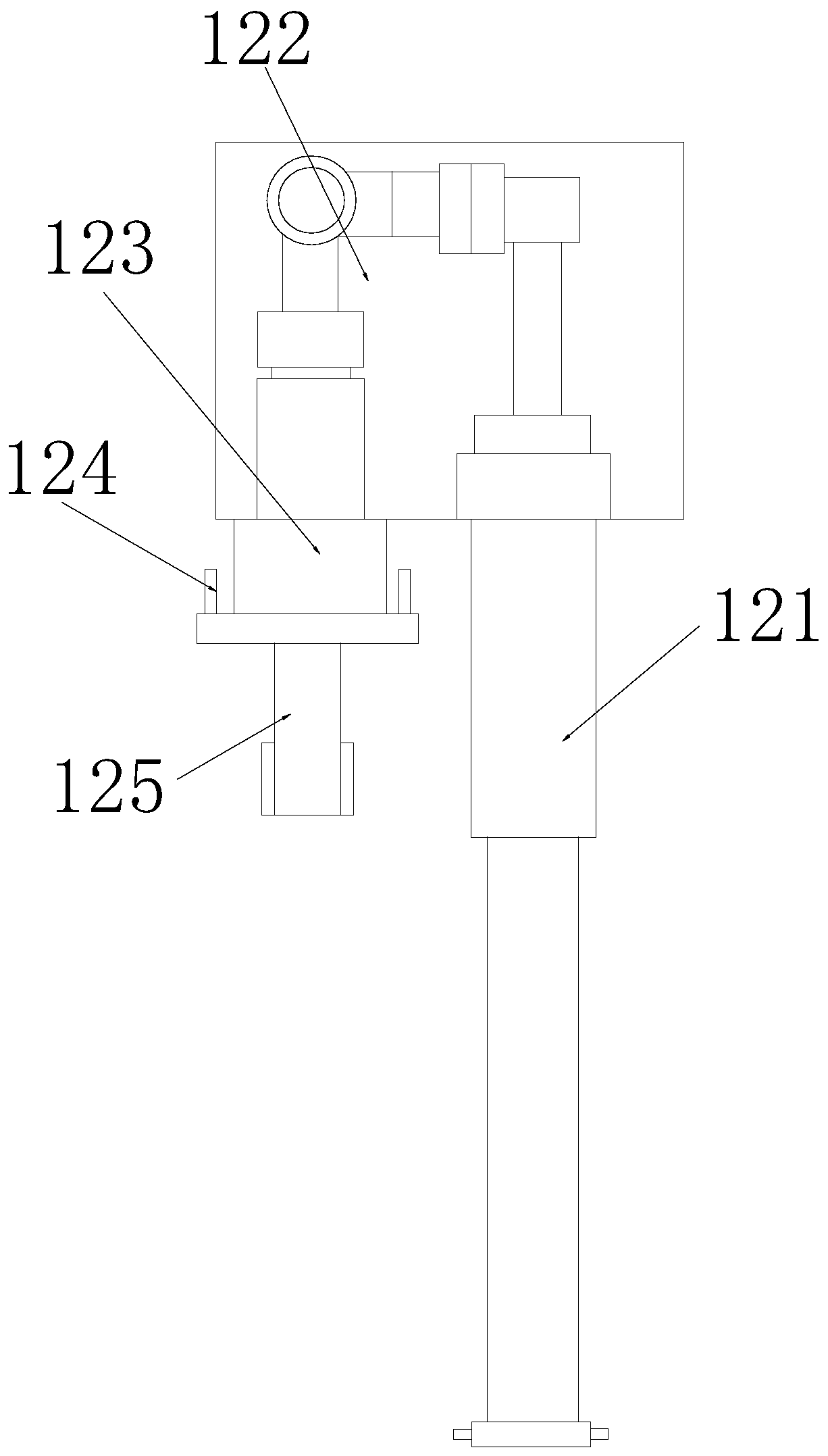

Shaft part processing manipulator with self-locking falling prevention function

InactiveCN109249383AWith self-locking anti-falling functionCase to prevent scratchesProgramme-controlled manipulatorGripping headsControl engineeringSelf locking

The invention discloses a shaft part processing manipulator with a self-locking falling prevention function, relates to the technical field of shaft part processing and fixing, and particularly discloses a shaft part processing manipulator with the self-locking falling prevention function. The shaft part processing manipulator comprises a mounting plate, a connecting block and a connecting rod, the connecting block is mounted on the upper portion of the mounting plate, the connecting rod is distributed at the inner center of the connecting block, a rotating shaft is mounted in the mounting plate, a first clamping plate and the rotating shaft are formed in a stamping manner, a second clamping plate is mounted on the left side of the first clamping plate, and an opening is formed in the right side of an extending plate. According to the shaft part processing manipulator with the self-locking falling prevention function, expansion and contraction of a hydraulic pushing rod drive the mounting plate to adjust a position in a vertical direction, an angle of the connecting block is adjusted by a rotary pneumatic cylinder, so that expansion, contraction and rotation of the manipulator canbe achieved, and functions of the manipulator are enriched.

Owner:DONGGUAN UNIV OF TECH

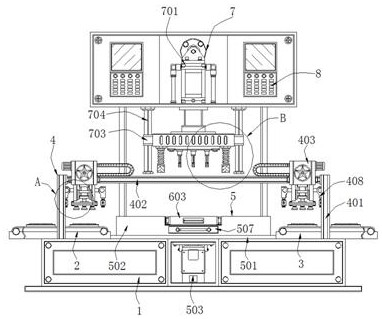

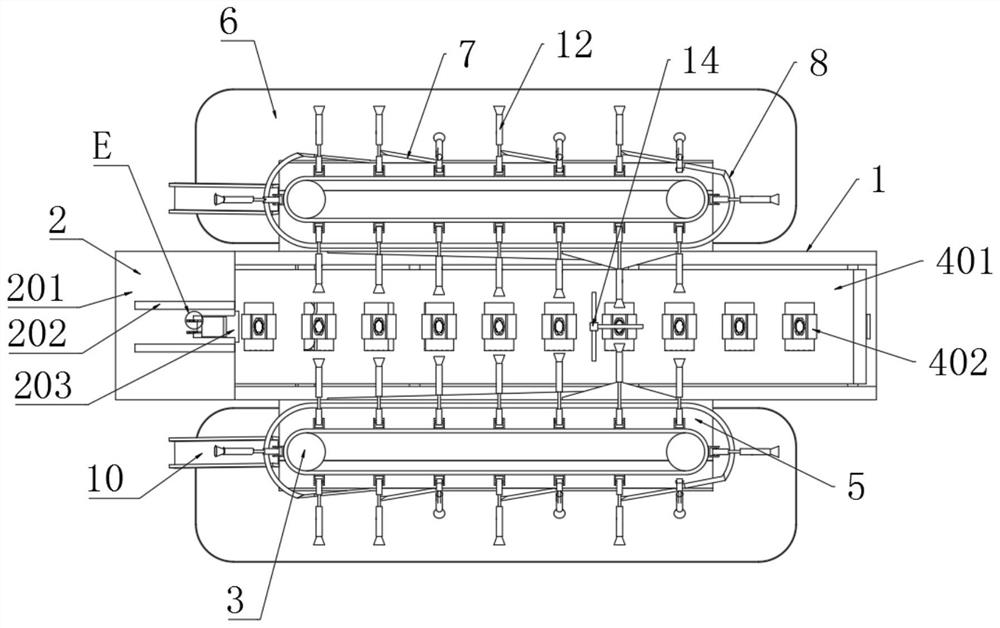

Numerical control punching lathe with dense feeding and discharging structure and facilitating workpiece alignment

PendingCN113953372AHigh degree of automationImprove processing efficiencyMetal-working feeding devicesPositioning devicesStructural engineeringManufacturing engineering

The invention discloses a numerical control punching lathe with a dense feeding and discharging structure and facilitating workpiece alignment, and relates to the technical field of numerical control punching lathes. The numerical control punching lathe comprises a bearing seat and a material conveying assembly, wherein a feeding conveying belt is arranged on the left side of the upper end of the bearing seat, a discharging conveying belt is arranged on the right side of the upper end of the bearing seat, and the material conveying assembly used for feeding and discharging parts is arranged at the front end of the upper end of the bearing seat. According to the numerical control punching lathe, the multiple assemblies are matched with one another, so that automatic punching work of the parts is realized, the simultaneous feeding, transferring, punching and discharging work of the multiple parts can be carried out at the same time, so that the automation degree of the punching lathe is higher, meanwhile, the machining efficiency of the punching lathe is improved, meanwhile, good buffering work is achieved, the situation that the parts are deformed and damaged due to the fact that the instantaneous pressure of a punching head is too large in the punching process of the parts can be avoided, corresponding adjustment can be conveniently carried out according to the sizes of the actually punched parts, and the actual application range of the lathe is wider.

Owner:黄雄辉

Hanger convenient to disassemble

Owner:许昌乐居科技有限公司

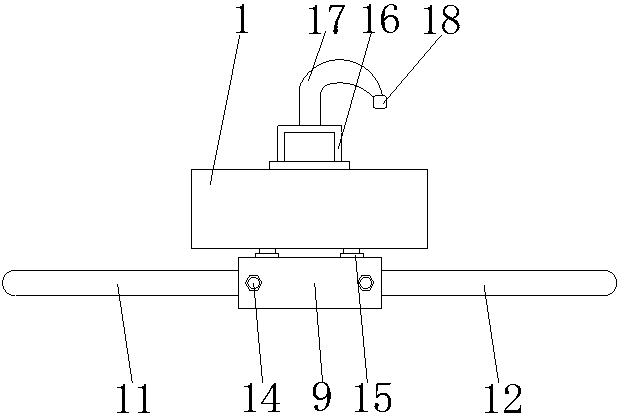

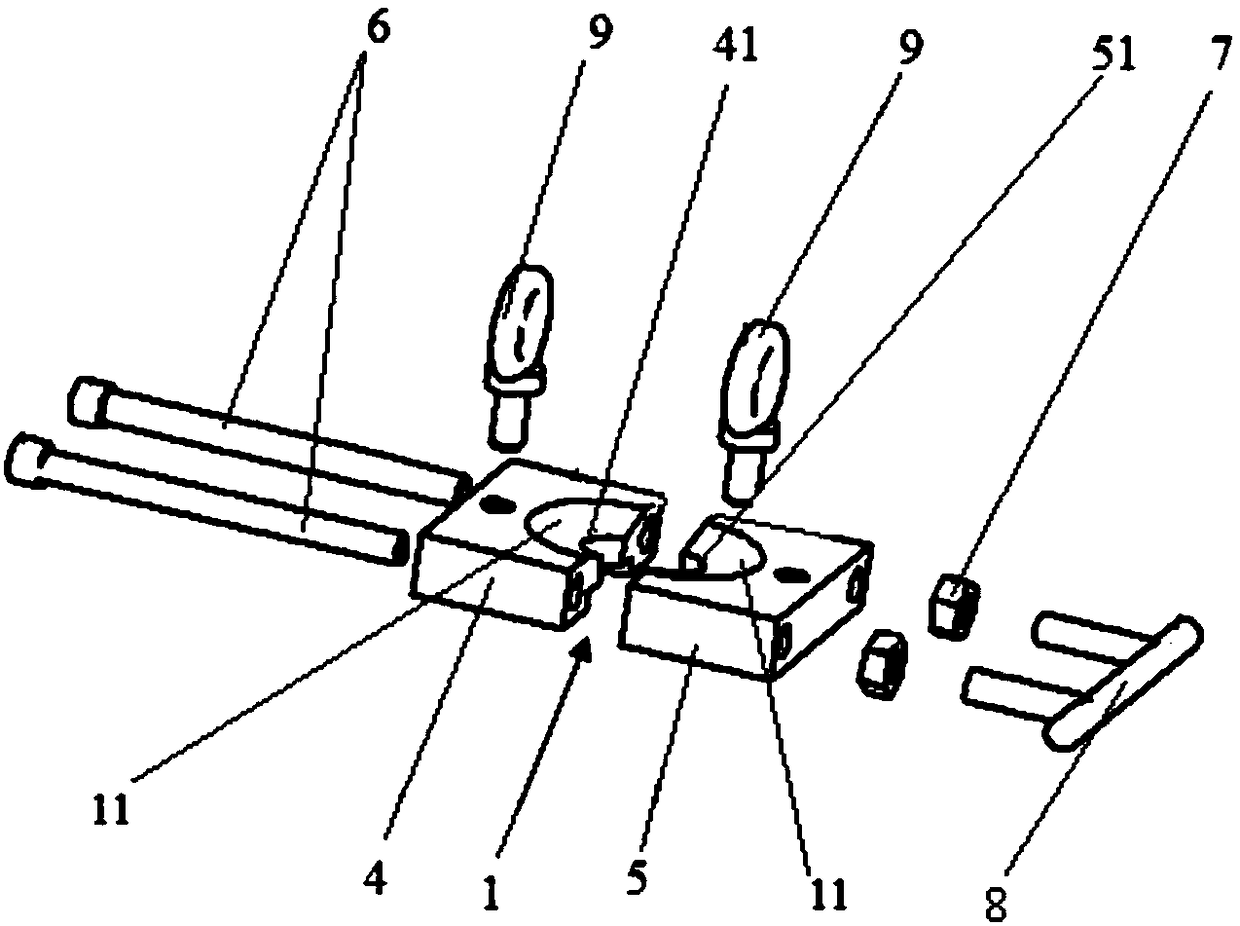

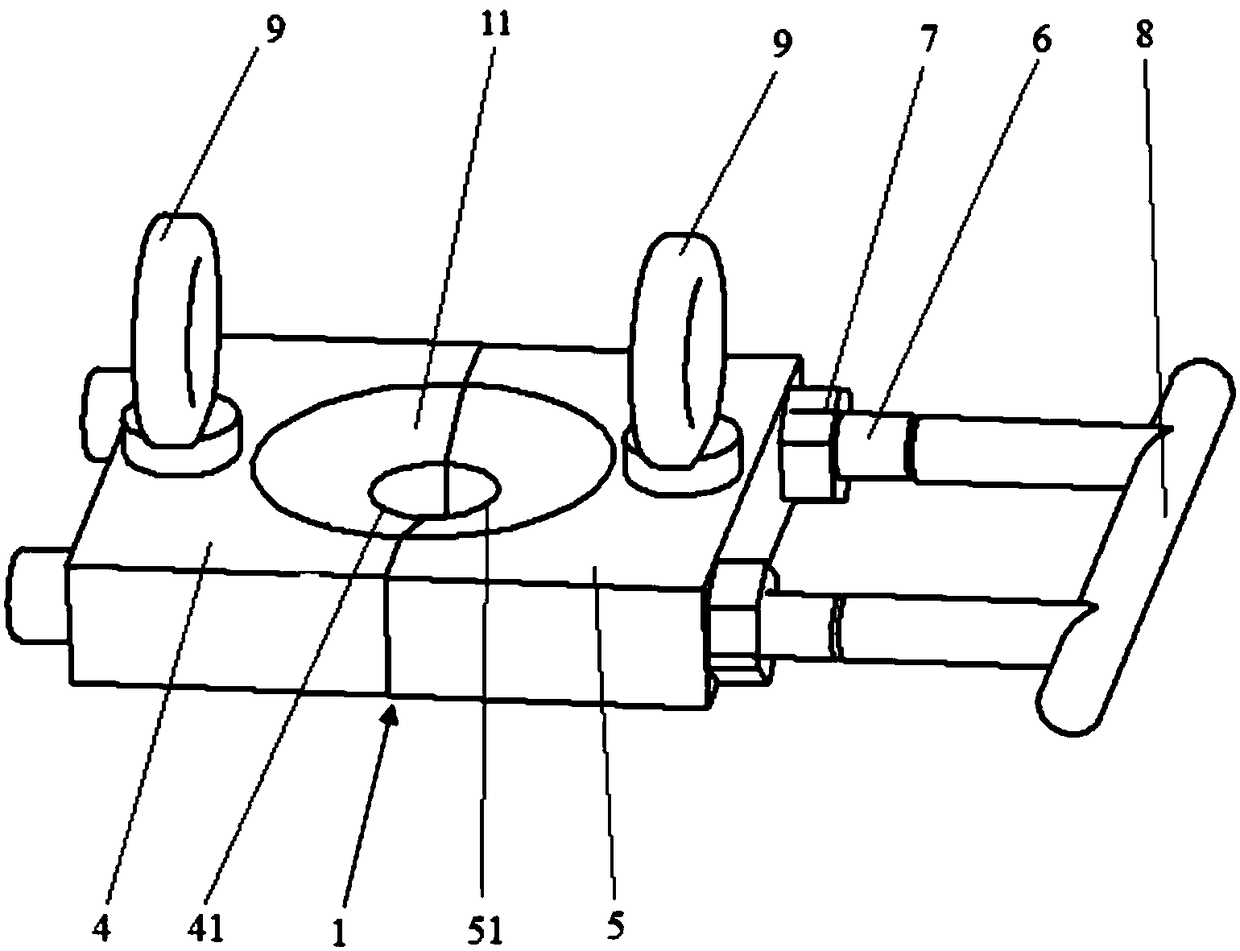

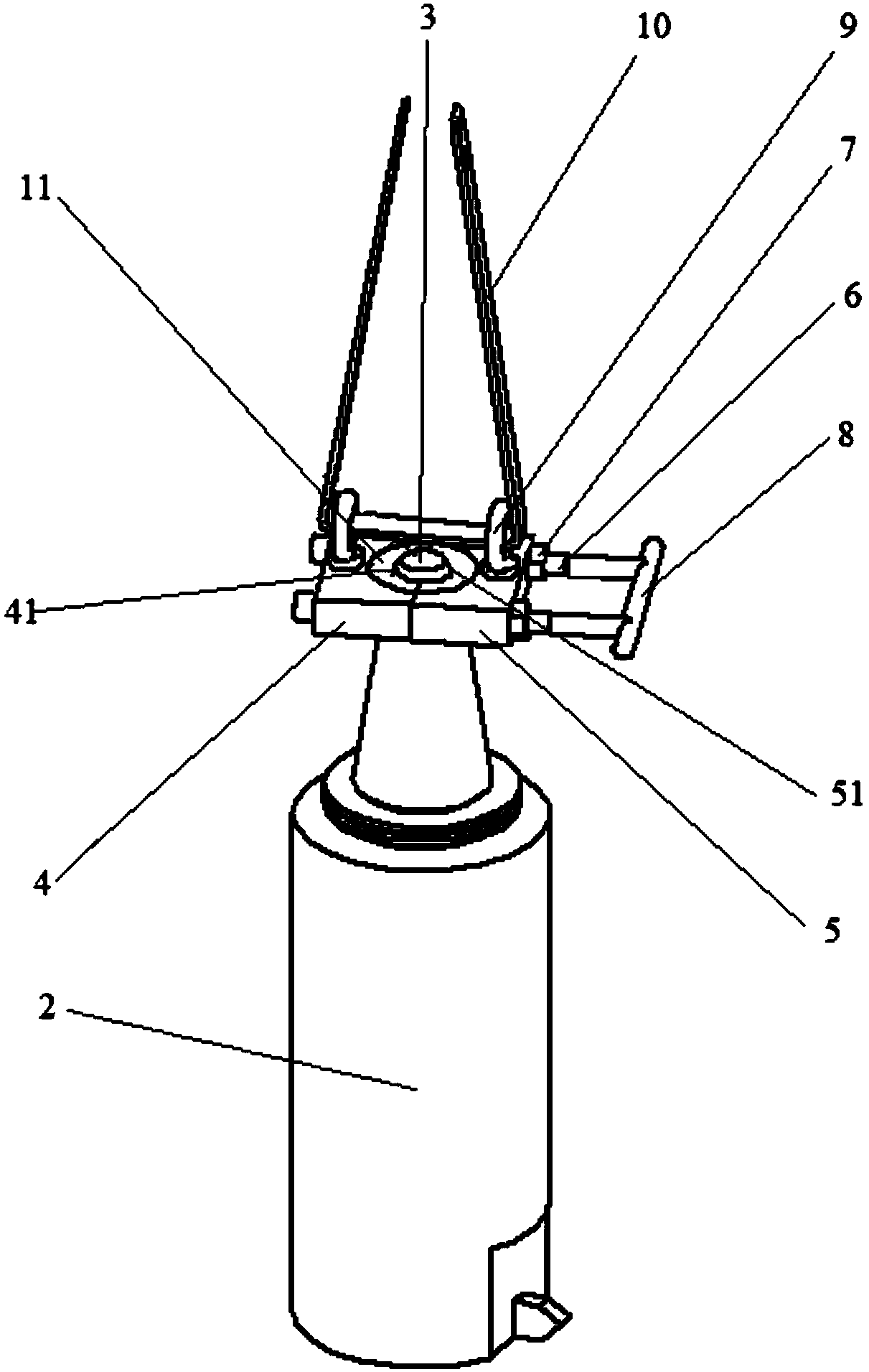

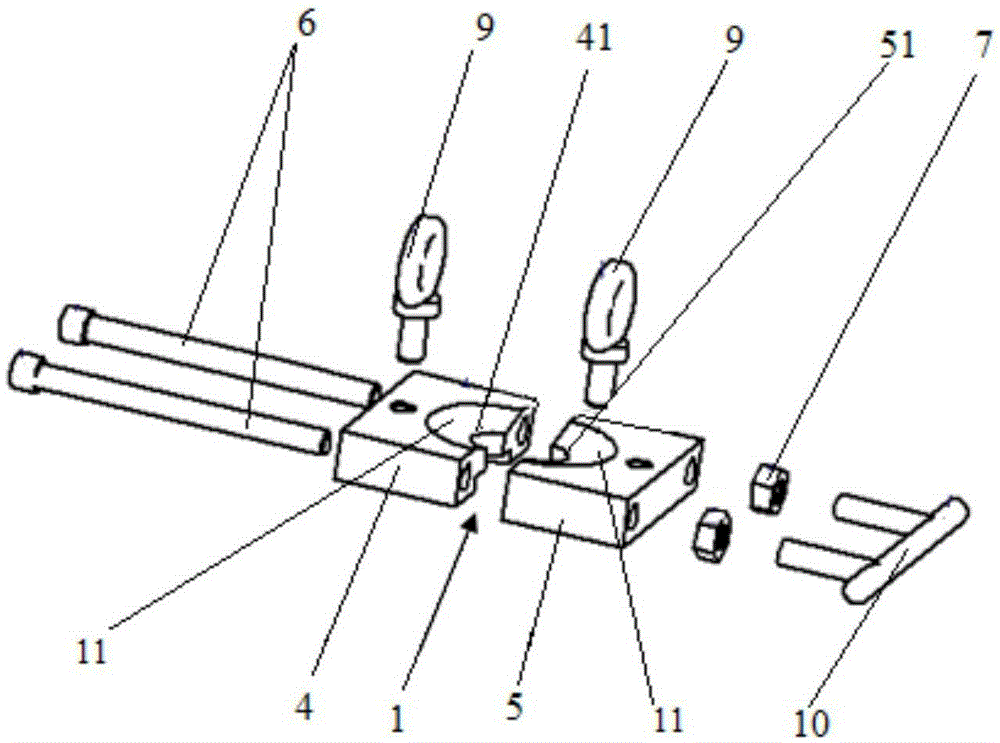

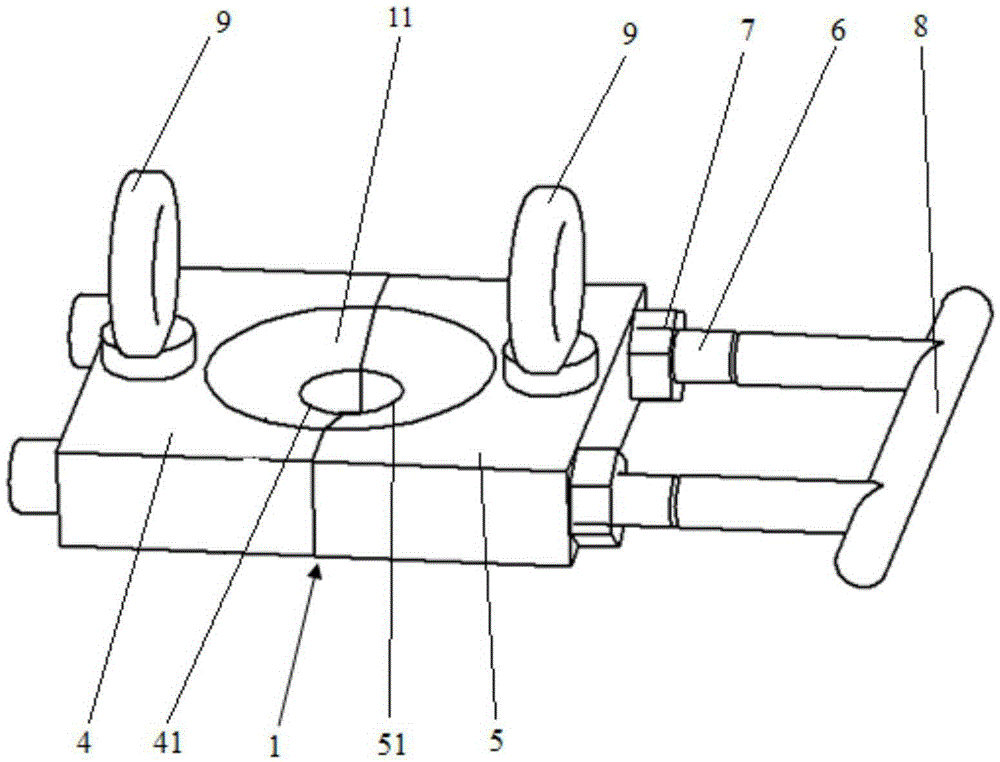

Method and tool for clamping type hoisting machining center outside heavy tool

ActiveCN105347183BSimple structureEasy to manufactureLoad-engaging elementsUltimate tensile strengthIndustrial engineering

The invention discloses a clamping method for hoisting a heavy cutter outside a machining center magazine. The method comprises the steps of arranging a combined clamping body for clamping a blind rivet on the cutter, arranging a hoisting part on the combined clamping body, hoisting the combined clamping body through the hoisting part and hoisting the cutter. The invention further discloses a clamping device for hoisting the heavy cutter outside the machining center magazine. According to the clamping method and device, the heavy cutter outside the machining center magazine can be fast hoisted, hoisting is convenient, the operation is simple, convenient, practical and fast and saves labor, the labor intensity of workers is lowered, the production cost is saved, the quality of the hoisted cutter is guaranteed, and the production efficiency is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

A new energy vehicle rear suspension sub-frame connector drilling processing machine

ActiveCN113275627BGuaranteed structural qualityCase to prevent scratchesWork clamping meansFeeding apparatusVehicle frameMotor vehicle part

The invention relates to the field of auto parts processing, in particular to a new energy vehicle rear suspension sub-frame connector drilling machine, including a support frame, an auxiliary device, a support device, a fixing device and a drilling device; the invention can solve the current problem The drilling device mainly exists in the drilling process of the connection parts of the full-frame rear suspension sub-frame. The position cannot be adjusted in a portable manner. Drilling is performed on various sizes of full-frame sub-frames, and the fixing device is difficult to adjust the fixed position. Stable clamping and fixing of full-frame sub-frames of various sizes, and the current punching device is prone to generate a large amount of iron filings splashing during the process of punching full-frame sub-frames, so that the splashed iron filings On the one hand, it is easy to hurt people, and on the other hand, the splashed iron filings are not convenient for the staff to clean the workplace and recycle the iron filings later.

Owner:江苏特塑新能源科技有限公司

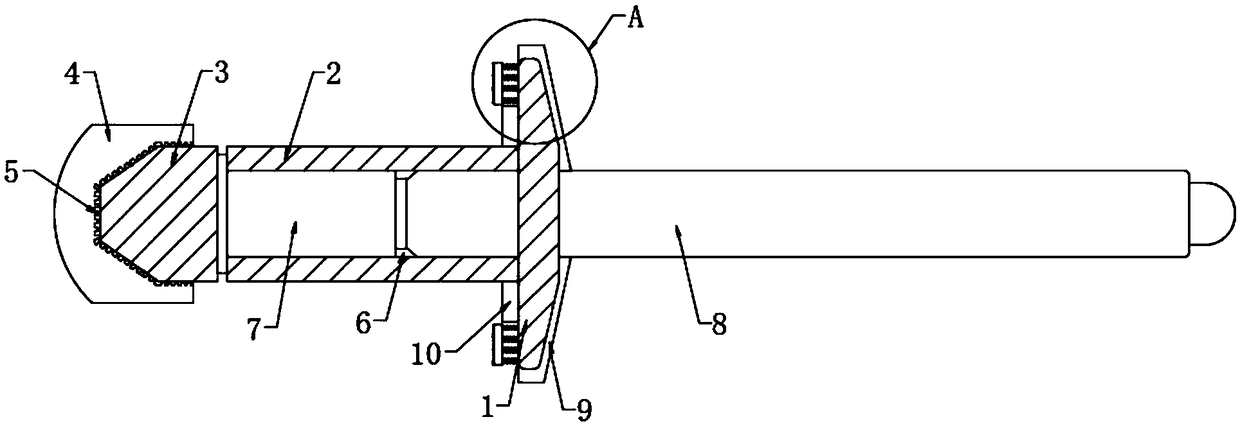

Scratch-resistant self-plugging rivet

The invention discloses a scratch-resistant self-plugging rivet. The scratch-resistant self-plugging rivet comprises a rivet cap, wherein one side of the rivet cap is fixedly equipped with a rivet sleeve; the position, at one end away from the rivet cap of the rivet sleeve, at one side of the rivet cap is fixedly equipped with a limiting cap; the position, at the outer side of the limiting cap, atone side of the screw cap is equipped with a scratch-resistant sleeve; one side, close to the limiting cap, of the scratch-resistant sleeve is equipped with anti-sliding threads; the position, insidethe rivet sleeve, of one side of the rivet cap is equipped with a core slot; one end inside the core slot is fixedly equipped with a connector; one end of the connector is fixedly connected with thelimiting cap; and the position, at one end away from the limiting cap of the connector, inside the core slot is movably equipped with a rivet core through a cracking part. The scratch-resistant sleeveand a scratch-resistant sleeve, which can prevent scratch, are arranged, so that scratch resistance of the self-plugging rivet is improved, the self-plugging rivet can be prevented from generating scraping with an object inside a workpiece, and the workpiece is protected; and meanwhile, a condition that the bulged part of the self-plugging rivet accidentally injures a worker also can be avoided.

Owner:WUXI ANSHIDA HARDWARE

An intelligent wild goose box incubator

ActiveCN110810281BImplementation of egg turning processEvenly heatedPoultry incubationSimultaneous control of multiple variablesAnimal scienceZoology

An intelligent wild goose box-type incubator, including an egg frame, a placing platform, a connecting rod, a first connecting plate, a second connecting plate, a first rotating shaft, a second rotating shaft, a box body and a control panel; the first rotating shaft and the second The rotating shafts are all rotated and arranged on the inner surface of the box; the first connecting plate is arranged on the first rotating shaft; the second connecting plate is arranged on the second rotating shaft; the first connecting plate and the second connecting plate are arranged side by side along the horizontal direction; There are two arranged side by side, and the horizontal ends of the connecting rod are respectively connected to the first connecting plate and the second connecting plate to form a parallelogram mechanism; the egg frame is placed on the top of the placing platform; the placing platform is arranged parallel to the first connecting plate, and the placing A plurality of tables are arranged side by side along the horizontal direction, and the longitudinal ends of the placing table are respectively connected to two connecting rods in rotation; a box cover is provided on the box body, and a driving mechanism for driving the first rotating shaft to rotate is arranged inside the box body. The invention can turn the wild goose eggs, so that the wild goose eggs are evenly heated, which is beneficial to hatching.

Owner:JIUJIANG POYAN CULTIVATION CO LTD

Manufacturing equipment for electronic components

ActiveCN107876661BEven vertical conditionAvoid damageTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureTransformerEngineering

The invention belongs to the technical field of electronic components and particularly relates to manufacturing equipment of electronic components. The manufacturing equipment comprises a rack, a motor, a power mechanism, a straightening mechanism and a transferring mechanism, the power mechanism comprises a transmission gear, a right gear, a center gear and a left gear which are engaged sequentially, and an output shaft of the motor is connected with the transmission gear. The straightening mechanism comprises a right squeezing wheel, a center squeezing wheel and a left squeezing wheel, and the transferring mechanism comprises a limiting strip and a supporting plate for supporting a transformer. One end of the limiting strip is connected with the supporting plate, engaged teeth are arranged at the other end of the limiting strip, the limiting strip is engaged with the left gear through the engaged teeth, and the supporting plate and a support are slidably connected. By adopting the technical scheme, the situation that in straightening, pins are pulled out or scratched, or soldering tin is damaged can be effectively prevented, meanwhile the straightening efficiency is improved, andthe labor intensity is reduced.

Owner:威海市多益电子有限公司

Clamping method and device for hoisting heavy cutter outside machining center magazine

ActiveCN105347183ASimple structureEasy to manufactureLoad-engaging elementsIndustrial engineeringRivet

The invention discloses a clamping method for hoisting a heavy cutter outside a machining center magazine. The method comprises the steps of arranging a combined clamping body for clamping a blind rivet on the cutter, arranging a hoisting part on the combined clamping body, hoisting the combined clamping body through the hoisting part and hoisting the cutter. The invention further discloses a clamping device for hoisting the heavy cutter outside the machining center magazine. According to the clamping method and device, the heavy cutter outside the machining center magazine can be fast hoisted, hoisting is convenient, the operation is simple, convenient, practical and fast and saves labor, the labor intensity of workers is lowered, the production cost is saved, the quality of the hoisted cutter is guaranteed, and the production efficiency is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Drying oven with air bearings and application method thereof

ActiveCN111195583ALow tension inputReduce tension deformationGas cushion bearingsPretreated surfacesInterior spaceAir bearing

The invention discloses a drying oven with air bearings and an application method thereof. The drying oven comprises an oven body, a conveying portion and a heating portion, wherein the oven body is provided with an inner space and an opening, the inner space is provided with a supporting plate, a feeding hole and a discharging hole correspondingly penetrate through two opposite sides adjacent tothe opening, the conveying portion is arranged on the supporting plate and comprises the plurality of air bearings, the air bearings are rotatably arranged on the supporting plate, a to-be-machined material belt penetrates through the feeding hole and the discharging hole to be attached to all the air bearings, and the heating portion is arranged in the inner space and is used for uniformly heating the material belt, in this way, the effects that in the process where the material belt is heated and the conveying portion conveys the material belt, due to the fact that air bearing supporting wheels are used as conveying media of the material belt, the material belt can be conveyed with low tension, so that the tension deformation of the material belt and sliding friction generated between the material belt and the supporting wheels are reduced, and then the material belt is prevented from being damaged are achieved.

Owner:GRP UP IND CO LTD

High-strength wear-resistant coated artificial leather and preparation method thereof

PendingCN114161780AImprove surface wear resistanceExtended service lifeLamination ancillary operationsSynthetic resin layered productsDi n butyl phthalatePolymer chemistry

The invention discloses high-strength wear-resistant coated artificial leather and a preparation method thereof.The high-strength wear-resistant coated artificial leather comprises 20-30% of fabric base cloth, 6-12% of a gel coating, 6-12% of a foaming film, 5-10% of an artificially synthesized high-molecular-weight polymer, 5-10% of dibutyl phthalate, 5-10% of a surface coating material and 5-10% of a high-strength composite film. The proportion of the foaming film is 10-15%, the proportion of the artificially synthesized high molecular weight polymer is 10-20%, the proportion of the dibutyl phthalate is 8-16%, the proportion of the surface coating material is 9-18%, and the proportion of the high-strength composite film is 10-20%. According to the high-strength wear-resistant coated artificial leather and the preparation method thereof, the surface coating film and the high-strength composite film are arranged, so that the surface wear resistance of the artificial leather can be improved, the surface is prevented from being scratched, the service life is prolonged, the use strength of the artificial leather can also be improved, and the high-strength wear-resistant coated artificial leather has a very good tear-resistant effect; and the use performance is more excellent.

Owner:苏州市广得利橡塑有限公司

Egg liquid filtering device for egg processing and use method of egg liquid filtering device

ActiveCN114451482AEffective separation of workCase to prevent scratchesProtein composition from eggsFood shapingYolkAnimal science

The invention relates to the technical field of egg processing, in particular to an egg liquid filtering device for egg processing and a using method thereof.The egg liquid filtering device comprises a fixed box body, the section of the fixed box body is in a U shape, an egg conveying assembly is arranged on the inner side of the fixed box body, and a feeding assembly is arranged at the opening end of the fixed box body; an eggshell separation mechanism is arranged on the side surface of the fixed box body; the eggshell separation mechanism comprises two supporting plates and a material receiving disc, the two supporting plates are symmetrically distributed about the center line of the fixed box body, a transmission assembly is rotationally arranged above the supporting plates, and an eggshell fixing assembly is arranged on the transmission assembly; according to the egg shell separation device, the egg shell separation mechanism is arranged, egg shells are adsorbed through an egg shell fixing assembly in the egg shell separation mechanism, the egg shells can be effectively separated, the situation that the egg shells scratch egg yolks is prevented, and the situation that the egg yolks are damaged is prevented.

Owner:WUHAN POLYTECHNIC UNIVERSITY

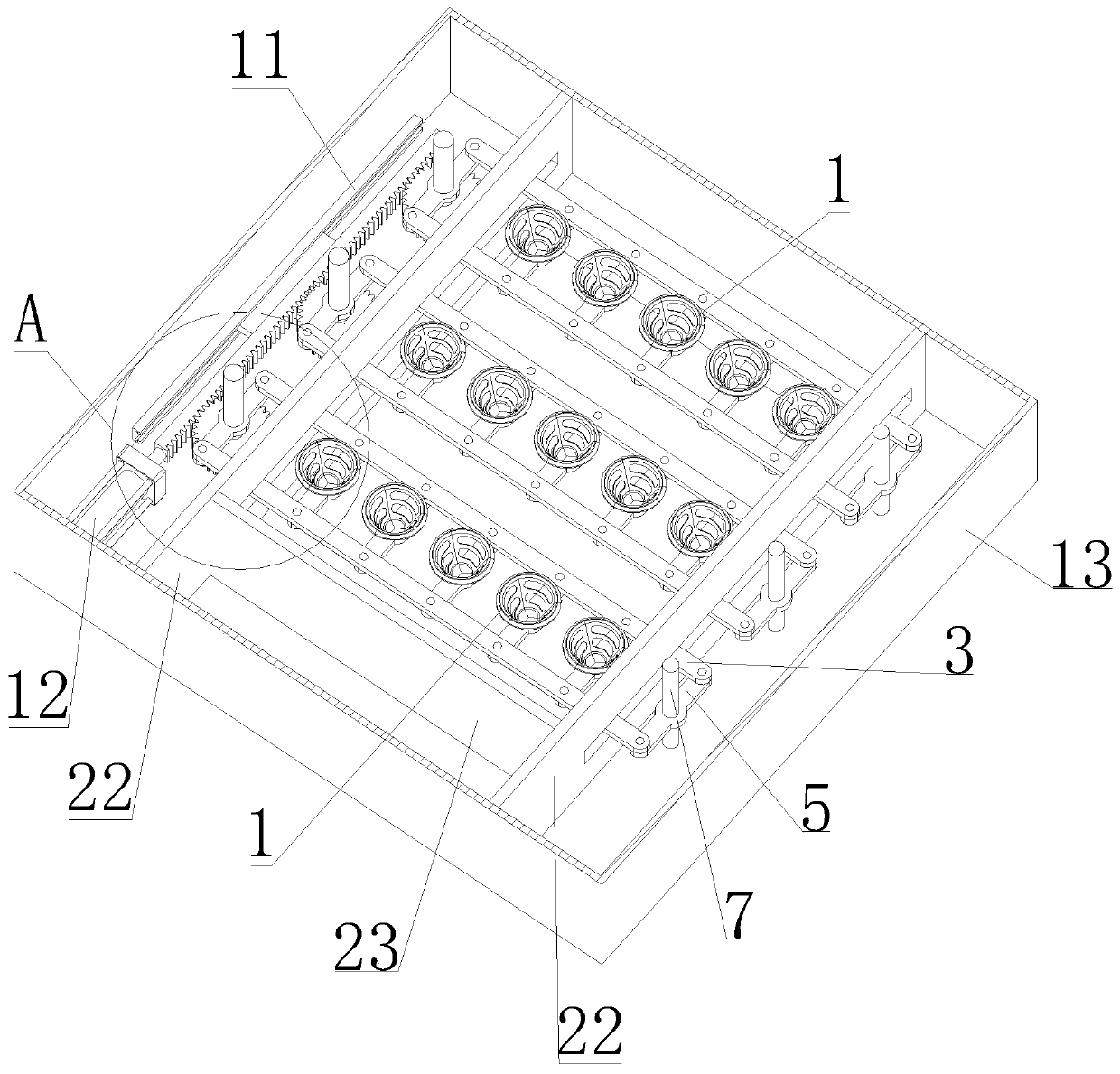

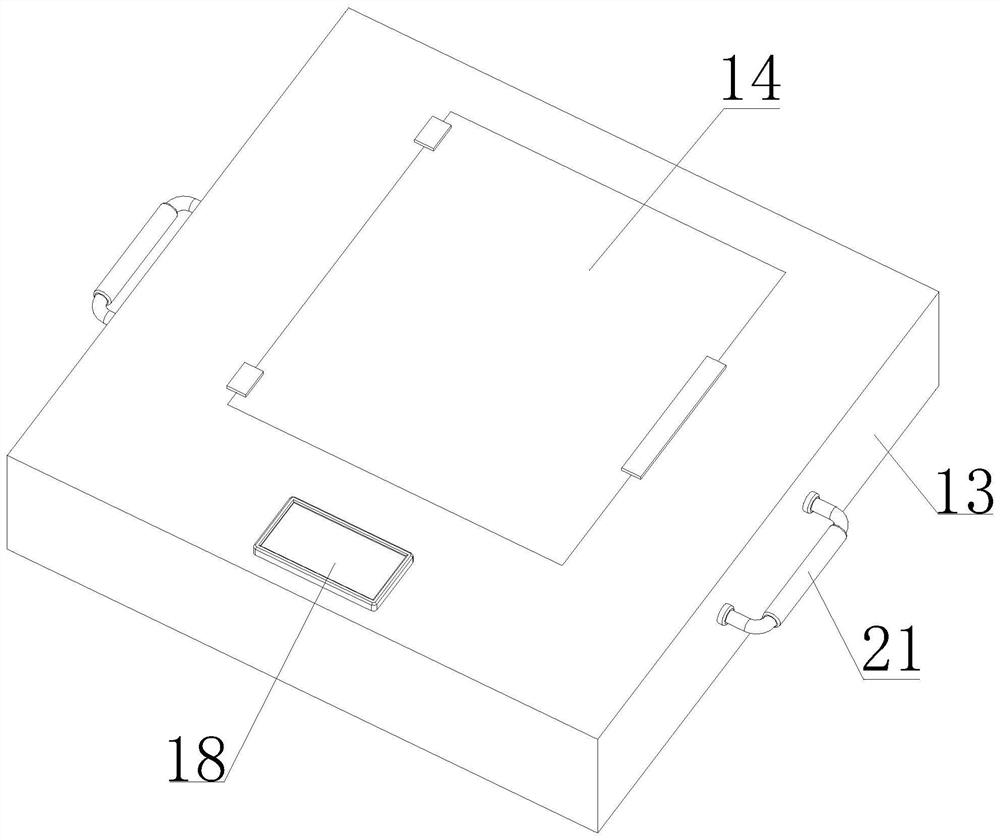

Automatic assembling equipment for intelligent manufacturing of wireless intelligent chargers

PendingCN113695904AQuality assuranceStrong linkageElectrical testingAssembly machinesControl engineeringReliability engineering

The invention discloses automatic assembling equipment for intelligent manufacturing of wireless intelligent chargers, and relates to the technical field of intelligent manufacturing of wireless intelligent chargers. The automatic assembling equipment comprises a placement seat and an assembling assembly, a placement frame body is arranged at the upper end of the placement seat, a control panel is arranged on the upper portion of the right side in the placement frame body, a transfer assembly used for transferring the wireless intelligent charger is arranged in the center of the upper end of the placement seat, and a feeding conveying belt is arranged in the middle of the rear end of the upper end of the placement seat. According to the automatic assembling equipment for intelligent manufacturing of the wireless intelligent chargers, through mutual cooperation of components through sensors, the linkage between the components is higher, the assembling quality of the wireless intelligent chargers is ensured while the automation degree of the equipment is improved, detection work can be conducted on the wireless intelligent chargers before assembling, the situation of resource waste caused by defective product assembling is avoided, and the equipment can be correspondingly replaced and adjusted according to the size of the actually assembled wireless intelligent chargers, so that the assembly work of the wireless intelligent chargers of different models can be met.

Owner:许继旭

Water body purification device using floating type combined technique to treat volatile organic pollutant

InactiveCN109205820AEasy to clean and replaceKeep clean and unobstructedWater contaminantsTreatment involving filtrationVolatile organic compoundPollutant

The invention discloses a water body purification device using a floating type combined technique to treat volatile organic pollutant, and relates to the technical field of organic pollutant treatment, in particular to the water body purification device using the floating type combined technique to treat the volatile organic pollutant. The water body purification device using the floating type combined technique to treat the volatile organic pollutant comprises a ship body, a fixing block and an operation chamber, the fixing block is arranged at the center of the interior of the ship body, theoperation chamber is arranged above the ship body, a water tank is arranged in the ship body, a water inlet valve is connected with the lower part of a water inlet, a clamping block is fixedly arranged at the top end of a filter net, and a reinforcing rib is fixedly arranged above the operation chamber. The water body purification device using the floating type combined technique to treat the volatile organic pollutant is characterized in that the large impurities in the water are filtered through the filter net, the situation that the large impurities in the water cause blockage of a thorough hole is prevented, meanwhile, operation staffs can conveniently clean or replace the filter net, and cleanness and smoothness of the filter net are ensured.

Owner:FOSHAN UNIVERSITY

A wearable bluetooth headset

ActiveCN109819370BPrevent discomfortCase to prevent scratchesEarpiece/earphone attachmentsEngineeringMechanical engineering

The invention discloses a wearable Bluetooth earphone. The structure of the device comprises: a device body, Intelligent wearing device, Device housing, Nasal bracket and telescopic belt, an electromagnetic block on an internal limiting block is fixedly connected with the head-mounted equipment; meanwhile, the telescopic rod is used for adjusting the height; meanwhile, when external force is applied to the equipment through an internal adjusting frame; the internal direction can be automatically adjusted; therefore, the earphone equipment under the telescopic rod is stabilized; the condition of scratching is prevented; meanwhile, the internal gas pumping frame is electrified to operate; ambient air is pumped into the internal air bag through the conveying pipe; When the headphone is used,the air bag is inflated and swelled longitudinally under the limit of the outer side, so that the headphone is adjusted to be suitable for being used by a wearer, internal air flow can be exhausted through the ventilation frame below along the pipeline after being adjusted, and therefore, discomfort caused by overheating in the headphone is prevented.

Owner:LUXSHARE ELECTRONICS TECH (KUNSHAN) LTD

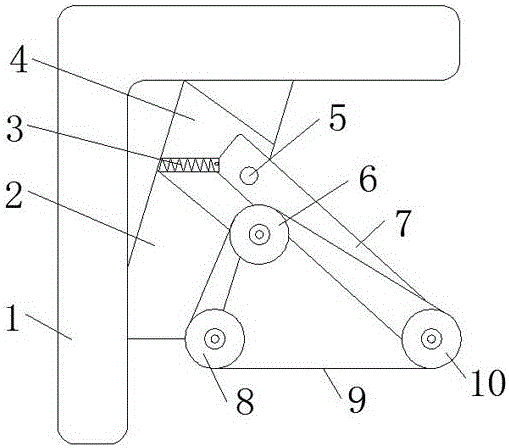

Plastic shell grinding equipment in intelligent imaging equipment

InactiveCN106041687AReduce labor intensityCase to prevent scratchesBelt grinding machinesManipulatorEngineeringDrive motor

The invention belongs to the technical field of manufacturing of intelligent imaging equipment and discloses plastic shell grinding equipment in the intelligent imaging equipment. By the adoption of the plastic shell grinding equipment in the intelligent imaging equipment, the problem that according to manual deburring in the prior art, machining efficiency is low is solved. The plastic shell grinding equipment in the intelligent imaging equipment comprises a manipulator. A supporting frame is fixedly arranged on the manipulator and comprises a first supporting arm and a second supporting arm. The second supporting arm is hinged to the first supporting arm and can rotate along the first supporting arm. A first guide roller is arranged at the end of the first supporting arm, and a second guide roller is arranged at the end of the second supporting arm. A driving roller is further arranged on the first supporting arm. The driving roller is driven by a driving motor fixed to the first supporting arm to rotate. The driving roller, the first guide roller and the second guide roller are wrapped with sand grinding belts.

Owner:CHENGDU RONGCHUANG ZHIGU SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com