Aluminum alloy liquid fine polishing wax and preparation method thereof

A technology of fine polishing, aluminum alloy, used in polishing compositions containing abrasives, lubricating compositions, petroleum industry, etc. and other problems, to achieve the effect of brightening the aluminum alloy surface, less investment in process equipment, and preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

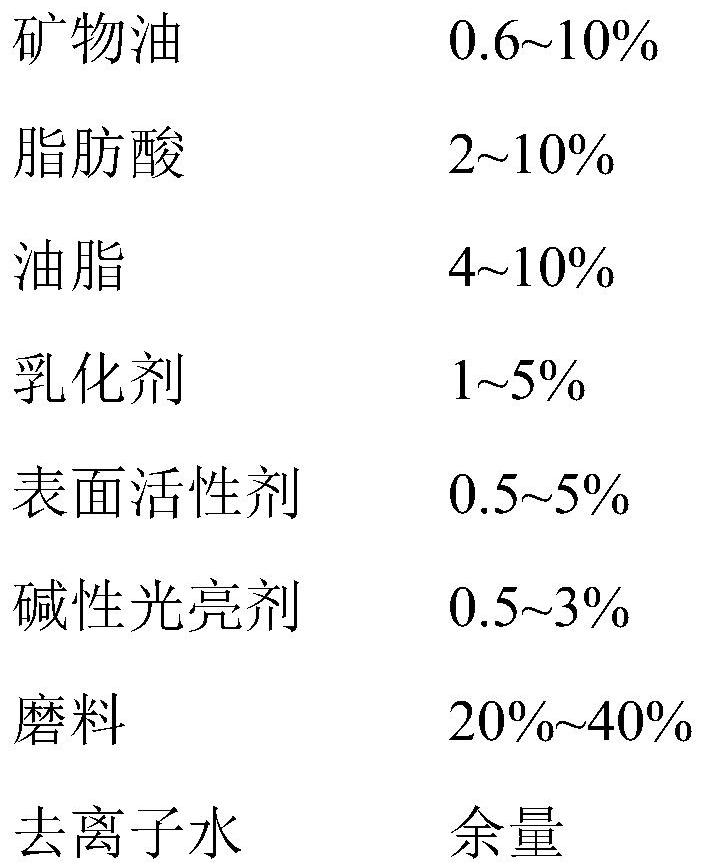

[0030] A liquid fine polishing wax for aluminum alloy, comprising the following components in mass percentage:

[0031]

[0032] Further, the mineral oil is white oil.

[0033] Further, the fatty acid is 6% by mass of stearic acid and 2% by mass of oleic acid.

[0034] Further, the grease is lanolin.

[0035] Further, the emulsifier is glyceryl monostearate.

[0036] Further, the surfactant is 1.5% by mass of fatty alcohol polyoxyethylene ether and 1.5% by mass of triethanolamine oleate.

[0037] Further, the basic brightener is triethanolamine.

[0038] Further, the abrasive is calcined alumina, and the particle size of the alumina is submicron, that is, the primary crystal size of alumina is 100 nm. Furthermore, the abrasive material is alumina calcined at a medium and low temperature, and the calcining temperature is 1000°C.

[0039] The preparation method of the aluminum alloy liquid fine polishing wax comprises the following steps:

[0040] (1) Under stirring con...

Embodiment 2

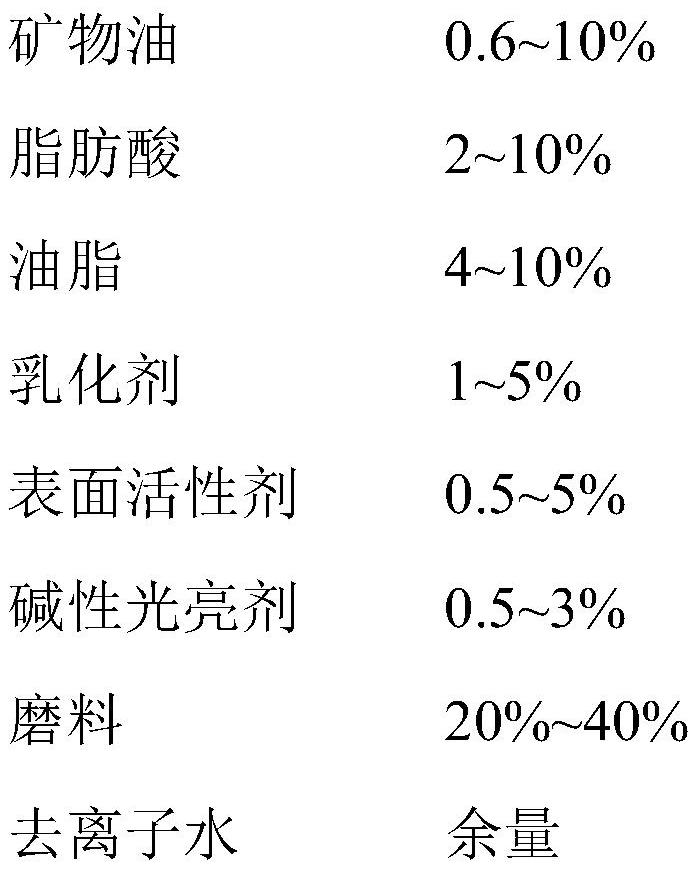

[0043] A liquid fine polishing wax for aluminum alloy, comprising the following components in mass percentage:

[0044]

[0045] Further, the mineral oil is petrolatum.

[0046] Further, the fatty acid is stearic acid.

[0047] Further, the fat is tallow.

[0048] Further, the emulsifier is glyceryl monostearate.

[0049] Further, the surfactant is octylphenol polyoxyethylene ether.

[0050] Further, the basic brightener is polyethyleneimine.

[0051]Further, the abrasive is calcined alumina, and the particle size of the alumina is submicron, that is, the primary crystal size of alumina is 500nm. Furthermore, the abrasive material is alumina calcined at a medium and low temperature, and the calcining temperature is 1050°C.

[0052] The preparation method of the aluminum alloy liquid fine polishing wax comprises the following steps:

[0053] (1) Under stirring conditions, add water, alkaline brightener, surfactant, emulsifier and abrasive into a constant temperature re...

Embodiment 3

[0056] A liquid fine polishing wax for aluminum alloy, comprising the following components in mass percentage:

[0057]

[0058] Further, the mineral oil is liquid paraffin.

[0059] Further, the fatty acid is palmitic acid and stearic acid.

[0060] Further, the grease is lanolin.

[0061] Further, the emulsifier is sorbitan monostearate.

[0062] Further, the surfactant is fatty alcohol polyoxyethylene ether.

[0063] Further, the basic brightener is triethanolamine.

[0064] Further, the abrasive is calcined alumina, and the particle size of the alumina is submicron, that is, the primary crystal size of alumina is 700nm. Furthermore, the abrasive material is alumina calcined at a medium and low temperature, and the calcining temperature is 1100°C.

[0065] The preparation method of the aluminum alloy liquid fine polishing wax comprises the following steps:

[0066] (1) Under stirring conditions, sequentially add water, alkaline brightener, surfactant, emulsifier an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com