Manufacturing equipment of electronic components

A technology for electronic components and manufacturing equipment, applied in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as scratches on the pin surface, high labor intensity, damaged solder, etc., to achieve uniform vertical pins, reduce High labor intensity and straightening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is a further detailed description through specific implementations:

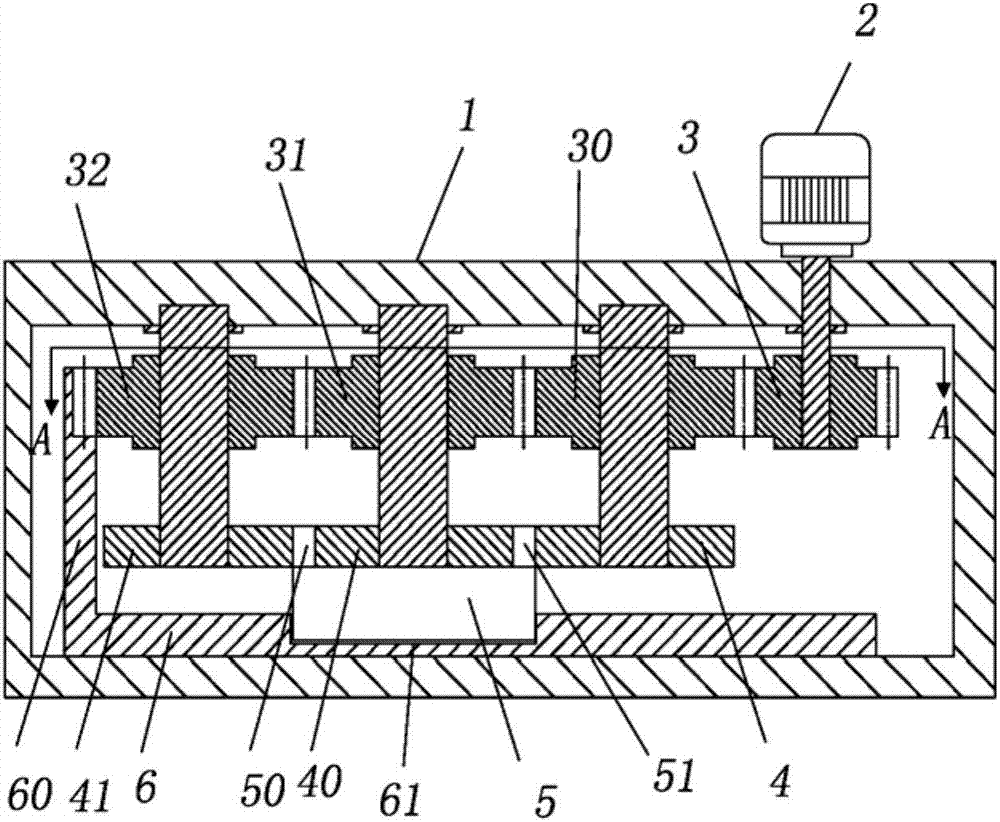

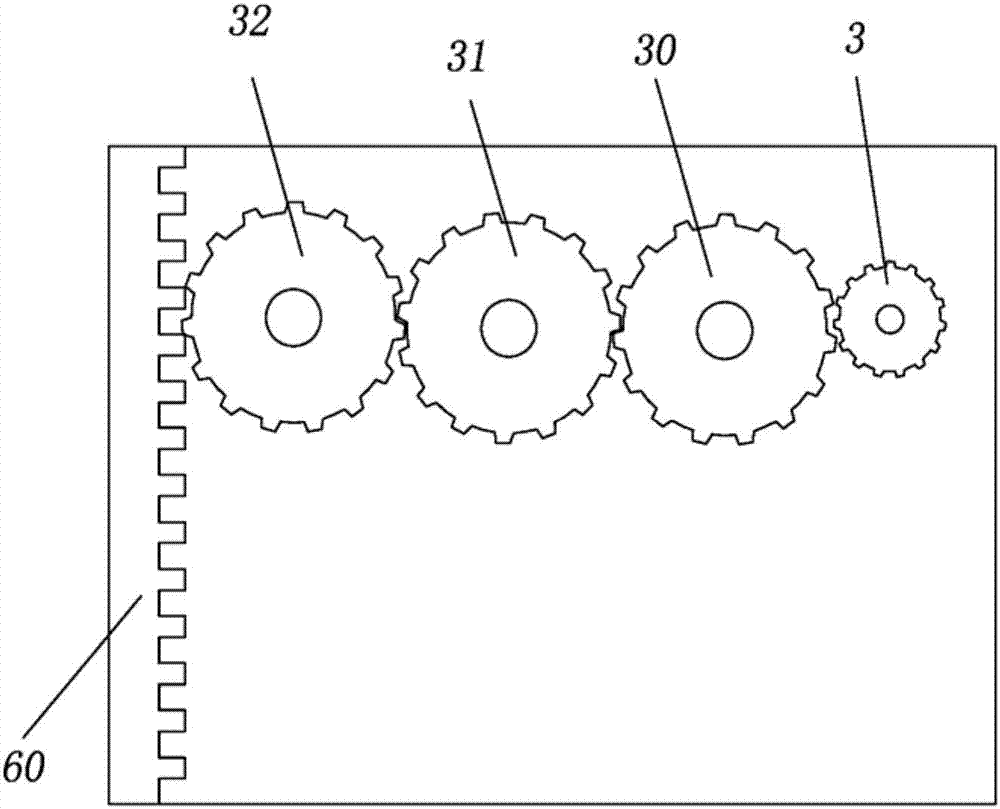

[0021] The reference signs in the drawings of the specification include: frame 1, motor 2, transmission wheel 3, right gear 30, center gear 31, left gear 32, right extrusion wheel 4, center extrusion wheel 40, left extrusion wheel 41 , Transformer body 5, left row of pins 50, right row of pins 51, support plate 6, limiting strip 60, groove 61.

[0022] The embodiment is basically as attached figure 1 Shown: manufacturing equipment for electronic components, including frame 1, motor 2, power mechanism, straightening mechanism and transmission mechanism. The longitudinal section of the stent is in a back shape.

[0023] The power mechanism includes a transmission wheel 3, a right gear 30, a center gear 31, and a left gear 32 that mesh in sequence. The output shaft of the motor 2 is connected to the transmission wheel 3. The diameters of the right gear 30, the center gear 31 and the left gear 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com