Method and tool for clamping type hoisting machining center outside heavy tool

A machining center and clamping technology, which is applied to the field of heavy tools outside the warehouse of clamping hoisting machining centers, can solve the problems of high labor intensity, low work efficiency, and easy scratching of workers, so as to reduce the hoisting labor. Strength, low cost, good clamping and hoisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

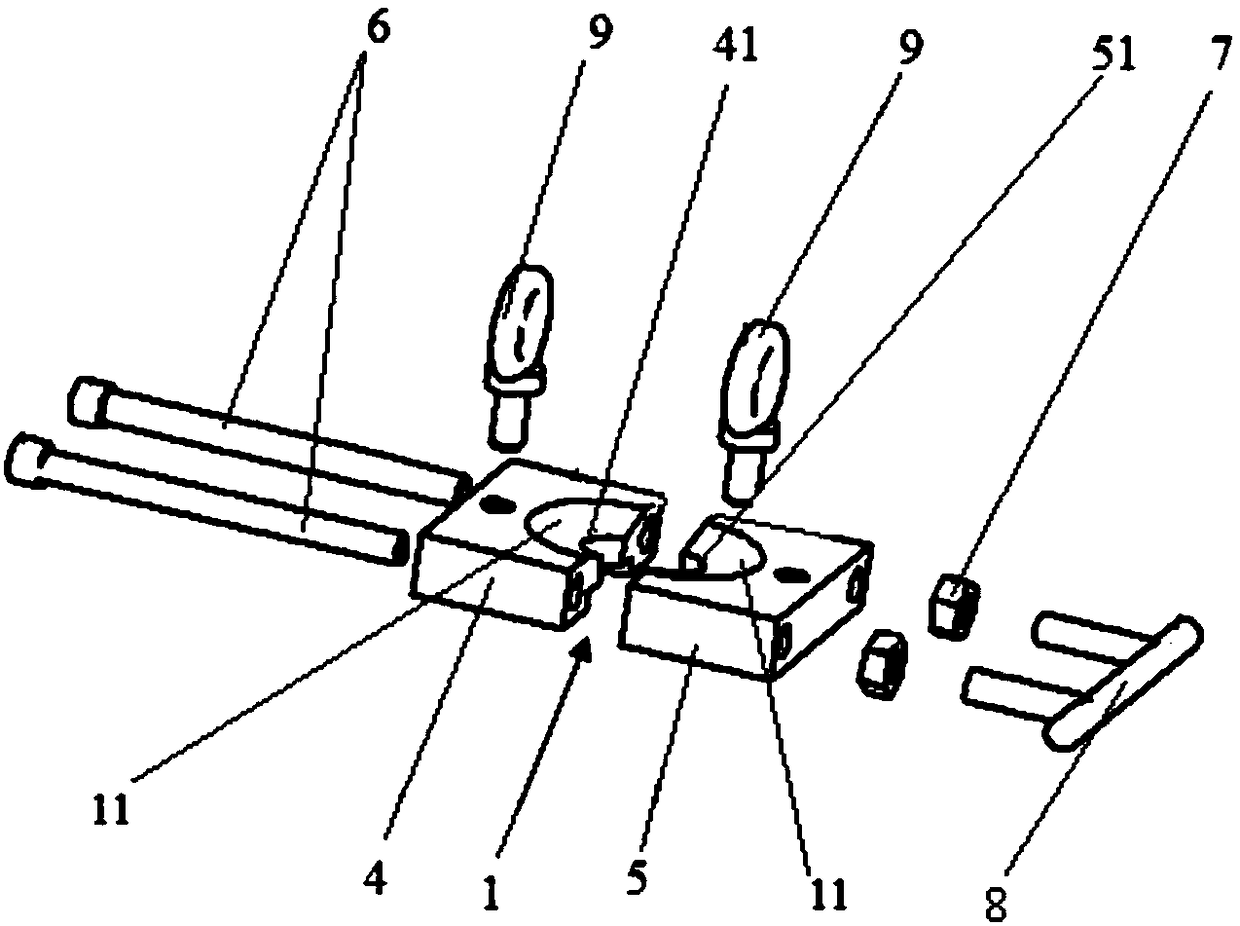

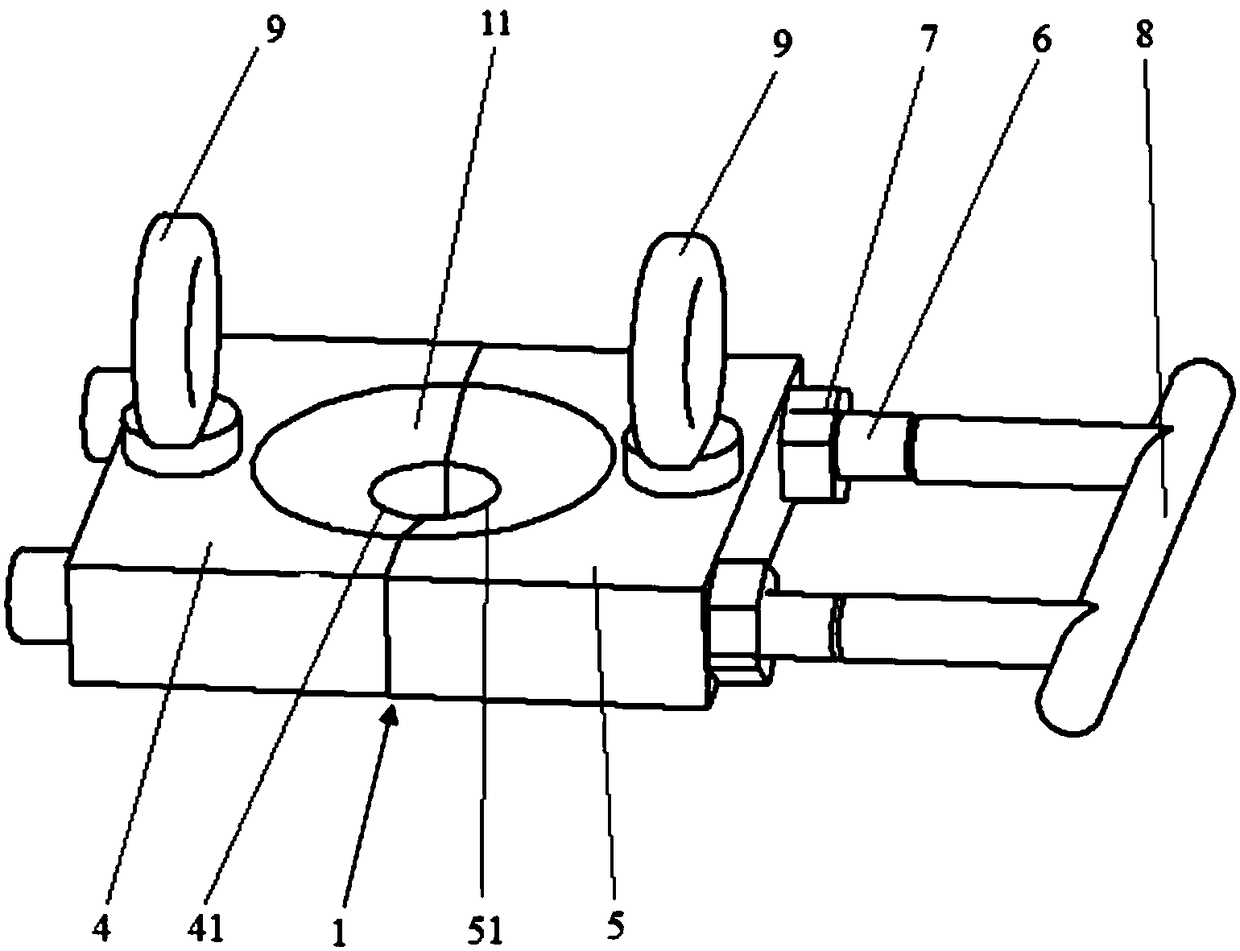

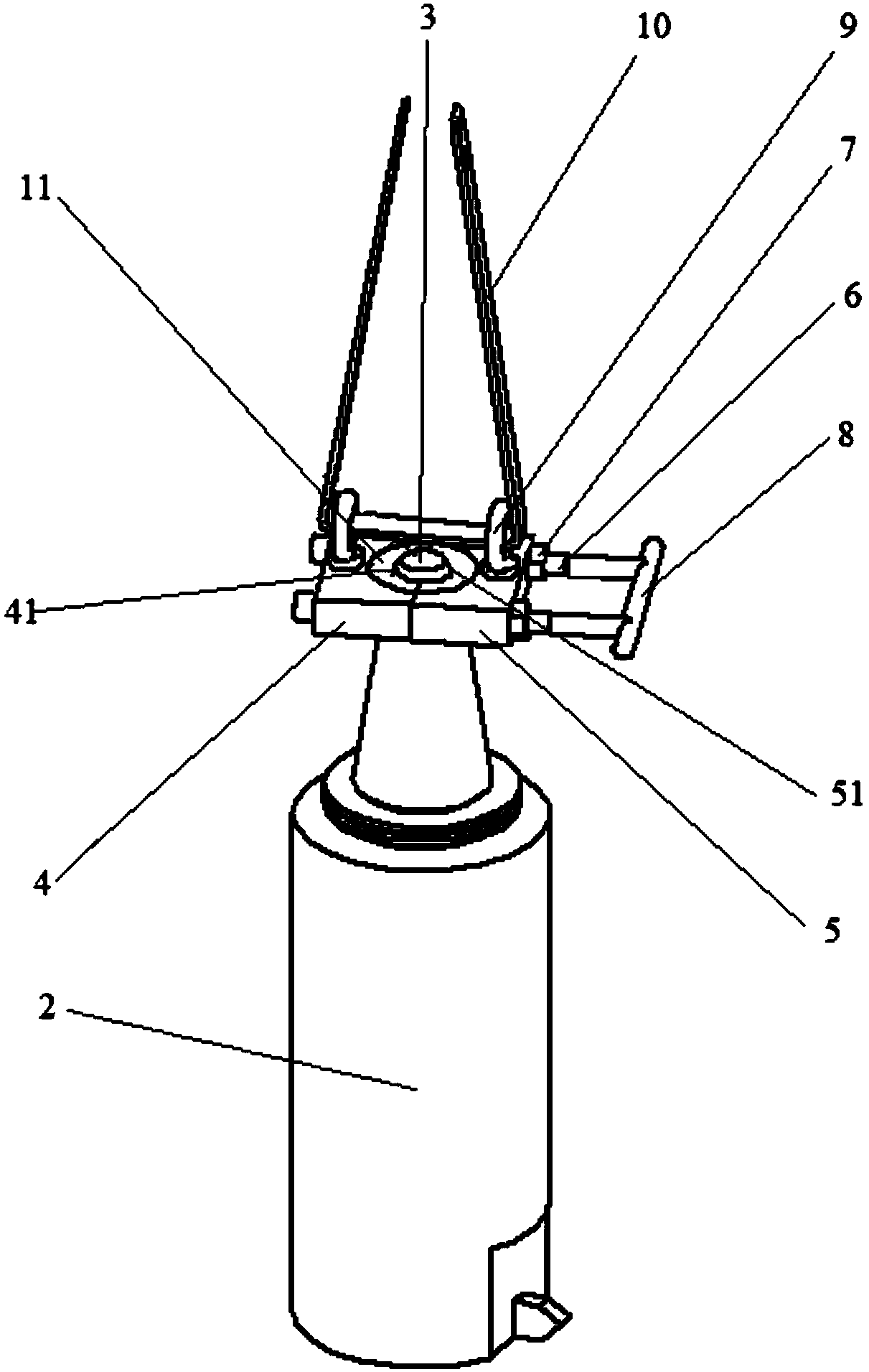

[0022] Embodiments of the present invention are as follows: Figure 1-Figure 4 As shown, a clamping tool for hoisting heavy tools outside the warehouse of a machining center includes a combined clamping body 1, which is provided with a clamping portion for clamping a pull stud 3, and the combined clamping body 1 also includes Square block-shaped left clamping block 4 and right clamping block 5, the clamping part includes left clamping opening 41 and right clamping opening 41 respectively opened on the left and right sides of the splicing section of left clamping block 4 and right clamping block 5. Port 51, the left clamping port 41 and the right clamping port 51 are spliced into a round hole matching the groove 31 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com