Plastic shell grinding equipment in intelligent imaging equipment

A technology for imaging equipment and plastic shells, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of low processing efficiency and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

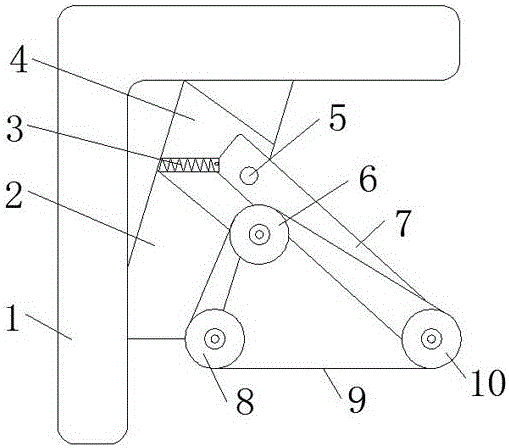

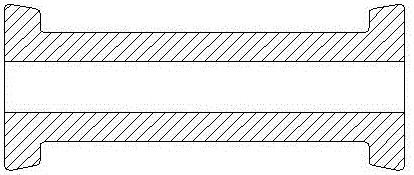

[0024] The plastic casing grinding device in the intelligent imaging device of this embodiment includes a manipulator, and a support frame is fixedly arranged on the manipulator, and the support frame includes a first support arm and a second support arm, and the second support arm Hinged on the first support arm, and the second support arm can rotate along the first support arm, the end of the first support arm is provided with a first guide roller, and the end of the second support arm is provided with The second guide roller, the first support arm is also provided with a driving roller, and the driving roller is driven to rotate by a driving motor fixed on the first support arm, and the driving roller, the first guide roller and the second guide roller The periphery is covered with a frosted belt.

Embodiment 2

[0026] The plastic casing grinding device in the intelligent imaging device of this embodiment includes a manipulator, and a support frame is fixedly arranged on the manipulator, and the support frame includes a first support arm and a second support arm, and the second support arm Hinged on the first support arm, and the second support arm can rotate along the first support arm, the end of the first support arm is provided with a first guide roller, and the end of the second support arm is provided with The second guide roller, the first support arm is also provided with a driving roller, and the driving roller is driven to rotate by a driving motor fixed on the first support arm, and the driving roller, the first guide roller and the second guide roller The outer periphery is coated with a frosted belt; the second support arm is hinged with the first support arm through a pin shaft.

Embodiment 3

[0028] The plastic casing grinding device in the intelligent imaging device of this embodiment includes a manipulator, and a support frame is fixedly arranged on the manipulator, and the support frame includes a first support arm and a second support arm, and the second support arm Hinged on the first support arm, and the second support arm can rotate along the first support arm, the end of the first support arm is provided with a first guide roller, and the end of the second support arm is provided with The second guide roller, the first support arm is also provided with a driving roller, and the driving roller is driven to rotate by a driving motor fixed on the first support arm, and the driving roller, the first guide roller and the second guide roller The outer periphery of the support arm is covered with a frosted belt; the second support arm is hinged with the first support arm through a pin shaft; the first support arm is provided with a cavity, and one end of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com