Numerical control punching lathe with dense feeding and discharging structure and facilitating workpiece alignment

A CNC punching and workpiece technology, which is applied to manufacturing tools, positioning devices, metal processing equipment, etc., can solve the problems of inability to punch multiple parts, no dense loading and unloading structure, and low lathe processing efficiency. Wide range of use, improved processing efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

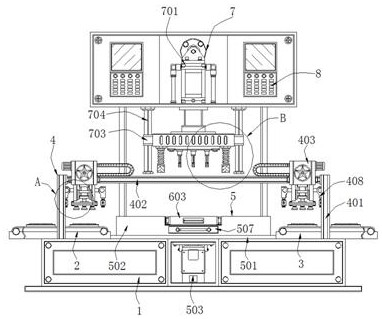

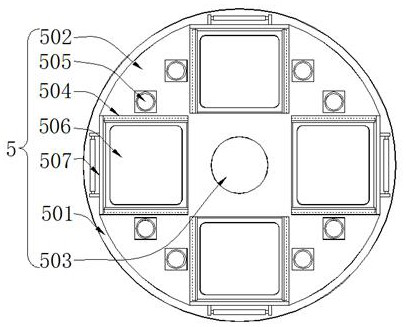

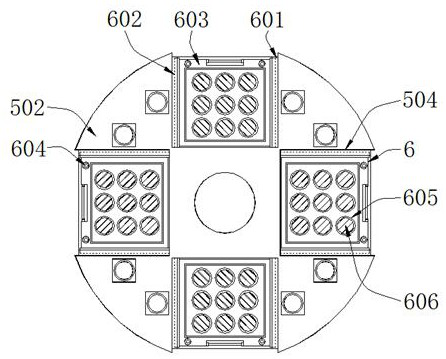

[0027] see Figure 1-5, the present invention provides a technical solution: a CNC punching lathe with a dense loading and unloading structure to facilitate workpiece alignment, including a bearing seat 1 and a material transport assembly 4, and a feeding conveyor belt 2 is provided on the left side of the upper end of the bearing seat 1 , and the right side of the upper end of the bearing seat 1 is provided with a blanking conveyor belt 3, and the material transport assembly 4 for loading and unloading parts is arranged on the upper front end of the bearing seat 1, and the material transport assembly 4 includes a placement frame 401, a placement rail 402, X-axis driving block 403, material transport cylinder 404, connecting block 405, suction cup 406, installation bolt 407 and infrared sensor 408, and the upper end of the installation frame 401 is connected with the installation horizontal rail 402, and the upper end of the installation horizontal rail 402 is connected on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com