Abrasive cloth wheel polishing machine for double-sided curve grinding and polishing method of abrasive cloth wheel polishing machine

A technology of curve grinding and emery cloth wheel, which is applied in grinding/polishing equipment, machine tools for surface polishing, grinding/polishing safety devices, etc. It can solve the problems of affecting the efficiency of grinding, scratches on the surface of workpieces, and high cost of use of mechanical arms. problems, to achieve the effect of accelerated grinding efficiency, low cost, and fast fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

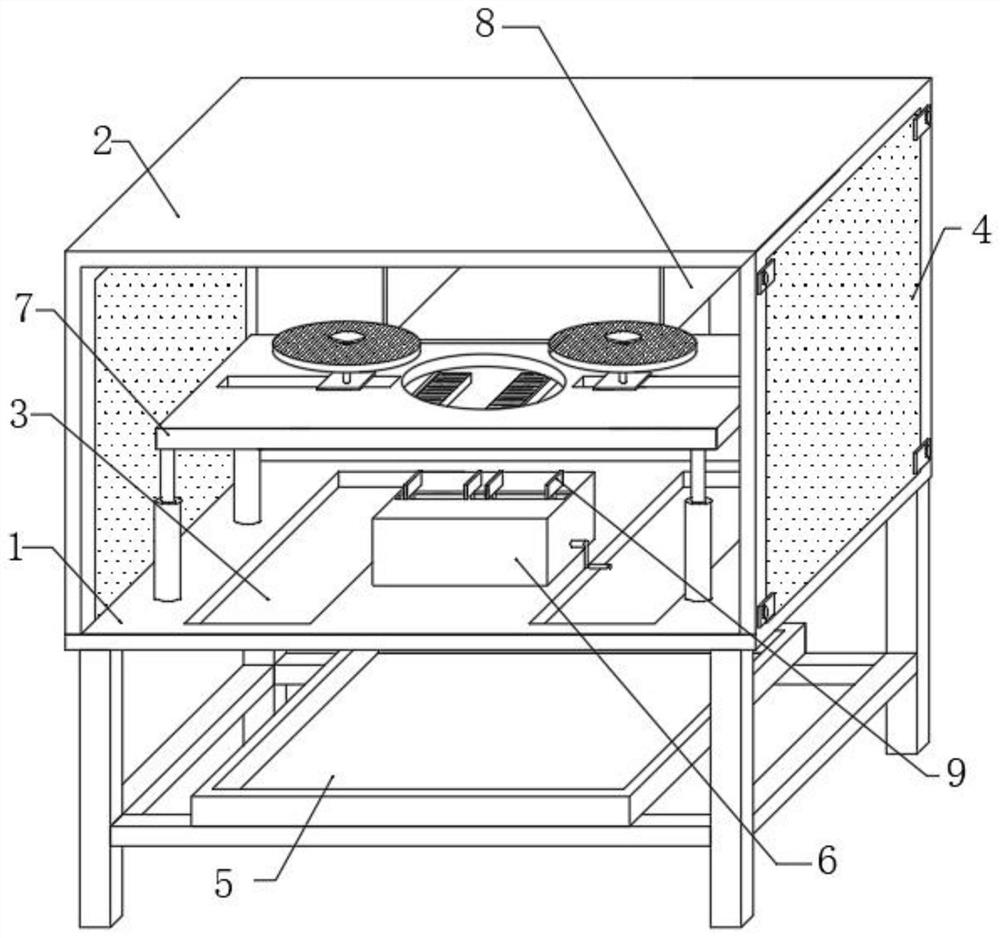

Embodiment 1

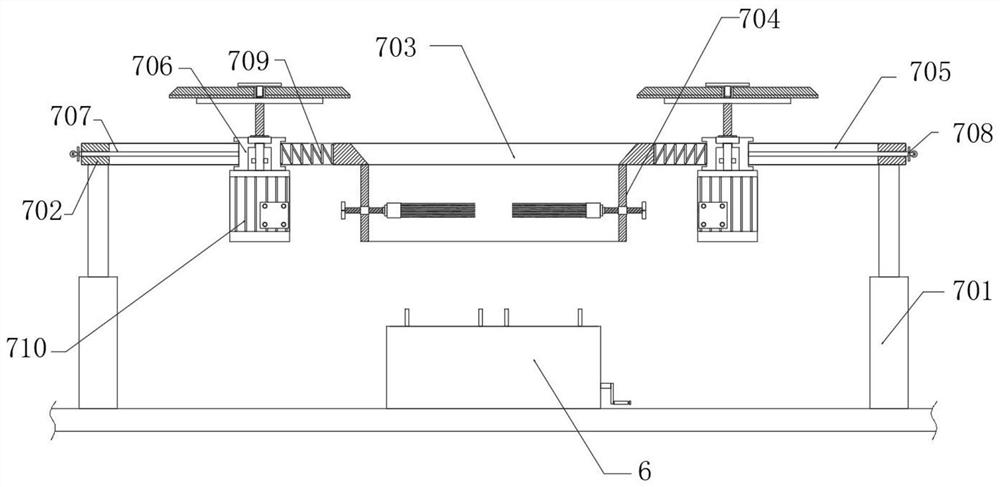

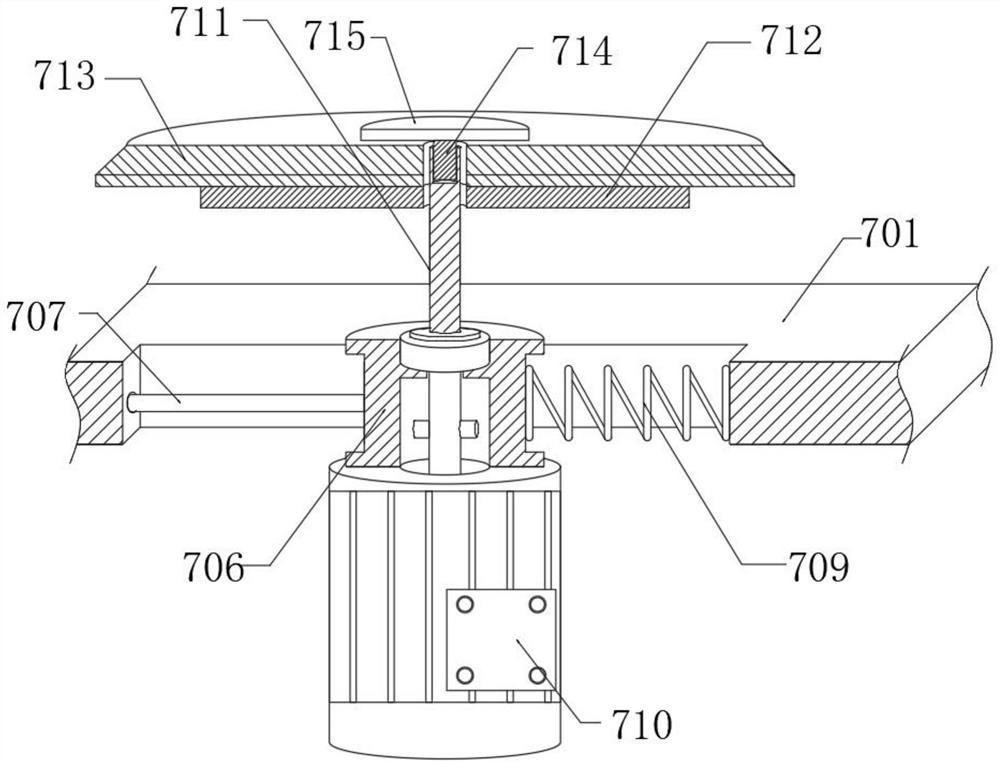

[0033] Please refer to Figure 2- Figure 4 , in the embodiment of the present invention, the grinding assembly 7 includes: four hydraulic rods 701 fixed on the upper end surface of the workbench 1, the upper output ends of the four hydraulic rods 701 are fixed with a support horizontal plate 702, and the support horizontal plate 702 is opened with a through Slot 703, the lower end surface of the supporting horizontal plate 702 is fixed with a connecting pipe 704 connected to the bottom of the through groove 703, and the inside of the supporting horizontal plate 702 is provided with a waist groove 705 symmetrically arranged with respect to the through groove 703; the socket is inserted into the waist groove 705 The sliding block 706 of the cavity, the side of the sliding block 706 away from the through groove 703 is fixed with a pull rod 707, the extended end of the pull rod 707 is fixed with a handle 708, and the side of the sliding block 706 away from the pull rod 707 is fixed...

Embodiment 2

[0035] see Figure 5 The difference from Embodiment 1 is that the collection assembly 8 includes: a suction pipe 801 embedded in the rear end of the protective cover 2, a collection bin 802 is fixed at the rear end of the suction pipe 801, and a suction pipe 802 is embedded in the rear end surface of the collection bin 802. Pump 803; fixed on the draw-in groove 804 at the bottom of the inner chamber of the collection bin 802, the inside of the draw-in groove 804 is sleeved with a multi-purpose filter screen 805 socketed with the collection bin 802; and fixed on one side of the inner cavity of the collection bin 802 and The brush 806 fitted with the multi-purpose filter screen 805, the input end of the suction pipe 801 is set opposite to the grinding yarn wheel 713, and is used to collect the waste impurities generated by the grinding yarn wheel 713 operation. The opening and closing door can also be installed at the feed port, which is used to discharge the accumulated impurit...

Embodiment 3

[0037] see Figure 6 The difference from Embodiment 1 is that the solid material assembly 9 includes: a drive rod 901 that rotates laterally in the inner cavity of the discharge table 6 through a bearing, and the surface of the drive rod 901 is equidistantly engaged with four moving plates 902 through opposite threads. A moving plate 902 upper end surface is fixed with a connecting rod 903 socketed with the discharge platform 6, and the upper end of the connecting rod 903 is fixed with a fixed plate 904; the limit rod 905 is horizontally fixed on the discharge platform 6 inner cavity, and the limit rod 905 is connected to the inner cavity of the discharge platform 6. The upper end of the moving plate 902 runs through the socket, and the side of the discharge platform 6 is socketed with the crank handle 906 fixed with the drive rod 901; The lower end surface of the discharge table 6 is fixed to drive the discharge table 6 to rotate axially. When the handle 906 is rotated in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com