LOGO code printing equipment for information technology chip processor

An information technology and processor technology, applied in the field of information technology chip processor LOGO coding printing equipment, can solve the problems of low production efficiency, error-prone, high labor cost, improve printing standards, realize automatic feeding, Avoid blurry effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] An information technology chip processor LOGO code printing equipment, such as figure 1 As shown, it includes a base 1, a telescopic mechanism 2 and an up and down mechanism 3, the right side of the top of the base 1 is provided with a telescopic mechanism 2, and the base 1 is provided with an up and down mechanism 3.

[0084] When people need to print the LOGO code on the chip, first pour the paint into the parts of the telescopic mechanism 2, then place the chip under the parts of the upper and lower mechanism 3, and then control the telescopic mechanism 2 so that the parts of the telescopic mechanism 2 will put the paint Continuously smear on the LOGO, and at the same time control the components of the upper and lower mechanism 3 to print the LOGO code on the chip.

Embodiment 2

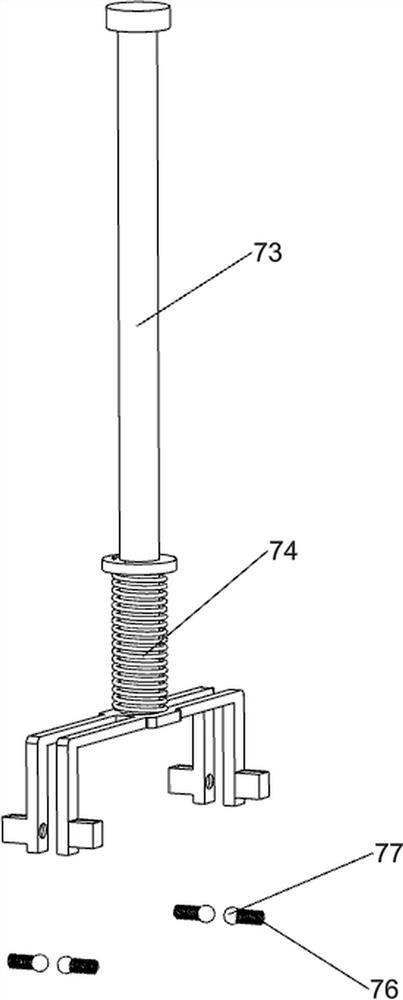

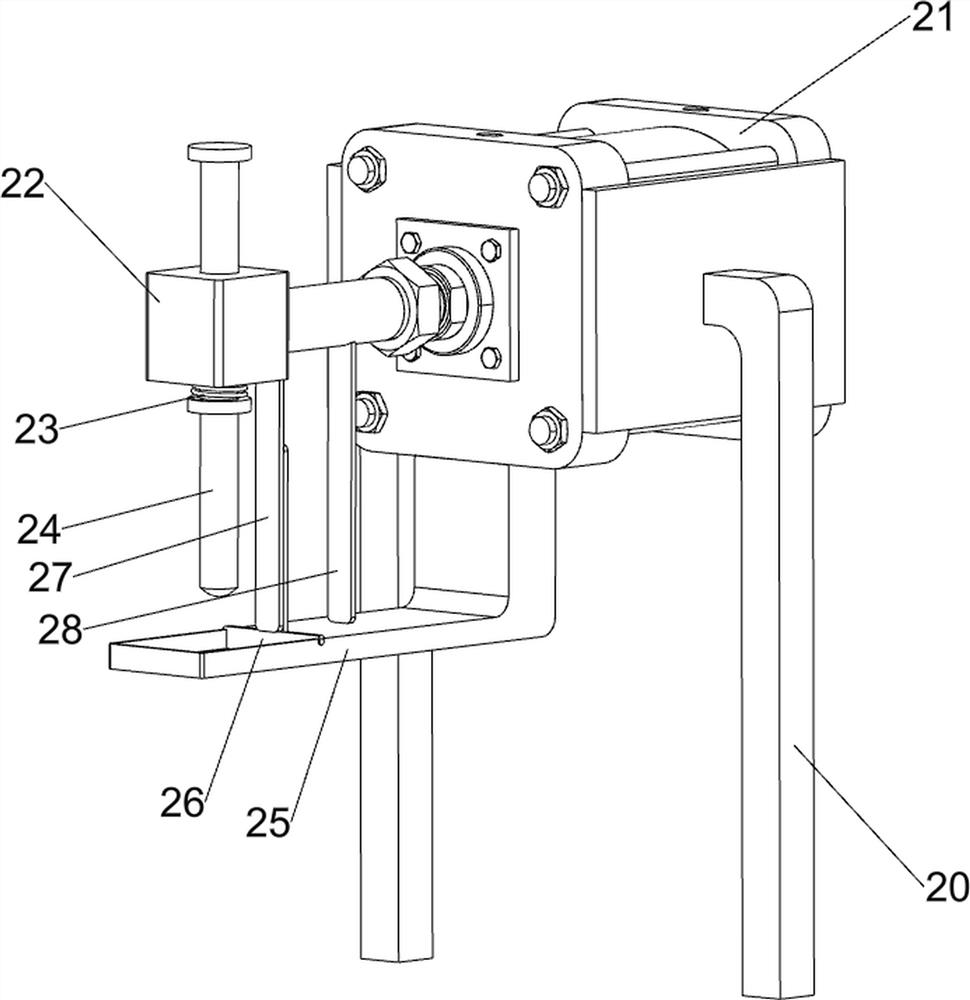

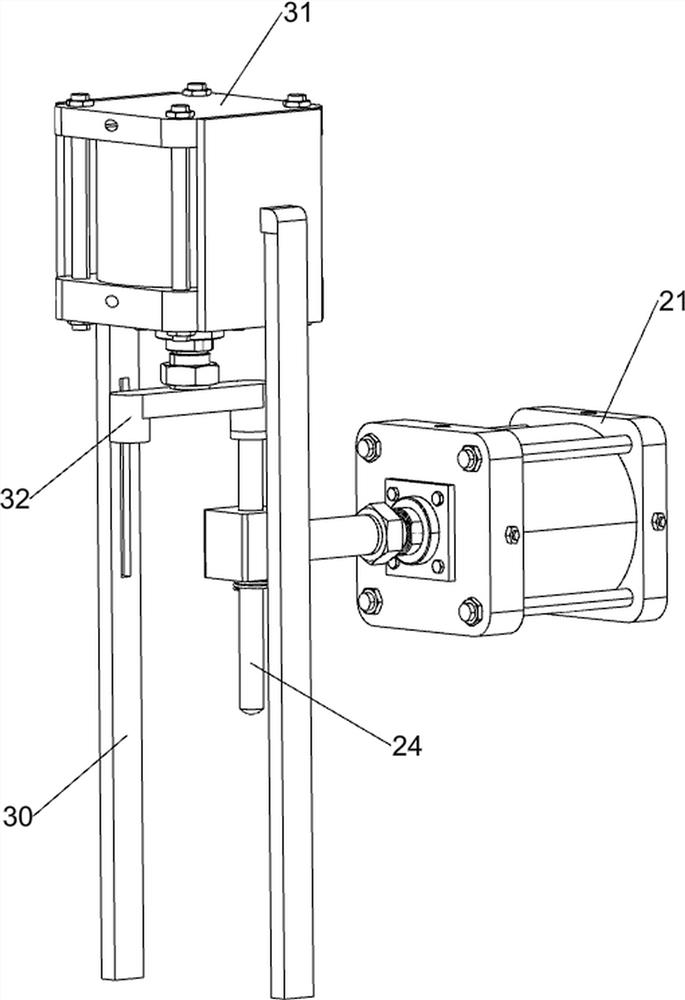

[0086] On the basis of Example 1, such as Figure 2-3 As shown, the telescopic mechanism 2 includes a first pillar 20, a first cylinder 21, a limiter block 22, a first spring 23, a first slider 24, a paint tank 25, a brush plate 26, a first transmission block 27 and a second transmission block. Block 28, the right side of the base 1 is provided with two first pillars 20, the first cylinder 21 is arranged between the first pillars 20, the left side of the first cylinder 21 is provided with a limit block 22, and the limit block 22 is slidingly connected with the first A slide block 24, a first spring 23 is arranged between the top of the first slide block 24 and the limiter block 22, the first spring 23 is set on the outside of the first slide block 24, a paint tank 25 is provided on the left side of the bottom of the first cylinder 21, The paint tank 25 is slidably connected with a brush plate 26, the left side of the first cylinder 21 is provided with a first transmission bloc...

Embodiment 3

[0091] On the basis of Example 2, such as Figure 4-12 As shown, a control mechanism 4 is also included, and the control mechanism 4 includes a first connecting block 40, a second sliding block 41, a second spring 42, a first switch 43, a second connecting block 44, a third sliding block 45, a first Three springs 46 and the second switch 47, the second strut 30 on the front side is provided with the first connecting block 40, the second sliding block 41 is slidably connected on the first connecting block 40, the second sliding block 41 is connected with the first A second spring 42 is arranged between the blocks 40, a first switch 43 is arranged on the right side of the second cylinder 31, and the first switch 43 is in contact with the second slide block 41, and the second support 30 on the rear side is connected with a second connection. block 44, the second connecting block 44 is slidably connected with a third sliding block 45, a third spring 46 is provided between the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com