Patents

Literature

30results about How to "Realize the centering function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

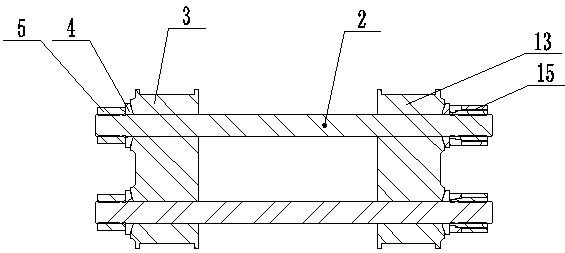

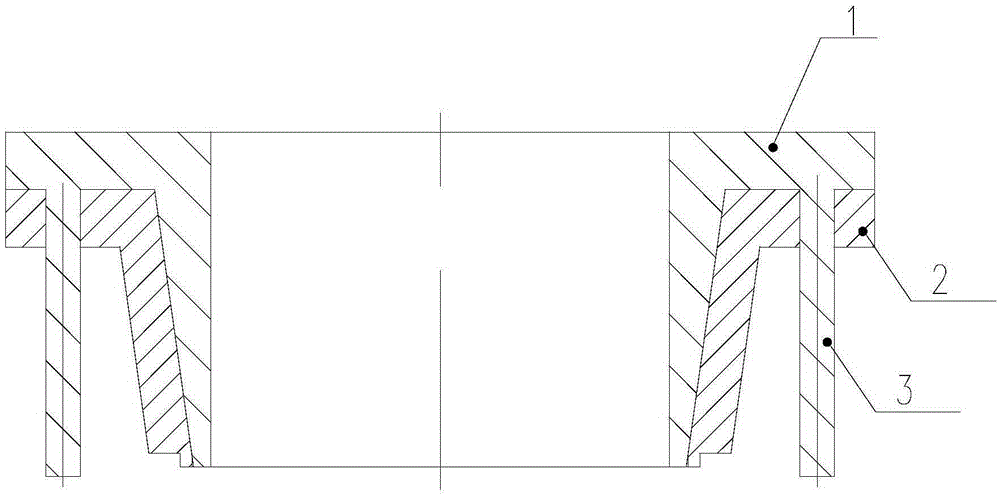

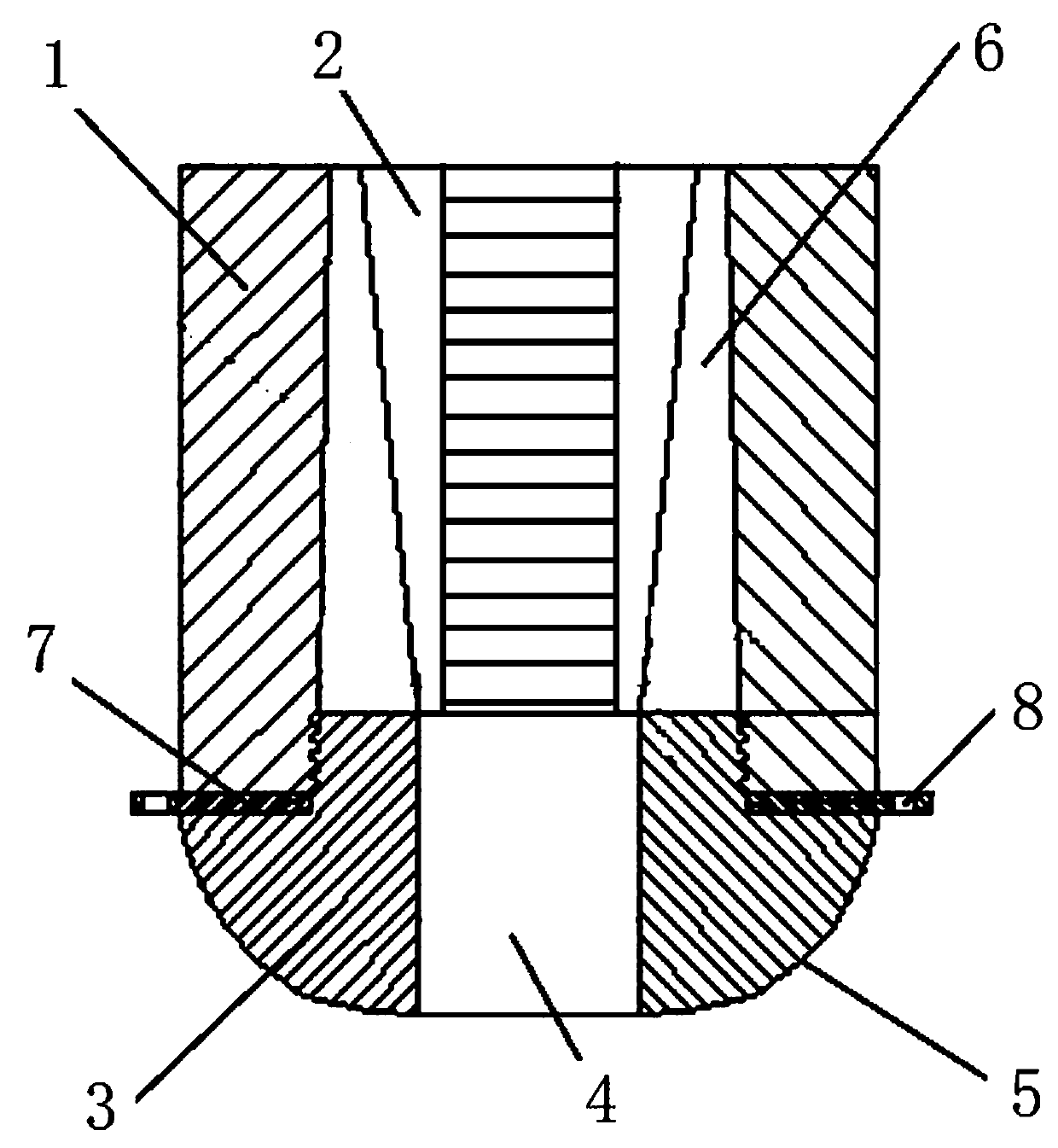

Bearing mounting tool with centering function

InactiveCN104551604ANo skewRealize the centering functionMetal working apparatusEngineeringMechanical engineering

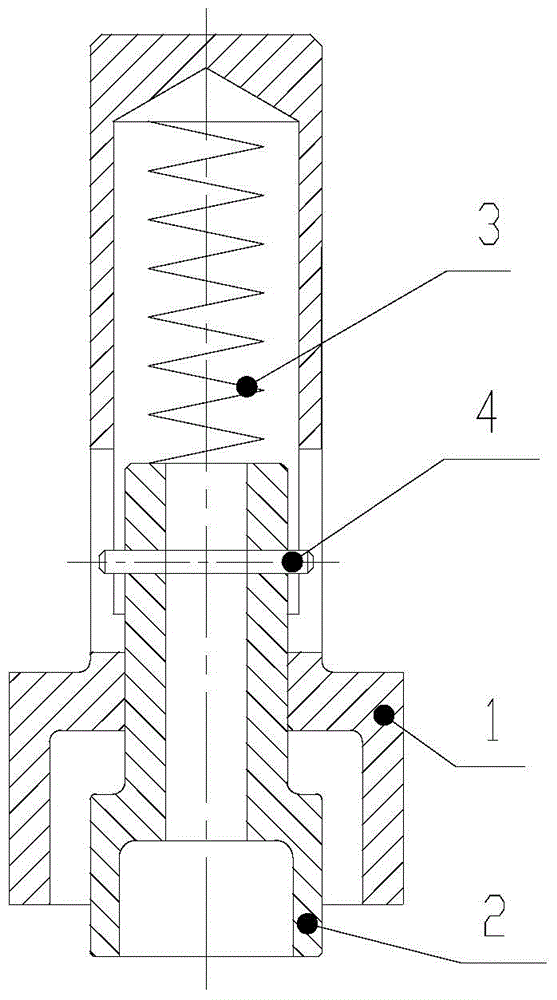

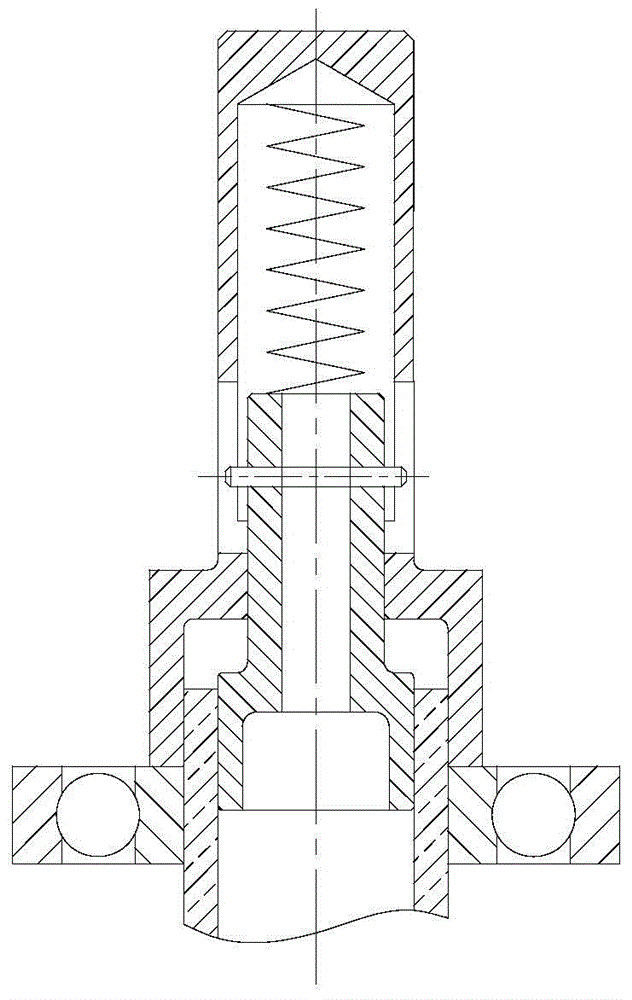

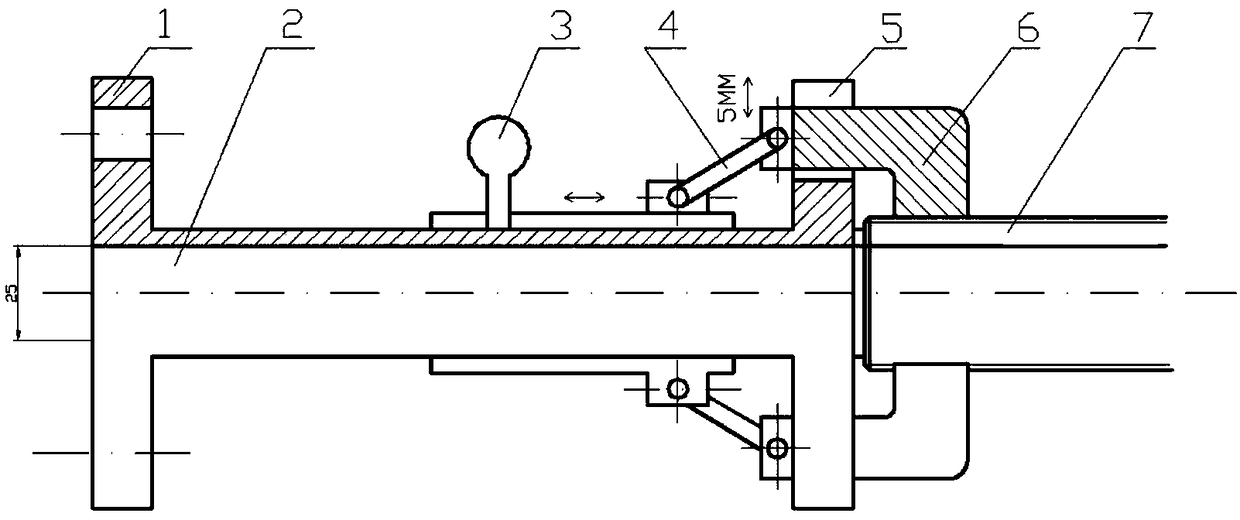

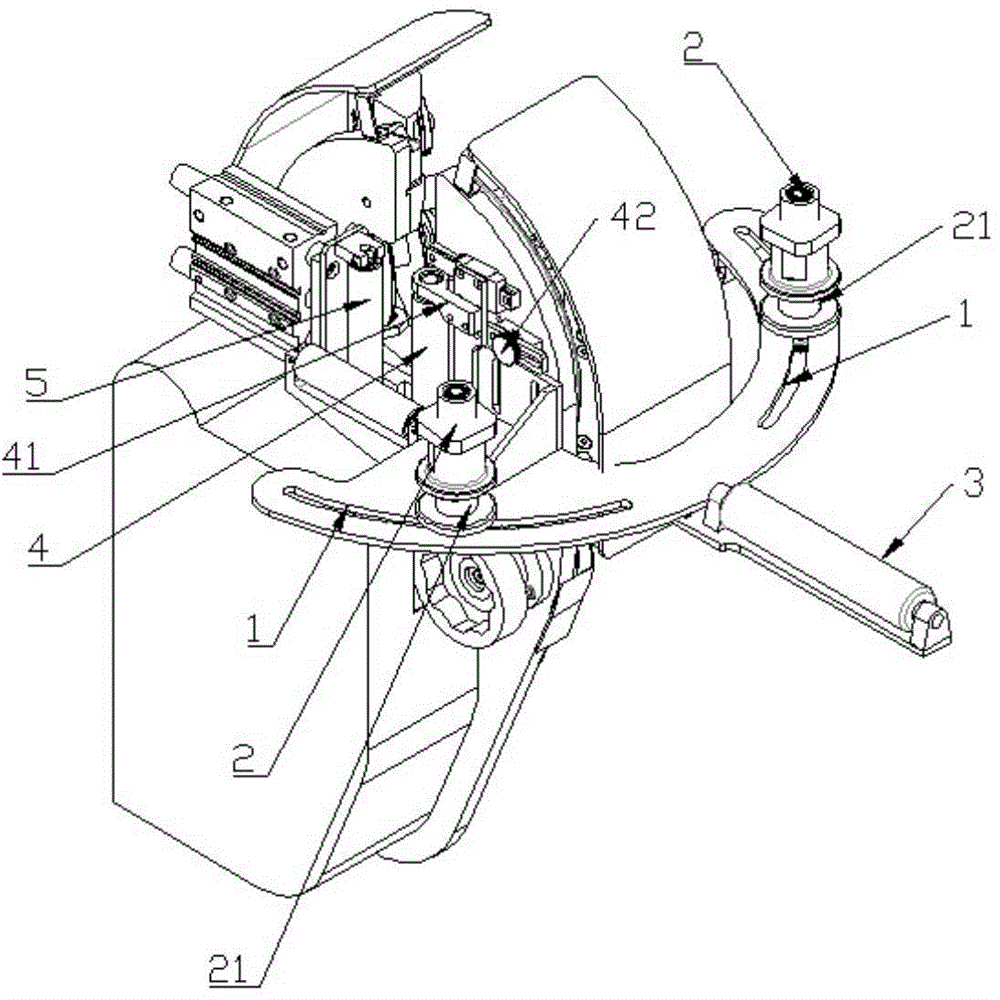

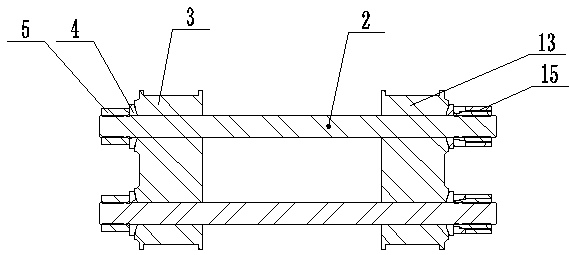

The invention relates to a bearing mounting tool with a centering function; the bearing mounting tool comprises a pressure head (1), a guide shaft (2) and a spring (3); the guide shaft (2) is installed inside the pressure head and is capable of moving axially inside the pressure head (1); the spring (3) is arranged at one end of the guide shaft (2); the other end of the spring (3) is pressed against the internal wall of the pressure head (1); the other end of the guide shaft (2) is capable of being stretched out of the end part of the pressure head (1); the external diameter of the part of the guide shaft (2) stretched out of the pressure head (1) is equal to the internal diameter of the hollow part of a shaft equipped with a bearing; and the internal diameter of the pressure head (1) matches with the external diameter clearance of the shaft to be mounted with the bearing. The centering function during installation is realized; no deflection of the bearing during installation is guaranteed and the requirement without damaging the bearing, the shaft and the bearing seat is satisfied.

Owner:HARBIN DONGAN ENGINE GRP

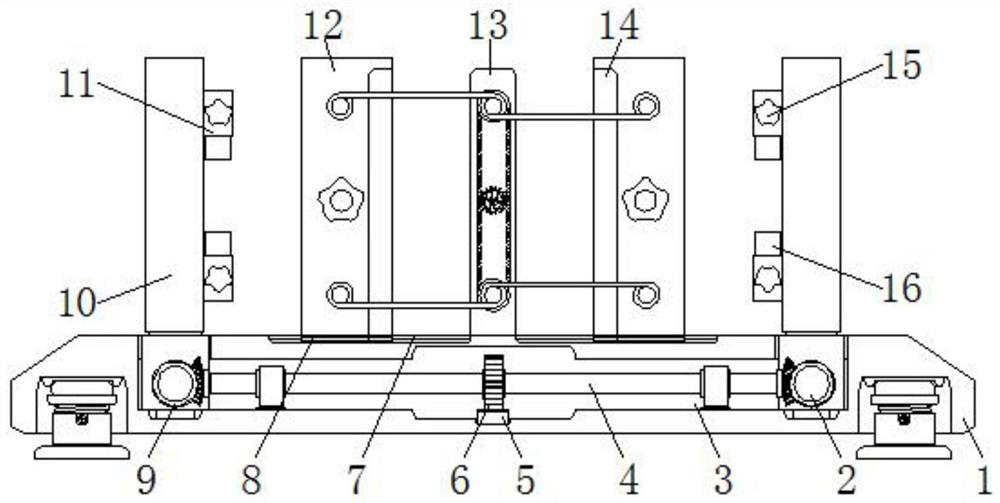

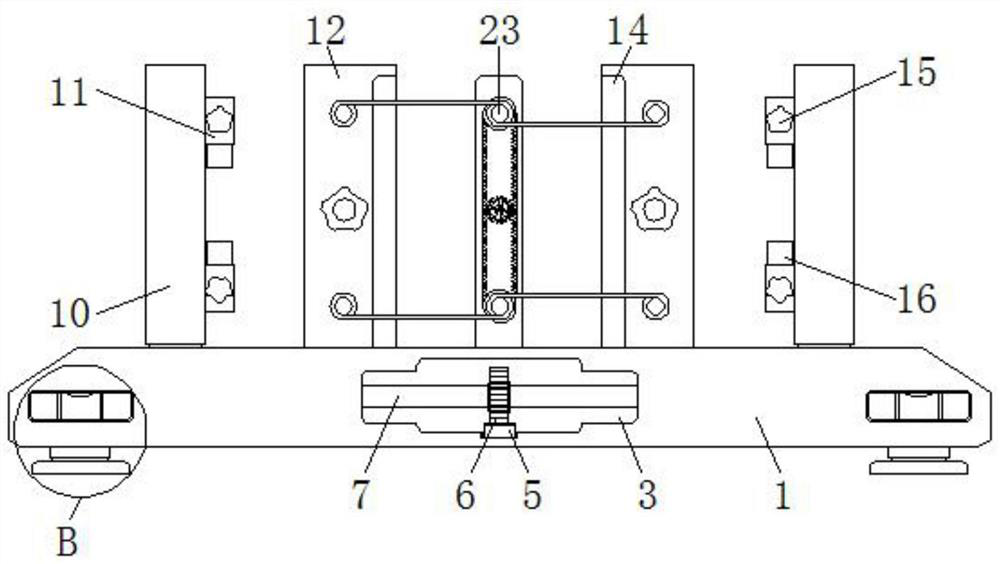

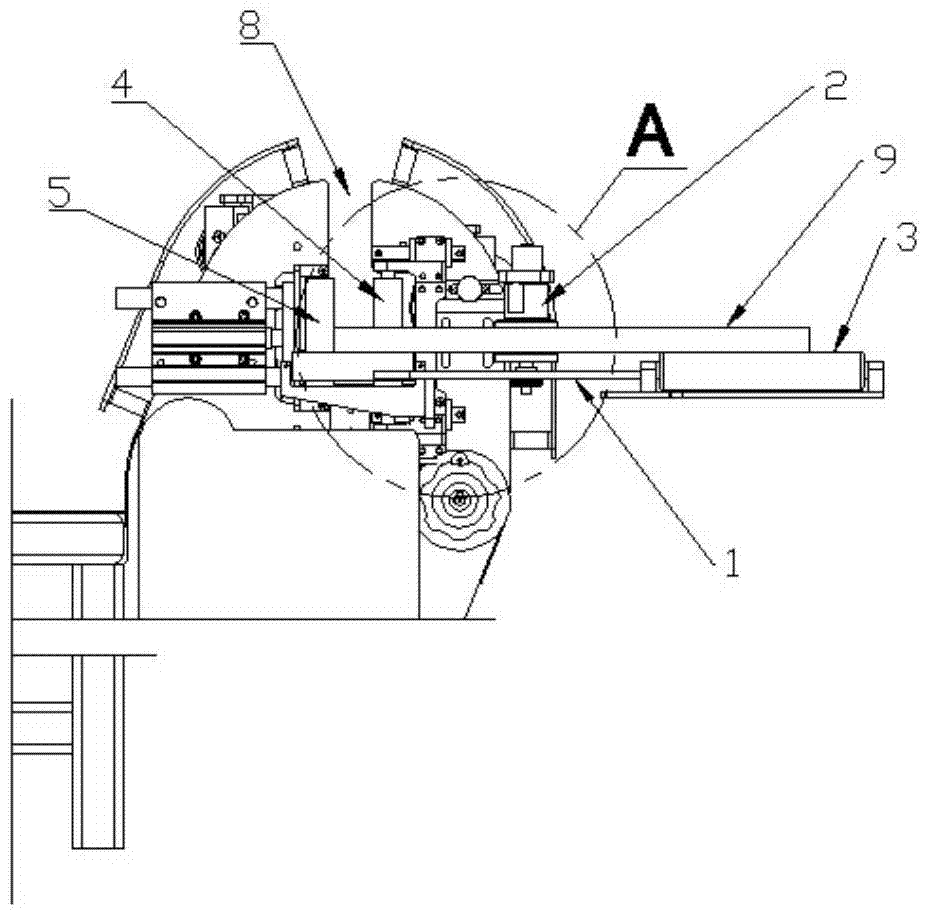

Tube tool centering device

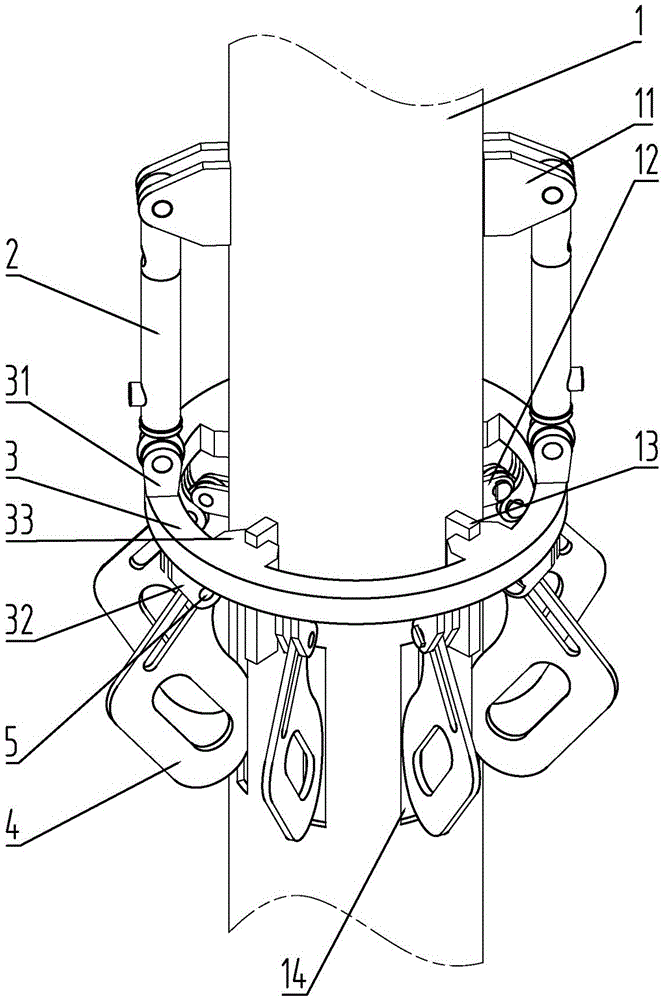

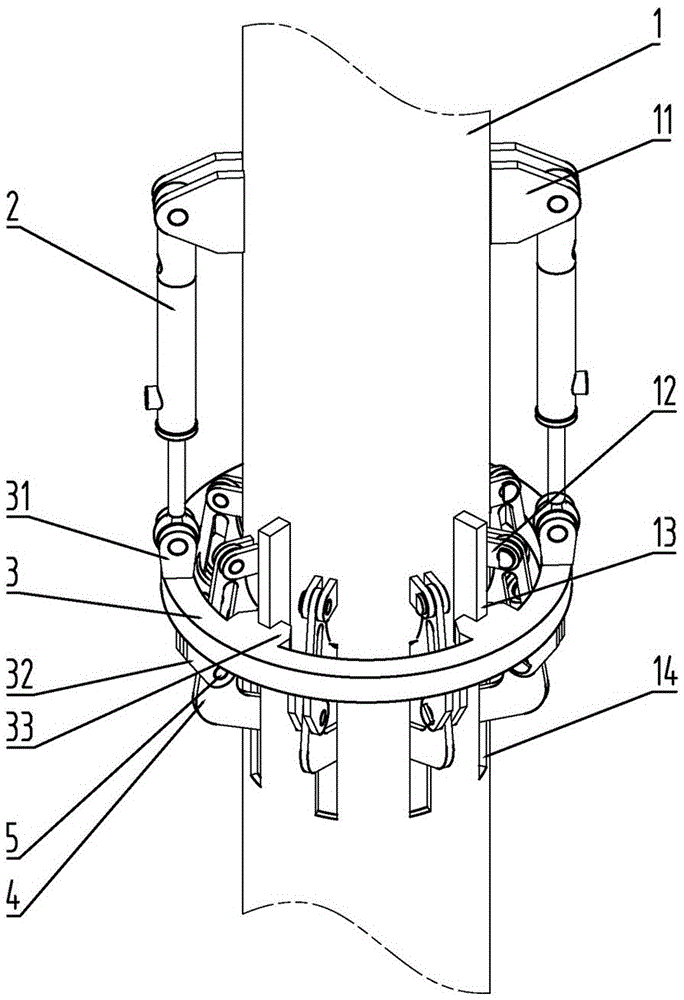

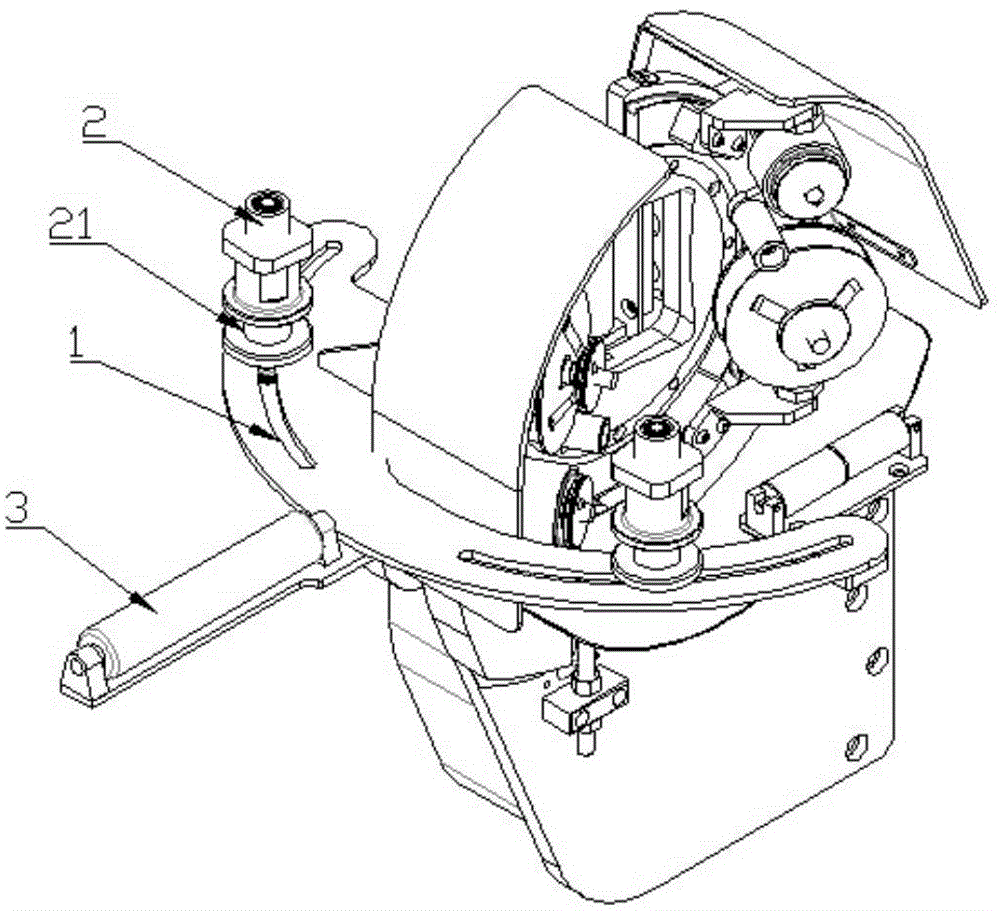

ActiveCN105937374ARealize the centering functionGood centering and reliableDrilling rodsDrilling casingsOil and natural gasTube tool

The invention relates to the technical field of oil and natural gas drilling, in particular to a tube tool centering device. The tube tool centering device comprises a foundation support fixedly connected with a mounting foundation, drive oil cylinders movably connected with the foundation support through support lugs on the foundation support, a transition bracket movably connected with the drive oil cylinders and the foundation support and centering plates movably connected with the foundation support and the transition bracket respectively. The tube tool centering device is simple in structure, small in size and high in centering accuracy.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

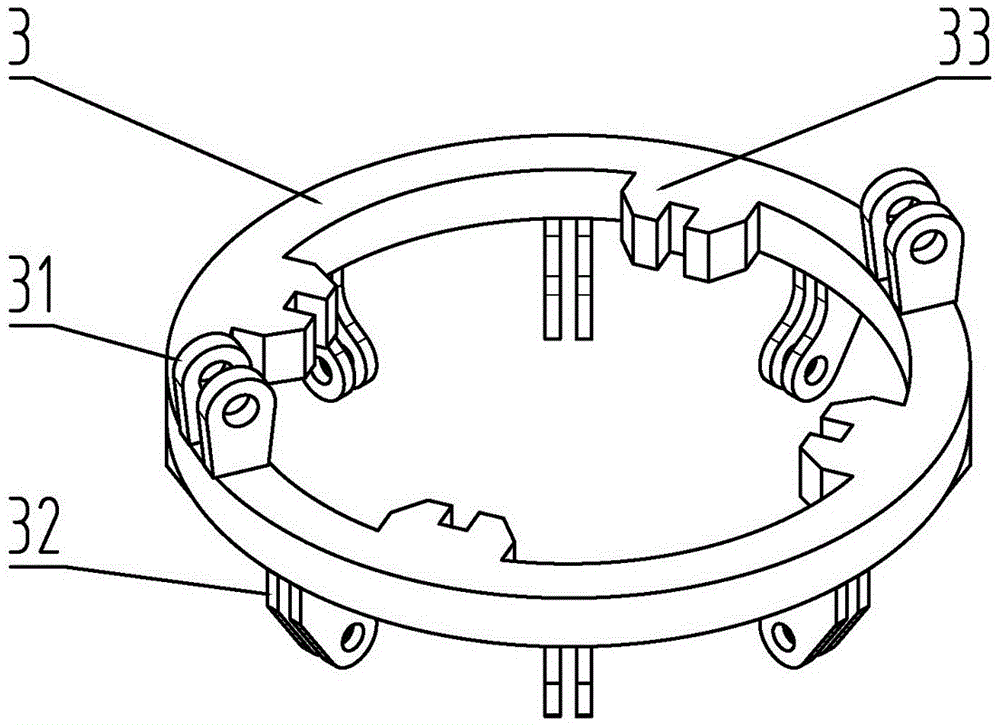

Self-centering chuck device

The invention discloses a self-centering chuck device. The self-centering chuck device comprises a pipeline flange plate provided with a standard straight pipe section and a chuck assembly which sleeves the pipeline flange pipeline, wherein the chuck assembly comprises a positioning screw rod, a chuck body and a movable clamping claw, wherein the chuck body is composed of a chuck and a sleeve; oneend of the sleeve sleeves the standard straight pipe section, the other end of the sleeve is connected with the chuck, and a boss is arranged on the outer wall of the sleeve; a clamping claw drivingrod is further arranged, and the two ends of the clamping claw driving rod are hinged to the boss and the movable clamping claw correspondingly; and a clamping groove used for containing the movable clamping jaw is formed in the chuck; a positioning hole is formed in the sleeve, and the positioning screw rod is connected with the positioning hole. According to the device, a portable design is adopted, the operation is simple and reliable, and the installation precision and the meter clamping efficiency of a flowmeter can be effectively improved, so that clamping requirements of various non-flange type flow meters can be met.

Owner:WUHAN INST OF MEASUREMENT & TESTING TECH

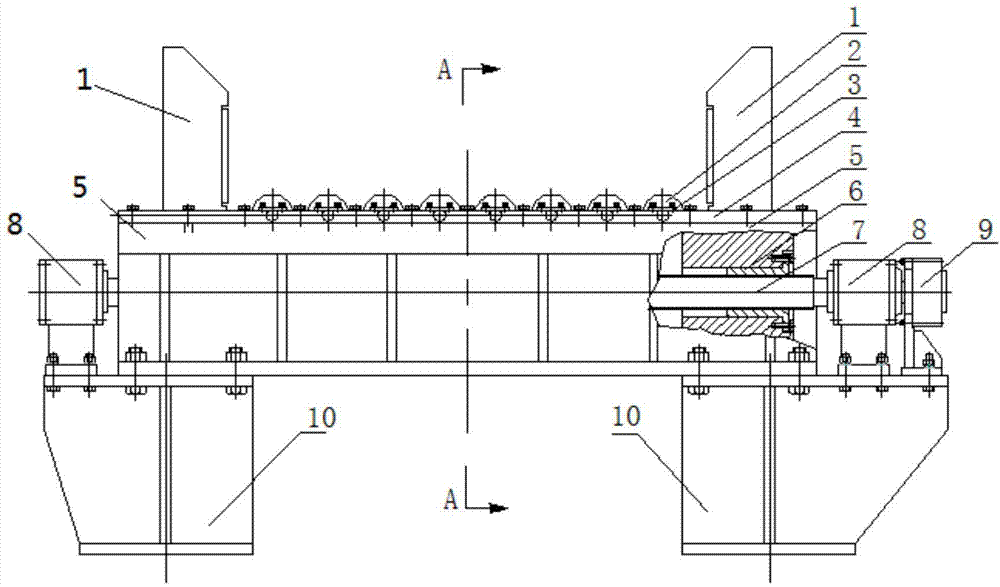

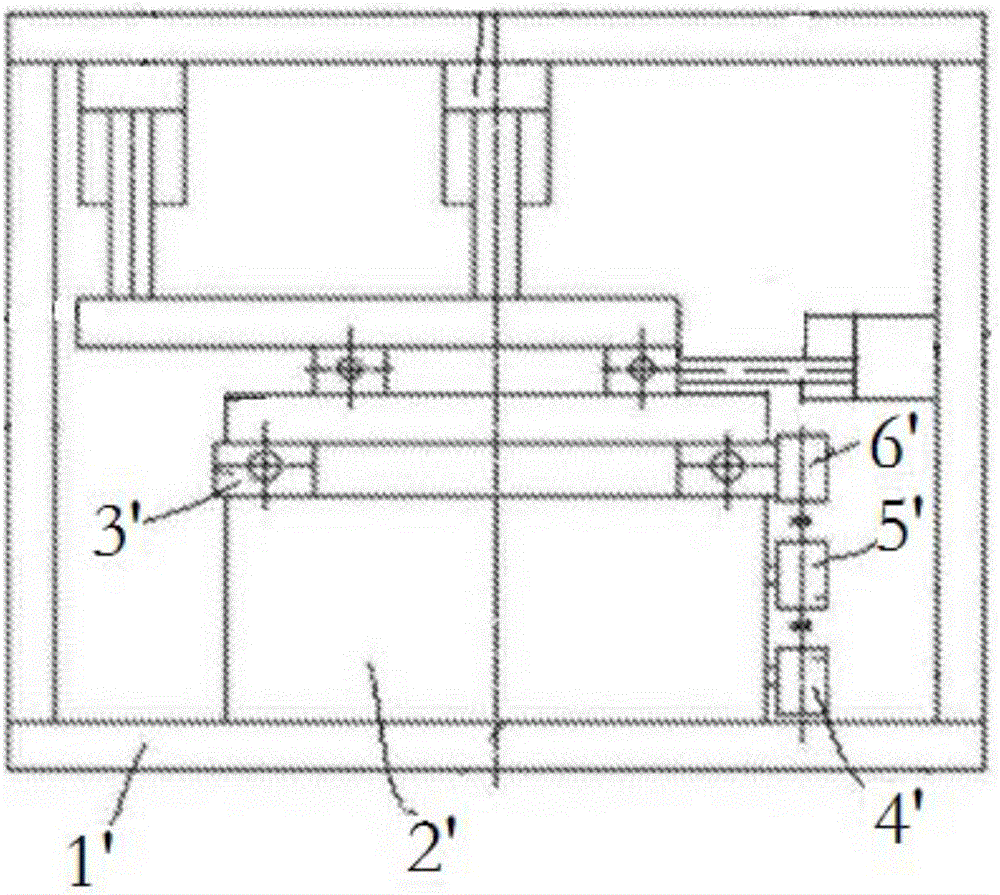

Centering mechanism

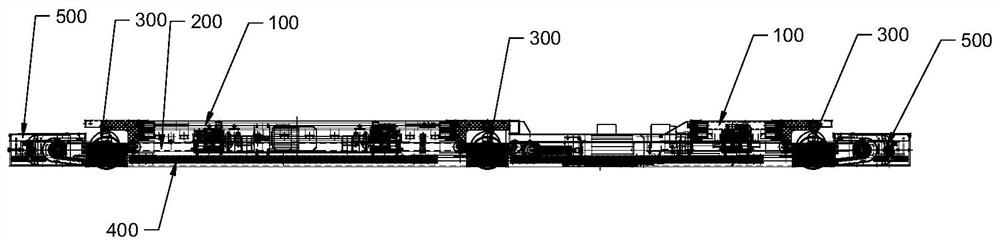

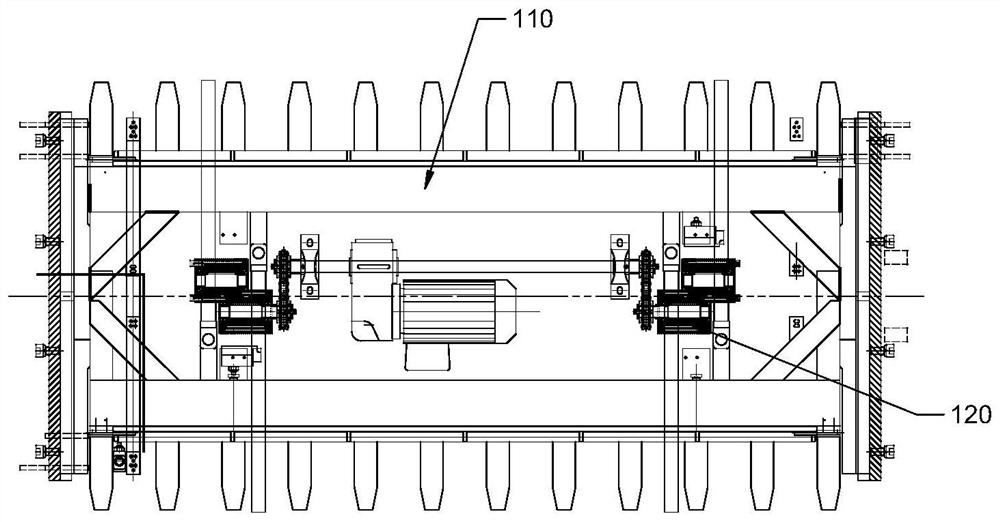

InactiveCN104843466ARealize the centering functionSimple structureConveyor partsReciprocating motionEngineering

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

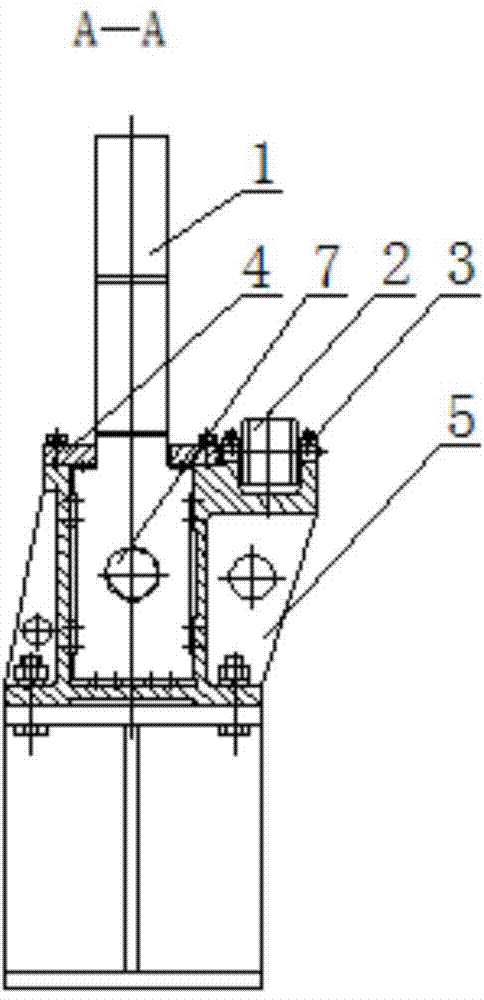

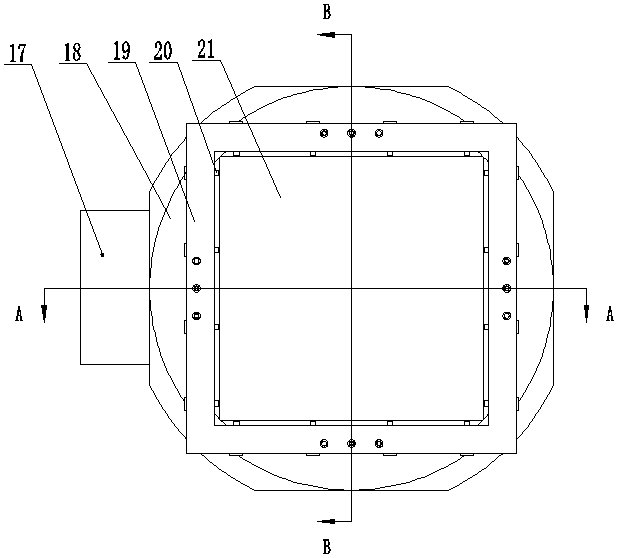

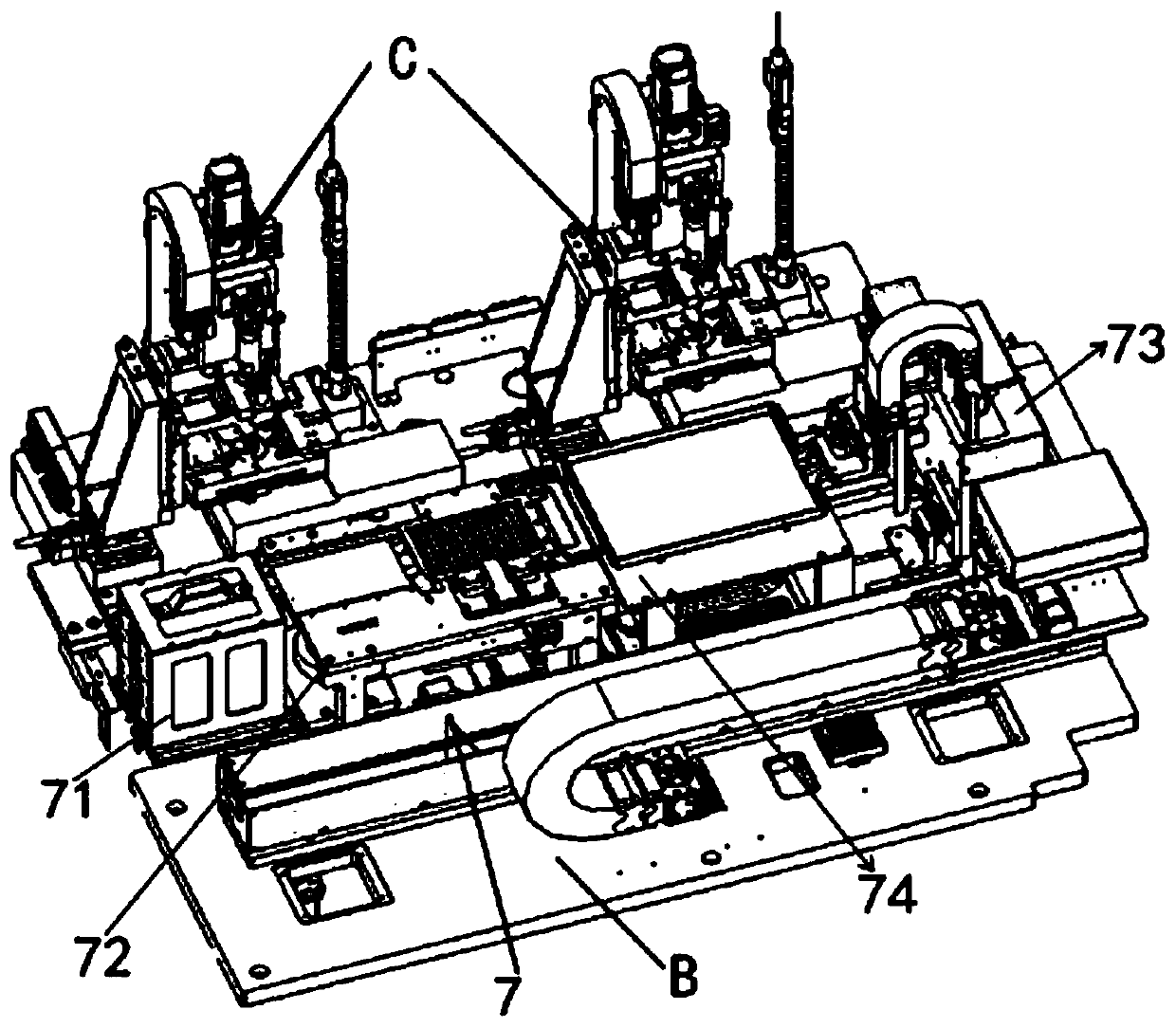

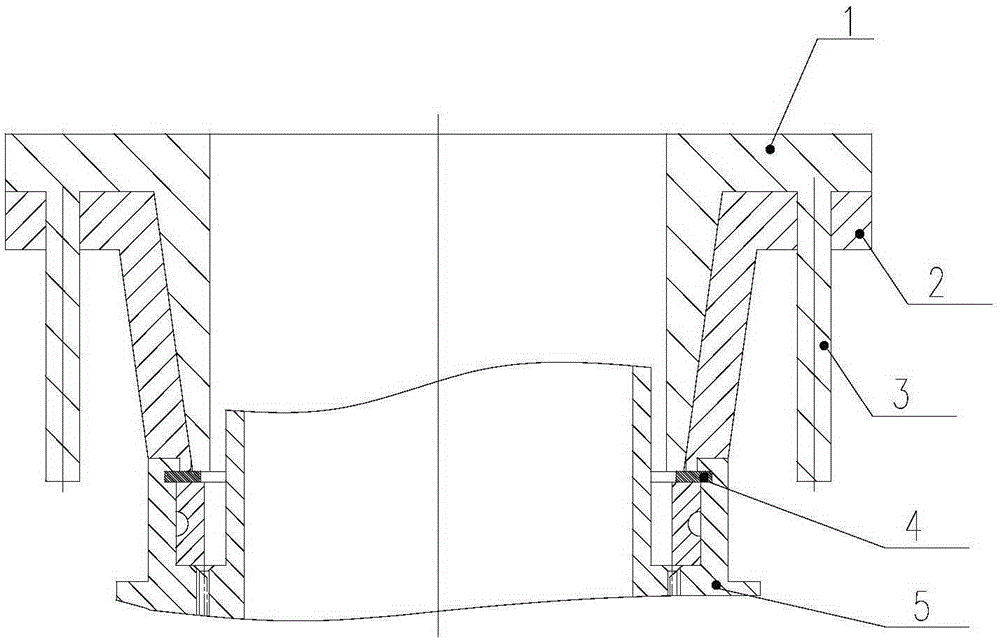

Big-tonnage rock engineering power disaster simulation experiment system

ActiveCN107860660AGuaranteed feasibilityCompact structureMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesEngineeringRock engineering

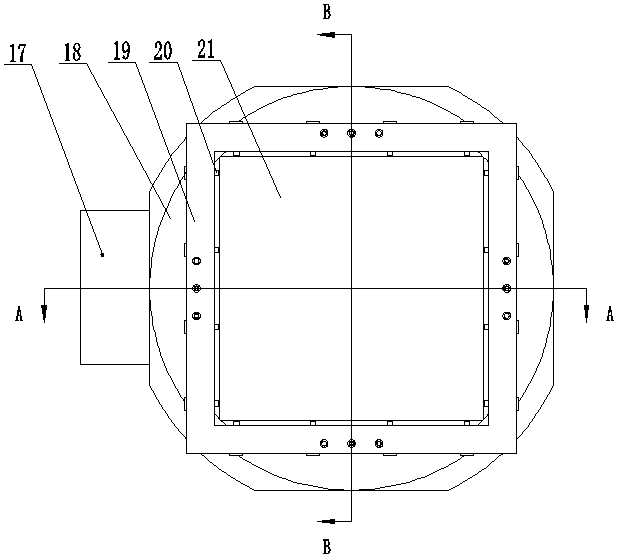

The invention provides a big-tonnage rock engineering power disaster simulation experiment system, and relates to equipment for performing experiments on big-tonnage rock. The equipment comprises a fixed base, a first base, an annular framework and a second base, wherein an upper and lower loading cylinder and a left and right loading cylinder are connected in the annular framework; a front and back loading cylinder is connected onto one side surface of the second base; each of the upper and lower loading cylinder, the left and right loading cylinder and the front and back loading cylinder comprises a static loading cylinder tube, a movable loading cylinder tube, a static loading piston rod and a movable loading piston rod; a movable loading cylinder tube installing cavity and a static loading rodless cavity are arranged in the static loading cylinder tube; the movable loading cylinder tube is arranged in a movable cylinder tube installing cavity; the static loading piston rod is arranged in the static loading rodless cavity; one end of the movable loading piston rod is provided with a movable loading piston; the movable loading piston is arranged in the movable loading cylinder tube; the other end of the movable loading piston rod penetrates through a press cover of the movable loading cylinder tube and the static loading piston rod, and is then connected with a replaceable punching head; one end, extending out of the static loading cylinder tube, of the static loading piston rod is provided with a fixing flange and a loading block. The static loading and the movable loading can be realized; the static loading and the movable loading can be also performed at the same time.

Owner:YANGZHOU JIANGDU YONGJIAN

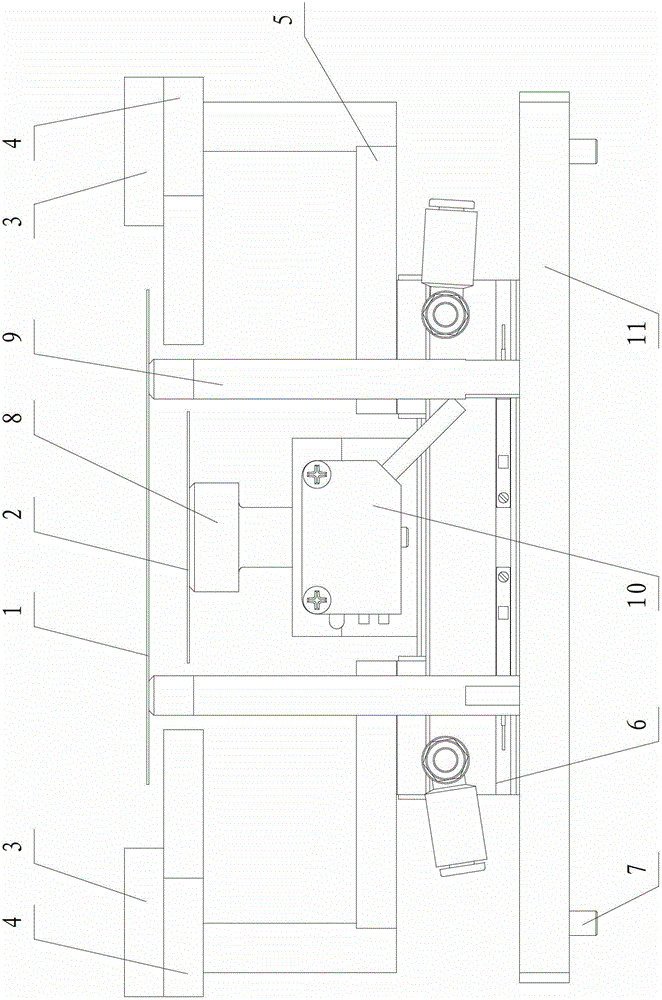

Lens centering device and automatic centering equipment

PendingCN109682578AGuaranteed accuracyGuaranteed eccentricity detection accuracyUsing optical meansOptical axis determinationAutomatic test equipmentOptoelectronics

The invention relates to a lens centering device and automatic centering equipment. The lens centering device comprises a supporting table (1), a lens supporting platform (2) connected with the supporting table (1), a light source assembly (3), a detection camera (5), an adjusting assembly (6) and an exposure assembly (4), wherein the light source assembly (3) and the detection camera (5) are located on two opposite sides of the lens supporting platform (2) and are coaxially arranged, and the adjusting assembly (6) is located on one side of the lens supporting platform (2); the lens supportingplatform (2) is provided with a rotary assembly (21) used for driving the lens supporting platform (2) to rotate. The automatic centering equipment can realize automatic feeding and discharging and automatic centering detection, eccentric detection can be carried out while the working efficiency is improved, and the centering precision can be guaranteed.

Owner:NINGBO SUNNY INSTR

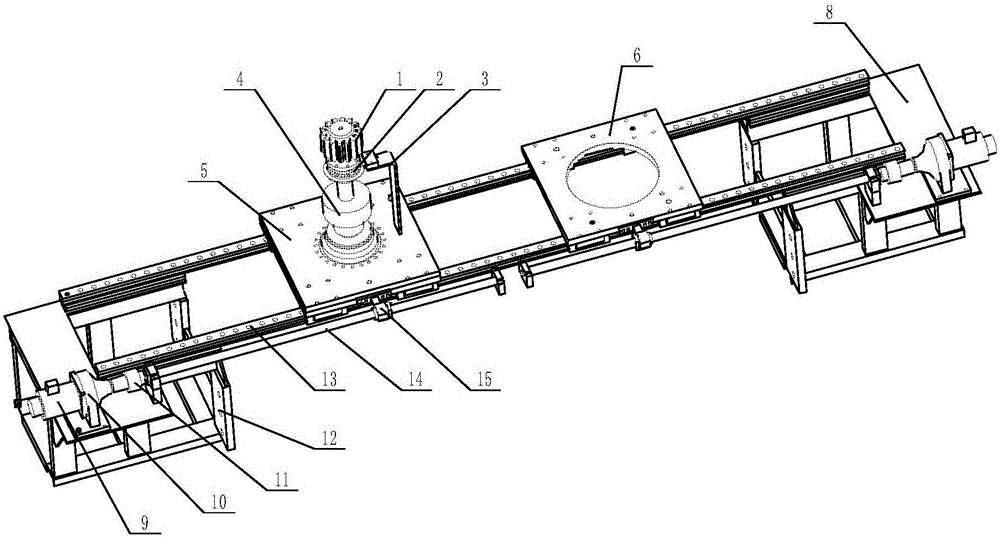

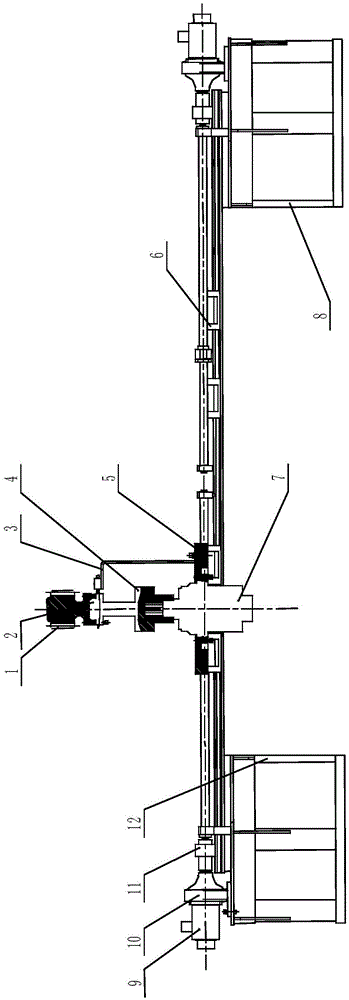

Rotary support test table aligning device and rotary supporting test table

ActiveCN106017933AGeneralizationRealize the centering functionMachine bearings testingComputer engineeringTranslatory motion

Owner:SUOTE TRANSMISSION EQUIP

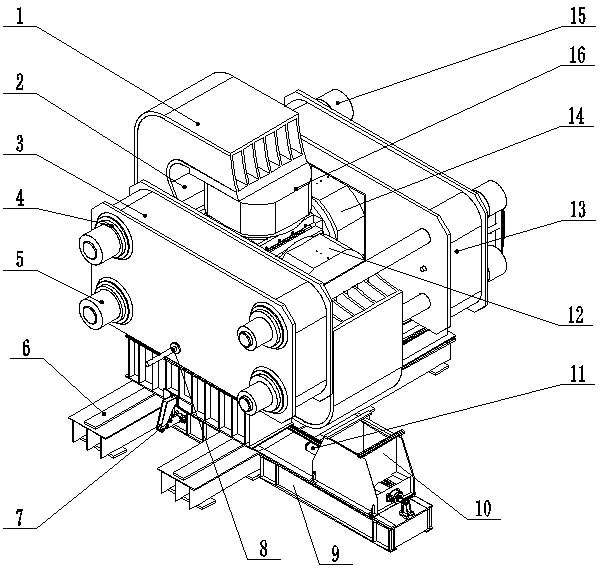

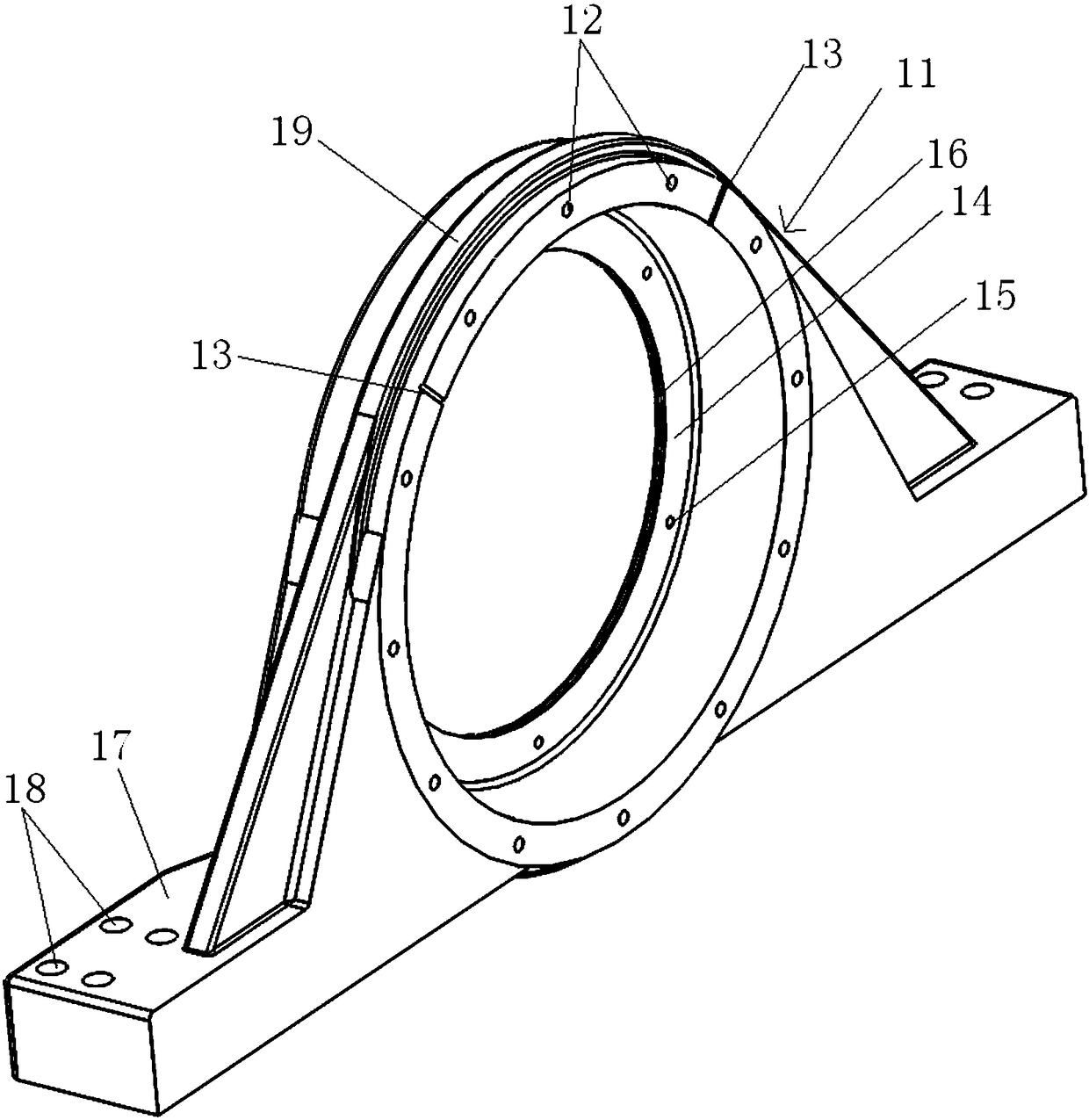

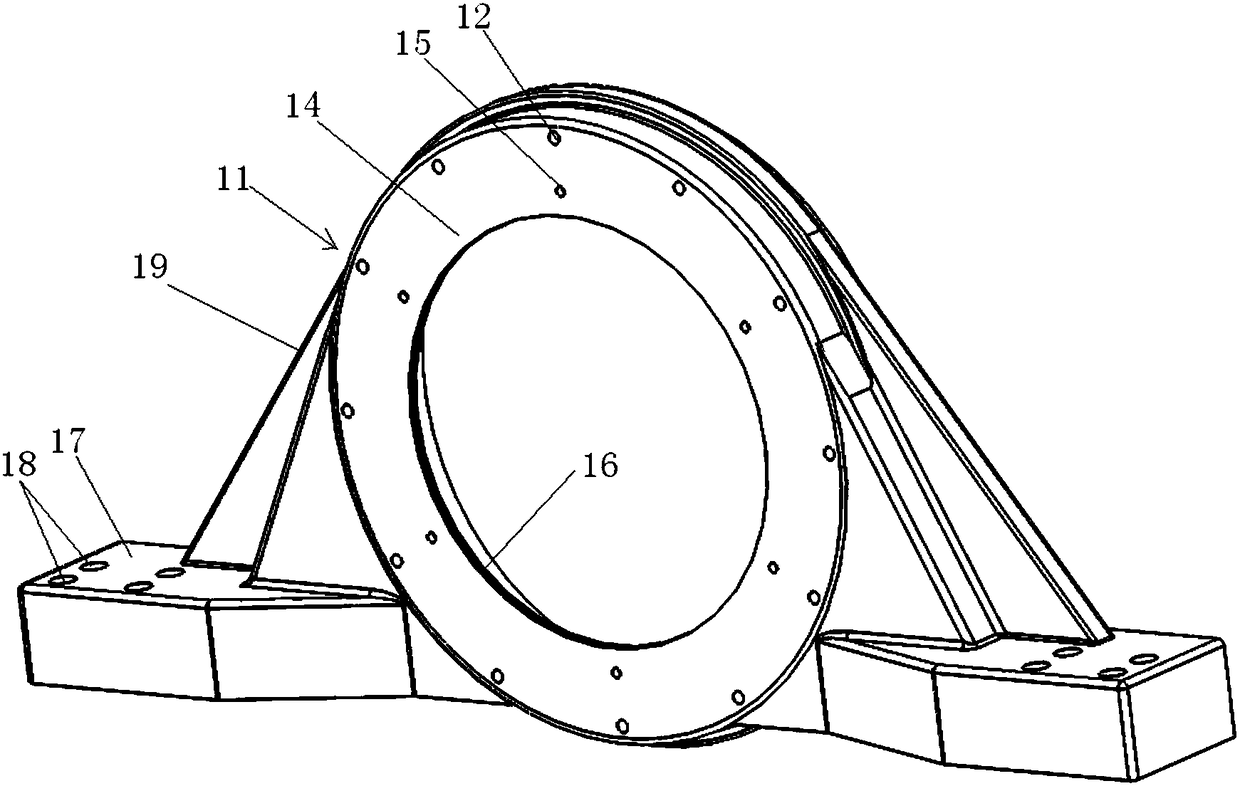

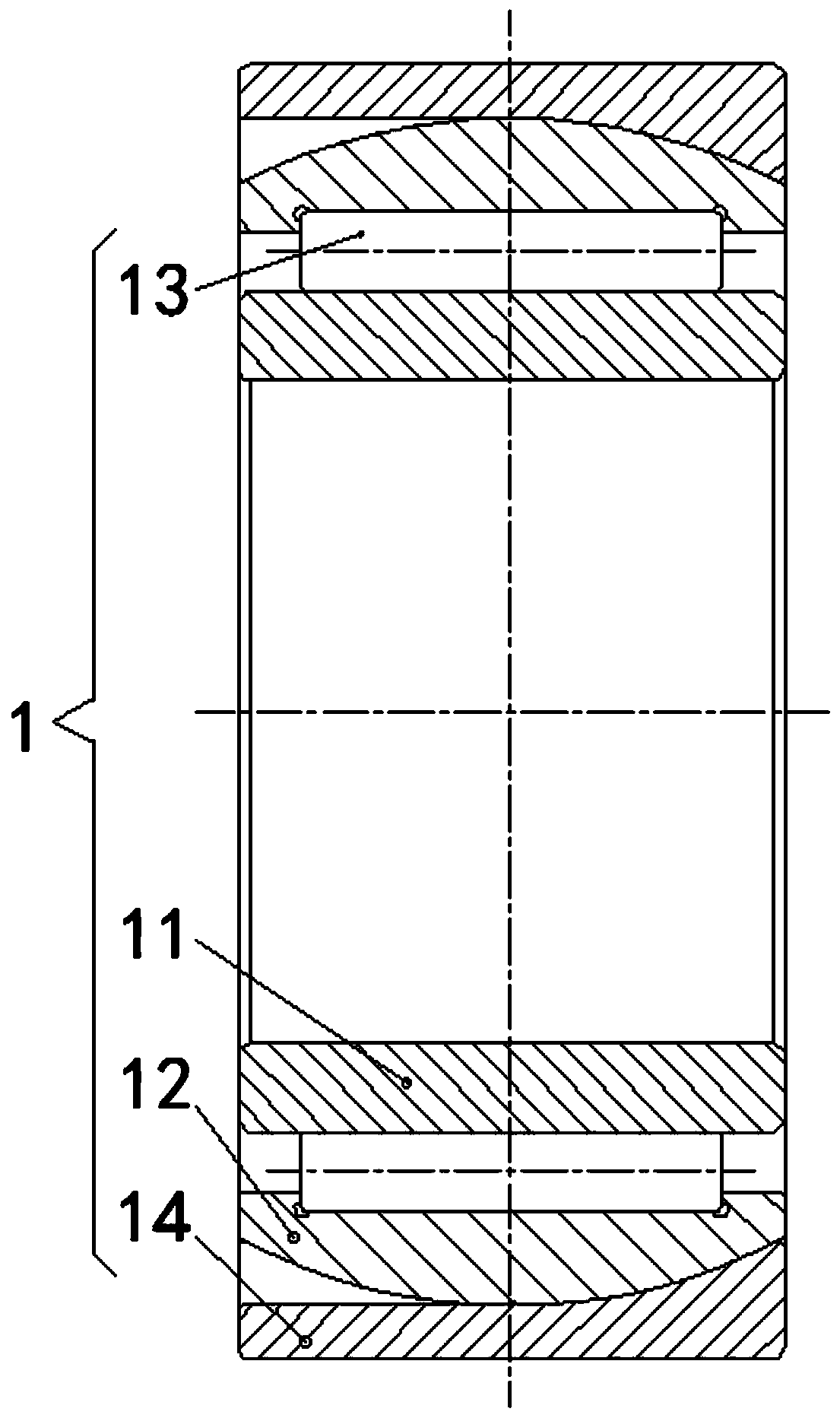

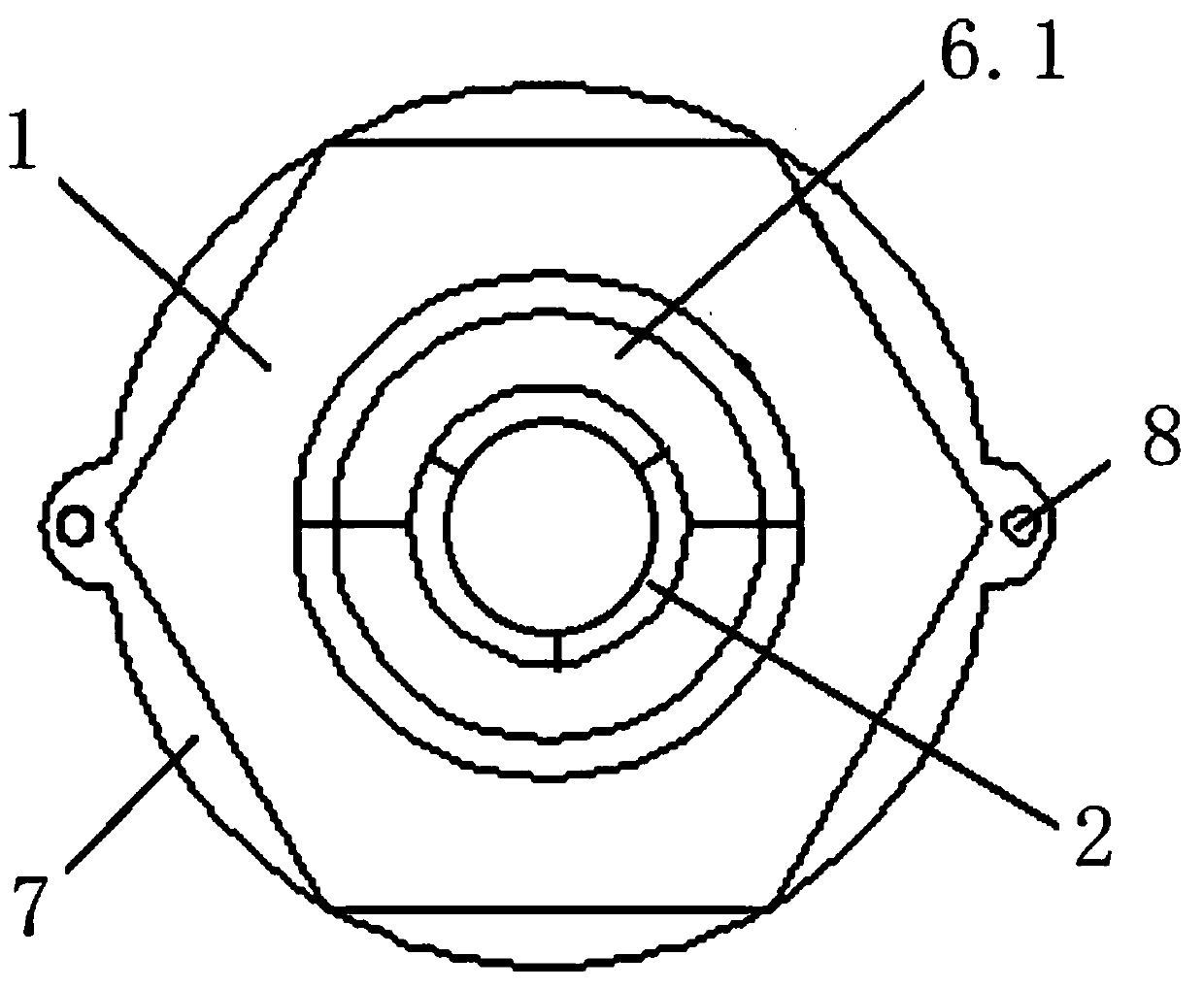

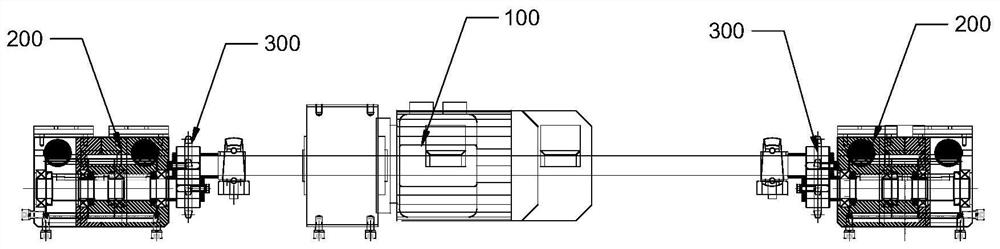

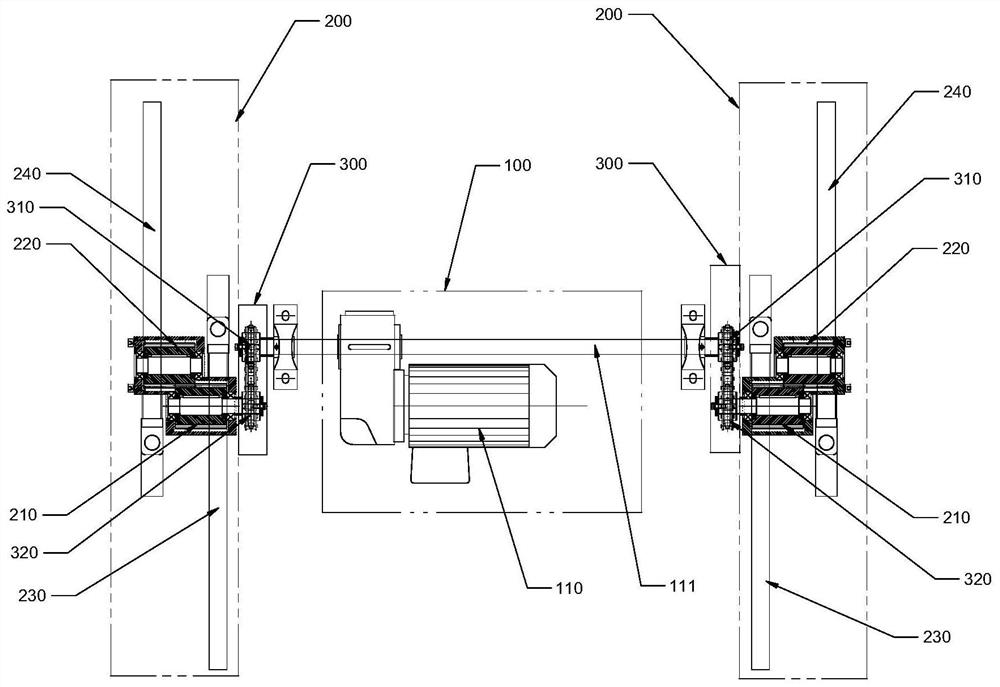

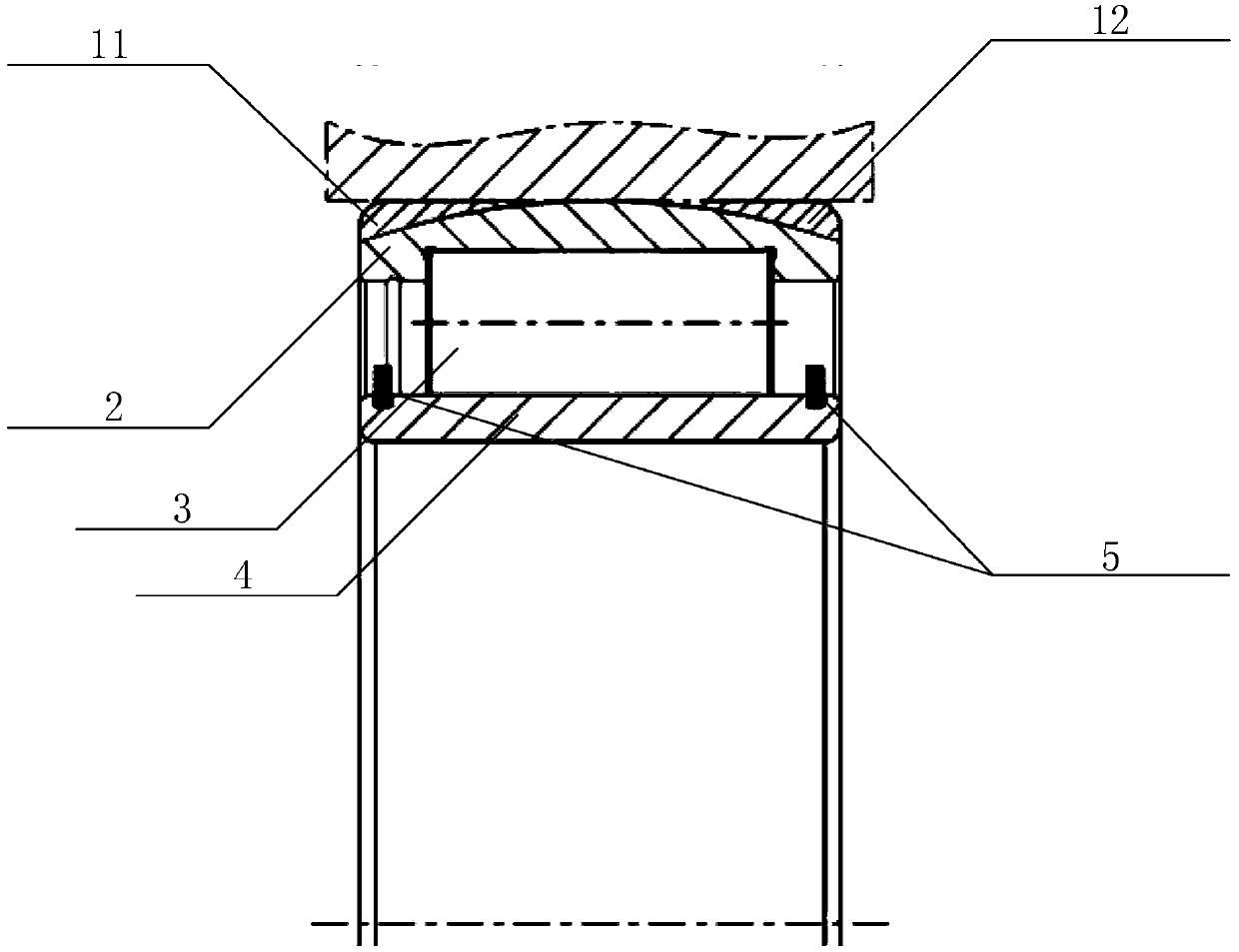

Modular centering bearing device

PendingCN108266456ARealize the centering functionEasy to useRoller bearingsBearing unit rigid supportModular designModularity

The invention discloses a modular centering bearing device, which comprises a division bearing box and a conical roller bearing arranged in the division bearing box, wherein the outer surface of the outer ring of the conical roller bearing and the radial surface of the inside of the bearing box are in gap matching by using a spherical surface structure. The conical roller bearing is a double-row conical roller bearing. The division bearing box comprises two bearing box units in symmetrical arrangement; the two bearing box units are connected through screw bolts; a radial oil injection hole isformed in the bearing box unit; an oil groove communicating with the oil injection hole is formed in the middle of the outer surface of the outer ring of the conical roller bearing along the circumference; a plurality of oil inlet holes are formed in the bottom of the oil groove. The advantages of the conventional centering roller bearing and the conical roller bearing are merged; the prestress caused by assembly errors in the assembly can be effectively avoided; the unbalance loading phenomenon can also be avoided. The modular design is used; the processing is convenient; the assembly is facilitated; the device is suitable for being used as thrust bearings capable of bearing radial loads and axial loads.

Owner:GUODIAN UNITED POWER TECH

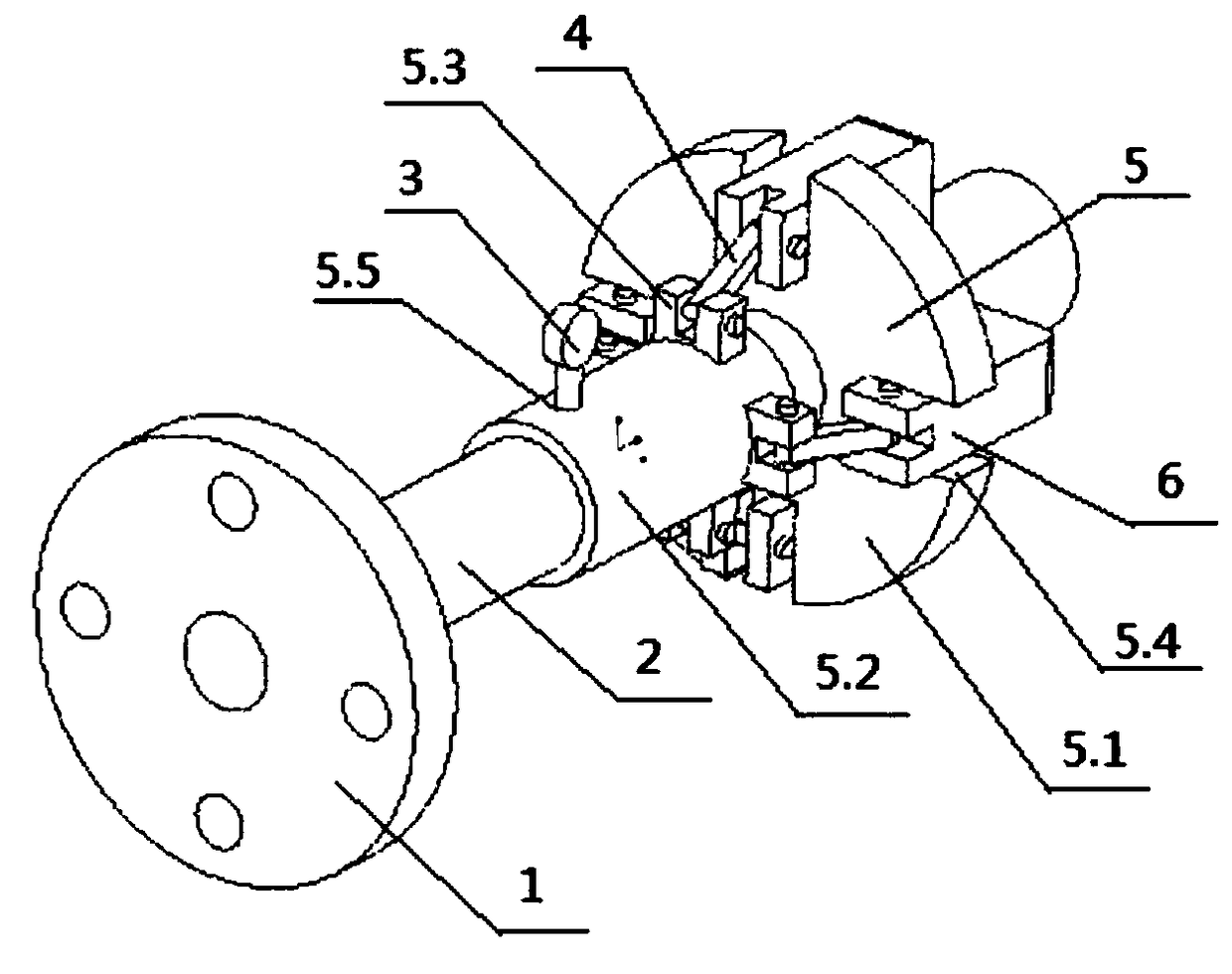

Self-centering pipeline mounting butt joint device

PendingCN112207554ARealize the centering functionImprove convenienceMetal working apparatusButt joint

The invention relates to the technical field of pipeline mounting, in particular to a self-centering pipeline mounting butt joint device. The self-centering pipeline mounting butt joint device comprises a device base body, wherein a centering cavity is formed in the device base body, lead screws are hinged to two ends in the centering cavity, and main oblique teeth are mounted in the centers of the surfaces of the lead screws. Nut blocks are in threaded connection to the surfaces of the lead screws on two sides of the main oblique teeth, clamping seats are arranged on two sides of two ends ofthe device seat body, supporting plates are fixed to the positions, on the inner sides of the clamping seats, of the surface of the device seat body, sliding grooves are formed in the positions, on two sides of the supporting plates, of the surface of the device seat body, and sliding seats are arranged in the sliding grooves; a traction base is fixed to the top end of the sliding base, and arc-shaped supporting plates are fixed to the outer walls of one sides of the clamping bases. According to the invention, the centering function of the butt joint device during pipeline butt joint is achieved, the convenience of the butt joint device during pipeline butt joint is improved, and the application range of the butt joint device is widened.

Owner:江苏申新工程有限公司

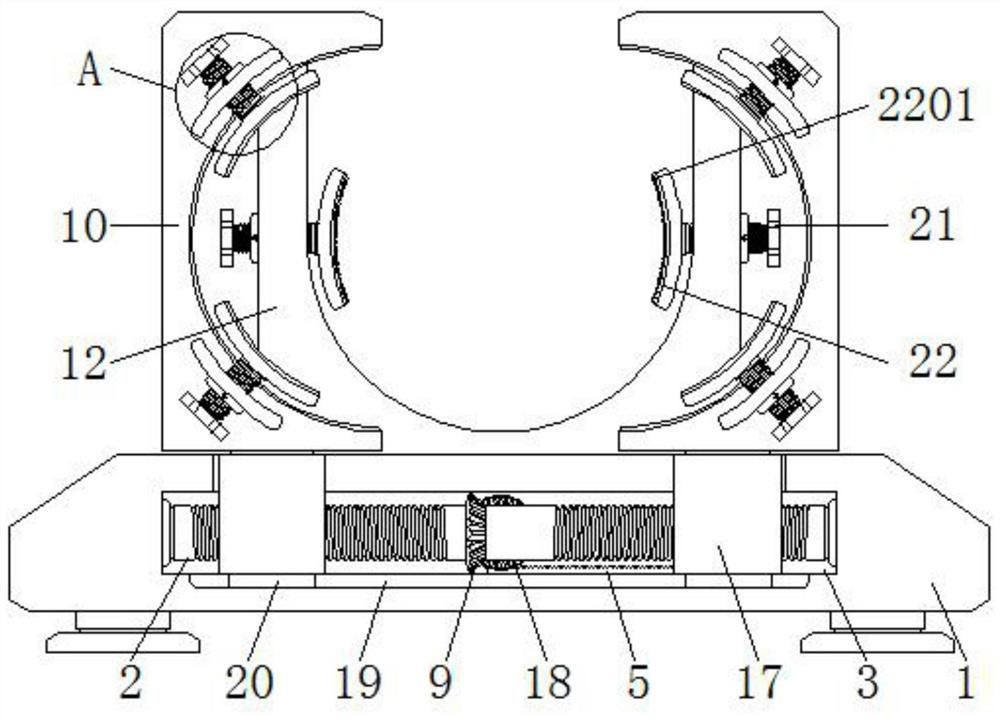

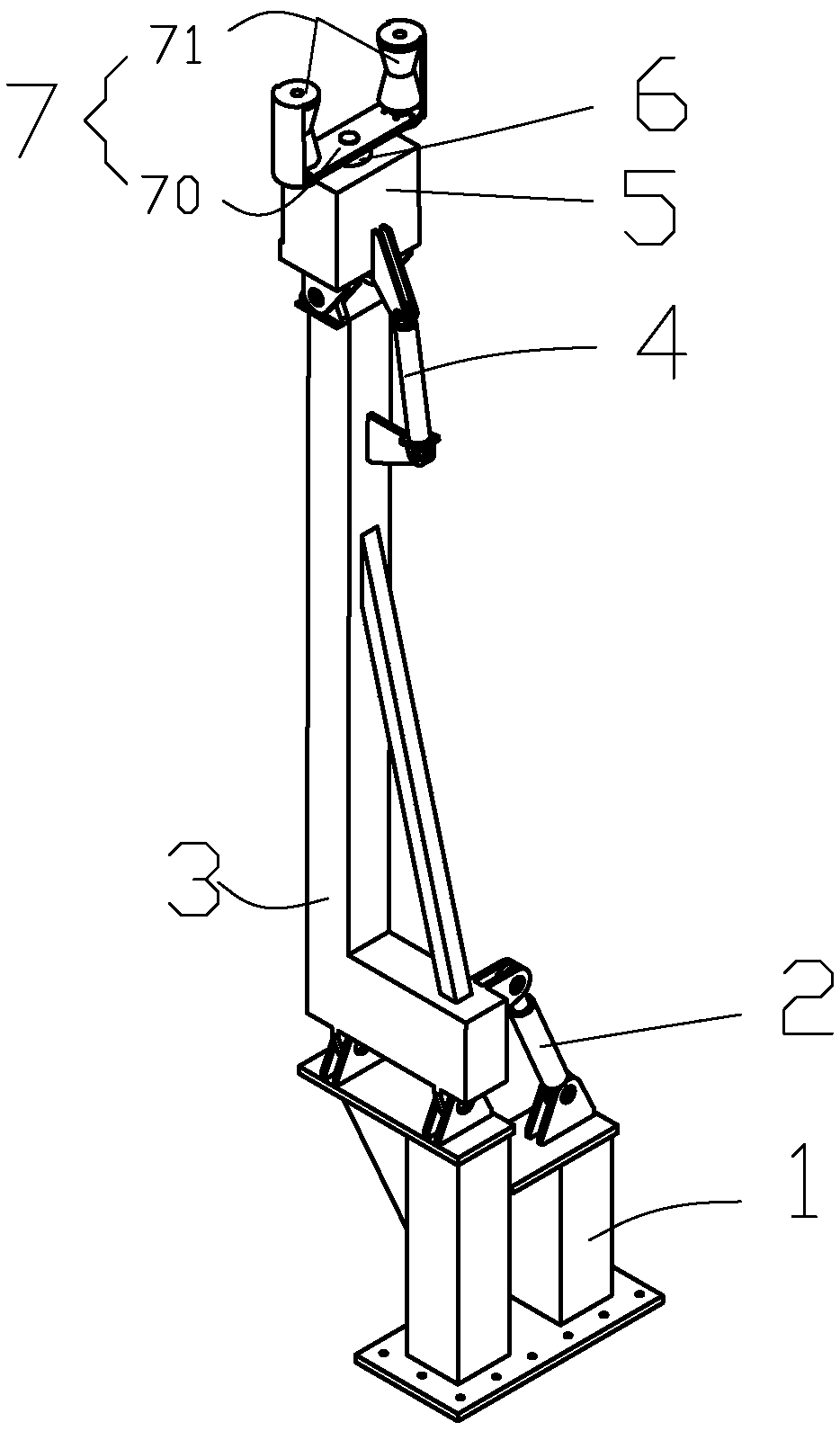

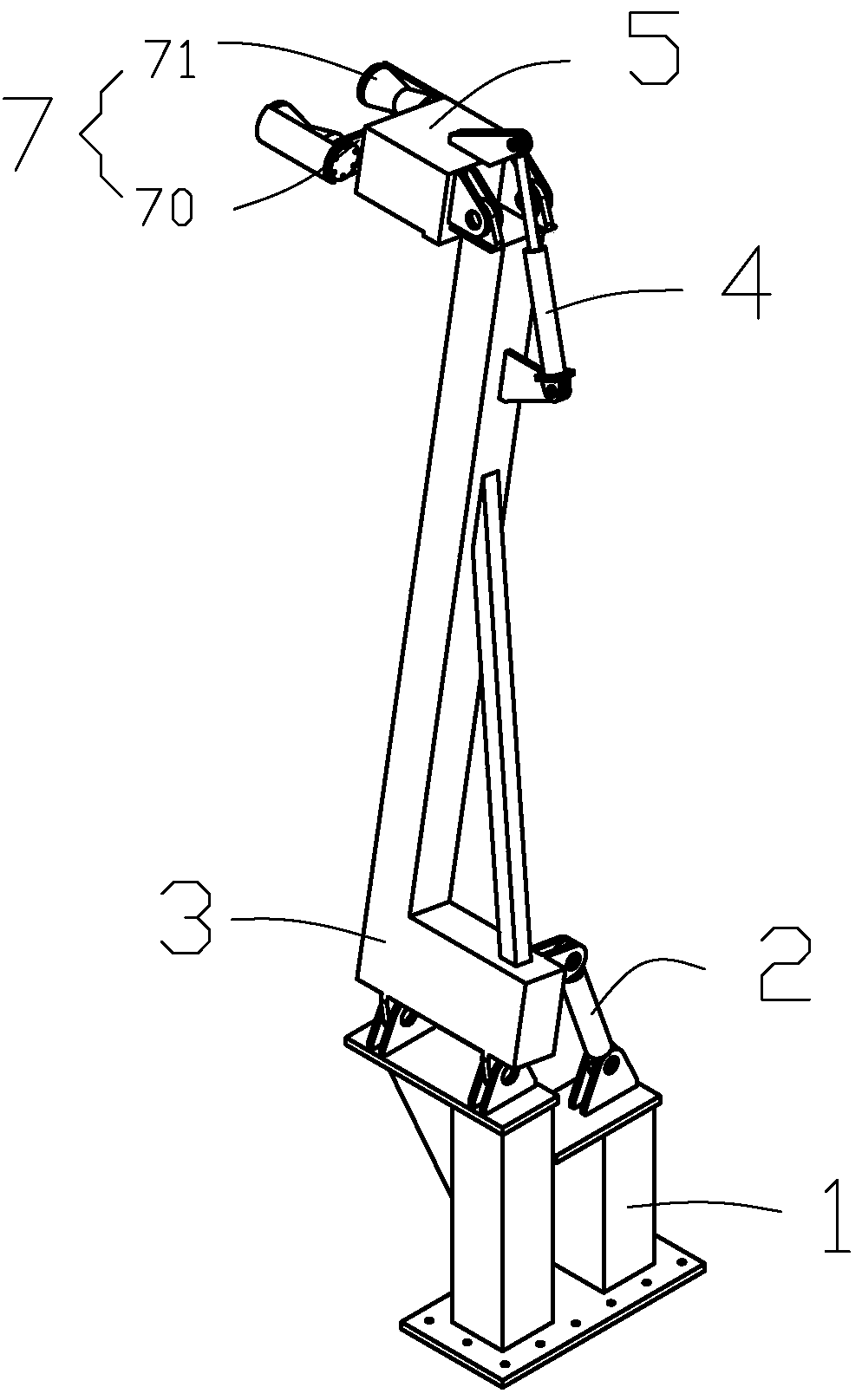

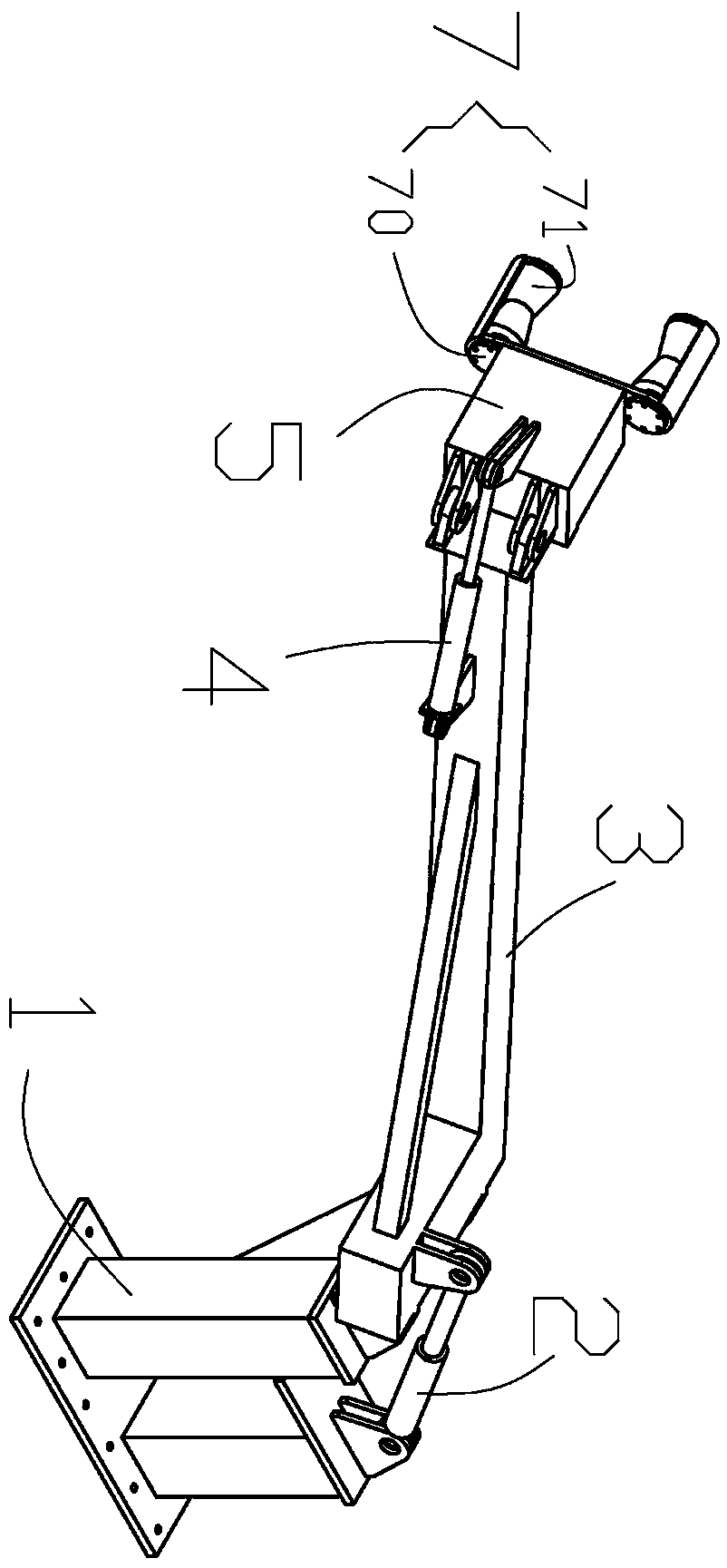

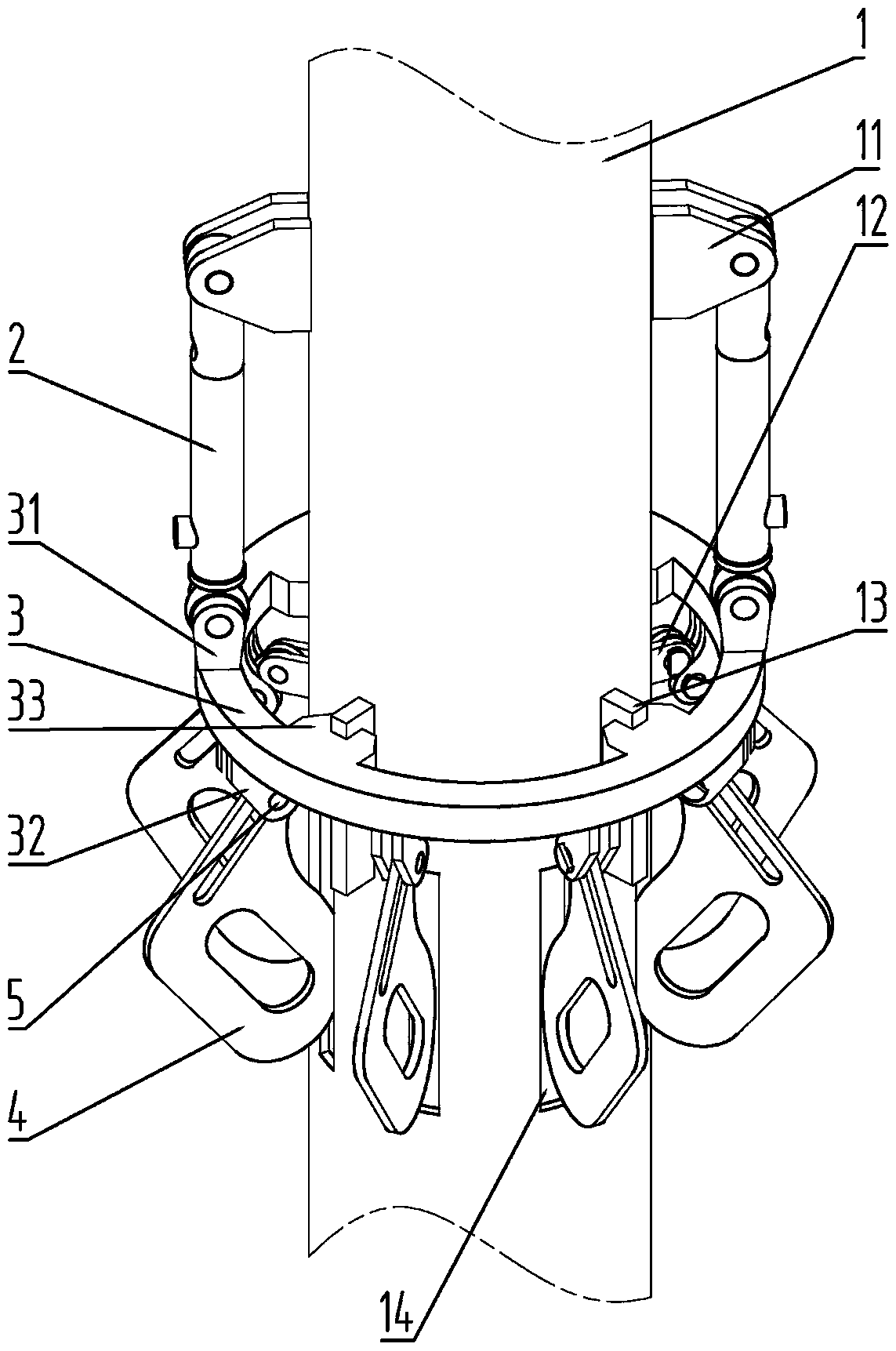

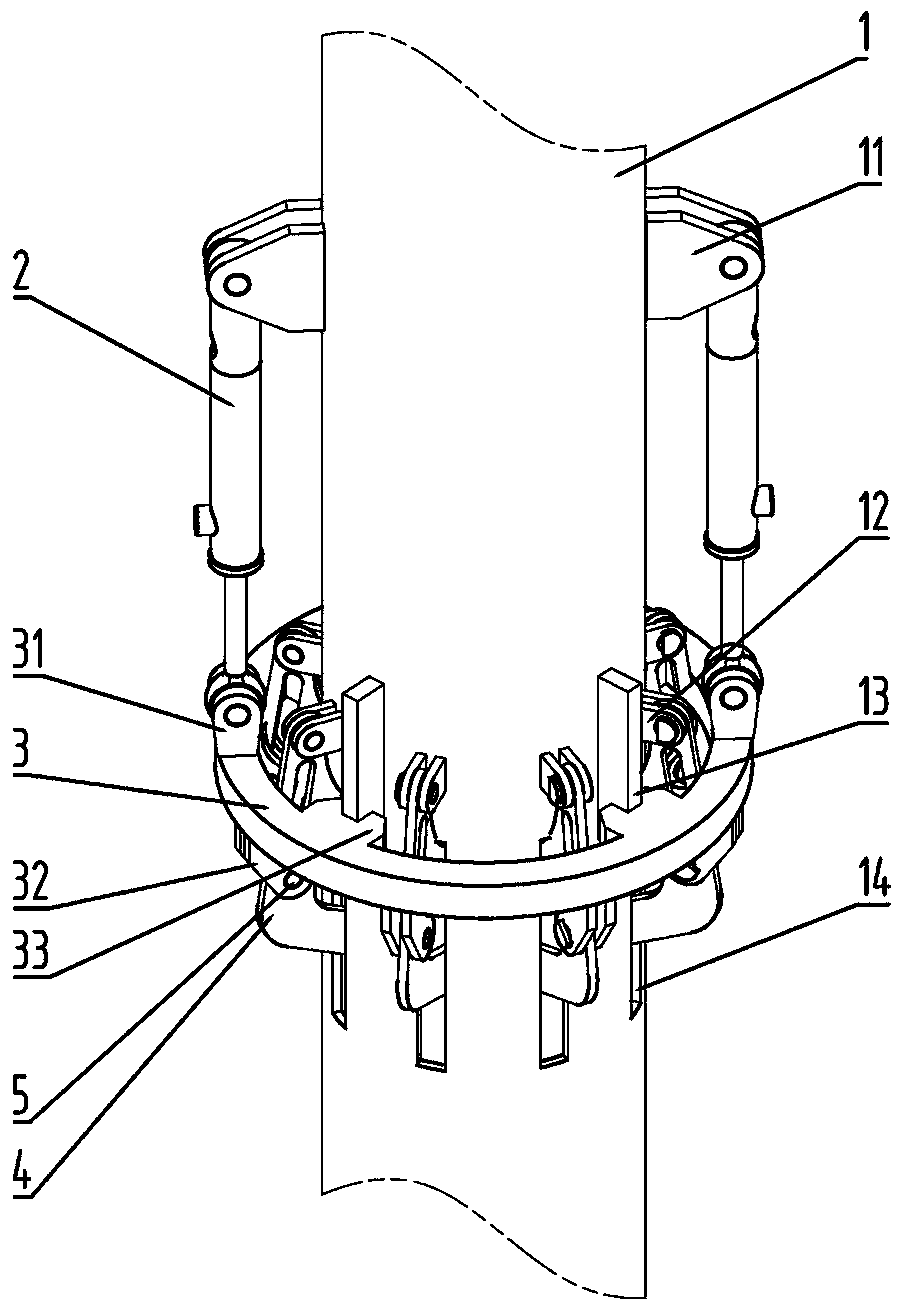

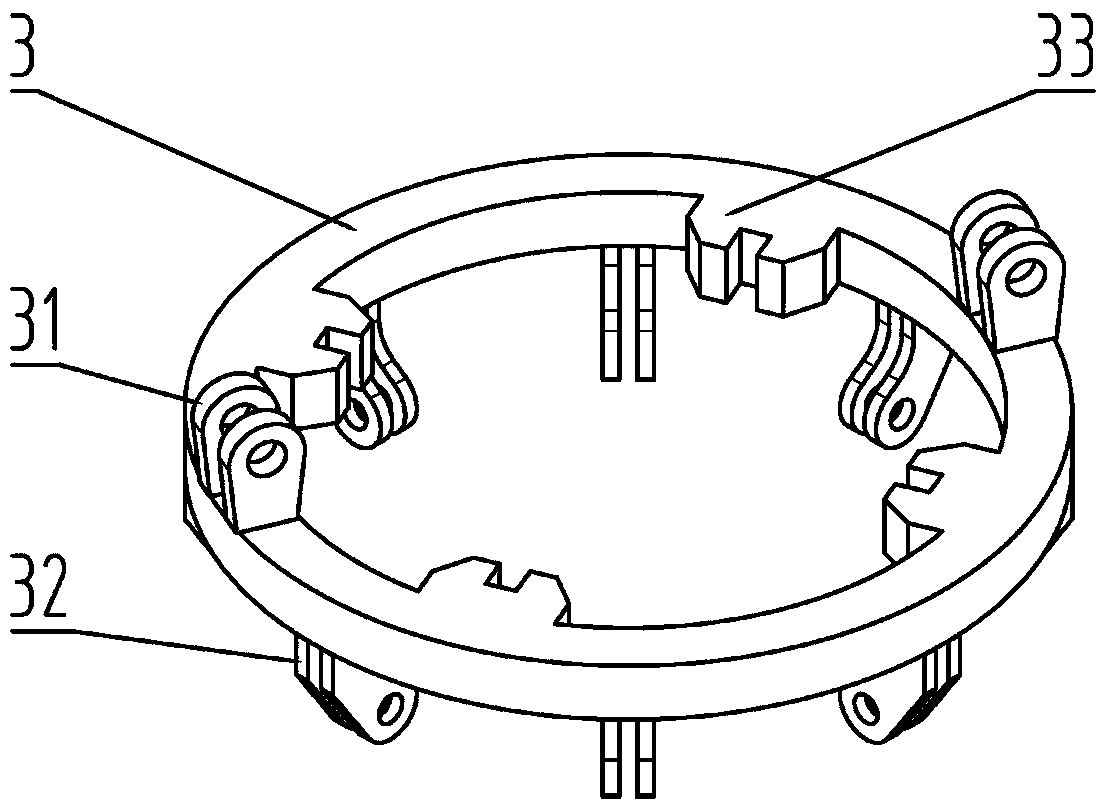

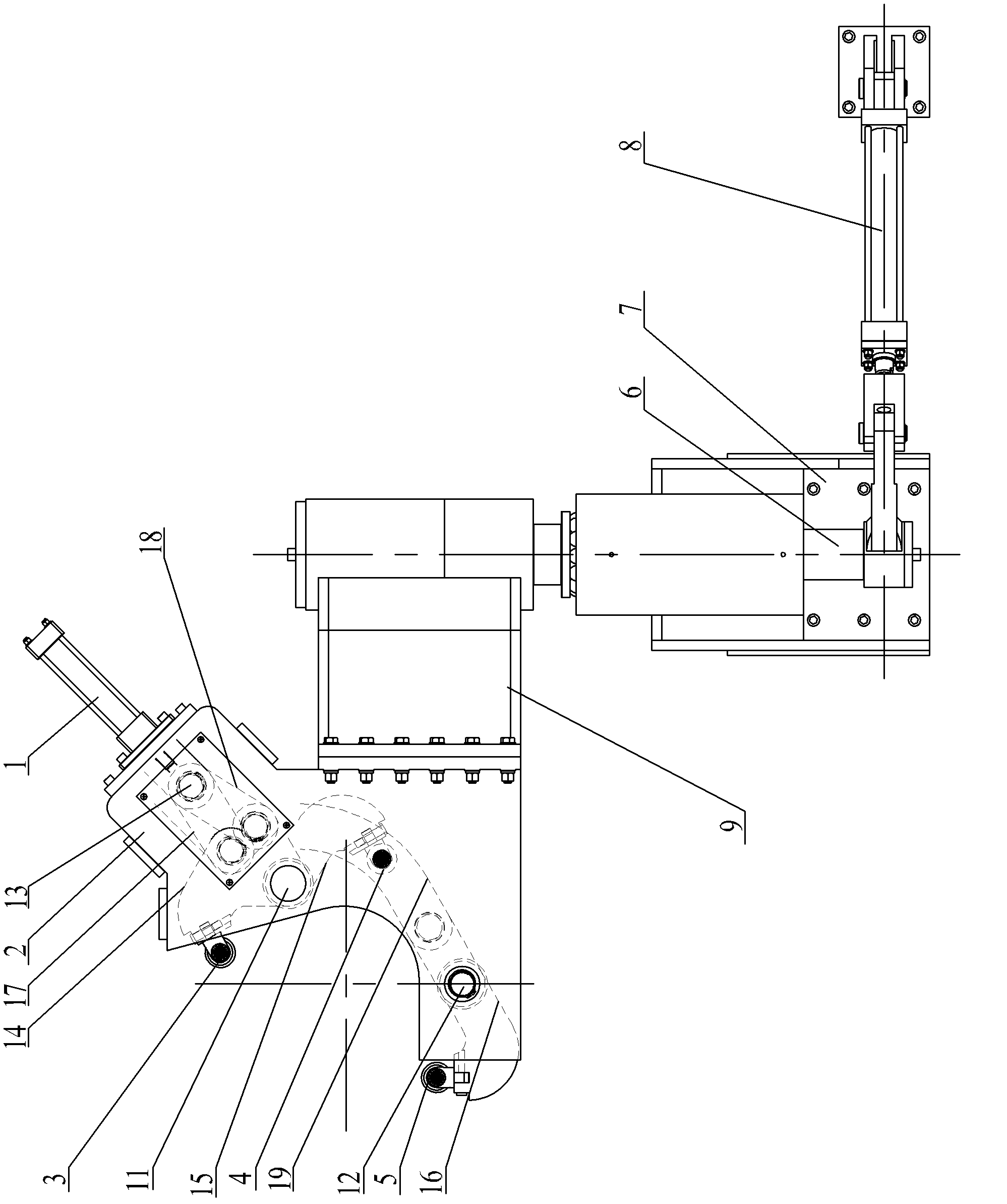

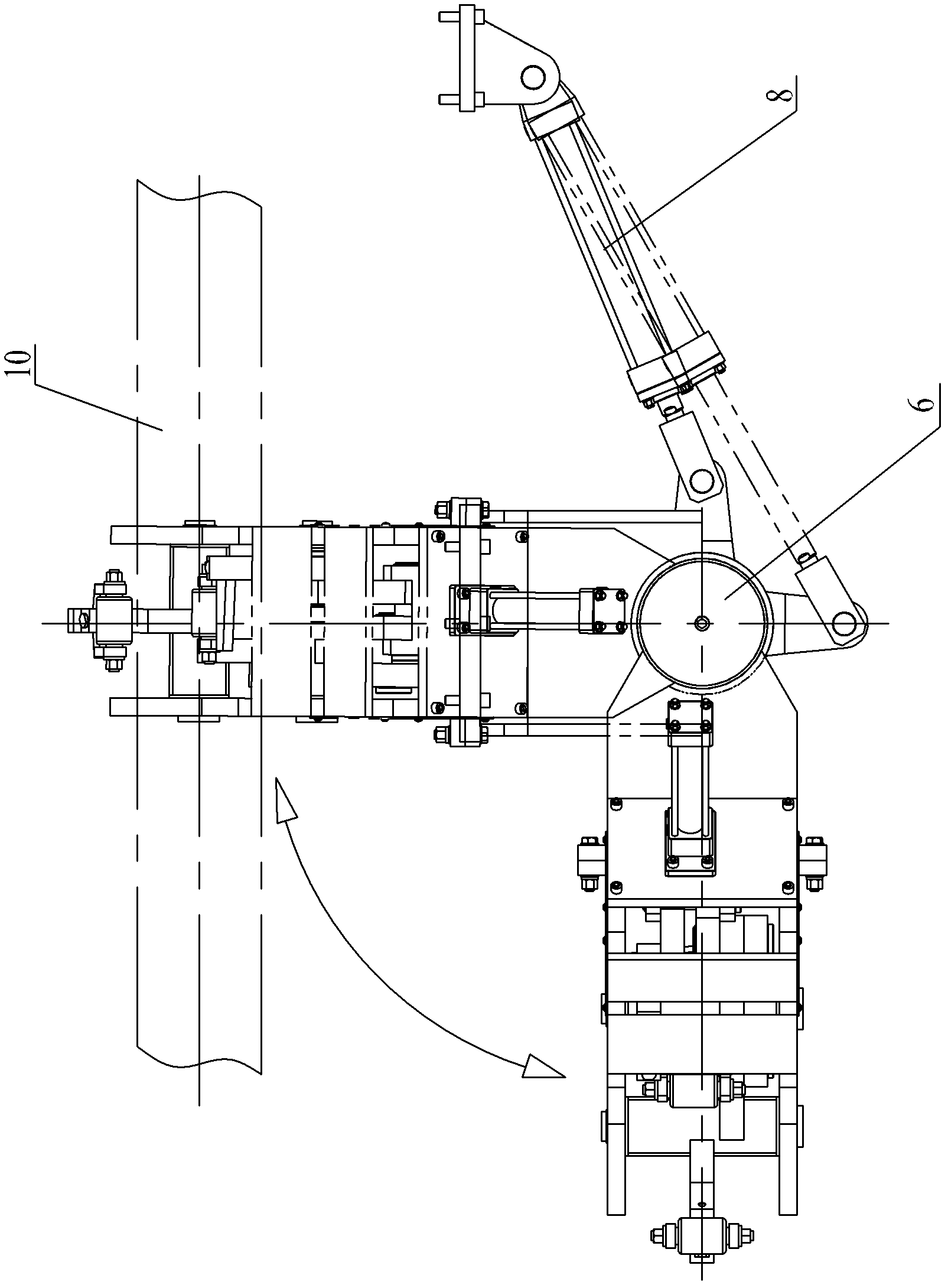

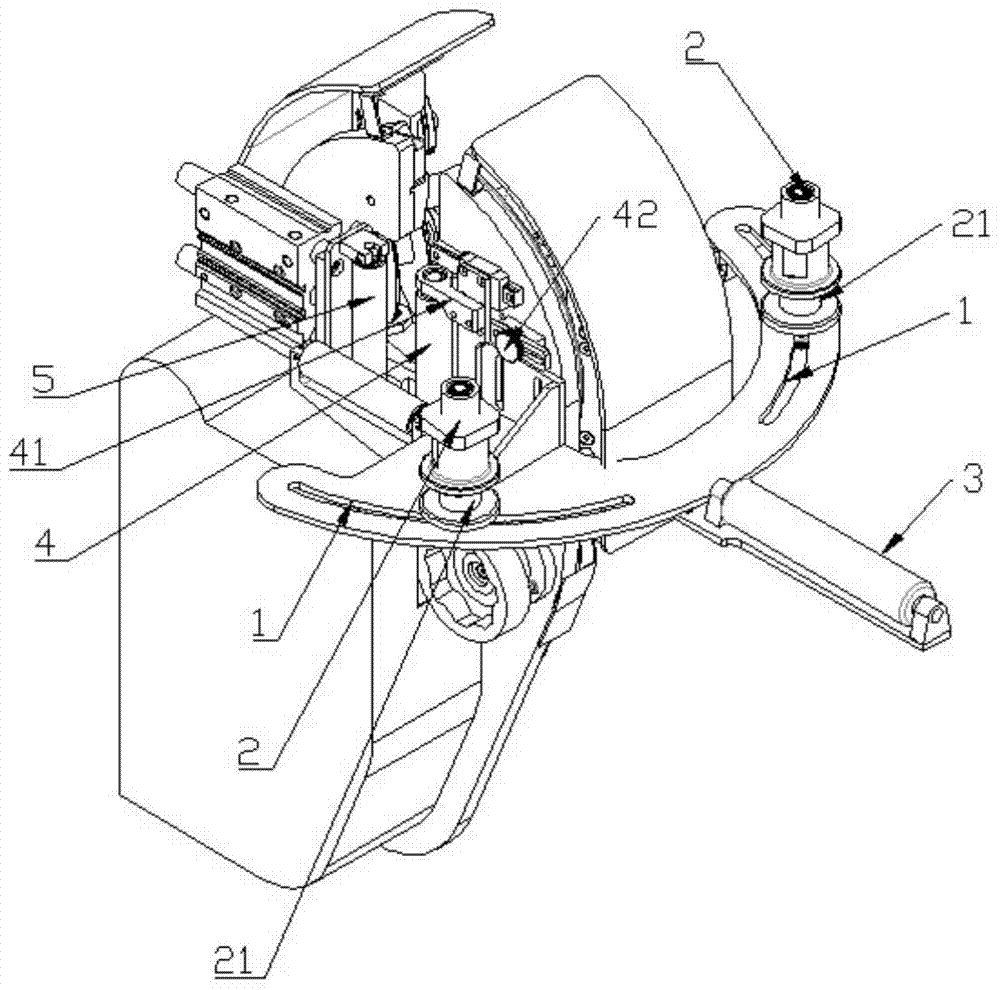

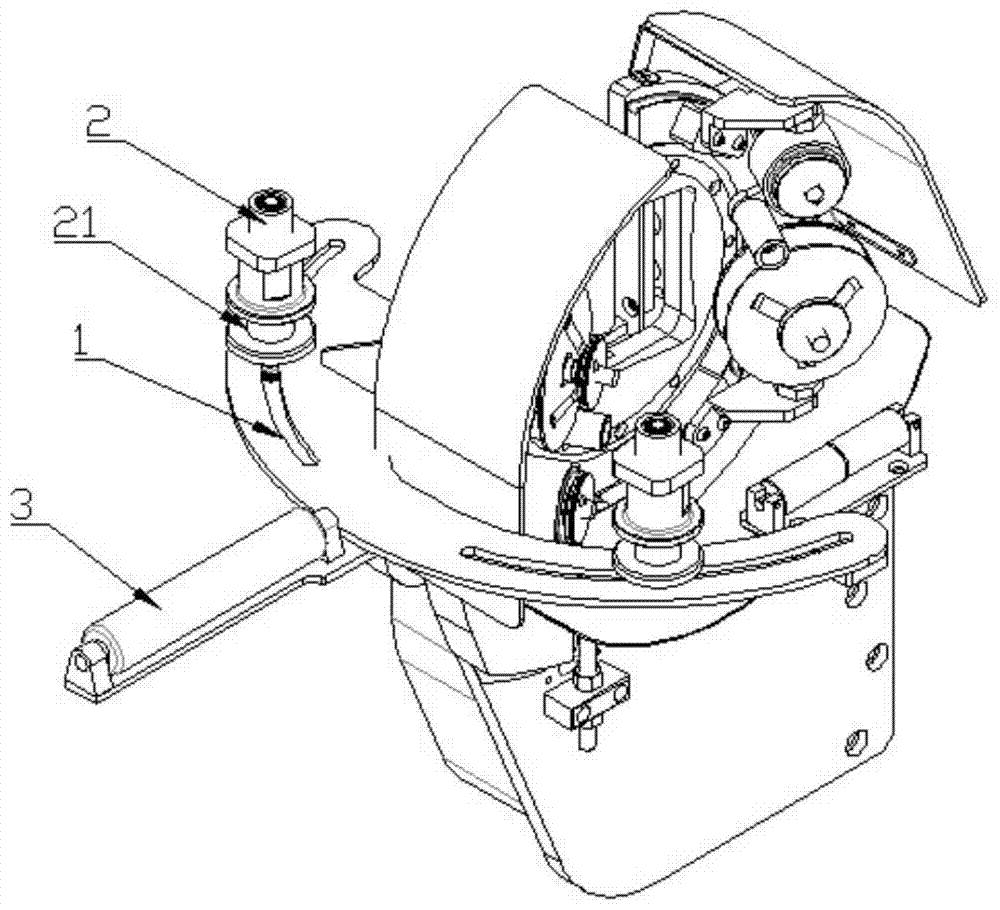

Tube tool centering device

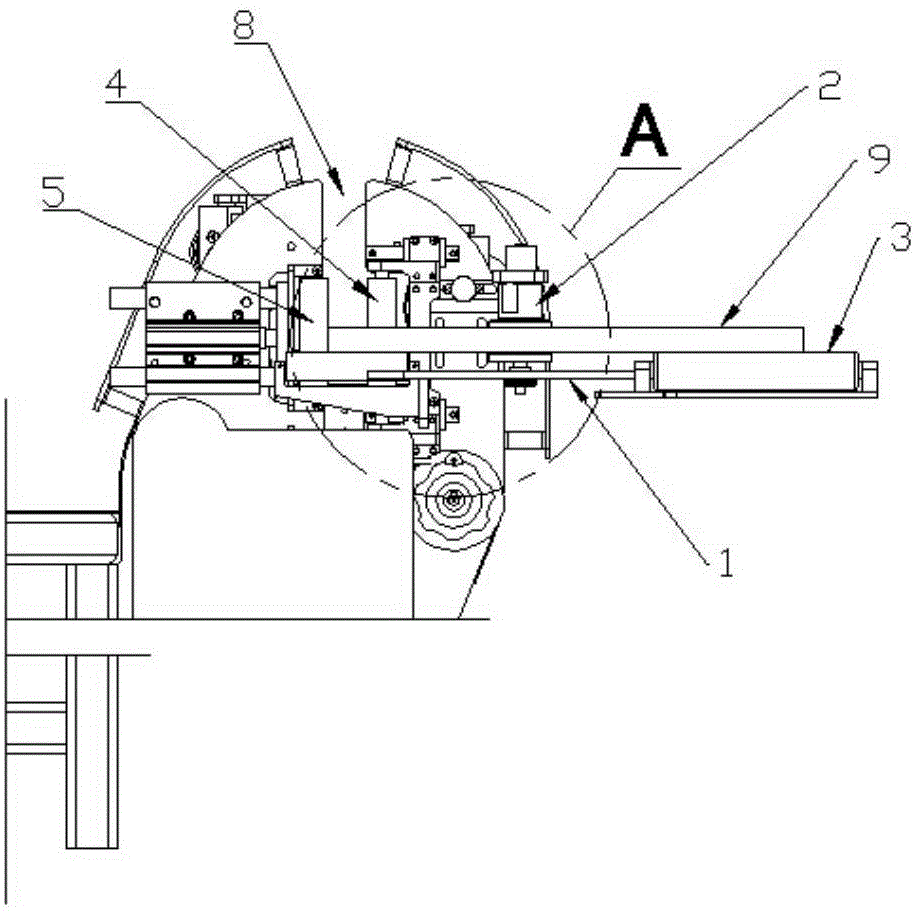

PendingCN110005347ARealize the centering functionIncrease contactDrilling rodsDrilling casingsPosition-sensing hydraulic cylinderTube tool

The invention relates to the field of engineering equipment, in particular to a tube tool centering device. The tube tool centering device comprises a base, a swinging hydraulic cylinder, a swinging arm, a guide arm, a guide hydraulic cylinder, a rotary motor and a centering mechanism, the swinging arm is hinged to the base, one end of the swinging hydraulic cylinder is hinged to the base, the other end of the swinging hydraulic cylinder is hinged to the swinging arm, the guide arm is hinged to the swinging arm, one end of the guide hydraulic cylinder is hinged to the swinging arm, the other end of the guide hydraulic cylinder is hinged to the guide arm, one end of the rotary motor is hinged to the guide arm, and the other end of the rotary motor is hinged to the centering mechanism. The rotary motor can drive the centering mechanism to rotate to adjust the centering angle, and the centering mechanism is ensured to be in good contact with tube tools to adapt the tube tools with different diameters; and the guide hydraulic cylinder extends and shrinks to realize the conversion of the working attitude and the waiting attitude, the swinging hydraulic cylinder shrinks to adjust the position, so that the tube tools are centered to another position from one position, as position adjustment is realized through hinged rotation, the size is small, the operation is stable, the precisionis high, the efficiency is high, and the purposes of reducing the cost and improving the efficiency are achieved.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

Bearing and reducer

PendingCN110671425AExtend your lifeLow failure rateRolling contact bearingsToothed gearingsFailure rateAxial Loadings

The invention provides a bearing and a reducer, and relates to the technical field of transmission devices. The bearing includes a bush and a bearing body, the bearing body includes an inner ring, anouter ring and a rolling body, the outer ring is arranged on the outer side of the inner ring in a sleeving manner, the rolling body is rotatably installed between the inner ring and the outer ring, and the rolling body is used for bearing the radial load; the bush is arranged on the outer ring in a sleeving manner, the outer surface of the outer ring is spherically matched with the inner surfaceof the bush to enable the axis of the bearing body to swing relative to the axis of the bush, and the outer ring and the bush are used for bearing the axial load. Since the rolling body of the bearingbears the radial load, and the outer ring and bush bear the axial load, so that the axial load and radial load are capable of being separated on different parts, the axial load and the radial load are prevented from being concentrated on the same part, the bearing life is prolonged, and the bearing failure rate is reduced.

Owner:SUOTE TRANSMISSION EQUIP

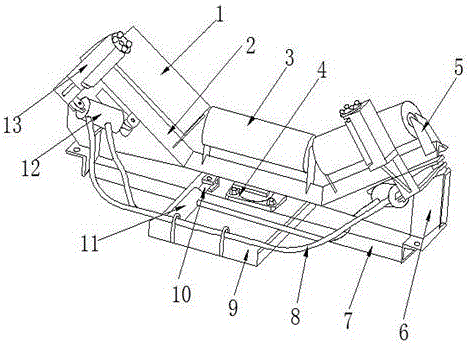

Full-automatic hydraulic deviation correcting device for belt conveyor

InactiveCN106628936ARealize the centering functionEasy to install and maintainConveyorsRollersJoistPiston rod

The invention discloses a full-automatic hydraulic deviation correcting device for a belt conveyor. The full-automatic hydraulic deviation correcting device comprises detecting carrier rollers, an adjusting bracket, an aligning carrier roller, a bearing support, a supporting frame, a cross joist, an aligning bracket, a composite oil cylinder, a deviation adjusting oil cylinder and a side deviation oil cylinder. The detecting carrier rollers are arranged at the two ends of the adjusting support. The aligning carrier roller is arranged in the center of the adjusting bracket. The lower end of the adjusting bracket is fixedly connected with the aligning support through a center base. The aligning bracket is fixedly connected with the middle of the cross joist. The other end of the side deviation oil cylinder is hinged to one end of the deviation adjusting oil cylinder. The other end of the deviation adjusting oil cylinder is hinged to the adjusting bracket. An oil suction port and an oil outlet of the deviation adjusting oil cylinder are connected with an oil port in the tail of the composite oil cylinder through oil conveying pipelines. The end of a piston rod of the composite oil cylinder is hinged to the aligning carrier roller. The detecting carrier rollers are hinged to a cylinder body of the side deviation oil cylinder. The full-automatic hydraulic deviation correcting device has the advantages that installation and maintenance are convenient, fewer faults exist, and the deviation correcting and adjusting performance is stable.

Owner:红安江陵机械制造有限公司

Device for assembling spiral check ring for hole

InactiveCN105269516ARealize the centering functionEasy to installMetal-working hand toolsEngineeringMechanical engineering

Owner:HARBIN DONGAN ENGINE GRP

A multi-size wafer centering device

ActiveCN103730400BRealize the centering functionReduce pollutionSemiconductor/solid-state device manufacturingEngineeringSupport point

The invention relates to a correction device for the positions of wafers of a semiconductor device, in particular to a centring device for the wafers of various sizes. The centring device comprises a work table, a power device, a clamping mechanism, a bearing table and supporting columns. The power device is installed on the work table, the bearing table is installed on the work table, a plurality of the supporting columns are distributed around the bearing table, and the top end of the bearing table and the top ends of the supporting columns are different in height and bear the wafers of different sizes. The clamping mechanism is connected with the output end of the power device, and the bearing table and the two sides of the supporting columns clamp the wafers inwards under driving of the power device, so that centring of the wafers is finished. The centring function is achieved by distinguishing the wafers of different sizes through the difference of supporting points of the wafers. The centring device is provided with one movement mechanism, and the pollution caused by movement friction is greatly reduced. The centring device has the advantages of being simple in structure, easy to install, convenient to adjust and low in cost, and saving the space.

Owner:SHENYANG KINGSEMI CO LTD

pipe centering device

ActiveCN105937374BRealize the centering functionGood centering and reliableDrilling rodsDrilling casingsOil and natural gasTube tool

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

Aligning self-unlocking anti-breaking anchor cable lock for mine

The invention relates to an aligning self-unlocking anti-breaking anchor cable lock for a mine. The problems that existing locks cannot be self-unlocked, are not prevented from breaking of anchor cables, cannot be self-aligned, and waste time and energy to remove anchor by using anchor removal devices are solved. The aligning self-unlocking anti-breaking anchor cable lock includes a sleeve and a lock cylinder, a stepped base is arranged on the lower side of the sleeve, an anchor cable hole is formed in the center of the stepped base, an aligning cambered surface is arranged at the outer edge of the lower end surface of the stepped base, the upper part of the stepped base is matched with a sleeve in a threaded mode, and the inner wall of the sleeve is of a conical surface structure; and a lock cylinder groove sleeves the outer side of the lock cylinder, an anti-falling ring pad is arranged between the bottom end of the sleeve and the step surface of the stepped base, lifting lugs integrated with the anti-falling ring pad are arranged on the opposite sides of the anti-falling ring pad. According to the aligning self-unlocking anti-breaking anchor cable lock for the mine, the unlocking and anchor removal functions are achieved through a wrench, an anchor removal device of an anchor cable is eliminated, the aligning function is achieved, and meanwhile, the anchor cable end is prevented from breaking and flying to hurt people, so that the efficiency of anchor removal of the anchor cable is greatly improved and the success rate of anchor removal is greatly increased.

Owner:HUOZHOU COAL ELECTRICITY GROUP +1

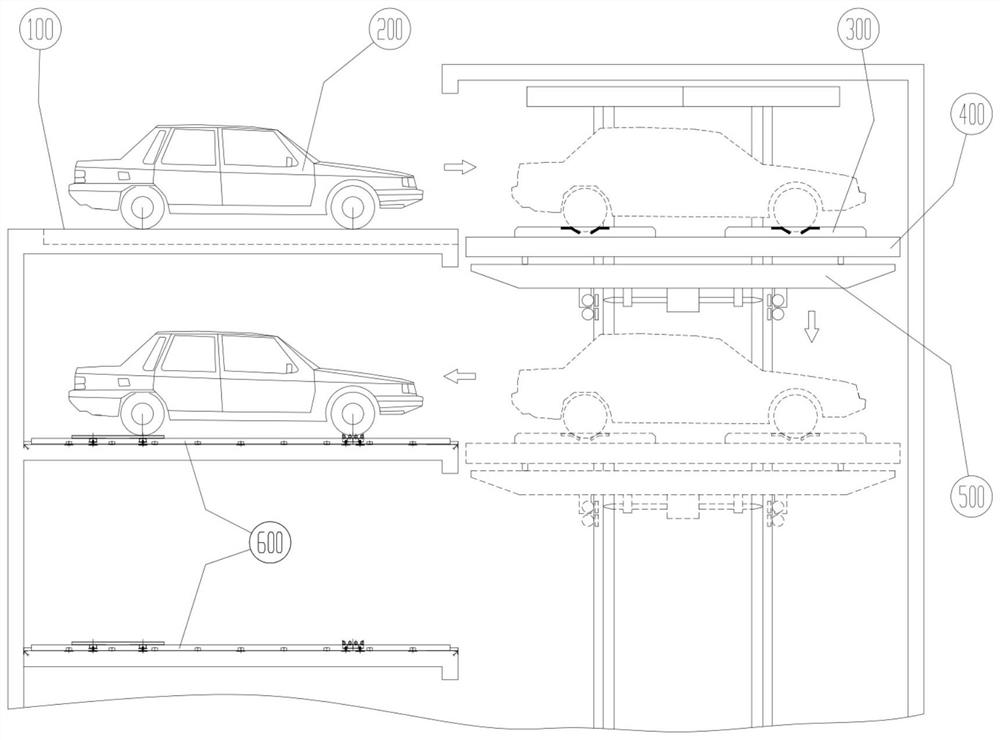

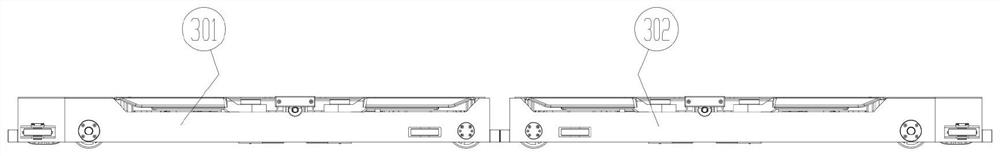

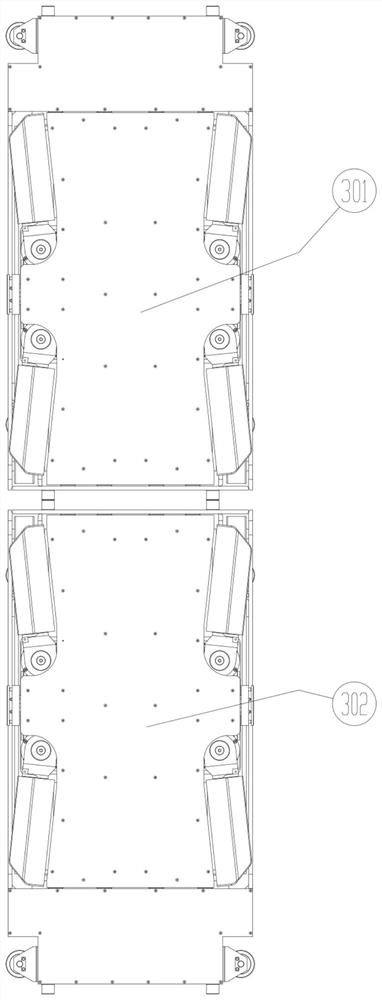

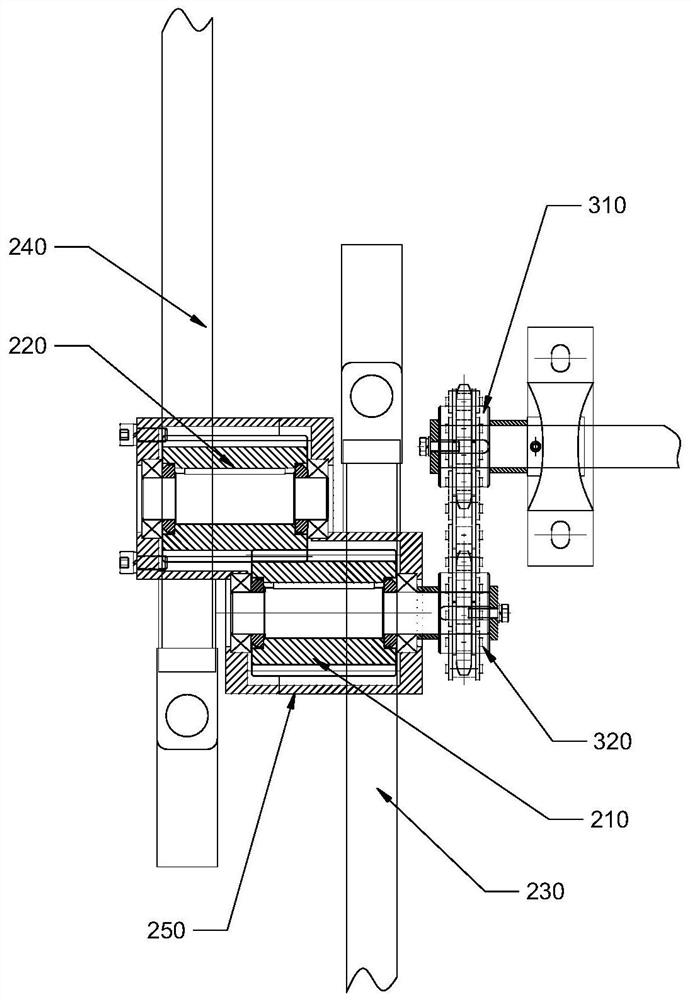

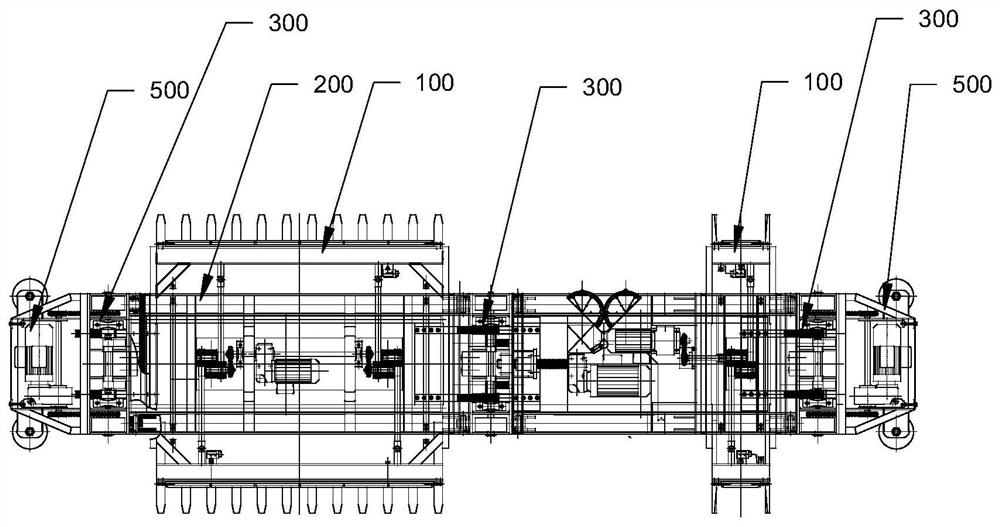

Split type automobile centering, lifting and carrying robot

PendingCN113027205AImprove the efficiency of car accessRealize the centering functionParkingsGear wheelParking space

The invention provides a split type automobile centering, lifting and carrying robot. The split type automobile centering, lifting and carrying robot comprises a front automobile body used for carrying and lifting front wheel parts of an automobile and a rear automobile body used for carrying and lifting rear wheel parts of the automobile; the front automobile body and the rear automobile body each comprise a walking transmission mechanism, wherein the walking transmission mechanisms are independent of one another and arranged on outer frames of the corresponding automobile bodies; the front automobile body and the rear automobile body are each provided with a functional unit; the rotating ends of clamping swing arms are each provided with a left vortex wheel worm transmission pair and a right vortex wheel worm transmission pair; lifting shaft main gears are engaged with corresponding transmission gears; lifting racks are fixedly connected to the outer frames of the corresponding automobile bodies; and the main gears and the transmission gears are engaged with the adjacent lifting racks. The split type automobile centering, lifting and carrying robot has the effects that the structure of a parking space is simple, the automobile storing and taking efficiency is improved, and tires are actively touched and found to be prevented from being scratched.

Owner:吉林省快安泊科技有限公司

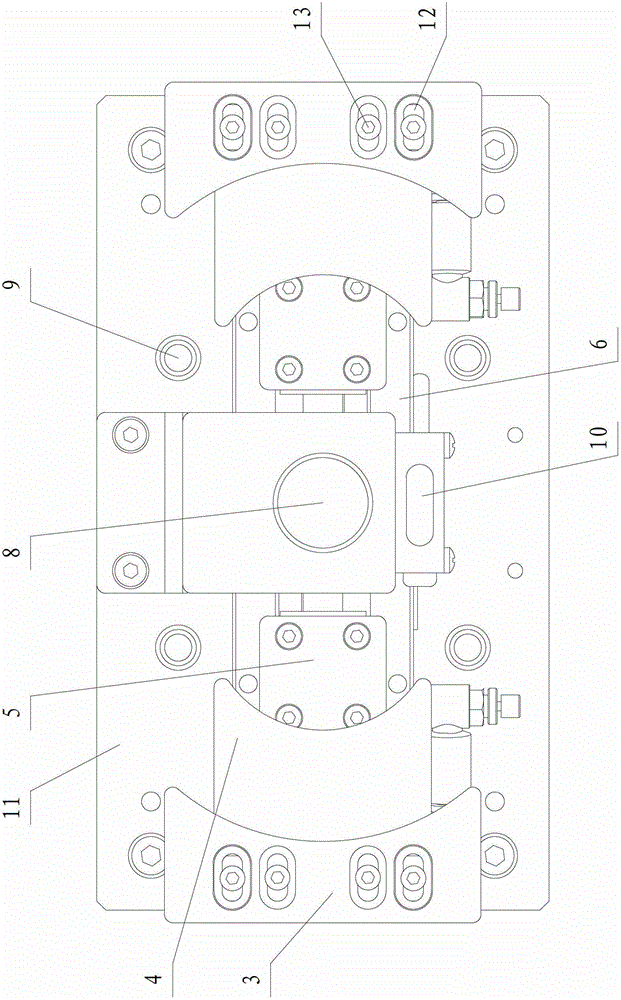

Open three-point centering mechanism

ActiveCN102513464BGuaranteed validityDoes not affect free extensionMetal-working feeding devicesPositioning devicesHydraulic cylinderEngineering

The invention relates to an open three-point centering mechanism. A rotating shaft is arranged in a connecting support in a rotating manner, the rotating shaft is fixed with a rotating support, the rotating support is fixed with an adhesion wheel support, a first rotating wheel is erected on a first mounting plate, a second rotating wheel is erected on a second mounting plate, a third rotating wheel is erected on a third mounting plate, the first mounting plate is hinged with a first connecting rod, the second mounting plate is hinged with a second connecting rod, the other end part of the first connecting rod and the other end part of the second connecting rod are all hinged on a third mounting shaft, and the adhesion wheel support is provided with a lifting driving component of the third mounting shaft. In the invention, one hydraulic cylinder is used for driving three adhesion centering wheels to move, circle centers of the three centering wheels are effectively ensured to be always located on concentric circles which have the circle centers on the same point and have different diameters, and centering function on pipes with different diameters can be realized.

Owner:WUXI NANTIAN SAFETY FACILITIES

Centering device, comb tooth structure comprising centering device and comb tooth carrier

InactiveCN112252788ATransmission is precise and accurateImprove job stabilityParkingsGear driveGear wheel

The invention discloses a centering device, a comb tooth structure comprising the centering device and a comb tooth carrier. According to the centering device, the comb tooth structure comprising thecentering device and the comb tooth carrier, one part of driving gears and one part of driven gears which are meshed with each other in the thickness direction are meshed with each other, the rest thickness part of the driving gears is meshed with first racks, and the rest thickness part of the driven gears is meshed with second racks; and therefore, when a driving mechanism drives the driving gears to rotate, the first racks and the second racks can be driven to do synchronous face-to-face or back-to-back movement relative to center lines, and the centering function is achieved. Due to the fact that gear transmission has the advantages of being precise, accurate, high in working stability and high in synchronism, the accuracy of the position can be guaranteed in the repeated movement process, and the centering effect is improved.

Owner:华源雄兴智能科技有限公司

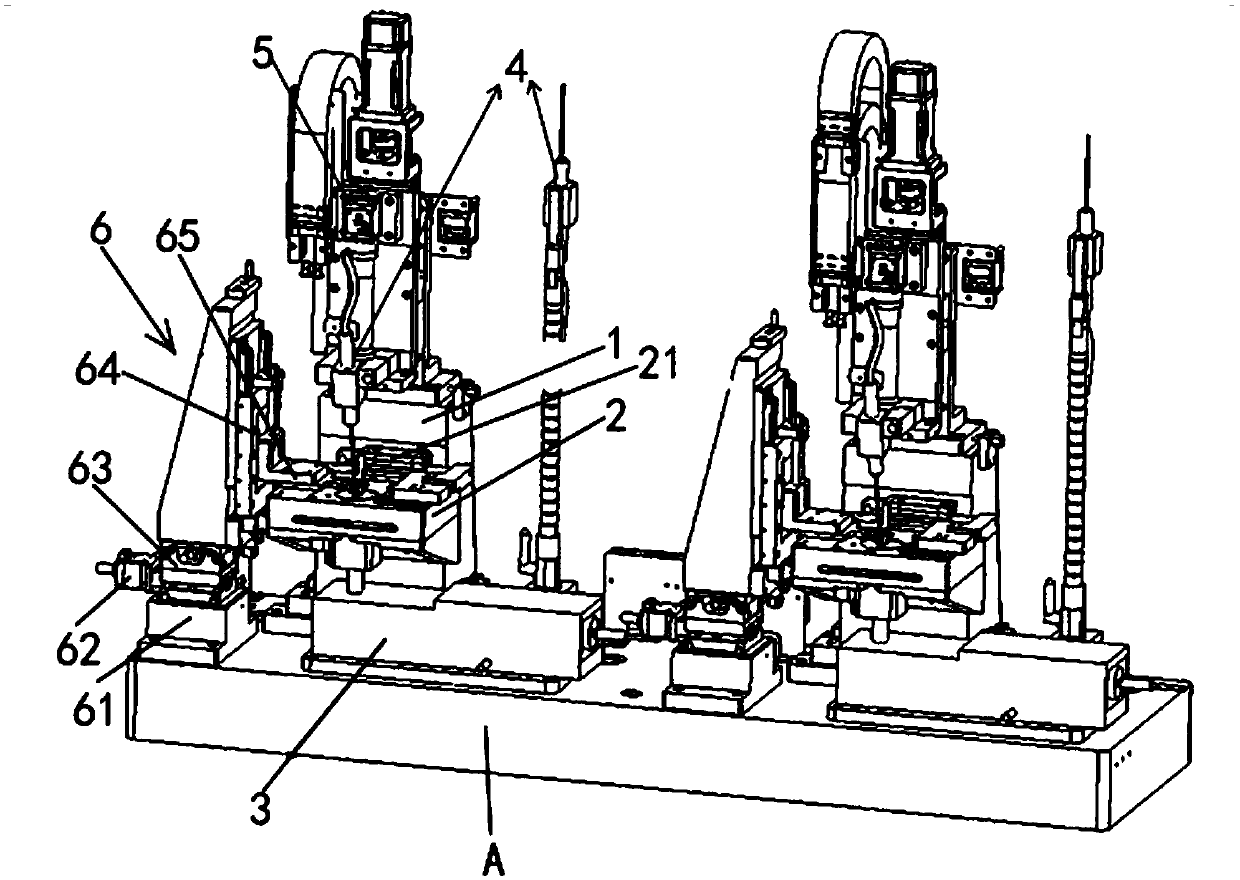

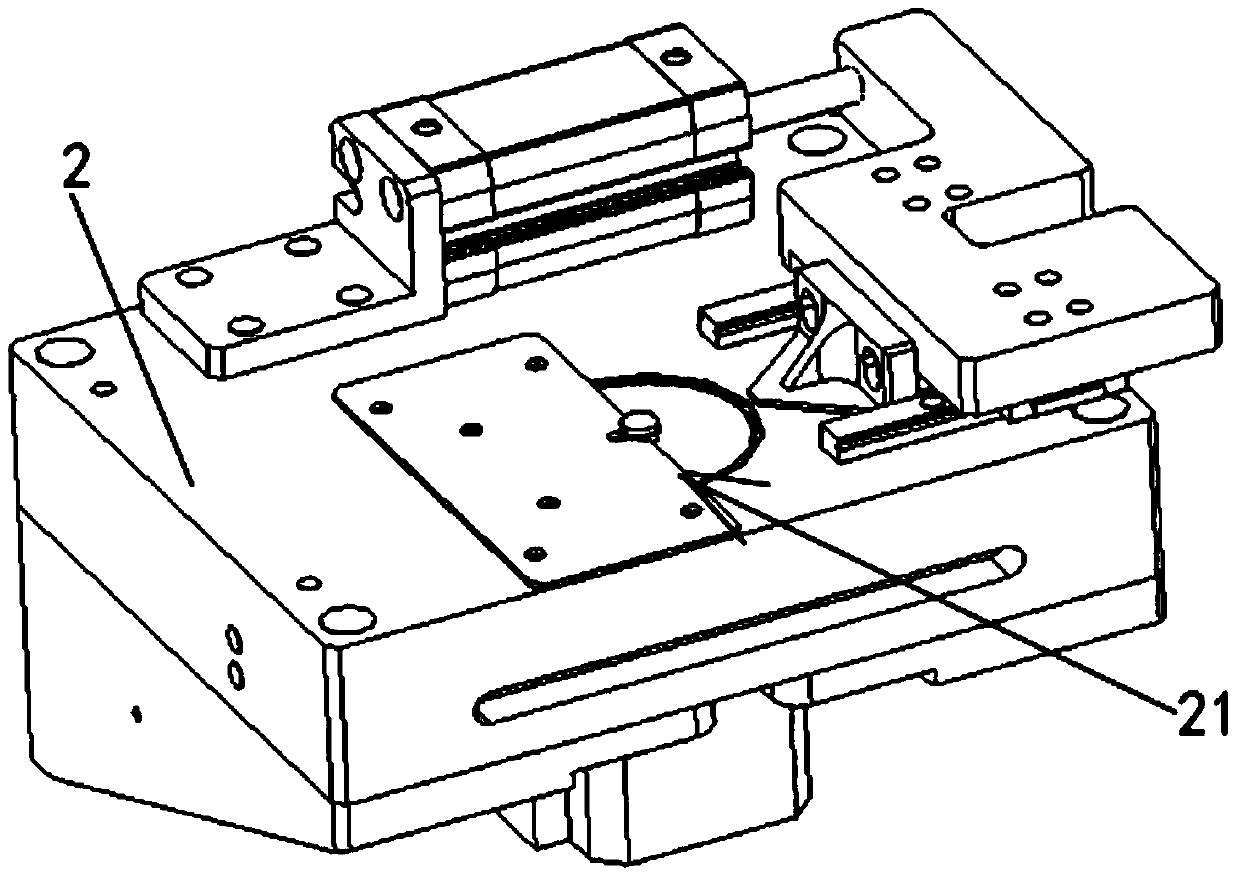

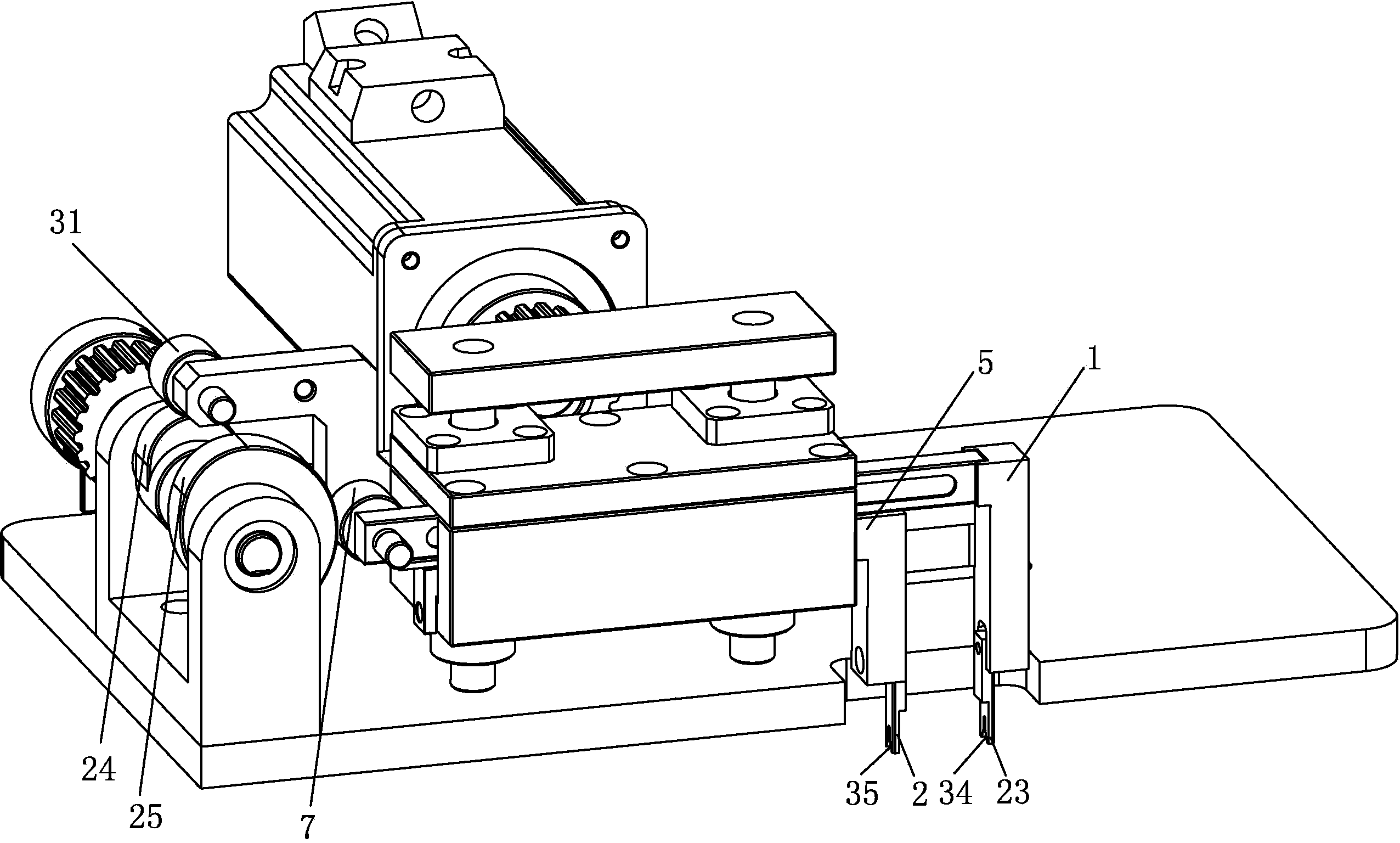

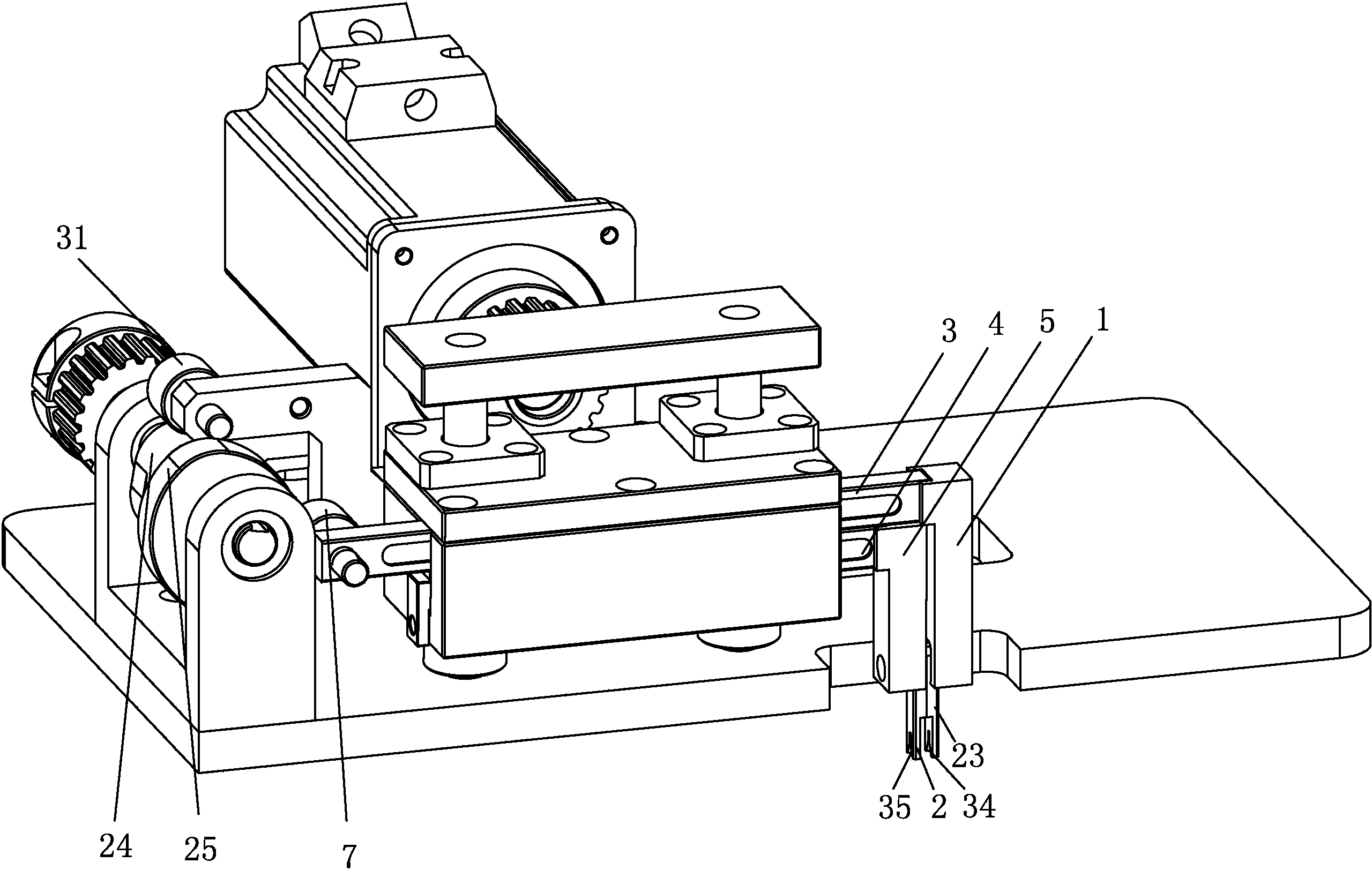

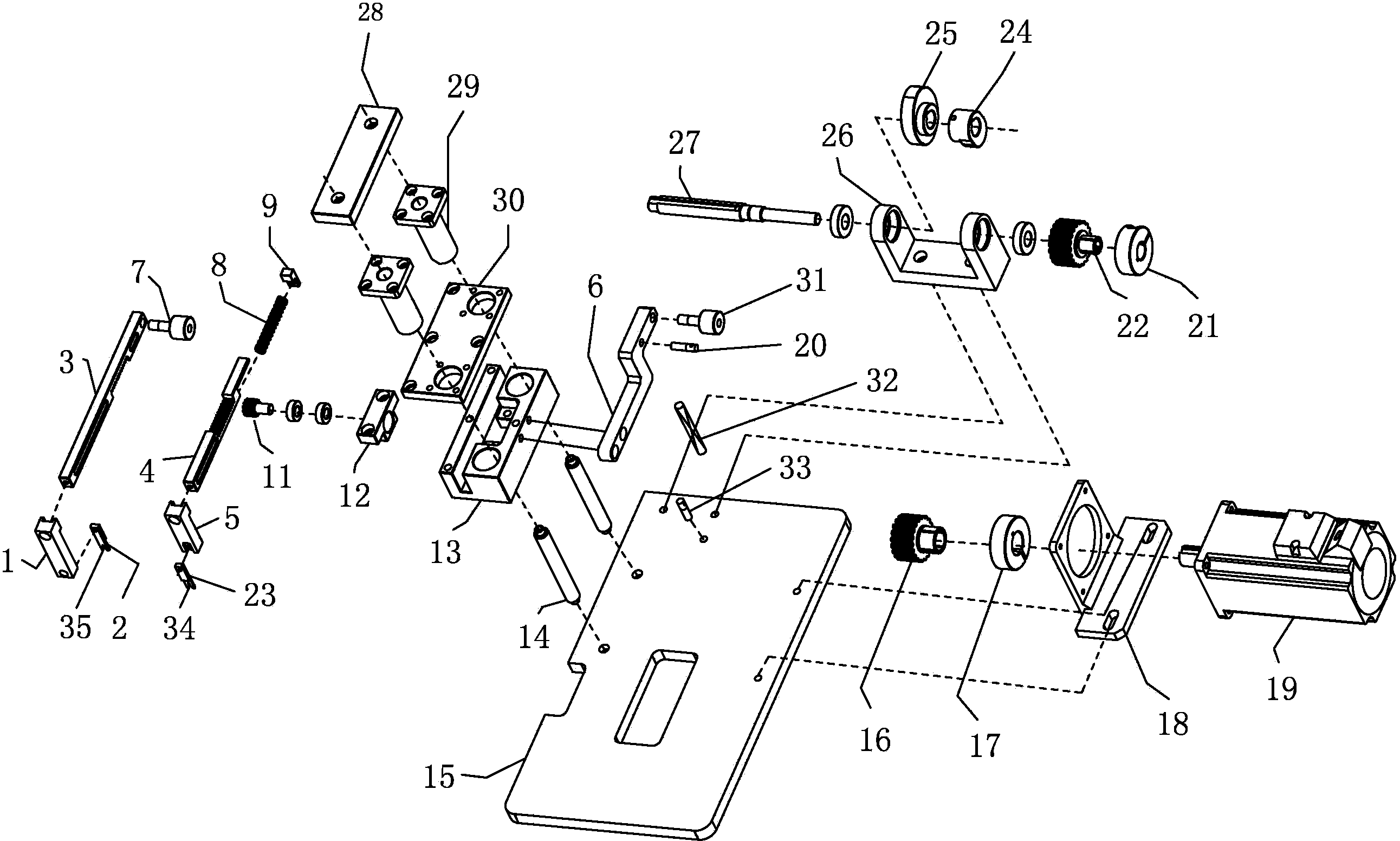

Element centering device of component inserter

ActiveCN102368898BRealize the centering functionHigh running precisionPrinted circuit assemblingElectrical componentsGear driveGear wheel

The invention relates to the component inserter technology field, especially relating to an element centering device of a component inserter. The device comprises a pedestal, a centering opening closing device and a drive device. The centering opening closing device is provided with a gear, and an upper tooth bar and a lower tooth bar which are in parallel. The drive device is provided with a left and right cam and a power apparatus driving rotation of the left and right cam. The left and right cam is provided at one side of the upper tooth bar and presses against one end of the side of the upper tooth bar. The upper tooth bar and the lower tooth bar are respectively provided with clamping elements which are perpendicular to the upper tooth bar and the lower tooth bar. In the invention, the drive device drives motion of the left and right cam, the left and right cam drives the upper tooth bar, when the upper tooth bar moves rightwards, the gear drives the lower tooth bar to move leftwards, when the upper tooth bar moves leftwards, the gear drives the lower tooth bar to move rightwards, with linkage of the upper tooth bar, the lower and the gear, clamping material is carried out, a centering function of a component is realized, an operation speed is fast, an automation control degree is high, machine operation precision is high, and operation is stable.

Owner:海宁经开产业园区开发建设有限公司

Auxiliary positioning mechanism of taping machine

ActiveCN106328369APrevent looseningRealize the centering functionCoils manufactureEngineeringMechanical engineering

The invention provides an auxiliary positioning mechanism of a taping machine. The auxiliary positioning mechanism comprises a track and at least two groups of adjusting wheels arranged outside a packaging channel of the taping machine, wherein the track is horizontally arranged and is fixed at the side of the packaging channel; the adjusting wheels are arranged on the track in a sliding manner and can be fixed on the track; and shafts of the adjusting wheels are arranged along the vertical direction. When the auxiliary positioning mechanism is used, one side of an annular coil can pass through the packaging channel and then is limited by two paper wheels and the other side of the annular coil is clamped by two groups of adjusting wheels; and the positions of the two groups of adjusting wheels are adjusted to adapt to the annular coils with different diameters and then the adjusting wheels are fixed, so that taping of the annular coil can be carried out.

Owner:NEWONDER SPECIAL ELECTRIC

Comb tooth carrier

InactiveCN112252795ATo achieve the stretch effectTransmission is precise and accurateParkingsGear driveGear wheel

The invention discloses a comb tooth carrier. The comb tooth carrier comprises at least one comb tooth part and a first frame body, wherein the comb tooth parts are arranged on the first frame body, each comb tooth part comprises a telescopic comb tooth frame and a centering device, each telescopic comb tooth frame comprises two parts which are separated from each other and are symmetrically arranged on the two sides of the center line of each centering device, the two parts of each telescopic comb tooth frame are arranged on the first frame body in a sliding mode, the centering devices are fixedly arranged on the first frame body, each centering device comprises at least one pair of driving gears and driven gears which have the same shape and size and are meshed with each other, meanwhile, the driving gears and the driven gears are meshed with first racks and the second racks respectively, the two parts of each telescopic comb tooth frame are fixedly connected with the first racks andthe second racks, the driving gears and the driven gears drive the first racks and the second racks to synchronously move towards each other or away from each other relative to the center lines respectively when rotating, and the two parts of each telescopic comb tooth frame are close to each other or away from each other accordingly. According to the comb tooth carrier, the centering effect of equipment is improved.

Owner:华源雄兴智能科技有限公司

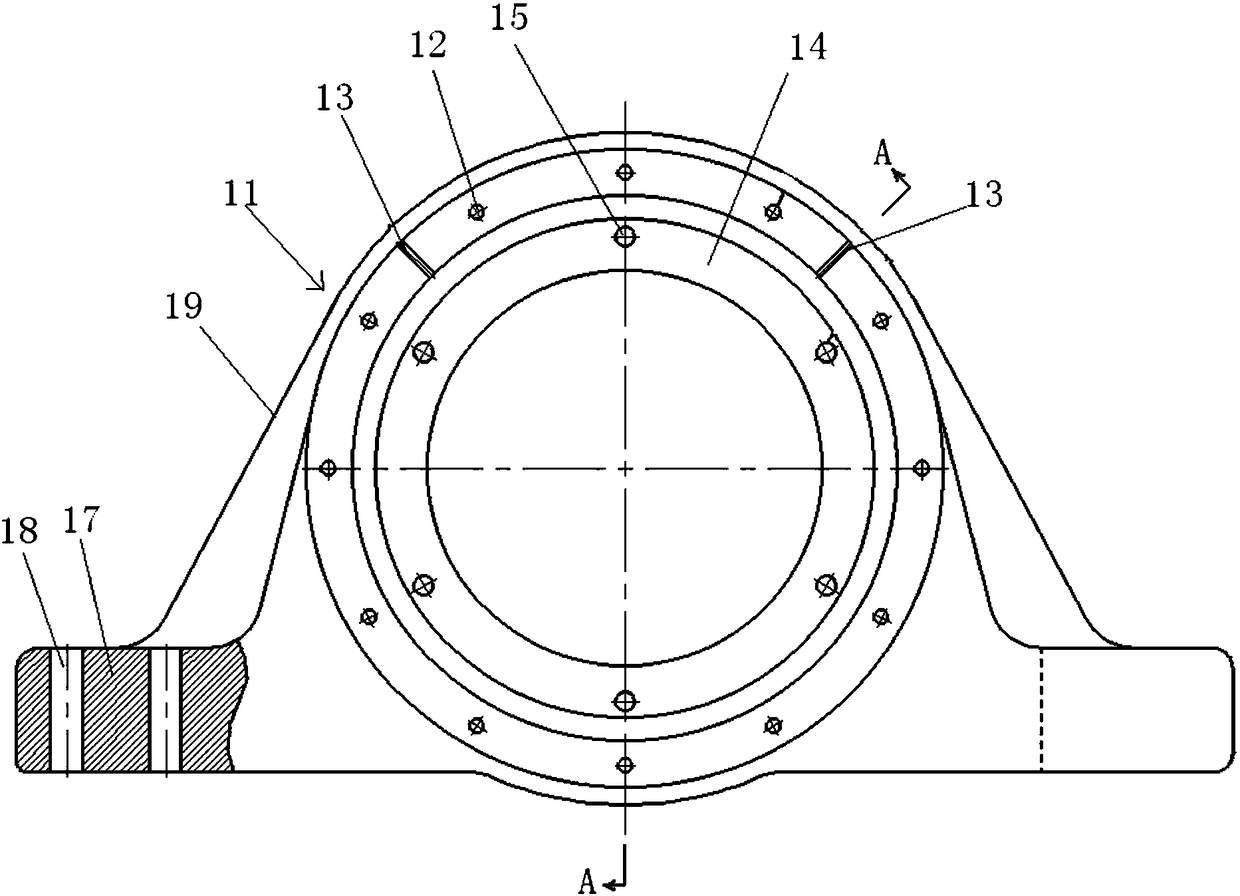

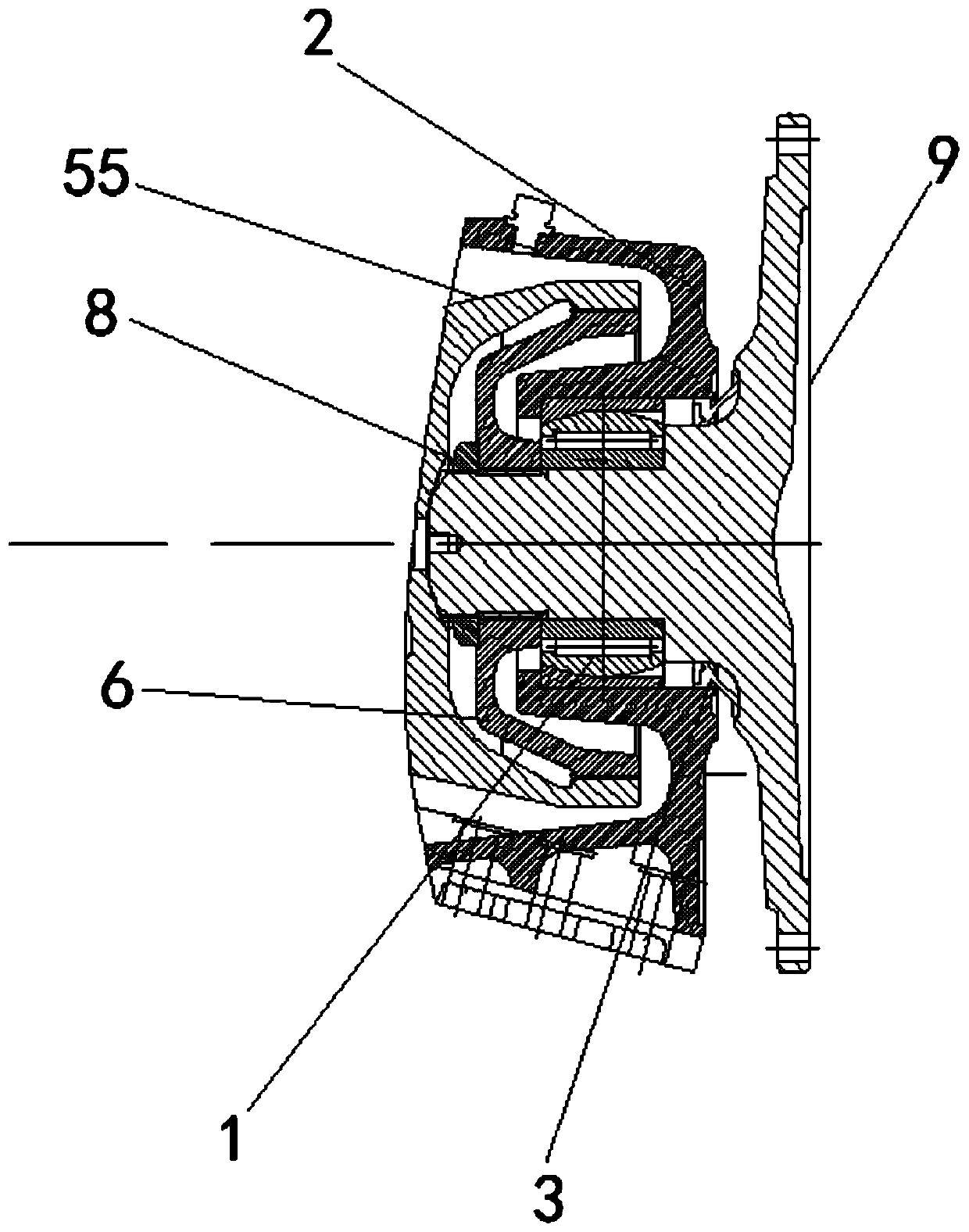

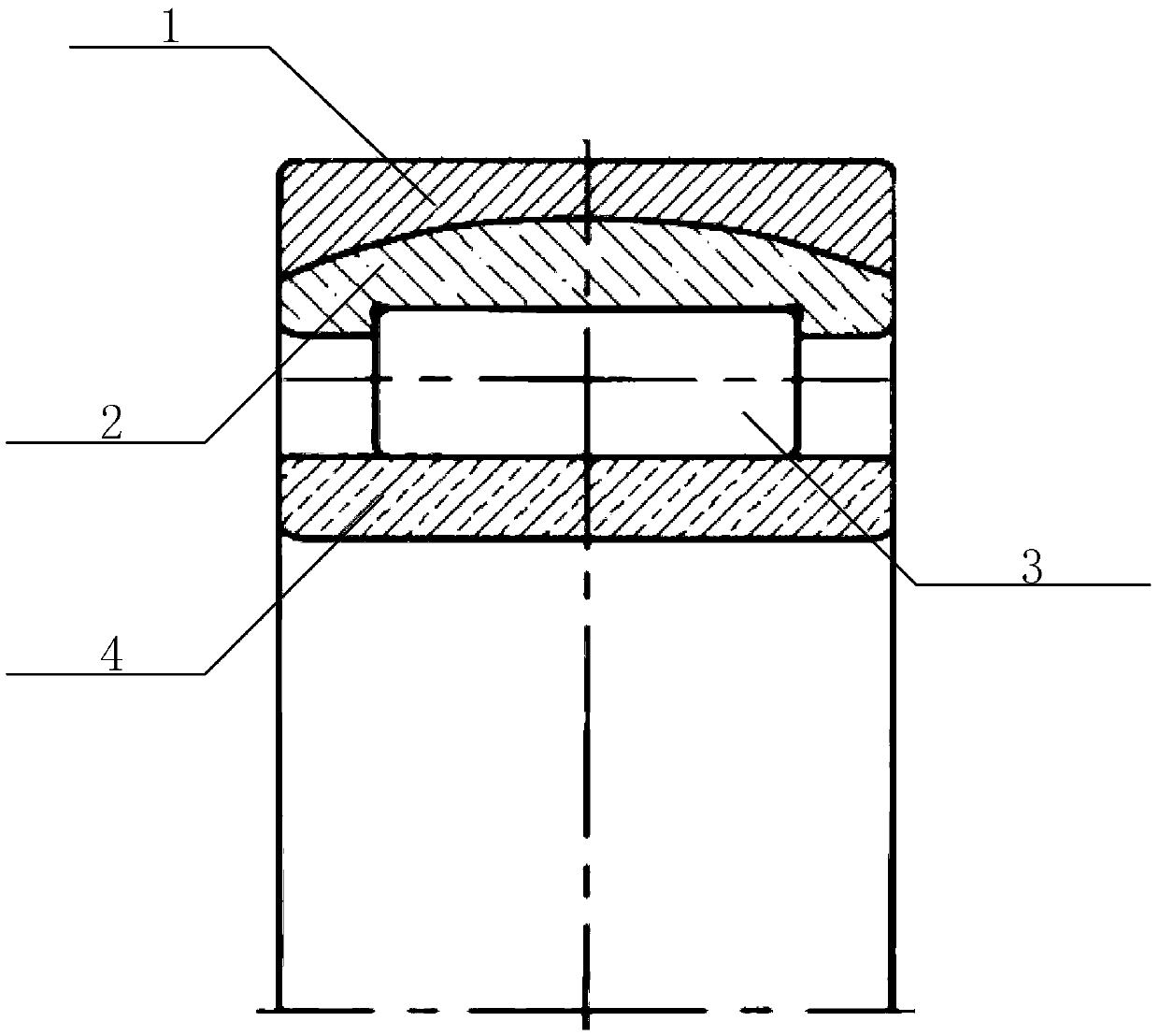

Aligning roller bearing and bearing assembling

InactiveCN110886771ARealize the centering functionImprove radial load capacityRoller bearingsClassical mechanicsStructural engineering

The embodiment of the invention provides an aligning roller bearing and a bearing assembling. The aligning roller bearing comprises an outer ring, a first aligning ring and a second aligning ring; theouter ring surface of the outer ring comprises a first wing surface, a main surface and a second wing surface; the surface where the first wing surface is positioned and the surface where the secondwing surface is positioned are the same spherical surface; the main surface is suitable for being in contact with the inner ring surface of a bearing seat; the first aligning ring is arranged outsidethe outer ring in a sleeving manner; the inner ring surface of the first aligning ring is fit with the first wing surface; the second aligning ring is arranged outside the outer ring in the sleeving manner; and the inner ring surface of the second aligning ring is fit with the second wing surface. According to the aligning roller bearing provided by the embodiment of the invention, an aligning function can be realized, and moreover, the radial thickness of the aligning rings and the outer ring can be reduced, so that the sizes of rollers of the aligning roller bearing are increased within limited space, thereby improving the radial bearing capacity of the aligning roller bearing.

Owner:SCHAEFFLER TECH AG & CO KG

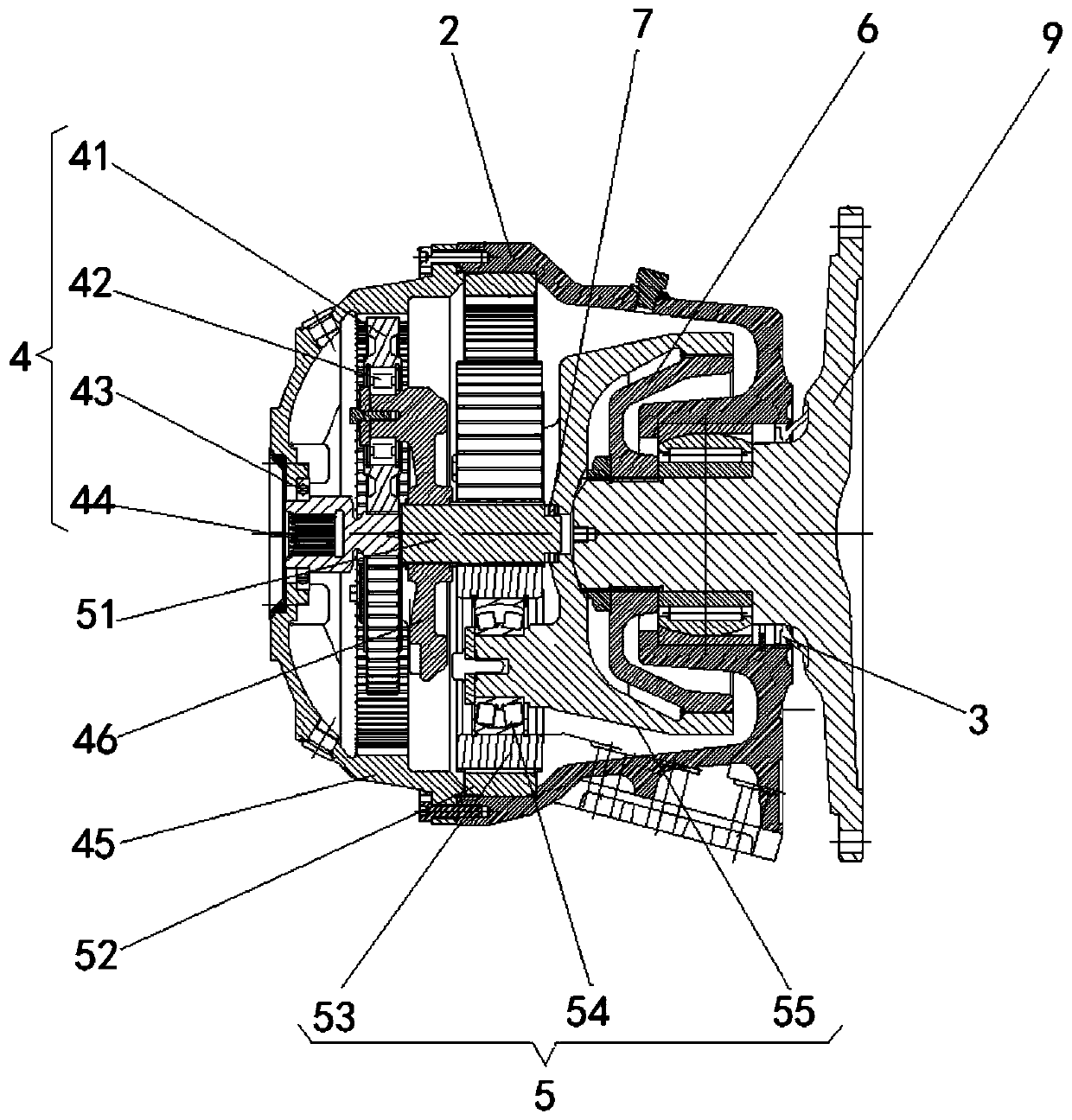

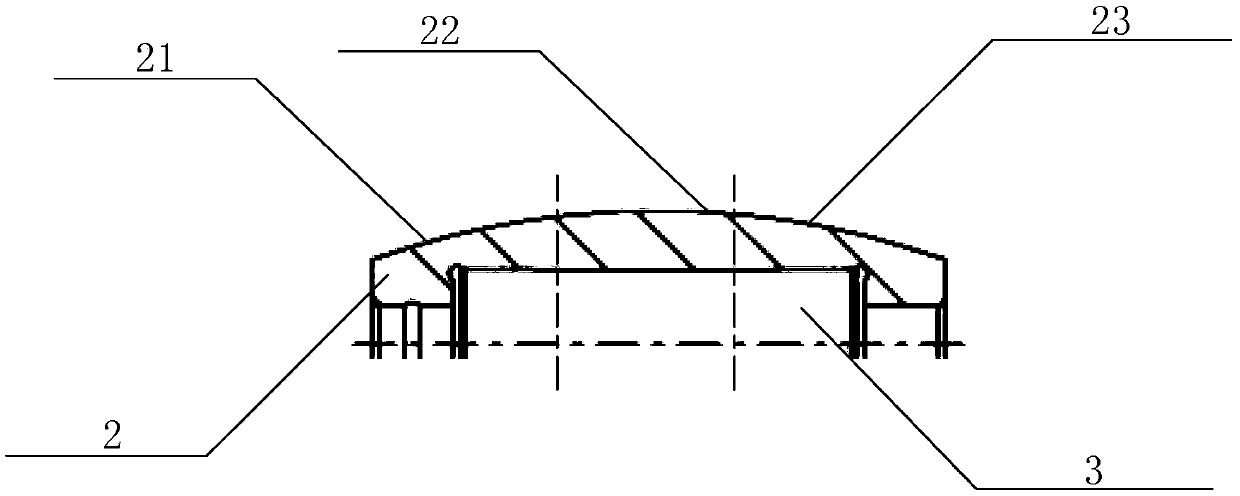

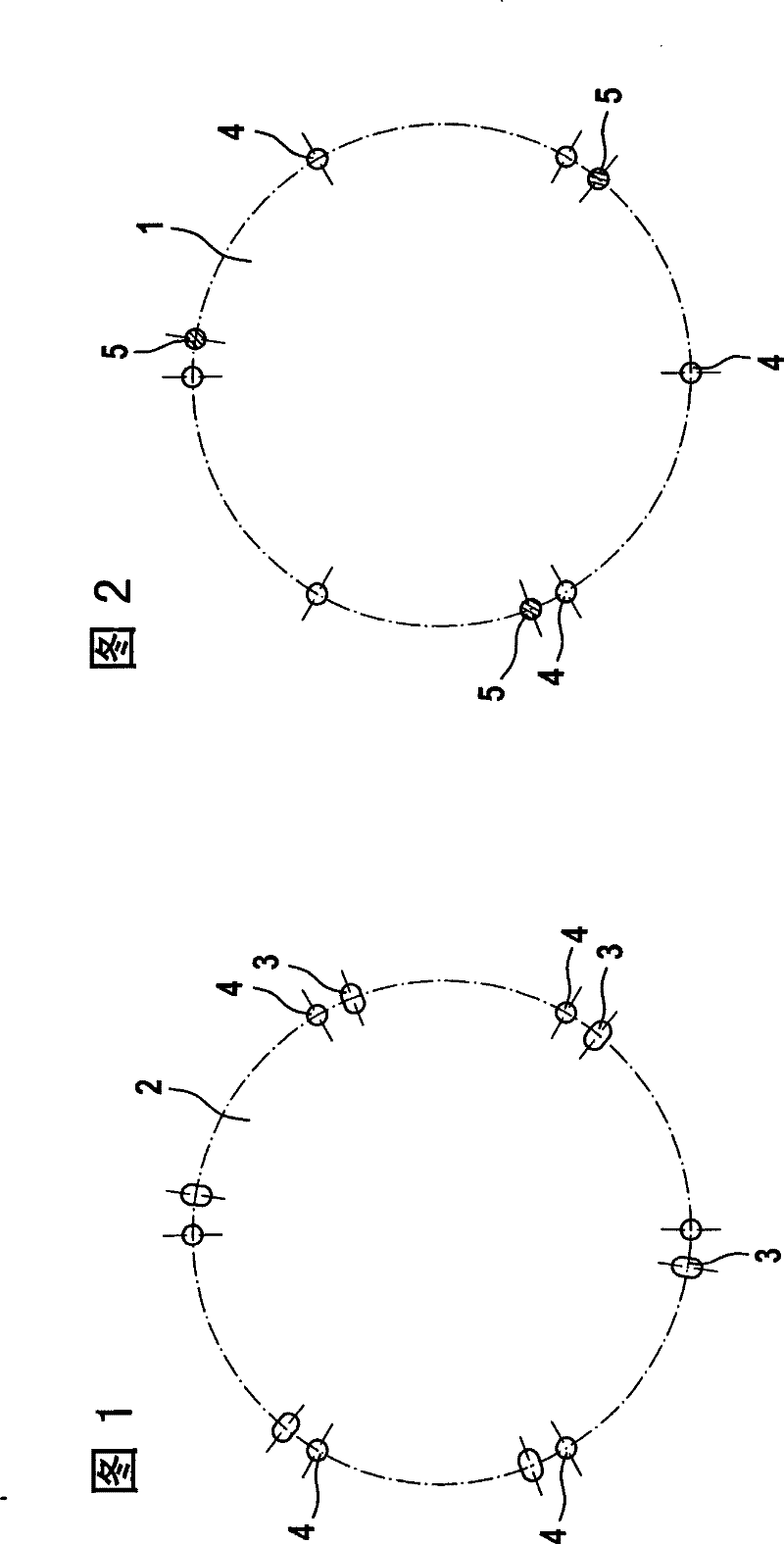

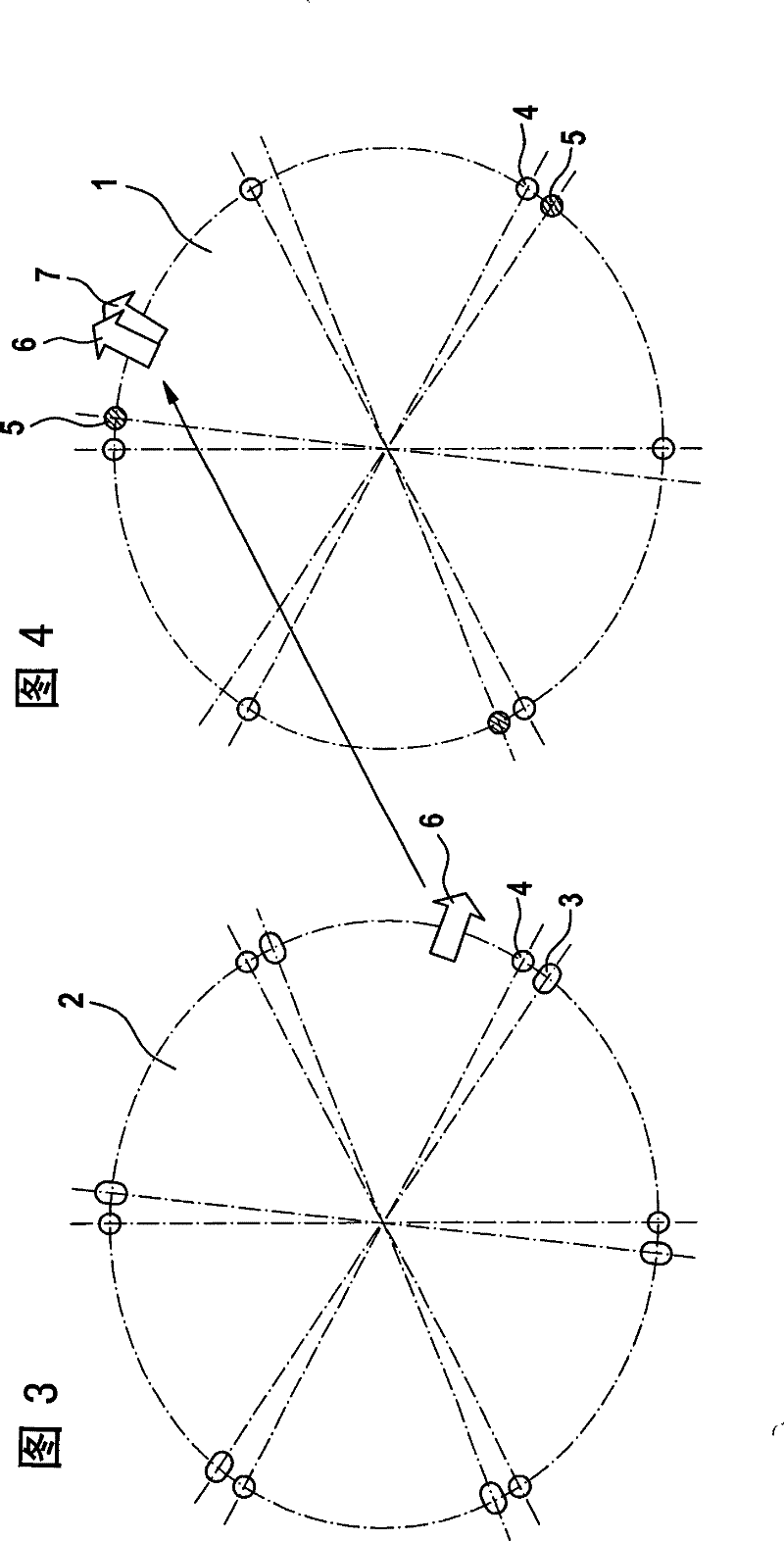

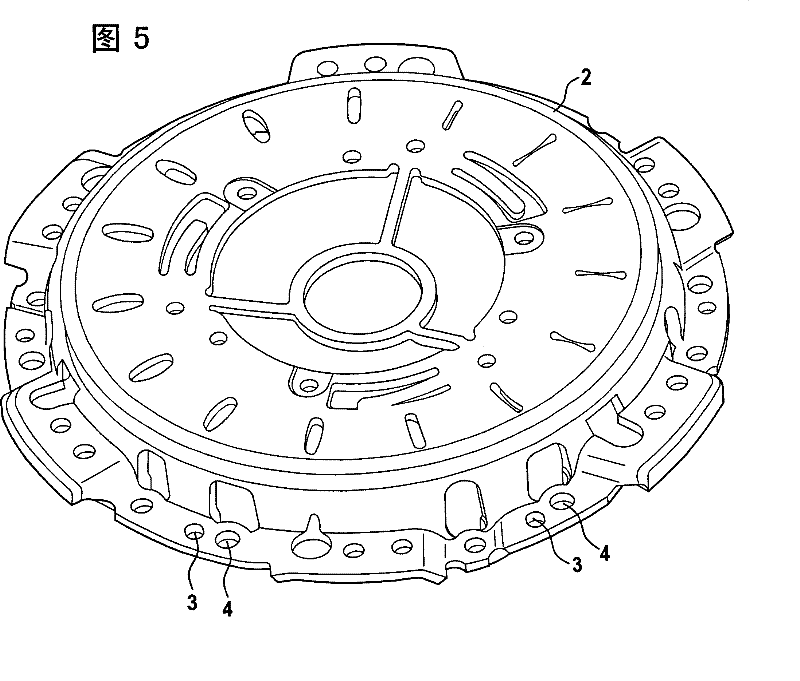

Method for assembling a clutch arrangement to a flywheel in a drive chain of a vehicle and assembling equipment therefor

InactiveCN1796824BAvoid imbalanceGood weight balanceRotating vibration suppressionStatic/dynamic balance measurementFreewheelEngineering

The invention discloses a method for assembling a clutch device on a flywheel in a vehicle drive unit, wherein, the flywheel and the clutch device are individually balanced and aligned by means of a positioning device relative to obtained imbalance respectively and positioned each other in the circumferencial direction. Moreover, the invention discloses an assembling device for assembling a balanced clutch device on a balanced flywheel in a vehicle drive unit axially, which includes at least one positioning device for positioning the clutch device on the flywheel, the positioning device comprises at least one group of heaves and at least two grooves related to the group respectively.

Owner:SCHAEFFLER TECH AG & CO KG

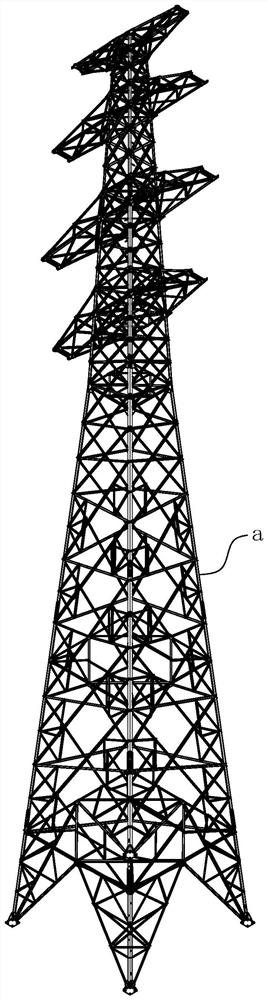

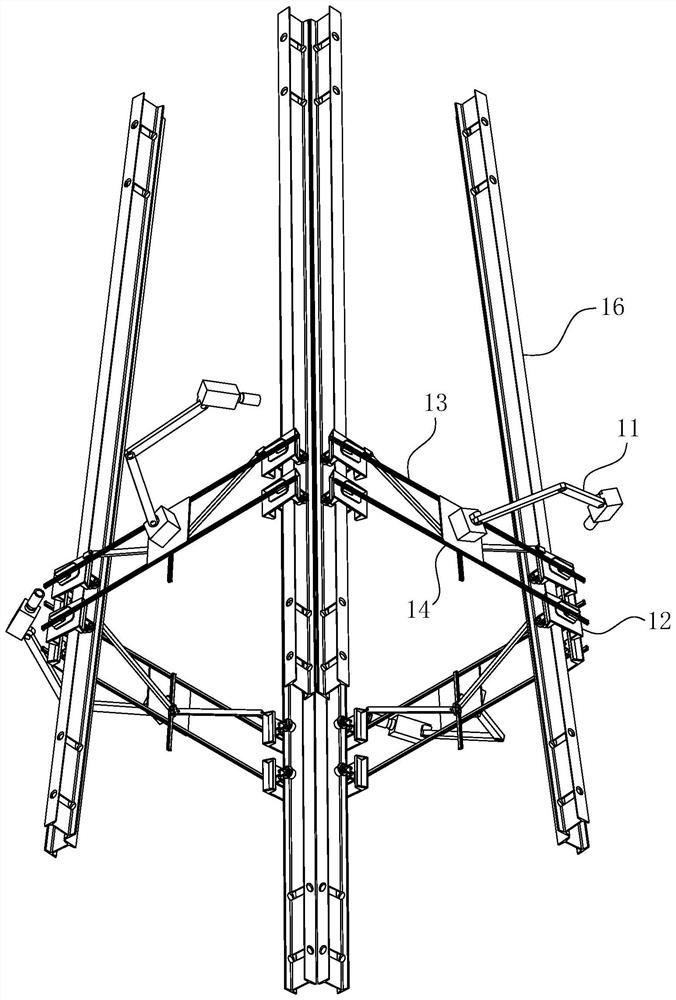

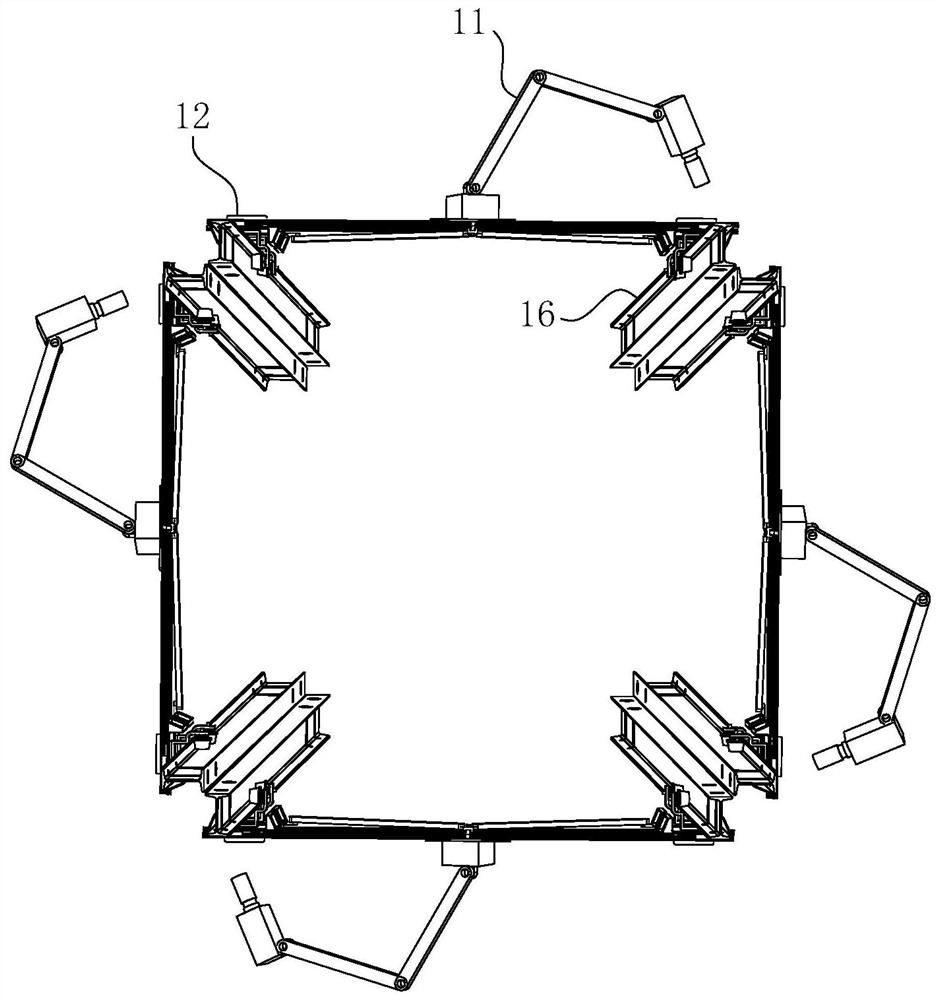

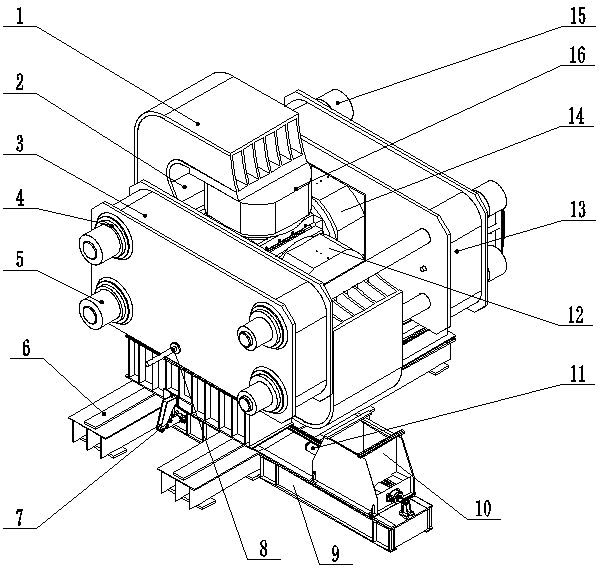

Rail type power angle steel tower maintenance robot

PendingCN113500580ADoes not affect normal functionRealize online maintenance functionManipulatorControl engineeringMachine

The invention belongs to the technical field of electric power operation climbing robots, and particularly relates to a rail type power angle steel tower maintenance robot. The robot comprises a main machine and a mechanical arm; the main machine comprises two sets of walking parts, and the two sets of walking parts are arranged on two adjacent angle steel main materials in a matched mode correspondingly; horizontal sliding tables are arranged on the two sets of walking parts; the mechanical arm is installed on the position, between the two sets of walking parts, of the front face of a base; and horizontal guide rods extend out of the positions, towards the horizontal sliding tables on the two sides, of the base, and sliding guide fit with the horizontal direction as the guide direction is formed between the horizontal guide rods and the horizontal sliding tables. The maintenance robot further comprises a centering assembly used for centering the position of the base. While the structure is light and reliable, the action stability and the action reliability of climbing operation can be synchronously ensured, so that the manpower inspection cost can be greatly saved, the maintenance efficiency is improved, and safe and reliable operation of a power transmission system is ensured.

Owner:STATE GRID ANHUI ELECTRIC POWER +1

A large-tonnage rock mass engineering dynamic disaster simulation test system

ActiveCN107860660BFull load testCompact structureMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesPunchingRock engineering

The invention provides a big-tonnage rock engineering power disaster simulation experiment system, and relates to equipment for performing experiments on big-tonnage rock. The equipment comprises a fixed base, a first base, an annular framework and a second base, wherein an upper and lower loading cylinder and a left and right loading cylinder are connected in the annular framework; a front and back loading cylinder is connected onto one side surface of the second base; each of the upper and lower loading cylinder, the left and right loading cylinder and the front and back loading cylinder comprises a static loading cylinder tube, a movable loading cylinder tube, a static loading piston rod and a movable loading piston rod; a movable loading cylinder tube installing cavity and a static loading rodless cavity are arranged in the static loading cylinder tube; the movable loading cylinder tube is arranged in a movable cylinder tube installing cavity; the static loading piston rod is arranged in the static loading rodless cavity; one end of the movable loading piston rod is provided with a movable loading piston; the movable loading piston is arranged in the movable loading cylinder tube; the other end of the movable loading piston rod penetrates through a press cover of the movable loading cylinder tube and the static loading piston rod, and is then connected with a replaceable punching head; one end, extending out of the static loading cylinder tube, of the static loading piston rod is provided with a fixing flange and a loading block. The static loading and the movable loading can be realized; the static loading and the movable loading can be also performed at the same time.

Owner:YANGZHOU JIANGDU YONGJIAN

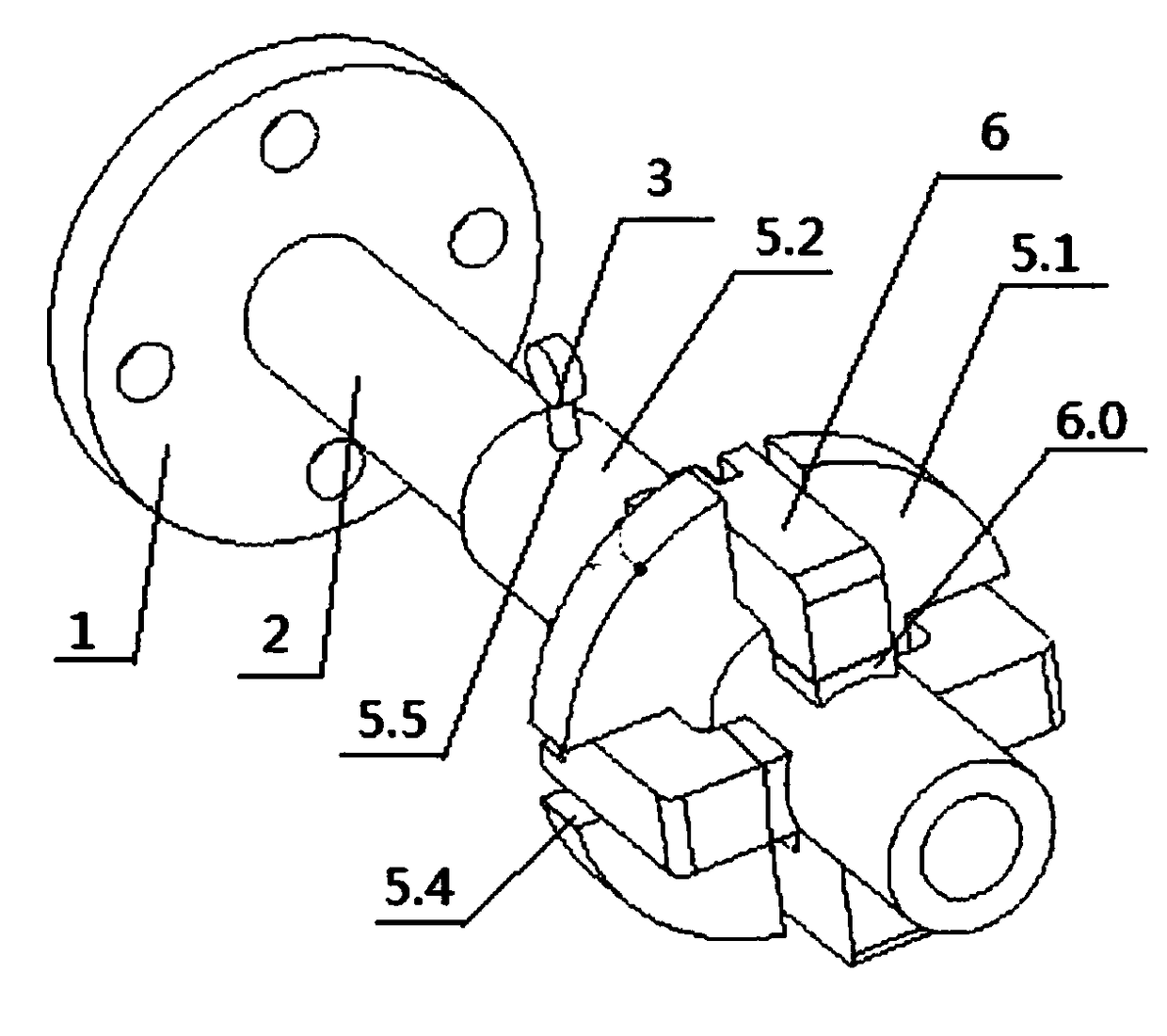

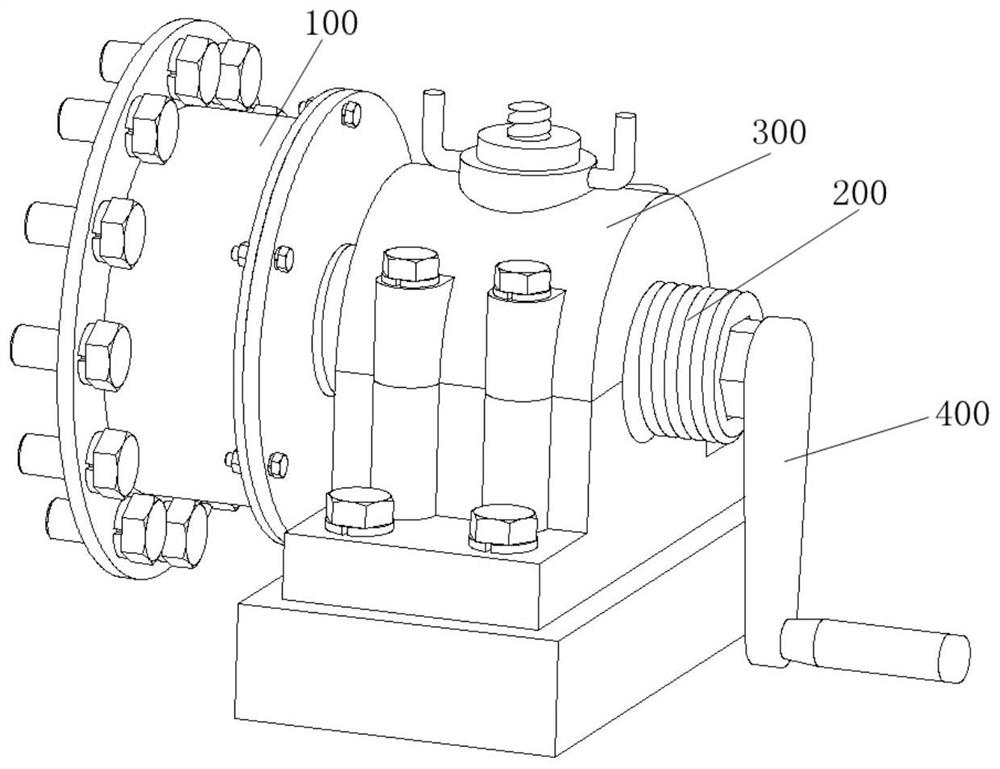

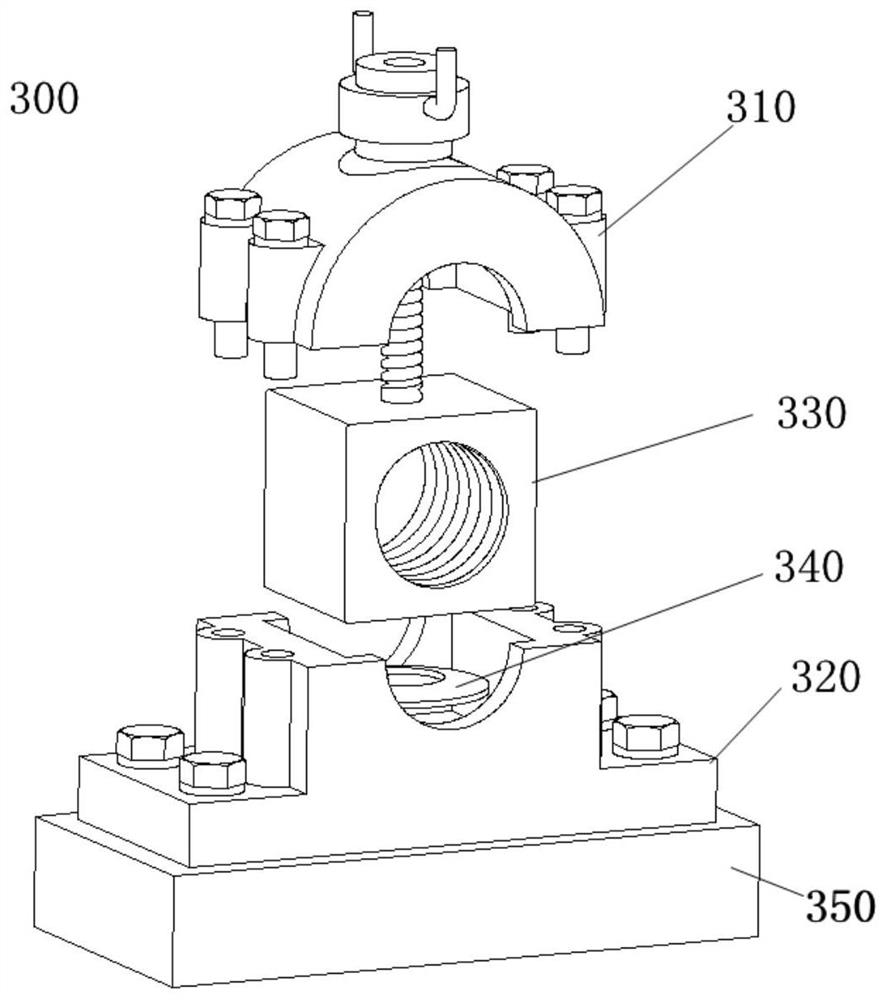

A quick-connect device suitable for heavy-duty rotary joints

ActiveCN114179026BProtectRealize coarse and fine two-stage centering functionMetal-working hand toolsClassical mechanicsScrew thread

The invention relates to a quick connection device suitable for heavy-duty rotary joints, comprising: a main shaft, the main shaft comprises a conical end part and a cylindrical body part, the body part is provided with a first thread; a main shaft guide seat, The main shaft guide seat is provided with a second thread, and the second thread is matched and connected with the first thread on the main shaft body; an expansion mechanism, the expansion mechanism includes: a shaft cylinder, and the inner surface of the shaft cylinder is a cone shape, which can be matched with the end of the main shaft; the barrel wall of the shaft barrel is provided with a plurality of grooves penetrating the barrel wall, and the expansion key includes a key body and a support part arranged on both sides of the key body, The surface of the key body close to the center of the shaft barrel is tapered; the expansion key is arranged in a groove on the wall of the shaft barrel, and the support part is arranged in the middle of the groove; a bearing, the bearing It is sleeved on the outside of the shaft barrel and the expansion key; the expansion structure shell is sleeved on the outside of the bearing.

Owner:国创机器人创新中心(哈尔滨)有限公司

A shaft pinch clamp centering device

ActiveCN104029043BConvenient centering pinchRealize pinching functionWork clamping meansWork holdersRocker armEngineering

Owner:TIANRUN IND TECH CO LTD

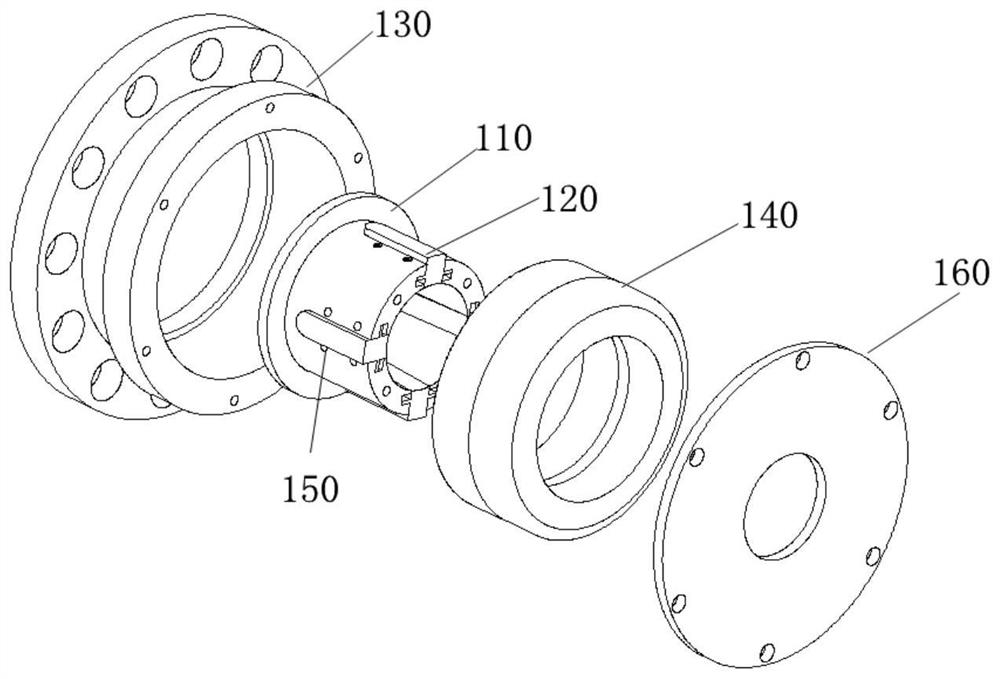

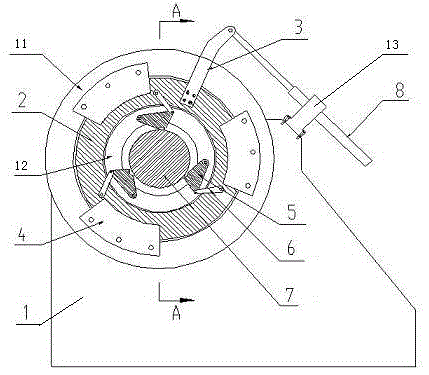

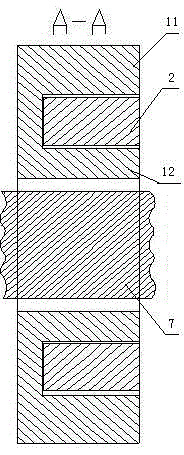

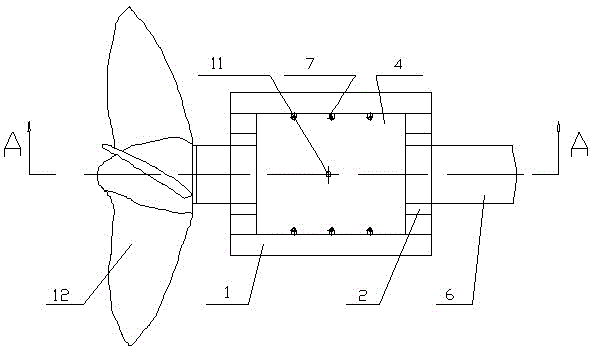

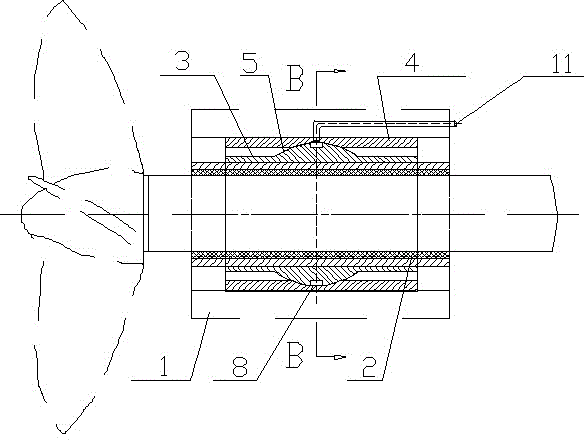

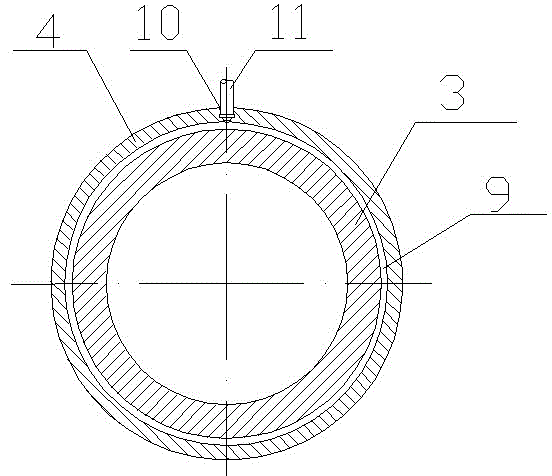

Adjustable center propeller bearing device

ActiveCN102840229BRealize the centering functionCentering function guaranteeBearing componentsSliding contact bearingsPropellerLubrication

Owner:CHINA SHIP DEV & DESIGN CENT

Auxiliary positioning mechanism for taping machine

ActiveCN106328369BRealize the centering functionPrevent looseningCoils manufactureMechanical engineeringEngineering

The invention provides an auxiliary positioning mechanism of a taping machine. The auxiliary positioning mechanism comprises a track and at least two groups of adjusting wheels arranged outside a packaging channel of the taping machine, wherein the track is horizontally arranged and is fixed at the side of the packaging channel; the adjusting wheels are arranged on the track in a sliding manner and can be fixed on the track; and shafts of the adjusting wheels are arranged along the vertical direction. When the auxiliary positioning mechanism is used, one side of an annular coil can pass through the packaging channel and then is limited by two paper wheels and the other side of the annular coil is clamped by two groups of adjusting wheels; and the positions of the two groups of adjusting wheels are adjusted to adapt to the annular coils with different diameters and then the adjusting wheels are fixed, so that taping of the annular coil can be carried out.

Owner:NEWONDER SPECIAL ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com