Element centering device of component inserter

A technology of alignment device and plug-in machine, which is applied in the direction of assembling printed circuits, electrical components, and electrical components with electrical components. High degree, fast running speed, stable running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

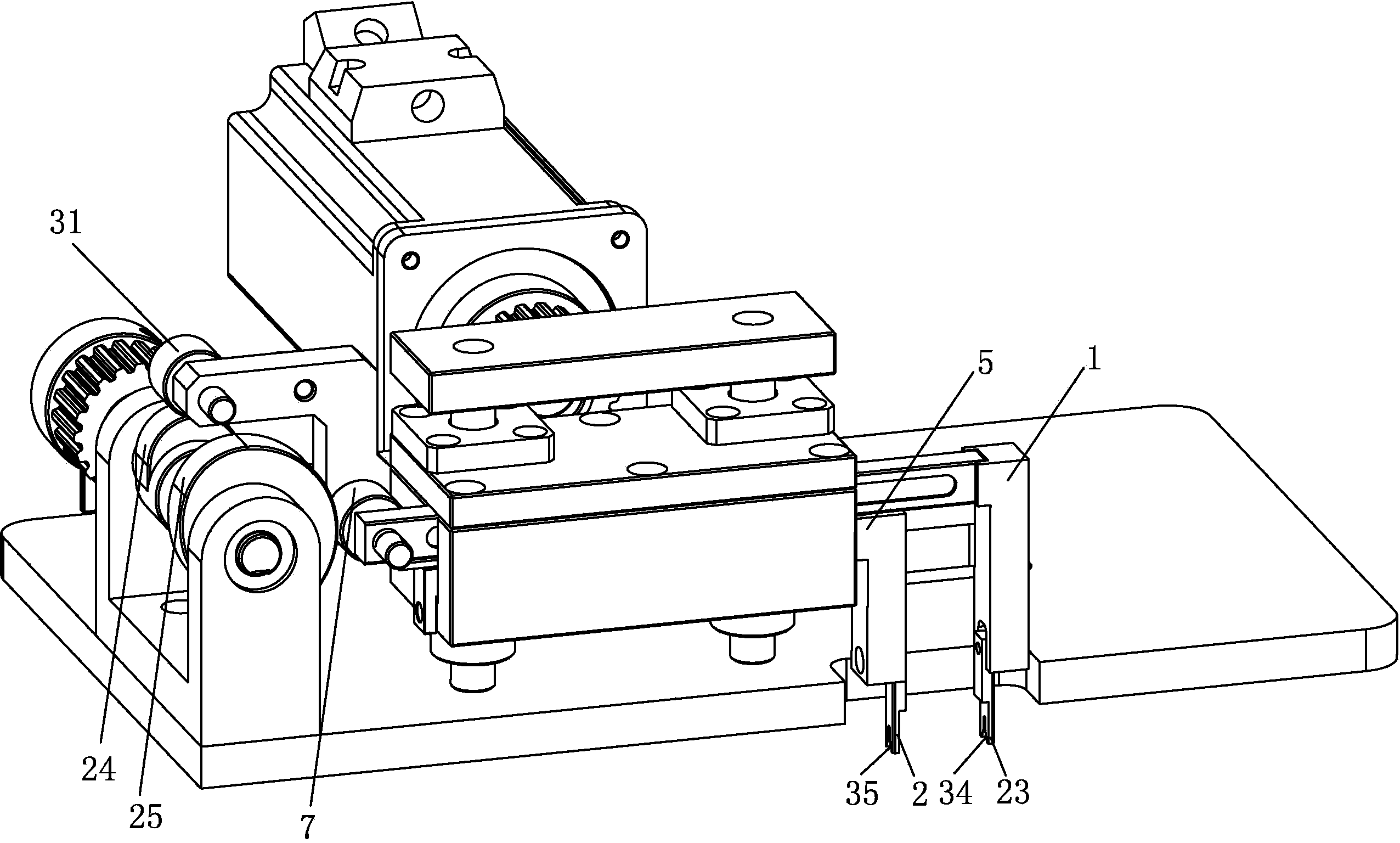

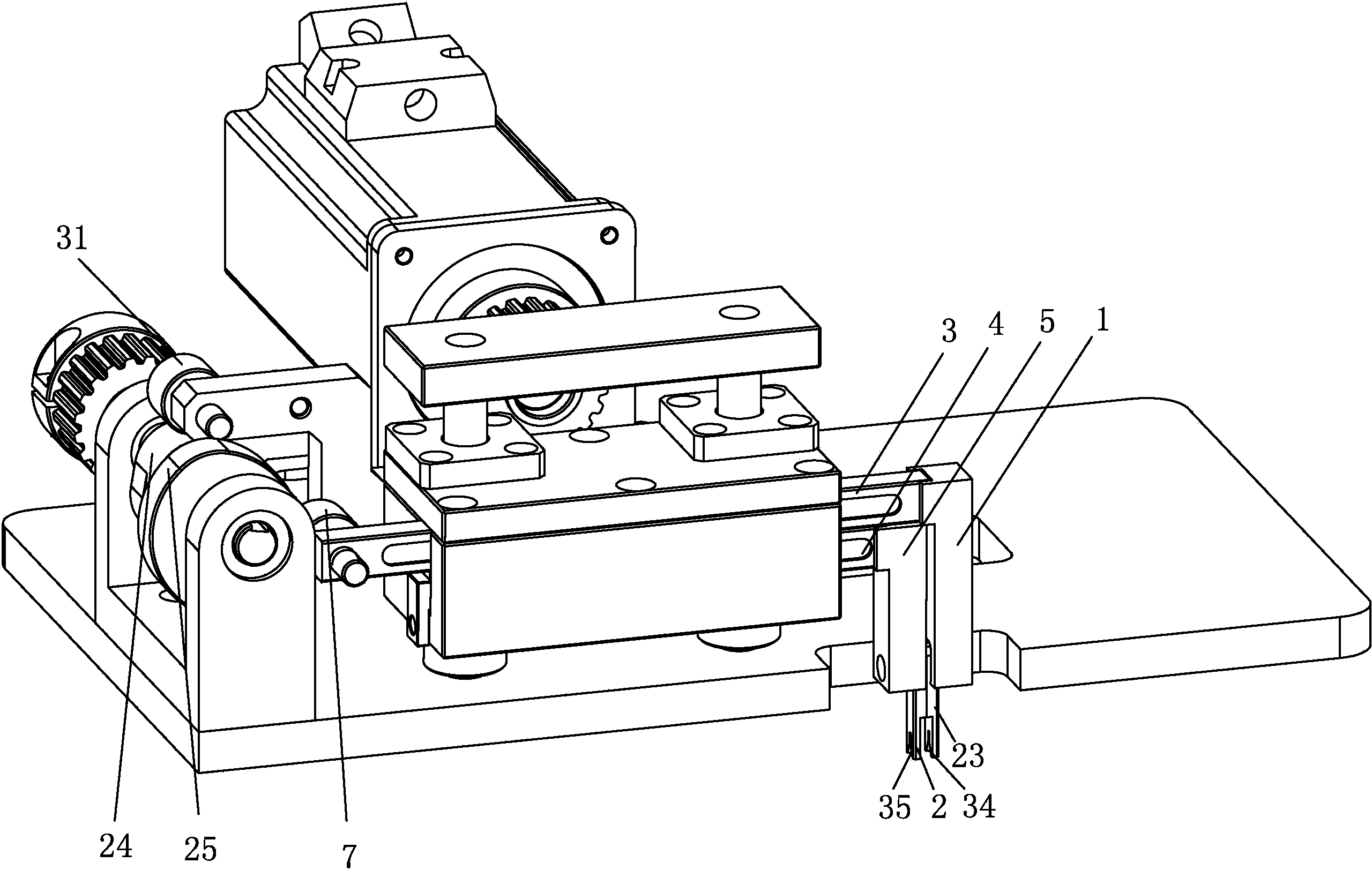

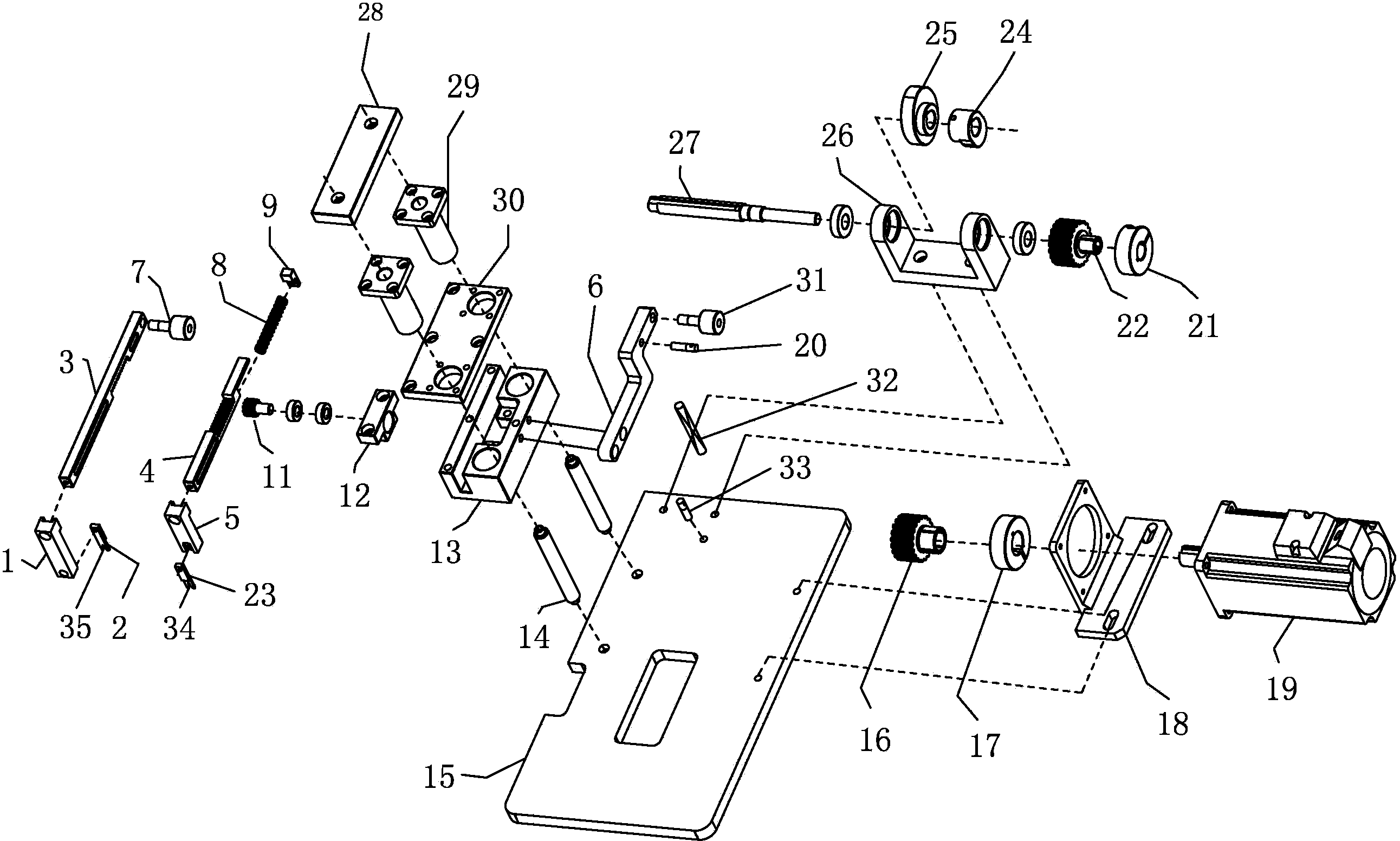

[0032] A component centering device of a plug-in machine in this embodiment such as Figure 1 to Figure 4 As shown, it includes a base 13, a centering opening and closing device and a driving device. The centering opening and closing device is arranged on the base 13; the centering opening and closing device is provided with a gear 11 and an upper rack 3 and a lower rack 4 parallel to each other. , the upper rack 3 and the lower rack 4 are meshed with the gear 11, the driving device is provided with a left and right cam 25 and a device for driving the left and right cam 25 to rotate, and the left and right cam 25 is arranged on one side of the upper rack 3 and resists the upper gear One end of the bar 3, the upper rack 3 and the lower rack 4 are respectively provided with clamping parts perpendicular to the upper rack 3 and the lower rack 4.

[0033] A reset device is also provided, one end of the reset device is set on the base 13 , and the other end of the reset device is se...

Embodiment 2

[0036] A component centering device for a plug-in machine, the other structures of this embodiment are the same as those of Embodiment 1, the difference is that: the upper rack is provided with a right clamping part, the lower rack is provided with a left clamping part, and the right clamping part The parts include an upper rack connecting block 1 and a right centering piece 23, the upper rack 3 connecting block 1 is vertically connected with the upper rack 3, one end of the right centering piece 23 is arranged on the upper rack connecting block 1 and the right centering piece The other end of 23 is exposed below the upper rack connection block 1, and the other end of the right centering piece 23 is provided with a first positioning groove 34;

[0037] The left clamping part includes a lower rack connecting block 5 and a left centering piece 2, the lower rack connecting block 5 is vertically connected with the lower rack 4, one end of the left centering piece 2 is arranged on t...

Embodiment 3

[0045] A component centering device of a plug-in machine, the other structure of this embodiment is the same as that of Embodiment 1, the difference is that: the base 13 is also provided with a spring stopper 9, and one end of the first return spring 8 is connected to the spring stopper 9 , the other end of the first return spring 8 is connected to the lower rack 4 .

[0046] When the first return spring 8 is compressed, the provided spring stopper 9 can provide a blocking force for the first return spring 8 .

[0047] The driving device is also provided with upper and lower cams 24 coaxial with the left and right cams 25 . The up and down cam 24 is used to control the up and down movement of the centering tensioning device.

[0048] A centering base plate 15 is also provided, and the base 13 is arranged on the centering base plate 15. The centering base plate 15 is also provided with a camshaft seat 26. The upper and lower cams 24 and the left and right cams 25 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com