A shaft pinch clamp centering device

A technology of shaft parts and fixing rings, which is applied in the field of shaft centering and fixing devices, can solve the problems of inability to achieve centering and centerline offset, and achieve the effects of convenient centering and clamping, reliable operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

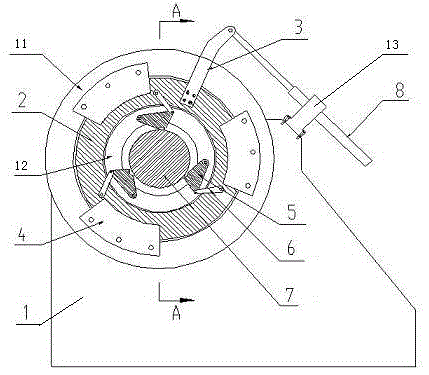

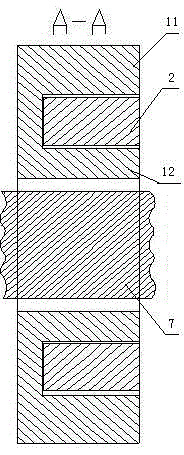

[0014] From figure 1 , figure 2 It can be seen from the figure that a pinch centering device for shafts includes a base 1, a rotating ring 2, a rotating rocker arm 3, a pressing plate 4, a locking block 5, a connecting rod 6, a pneumatic telescopic rod 8, and the like. The base 1 is provided with an outer fixing ring 11 and an inner fixing ring 12, the center of the inner fixing ring 12 is provided with a circular through hole of a shaft part, and a circular groove is arranged between the outer fixing ring 11 and the inner fixing ring 12 The rotating ring 2 is installed in the circular ring groove through the pressure plate 4; the locking blocks 5 are evenly distributed on the outer end surface of the inner fixing ring 12 around the shaft parts 7, and one end of each locking block 5 is hinged and fixed by screws On the fixed ring 12 in the base, the other end is hinged with the connecting rod 6, and the inner side of the locking block 5 is provided with an arc surface in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com