A large-tonnage rock mass engineering dynamic disaster simulation test system

A technology for simulating test systems and dynamic disasters, applied in the direction of testing material strength by applying repetitive force/pulsation force, testing material strength by applying stable tension/pressure, instruments, etc., which can solve the problem of strain field range and uniformity of test equipment. It satisfies the problems of engineering practice and achieves the effect of compact structure, reducing direct damage and ensuring feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

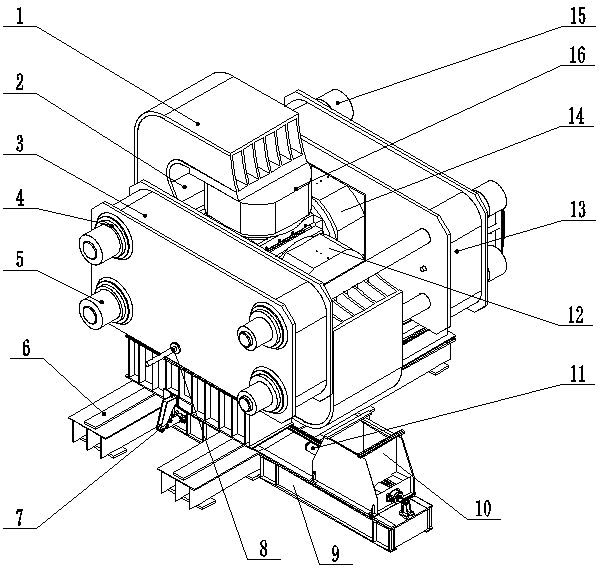

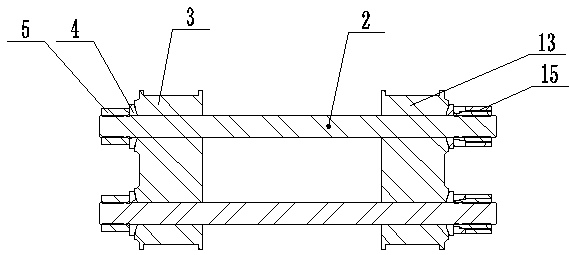

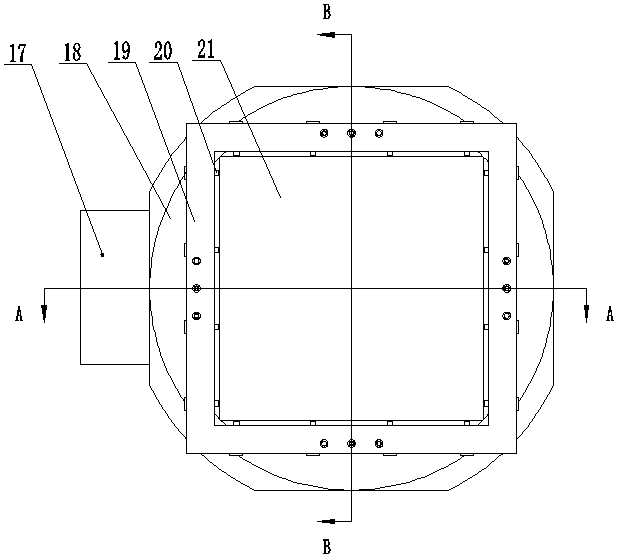

[0025] like figure 1 , 2 As shown, the large-tonnage rock mass engineering dynamic disaster simulation test system includes a fixed base 9 on which a first base 3, an annular frame 1, and a second base 13 are connected. The first base 3 and the second base 13 are respectively The connection base drives the oil cylinder 7, and is connected to the fixed base 9 through the guide rail 6. The first base 3 and the second base 13 are respectively located on the front and rear sides of the annular frame 1. The first base 3, the annular frame 1, and the second base 13 pass through The tie rod 2 is connected. One end of the tie rod 2 extends out of the first base 3 and then connects with the nut 5. A spherical pad 4 is arranged between the nut 5 and the first base 3, and the other end of the tie rod 2 extends out of the second base 13 and then connects with the hydraulic nut 15.

[0026] The moving trolley 10 is connected to the fixed base 9 through the moving trolley driving cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com