Modular centering bearing device

A self-aligning bearing, modular technology, applied in the direction of bearings, bearing components, roller bearings, etc., to achieve the effect of enhancing strength, facilitating processing, and improving reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

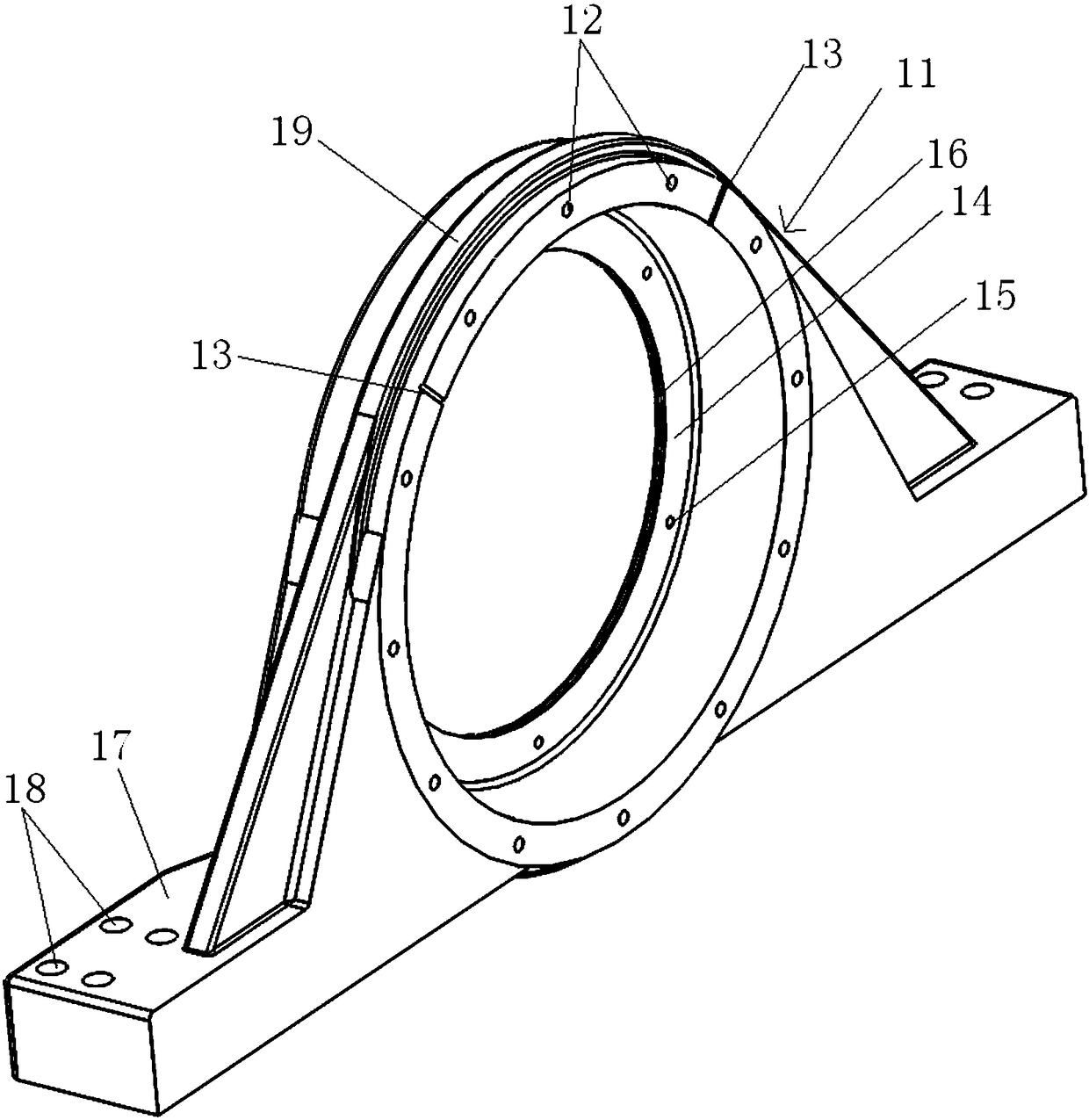

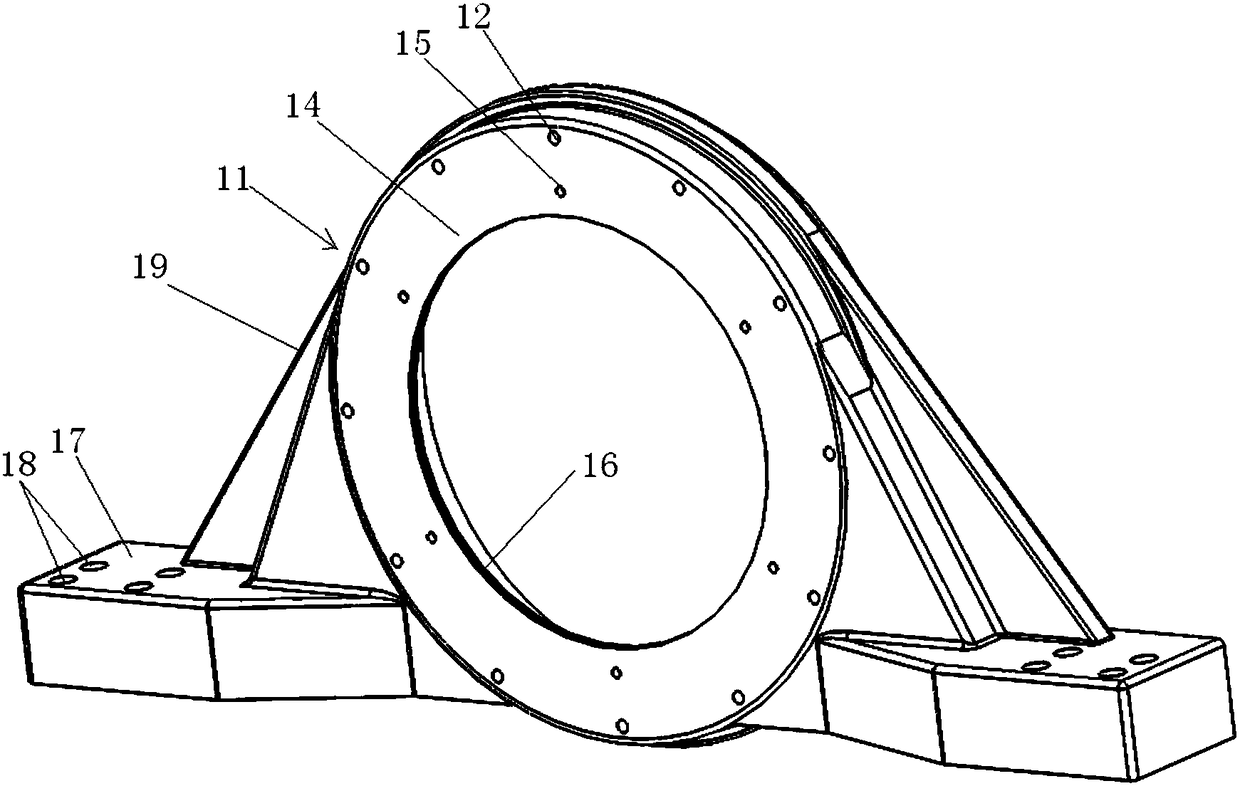

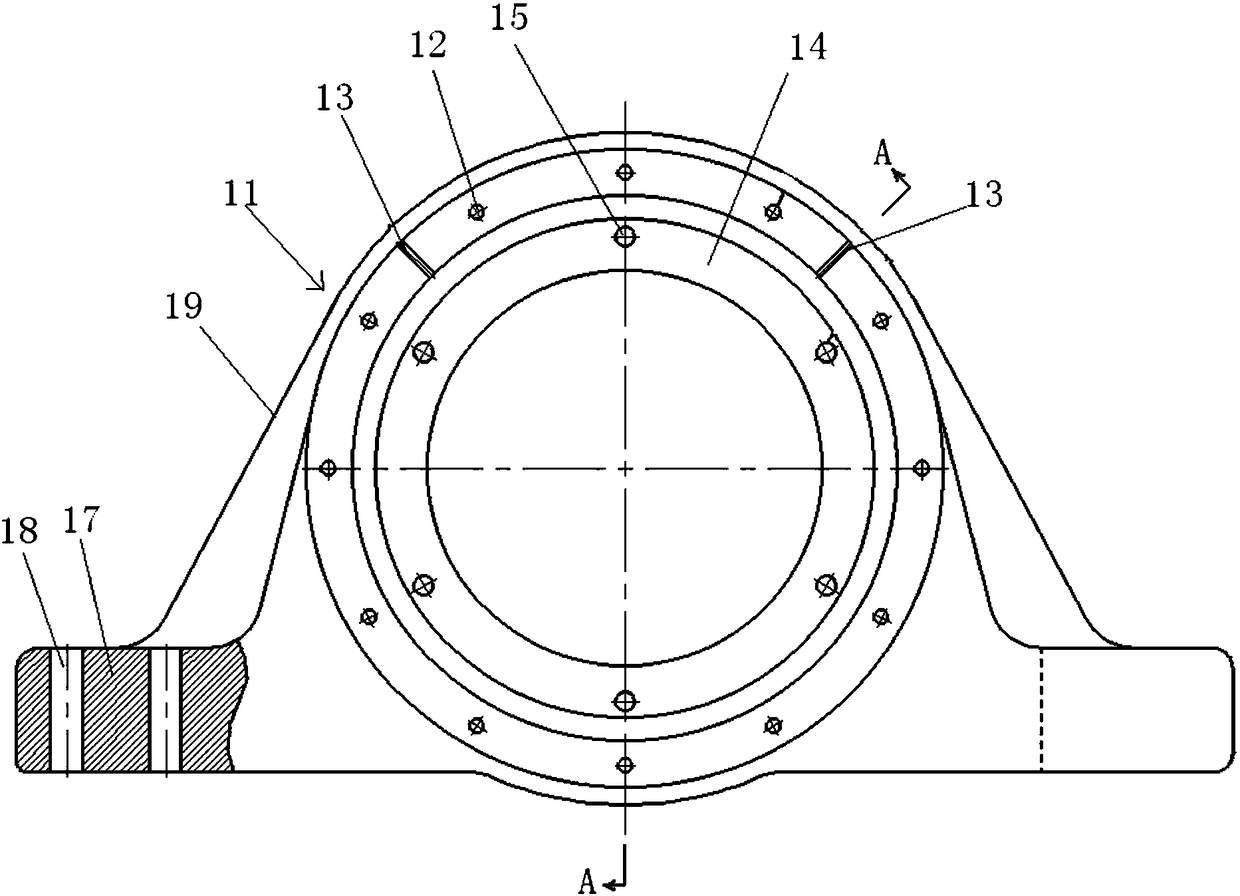

[0032] This embodiment takes the thrust bearing applied to the main shaft of a wind turbine as an example to describe the modular self-aligning bearing device of the present invention in detail, which should not be construed as any limitation to the bearing device. The specific structure is as follows:

[0033] Refer to attached Figures 1 to 7 As shown, the modular self-aligning bearing device of the present invention includes a split bearing housing 1 and a tapered roller bearing 2 arranged in the bearing housing 1 . The outer surface of the outer ring of the tapered roller bearing 2 and the inner radial surface of the bearing housing 1 adopt a clearance fit of a spherical structure to realize the alignment between the outer ring of the bearing and the split bearing housing and avoid misassembly The assembly stress generated in the middle, and can avoid the unbalanced load phenomenon.

[0034] Wherein, the tapered roller bearing 2 in this embodiment is a double-row tapered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com