Device for assembling spiral check ring for hole

An assembling device and screw technology, which is applied in the field of assembling spiral retaining rings for holes, can solve the problems of small volume, small installation space and large elasticity of the spiral retaining ring, and achieve the effects of improving assembly efficiency, reducing contact area and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

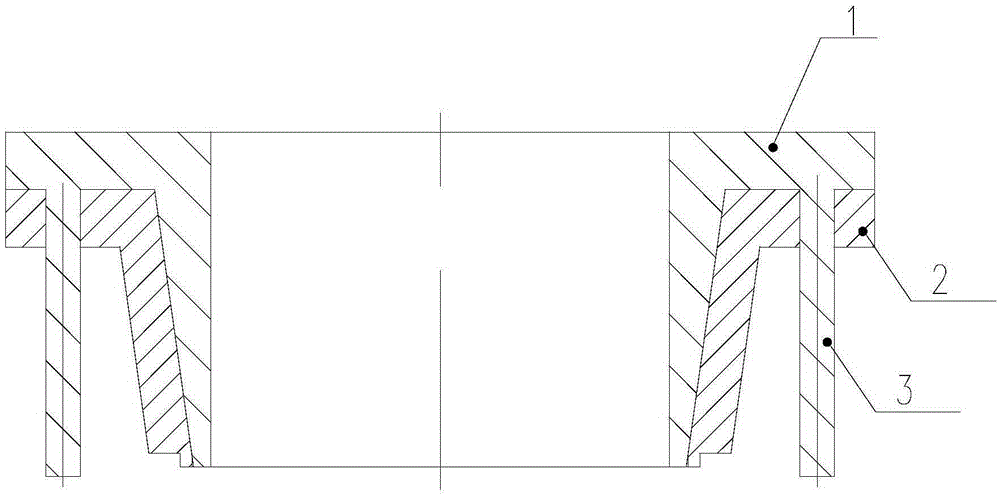

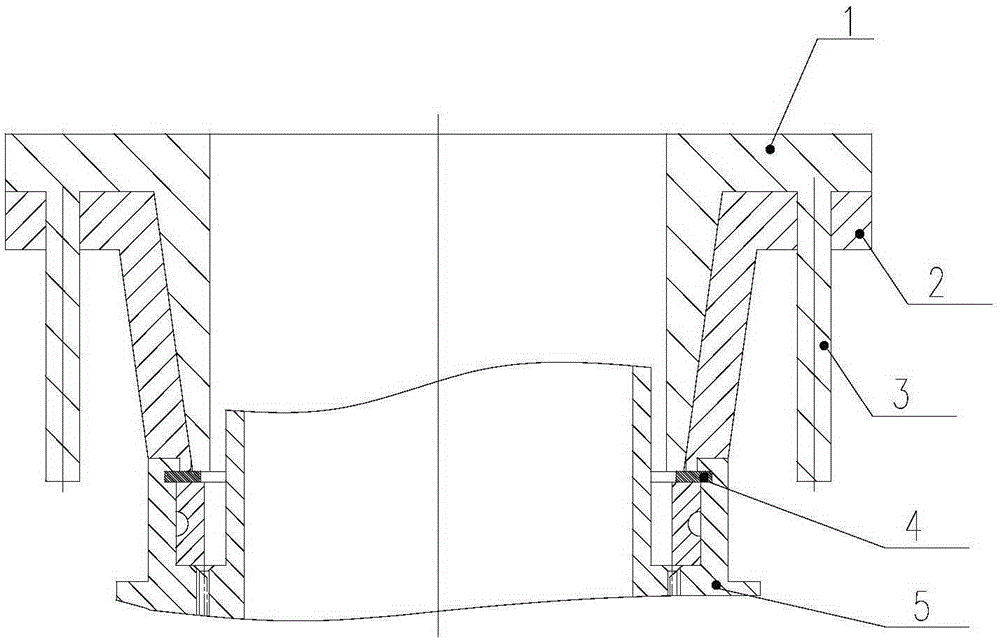

[0009] As shown in the figure, the assembly device for the spiral retaining ring for holes includes an indenter 1 and a guide cone 2. The indenter 1 is T-shaped, the lower part is conical, and the guide cone 2 is annular. The taper is matched with the taper, the indenter 1 is provided with a guide pin 3 extending downward, and the guide cone 2 is provided with a hole, and the guide pin 3 can pass through the hole on the guide cone 2, so that the indenter 1 Vertical movement, the length of the generatrix of the conical surface of the indenter 1 is not less than the length of the generatrix of the inner conical surface of the guide cone 2, so as to ensure that the conical shape of the indenter can move to the lower part of the guide cone; the guide cone 2. The lower part is provided with a step, and the step is matched with the inner hole of the shaft 5 to be installed with the spiral retaining ring 4, and is extended to the installation position of the spiral retaining ring 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com