Split type automobile centering, lifting and carrying robot

A handling robot and split-type technology, which is applied to the field of split-type vehicle centering, lifting and handling robots, can solve the problems of complex production, driver parking interference, increased control difficulty and control time, etc., to improve stability and prevent vehicle scratches. Or bump, improve the efficiency of car access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

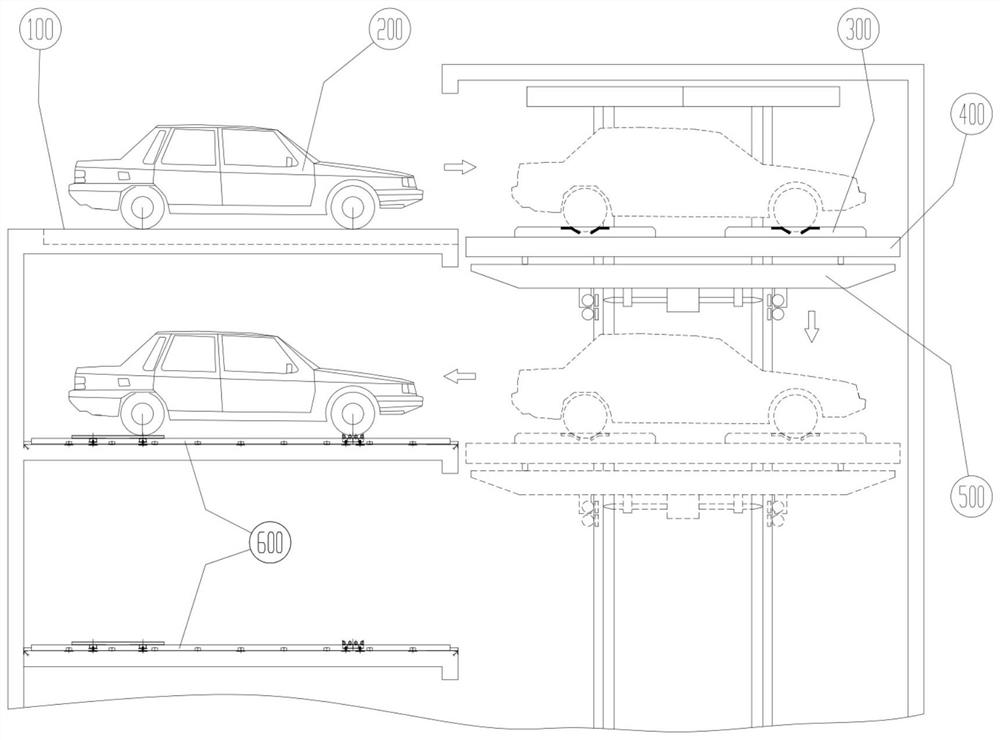

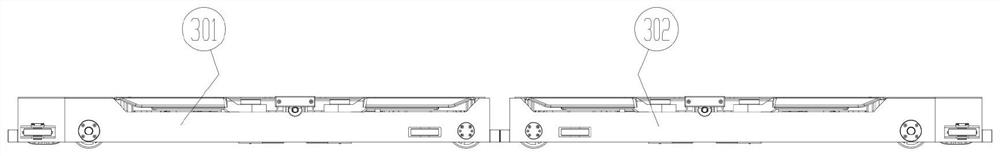

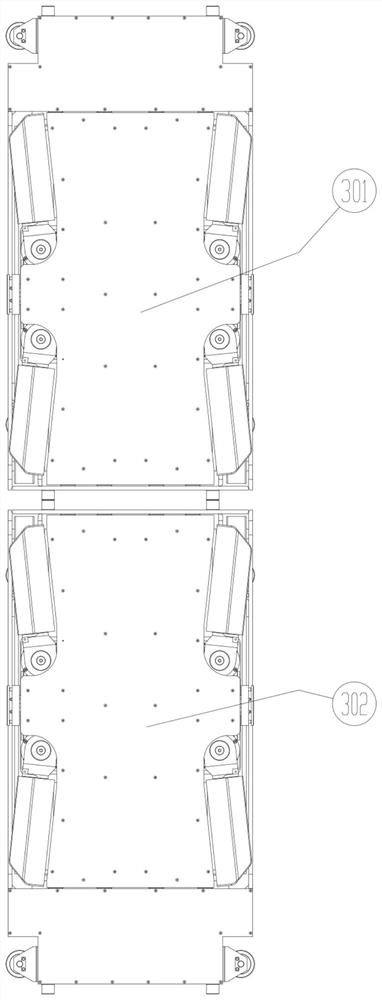

[0036] Such as figure 1 As shown in -3, the present invention provides a split type automobile centering lifting and transporting robot, comprising: a front body for lifting the front wheel part of the vehicle and a rear body for lifting the rear wheel part of the vehicle, the front Both the car body and the rear car body have an inner and outer double-layer frame structure. The front car body and the rear car body respectively include mutually independent travel transmission mechanisms, and the travel transmission mechanisms are arranged on the outer frame of the corresponding car body. Both the front body and the rear body are provided with functional units;

[0037] The functional unit includes: two sets of clamping and swinging arm mechanisms, vehicle centering mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com