Retrievable through tubing tool and method

a tubing whipstock and tool technology, applied in the direction of directional drilling, sealing/packing, and wellbore/well accessories, etc., can solve the problems of inability to manufacture apparatus and methods, time-consuming and labor-intensive, and difficulty in removing tubular strings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

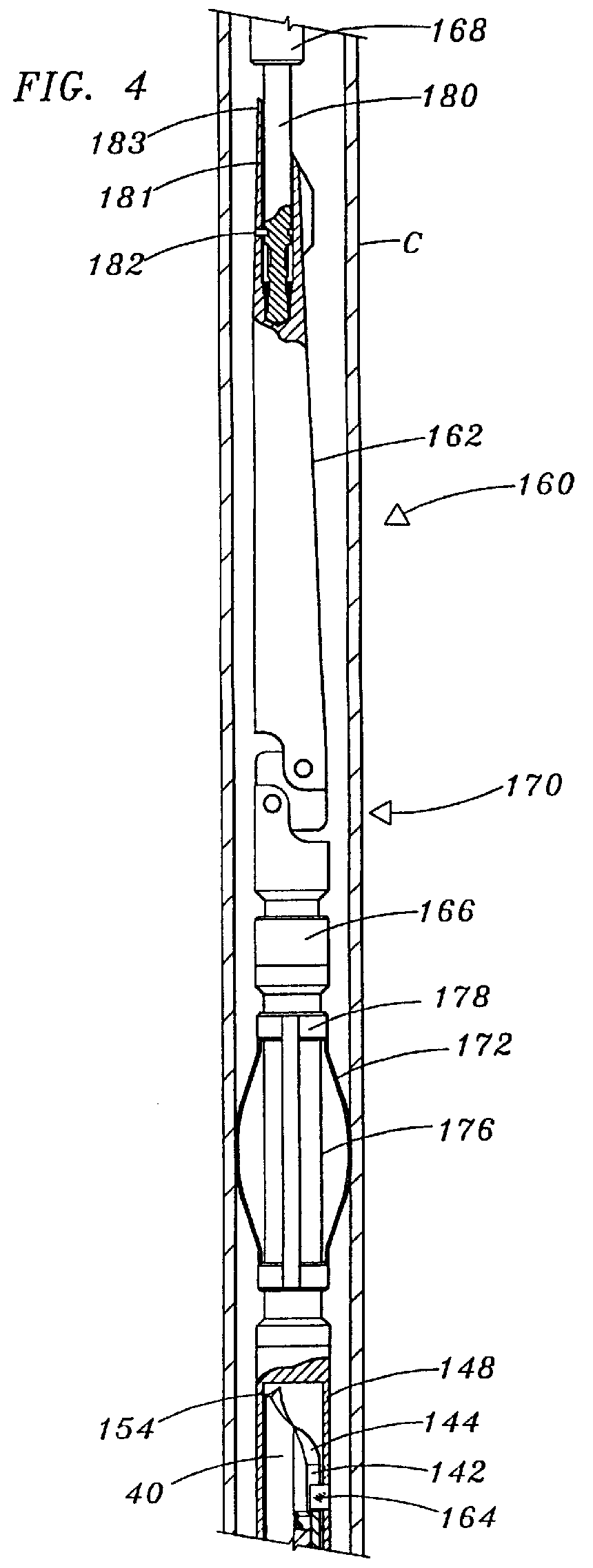

The present invention provides a through tubing whipstock and anchor assembly for milling a window in a wellbore tubular that may be lowered through a smaller diameter tubular string and set for performing a whipstock operation within a larger diameter tubular string, and may subsequently be unset and retrieved from the wellbore through the smaller diameter tubular string.

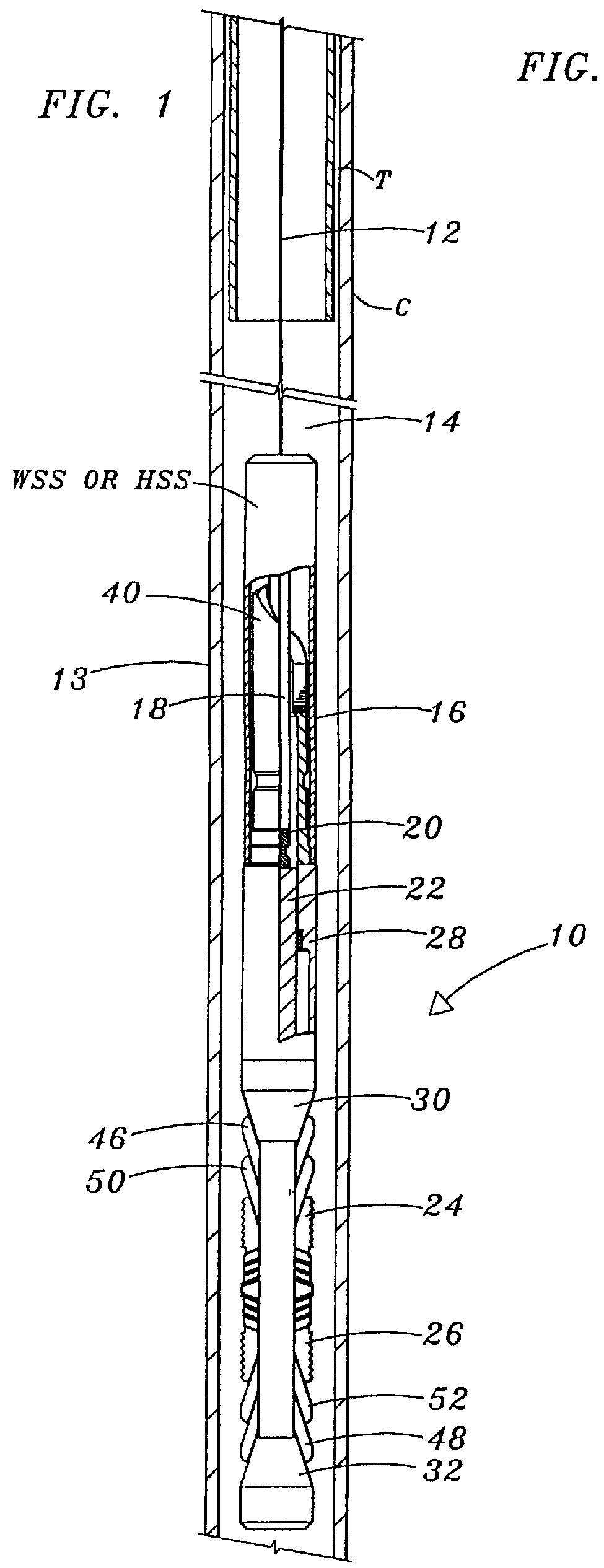

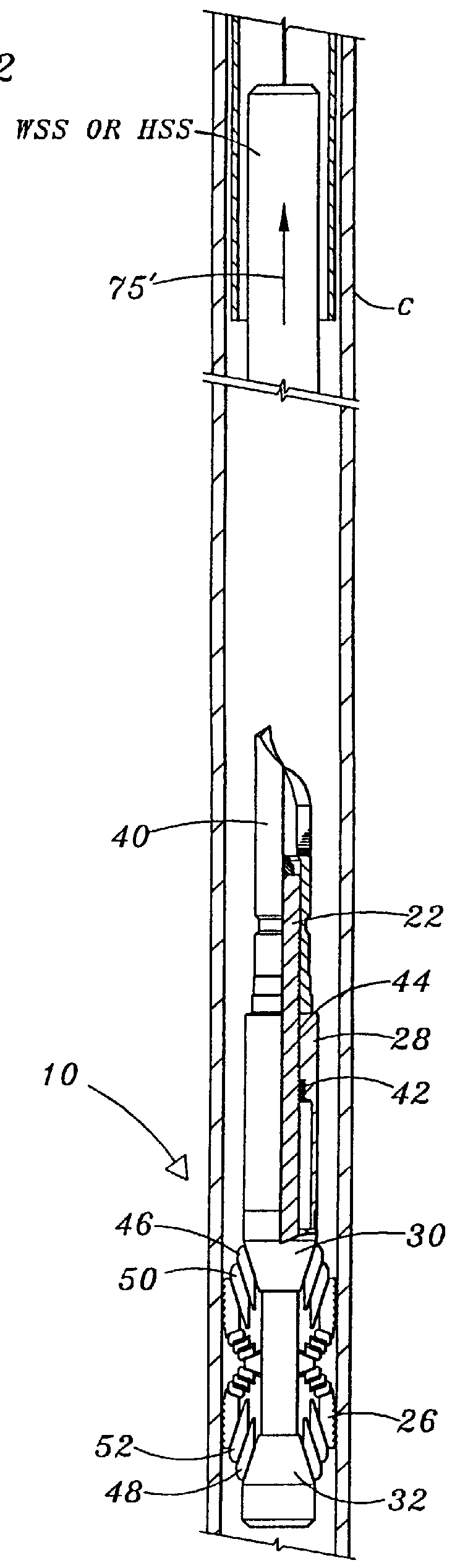

By way or example only and not by way of limitation, a whipstock operation according to a presently preferred embodiment of the invention may proceed by first lowering the anchor assembly, that is attached to an electrically activated setting tool, through the bottom of the tubing into a casing string as schematically indicated in FIG. 1. It will be understood that the anchor assembly may also be lowered from a coiled tubing string or work string, then set with a hydraulically activated setting tool. After the anchor assembly has been set within the casing string, the setting tool may be removed as shown in FIG. 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com