Laser-jet electrolysis combined machining double-pipe tool electrode and milling machining method

A tool electrode and compound processing technology, which is applied in the direction of manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problems of high-efficiency and high-precision processing of difficult and high material removal rates, and achieve high processing accuracy, large area and stable process good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

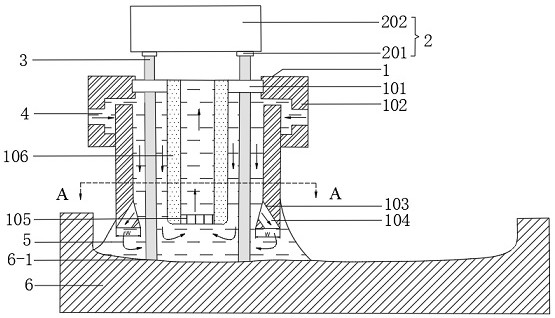

[0033] The present invention will be further explained below in conjunction with the specific drawings.

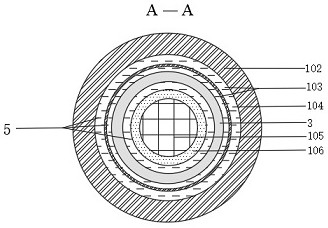

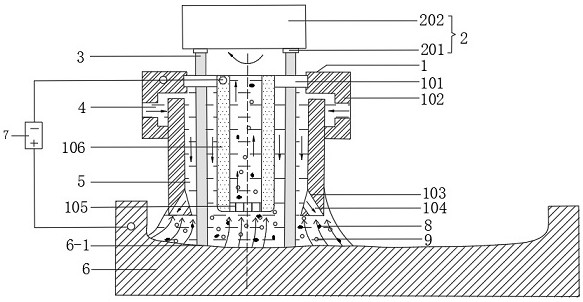

[0034] like figure 1 and figure 2 As shown, a double-tube tool electrode for laser-jet electrolysis composite processing includes a power supply 7 and a laser generating system 2, and is characterized in that: it also includes an optical lens 101, an outer cathode tube 102, an inner oblique convex ring 103, an array outer oblique Holes 104 , grid 105 , inner cathode tube 106 and annular laser beam 3 . The outer cathode tube 102 is coaxially sleeved outside the inner cathode tube 106 , and the outer diameter of the inner cathode tube 106 is 5 mm smaller than the inner diameter of the outer cathode tube 102 . The inner cathode tube 106 has an inner diameter of 15 mm and a wall thickness of 1 mm. The inner diameter of the outer cathode tube 102 is 20 mm, and the wall thickness is 1 mm. The mesh grid 105 is fixed at the lower end of the inner cathode tube 106, the mesh of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com