Discharge method of electro-corrosion products in EDM

A technology of electric spark and electric erosion, which is applied in the field of discharge of electric discharge products in electric discharge machining, can solve problems such as difficulty in removing electric corrosion products, and achieve the effects of avoiding electrode feed stagnation, preventing deflection, and improving discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

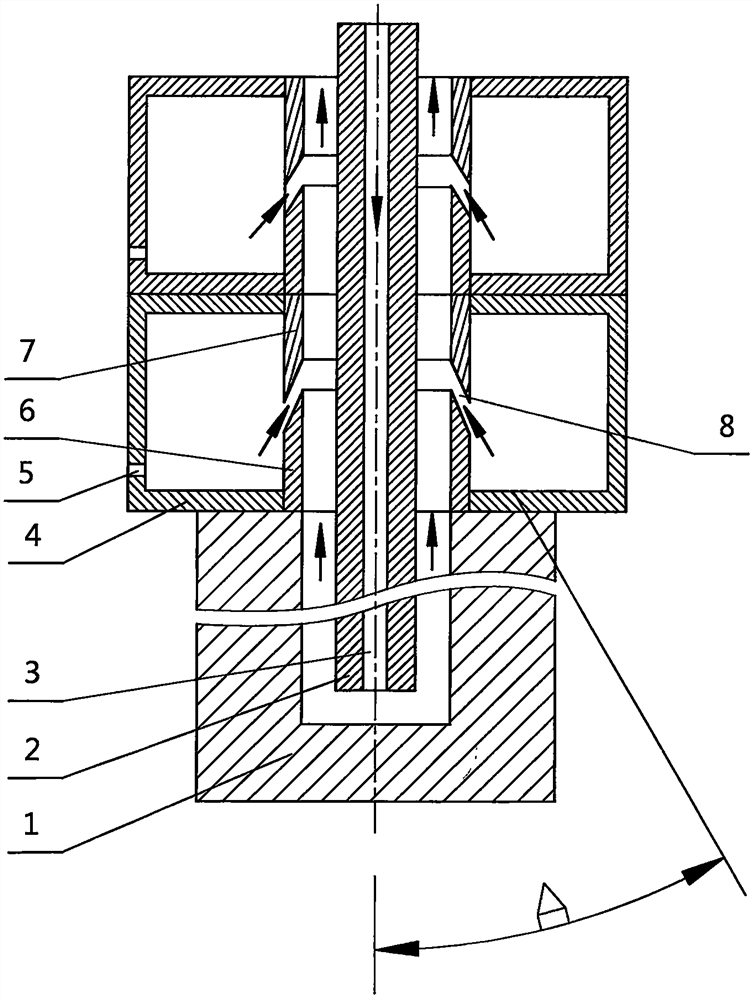

[0021] Embodiment 1: At the beginning of the processing process, liquid with pressure is input into the hydraulic tank 4 to fill the semi-closed space. The liquid flows out from the annular gap 8 and mixes with the working liquid to take away the electrolytic corrosion products .

Embodiment approach 2

[0022] Embodiment 2: At the beginning of the processing process, no pressurized liquid is input into the hydraulic tank 4 . When it is difficult to discharge the electro-corrosion products during the processing, the liquid with pressure is input into the hydraulic tank 4, and the additional fluid is used to help discharge the electro-corrosion products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com