Visual programming method and operation system of truss mechanical arm

A programming method and operating system technology, applied in the field of automation equipment, can solve problems such as increasing user capital costs, delaying debugging progress, etc., to achieve the effect of speeding up debugging progress and saving debugging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

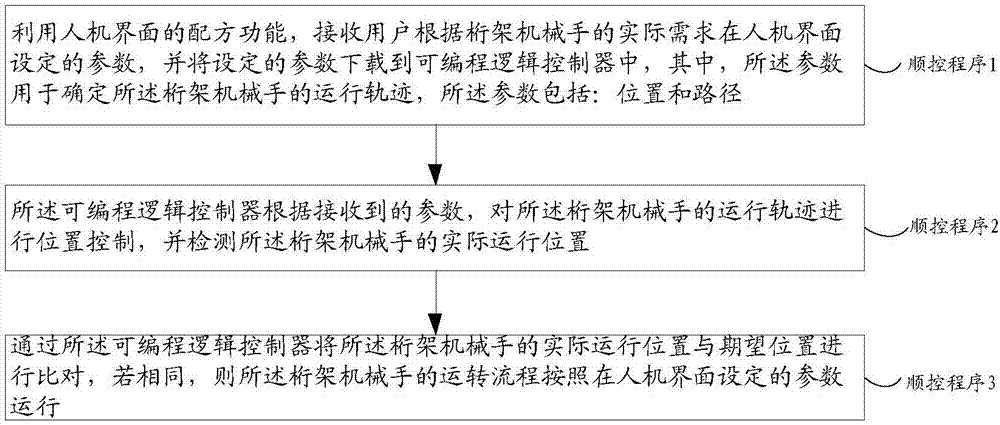

[0041] Such as figure 1 As shown, the visual programming method of the truss manipulator provided by the embodiment of the present invention includes:

[0042] The sequence control program 1 uses the formula function of the man-machine interface to receive the parameters set by the user on the man-machine interface according to the actual needs of the truss manipulator, and download the set parameters to the programmable logic controller, wherein the parameters For determining the running trajectory of the truss manipulator, the parameters include: position and path;

[0043] Sequential control program 2, the programmable logic controller performs position control on the running trajectory of the truss manipulator according to the received parameters, and detects the actual running position of the truss manipulator;

[0044] Sequential control program 3, compare the actual running position of the truss manipulator with the expected position through the programmable logic cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com