Balance oscillating dyeing machine

An oscillating and balanced technology, which is applied in vibration treatment, dyeing equipment for textile materials, textiles and papermaking, etc., can solve problems such as trouble-free working time, noise pollution, and large vibration that affect the service life of the crank-link mechanism. , to achieve the effect of simple structure, stable operation and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

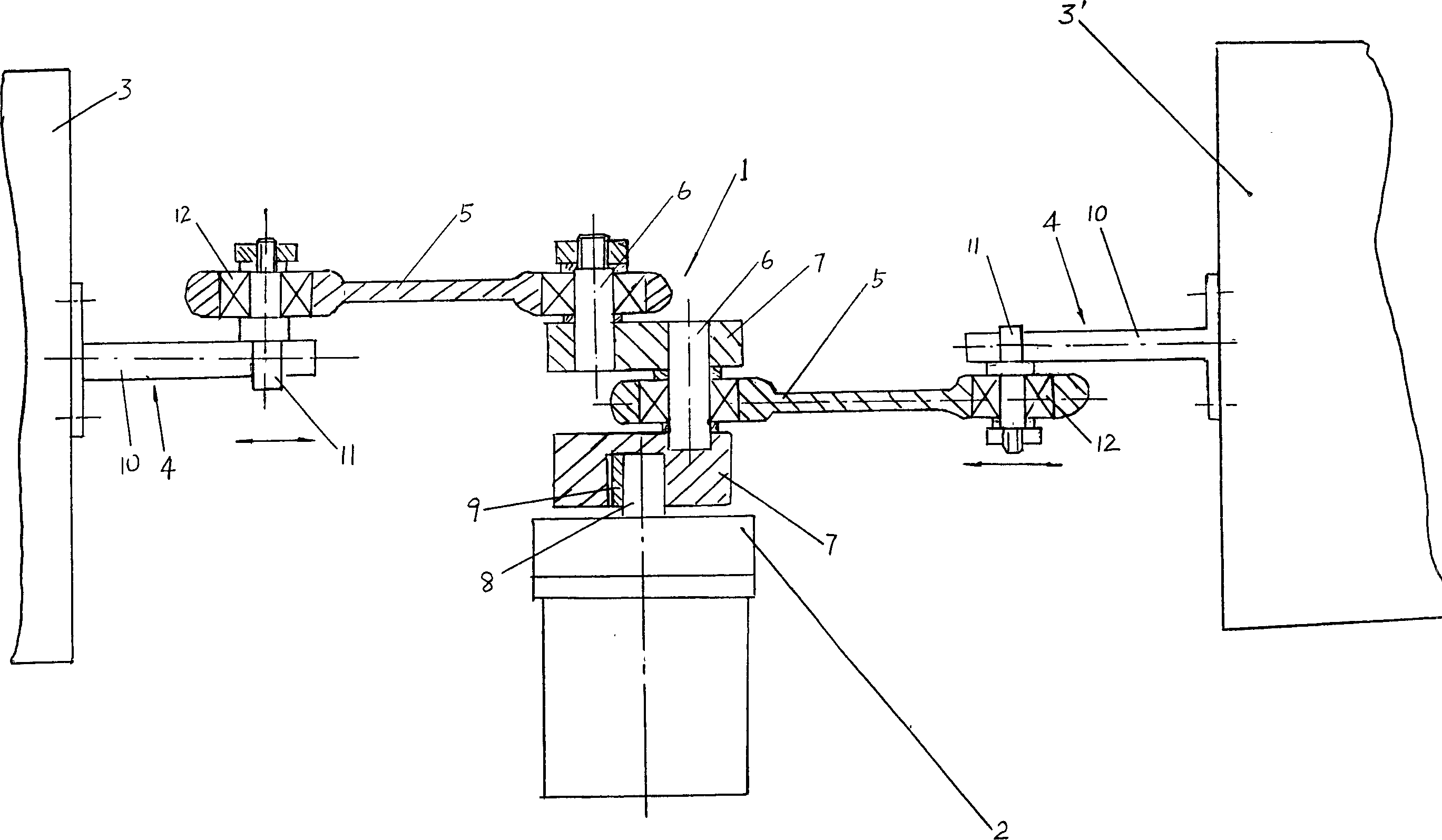

[0018] like figure 1 As shown, a balanced oscillating dyeing machine includes a crank-link mechanism 1. The crank-link mechanism 1 is at least composed of two crank discs 7, two cranks 6 and two connecting rods 5. One crank 6 is located on two Between the crank plates 7, another crank 6 is suspended on one crank plate 7, and the center of the other crank plate 7 is provided with a connecting hole with a keyway, which drives the output shaft 8 of the power assembly 2 of the whole crank linkage mechanism 1 to rotate. Inserted into the connection hole and connected to the crank plate 7 through the key 9, the crank plate 7 and the crank 6 in the crank linkage mechanism 1 can be an integral structure, or a split combined structure, and this embodiment is a split structure; Power assembly 2 can adopt the motor or speed-regulating motor that has reduction box, also can be the motor of belt deceleration, can also be diesel engine etc., what present embodiment adopted is the motor that...

Embodiment 2

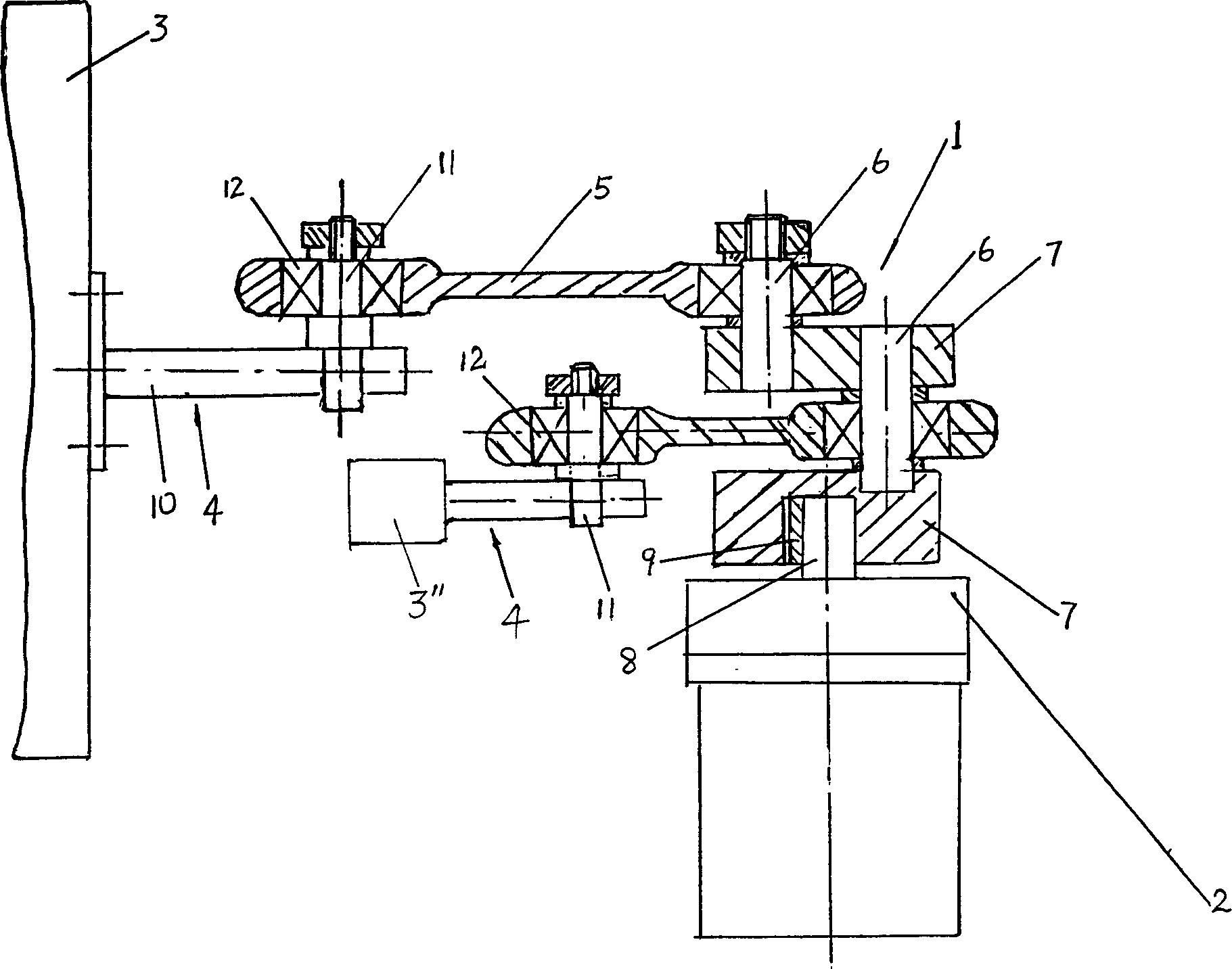

[0022] like figure 2 shown.

[0023] The difference between the present embodiment and the first embodiment is that the balance weight 3 " (the vibration box 3 ' can also be used in specific implementation) and the vibration box 3 are both located at the center axis of the crank connecting rod mechanism 1. On the same side, the balance weight 3 "can adopt a metal block, and its weight is determined after the counterweight calculation.

[0024] The other parts of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com