Rolling water drying machine

A drying machine and water-rolling technology, applied in textile and papermaking, liquid/gas/steam textile material processing, textile material processing, etc. Simple and convenient operation, good drying effect, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

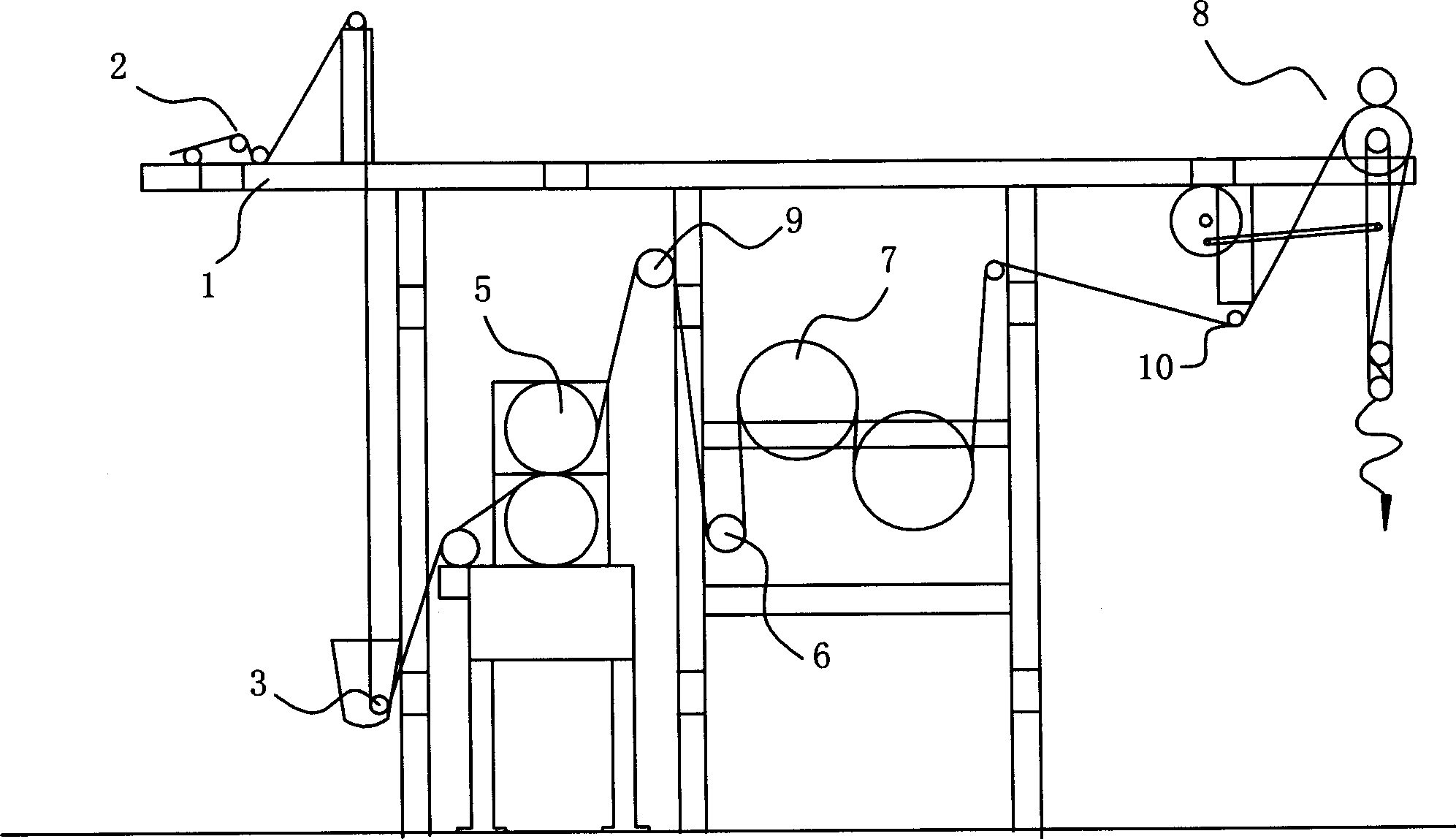

[0007] See attached figure 1 As shown, this embodiment consists of a power distribution box, three AC frequency conversion motors, a cloth feeding frame 1, a cloth feeding guide roller 2, a dip dyeing roller 3 located in a dipping tank, a tenter roller 4, an air press hydraulic roller 5, a tension Roller 6, two drying cylinders 7, cloth guide output and doffing roller 8, wherein the air pressure roller 5 is connected with the steam pressure device, and the tension roller 6 is connected with the tension sensor, and the tension of the tension roller is adjusted by the tension sensor. The two drying cylinders 7 are connected with the electric heating device, and the cloth guide roller 9 is arranged between the air pressure rolling water pressure roller 5 and the tension roller 6 in front of the drying cylinder 7, and there is also a cloth guide roller 9 between the drying cylinder 7 and the cloth drop left and right rollers 8. It is equipped with a cloth guide roller 10, an air p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com