Dyeing hand sample machine and dyeing method thereof

A small prototype and dyeing kettle technology, applied in the field of fabric dyeing, can solve the problems that printing and dyeing factories cannot realize batch fabric dyeing, cannot obtain dyeing process conditions, cannot realize industrial application, etc., achieve complete functions, reduce costs, and fast proofing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below.

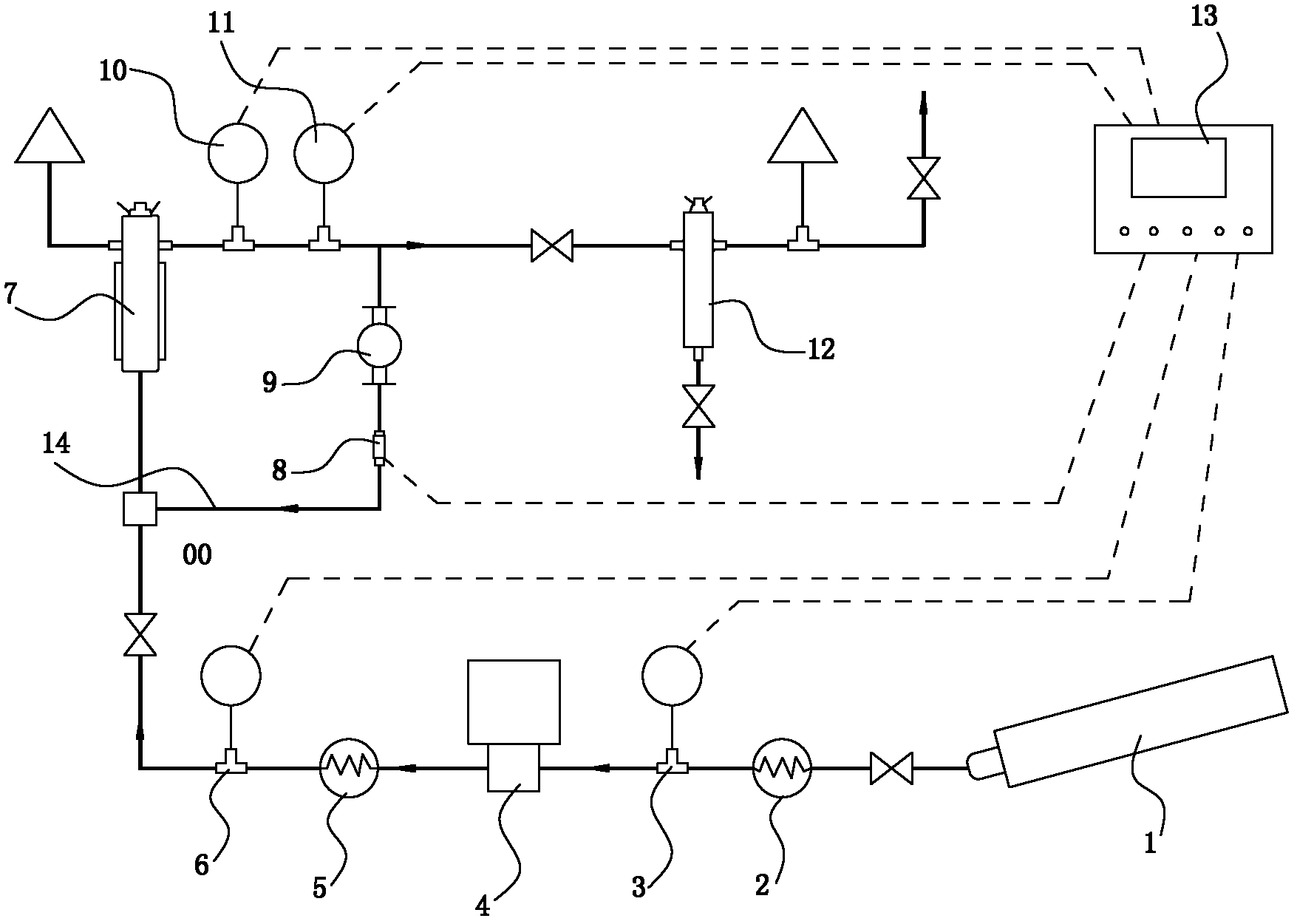

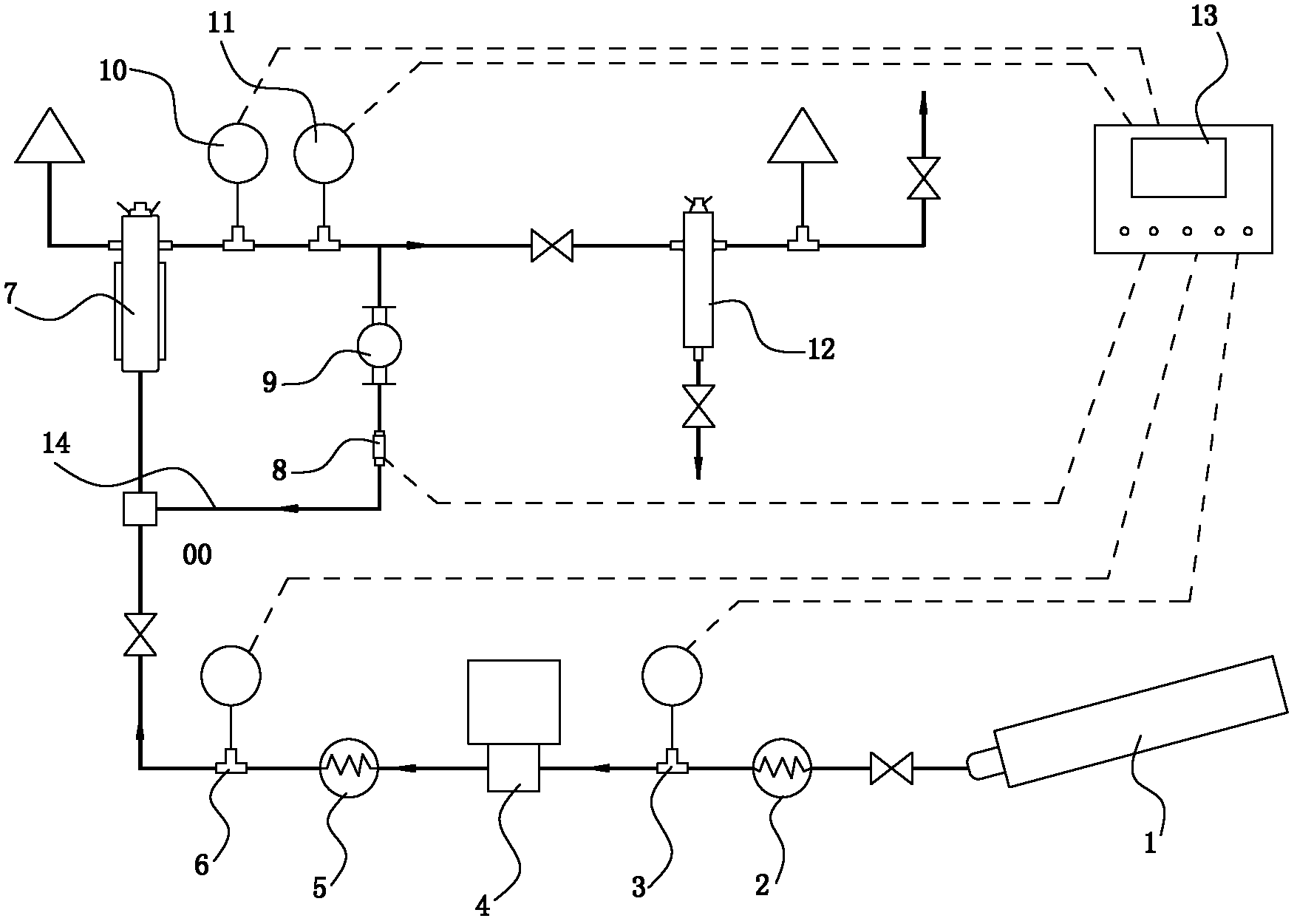

[0026] Such as figure 1 As shown, a small sample dyeing machine includes a dyeing kettle 7, a front-end pipeline, a rear-end pipeline, a dye recovery tank 12, a cold water constant temperature bath 2, a carbon dioxide high-pressure pump 4 and a decompression device (in this embodiment, the decompression device It is a pressure reducing valve), the front-end pipeline and the back-end pipeline are respectively communicated with the dyeing kettle 7, the front-end pipeline is provided with a carbon dioxide input port, the cold water constant temperature bath 2, and the carbon dioxide high-pressure pump 4, and the rear-end pipeline is provided with a reducing valve. Pressure device and dye recovery tank 12, and dye recovery tank 12 is positioned at the rear end of decompression device. A carbon dioxide cylinder 1 is provided at the carbon dioxide input port, and a hot oil constant temperature bath 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com