Multi-container dyeing machine with individual container temperature control and quantitative chemical-feeding control

a dyeing machine and container technology, applied in the field of dyeing machines, can solve the problems of uneven dyeing, inability to dye, and inability of conventional dyeing machines to be practical, and achieve the effect of accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

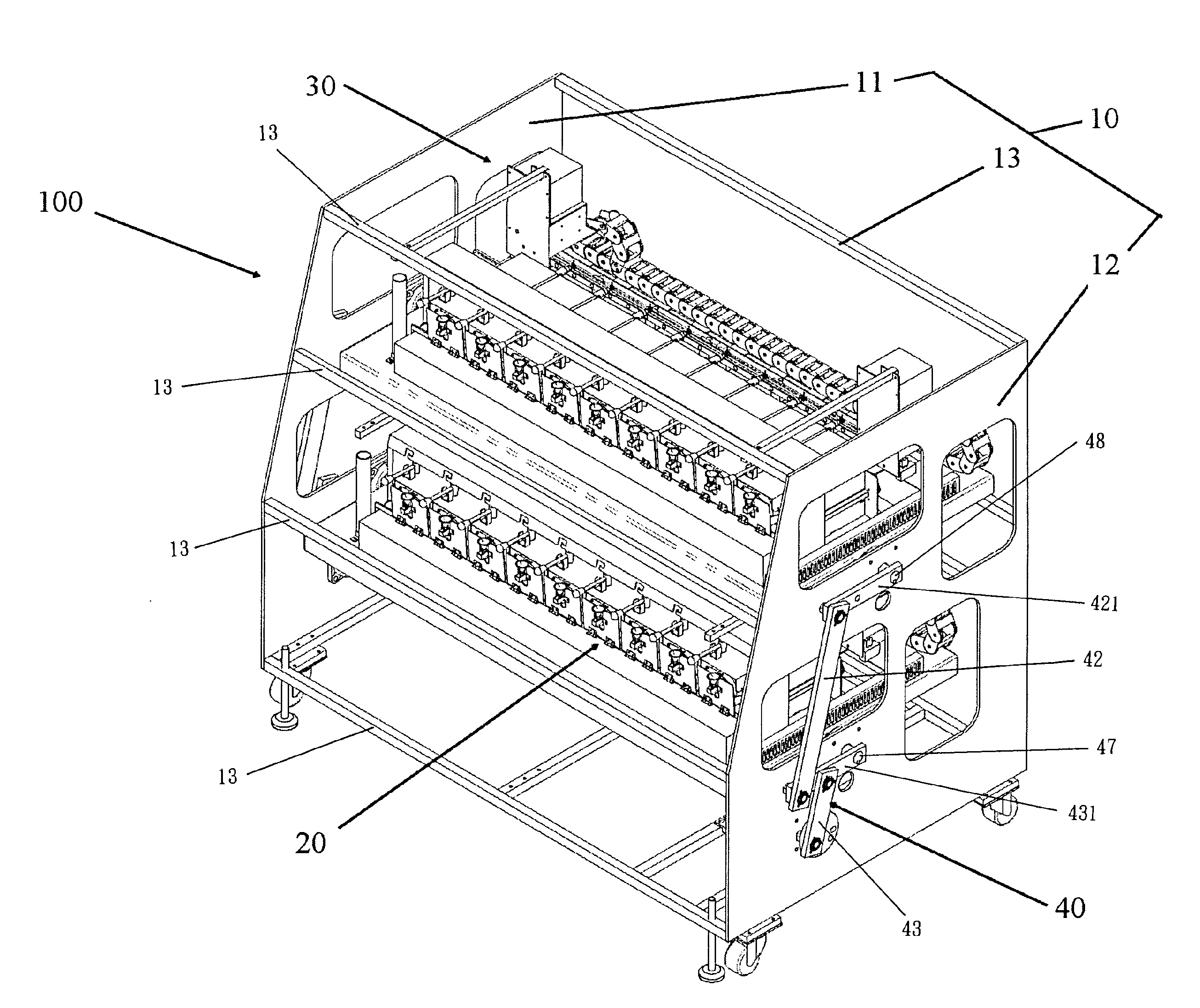

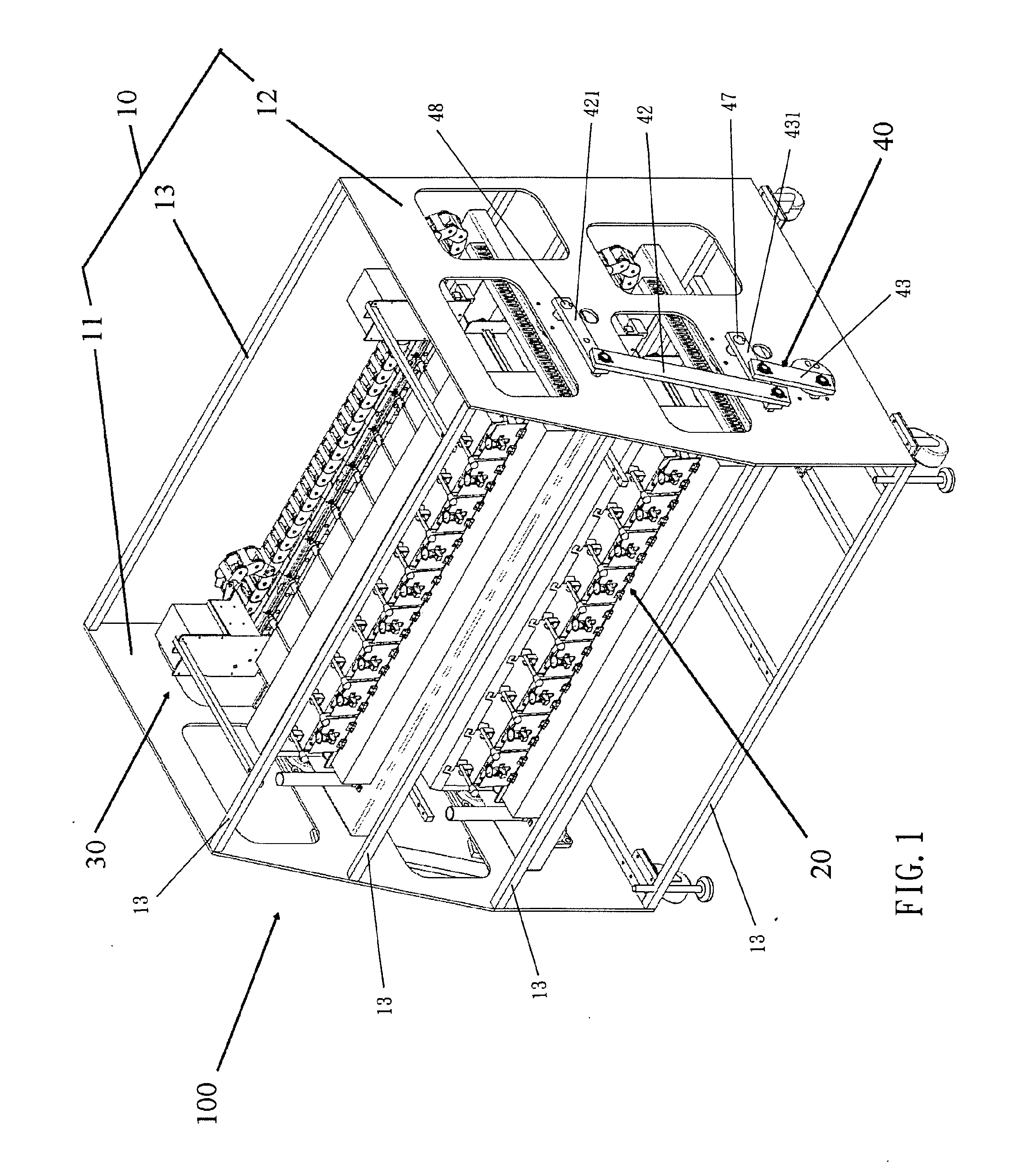

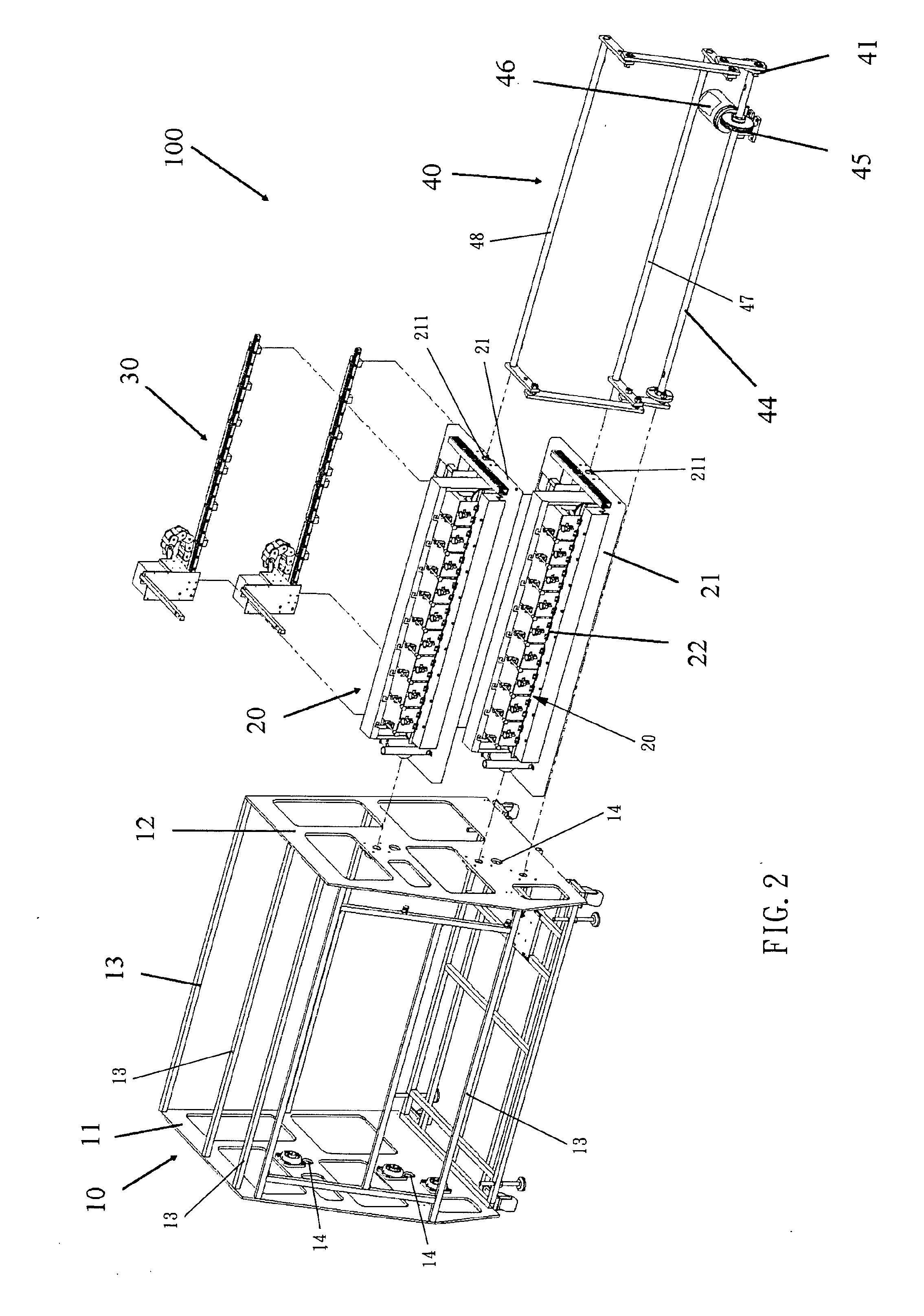

[0025]Referring to FIGS. 1˜8, a multi-container dyeing machine 100 in accordance with the present invention is shown comprising a machine frame base 10, and at least one heating and cooling module 20.

[0026]As shown in FIGS. 1 and 2, the machine frame base 10 can be firmly positioned on the floor (or a flat surface), comprising opposing first upright sidewall 11 and second upright sidewall 12 and a plurality of connection bars 13 connected between the first upright sidewall 11 and the second upright sidewall 12. The first upright sidewall 11 and the second upright sidewall 12 each have a plurality of through holes 14 arranged in a symmetric manner.

[0027]Referring to FIGS. 1˜3 again, two heating and cooling modules 20 are provided in machine frame base 10 according to the present preferred embodiment. These two heating and cooling modules 20 are identical and respectively pivotally connected between the first upright sidewall 11 and the second upright sidewall 12. Each heating and coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com