Textile mini-type dyeing machine

A technology for dyeing machines and textiles, applied in the field of dyeing machines, can solve problems such as dyeing samples within 100g, and achieve the effects of material saving, simple heating method and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

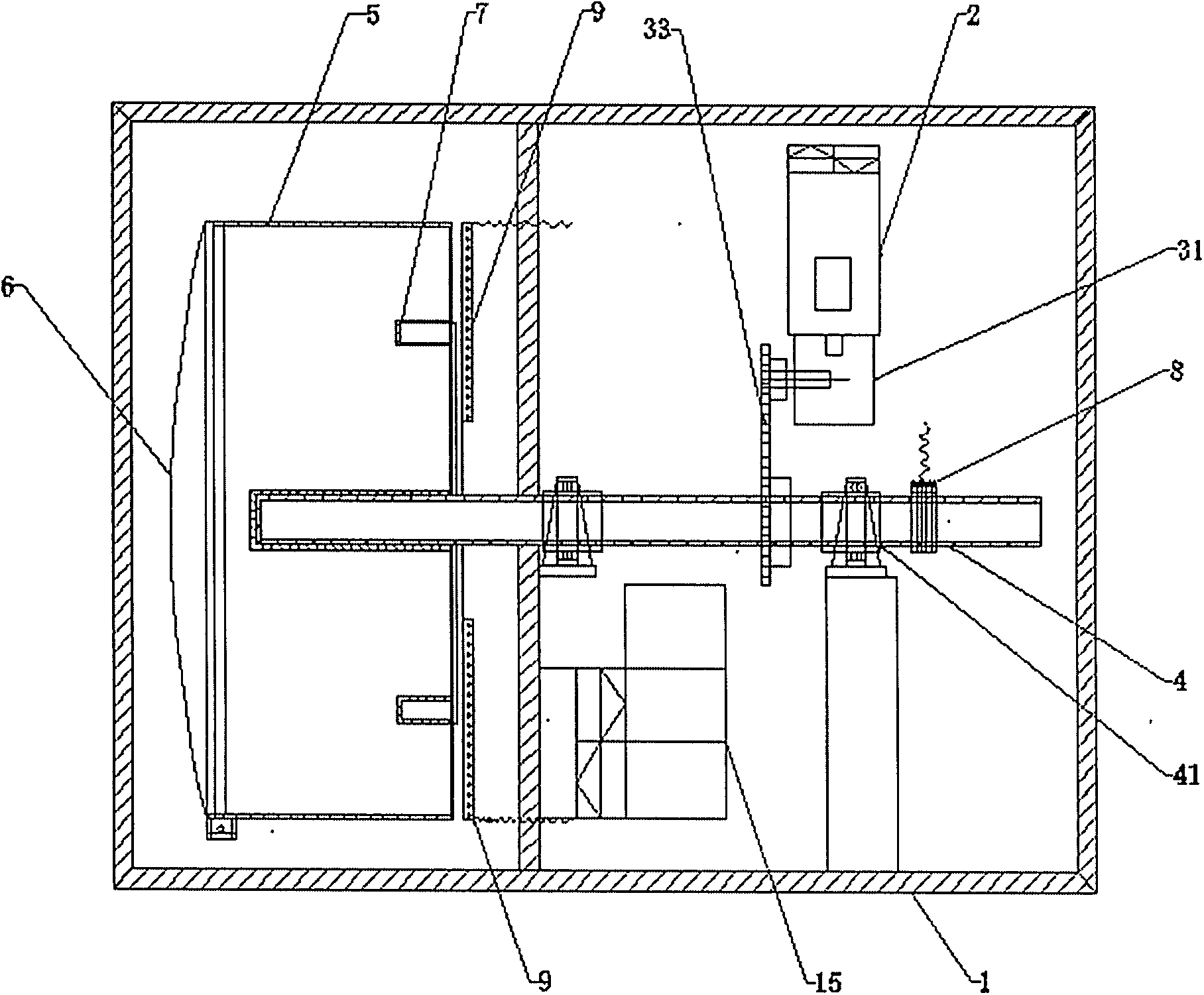

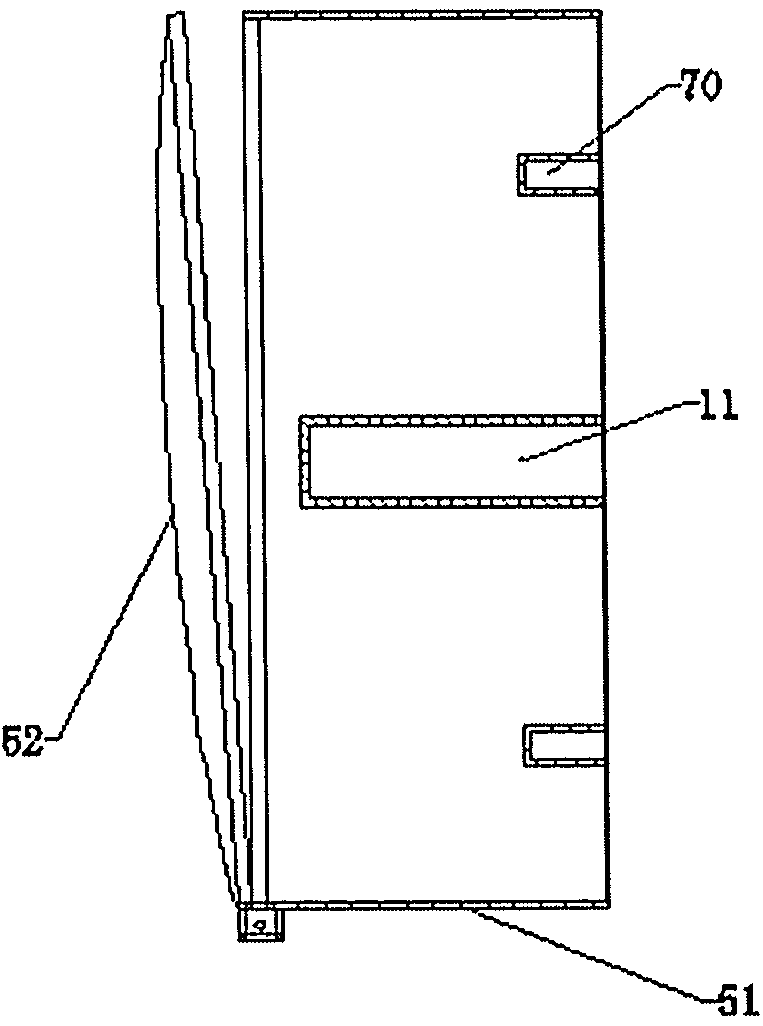

[0020] see figure 1 and 2 , the present embodiment is provided with frame 1, motor 2, transmission device, rotating shaft 4, dyeing drum (comprising cylinder body 51 and cylinder cover 52), liquid-through valve (not shown), temperature sensor 7, electric slip ring 8 , electric heater 9 and control circuit (not shown).

[0021] The frame 1 is a box-type frame, the right side is an electric control chamber, the left side is a dyeing chamber, and the motor 2 is arranged on the frame 1. The transmission device is provided with a speed reducer 31 and a chain transmission mechanism, the speed reducer 31 is connected with the output shaft of the motor 2, the driving sprocket of the chain transmission mechanism is connected with the output shaft of the speed reducer 31, and the driven sprocket of the chain transmission mechanism is connected with the rotating shaft 4, Label 33 is chain. The rotating shaft 4 is a hollow tubular rotating shaft, and the rotating shaft 4 is rotationall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com