A method and system for enriching trace heavy nuclear hydrogen isotopes in hydrogen isotopes by hydrogen displacement adsorption

A hydrogen isotope and adsorption technology, applied in the separation of different isotopic elements, hydrogen isotope, separation methods, etc., can solve the problems of long single separation time, complicated process control, complicated control program, etc., and achieve convenient temperature control. The heating method is simple, and the effect of improving the enrichment factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Offline enrichment and separation of naturally abundant deuterium in pure protium

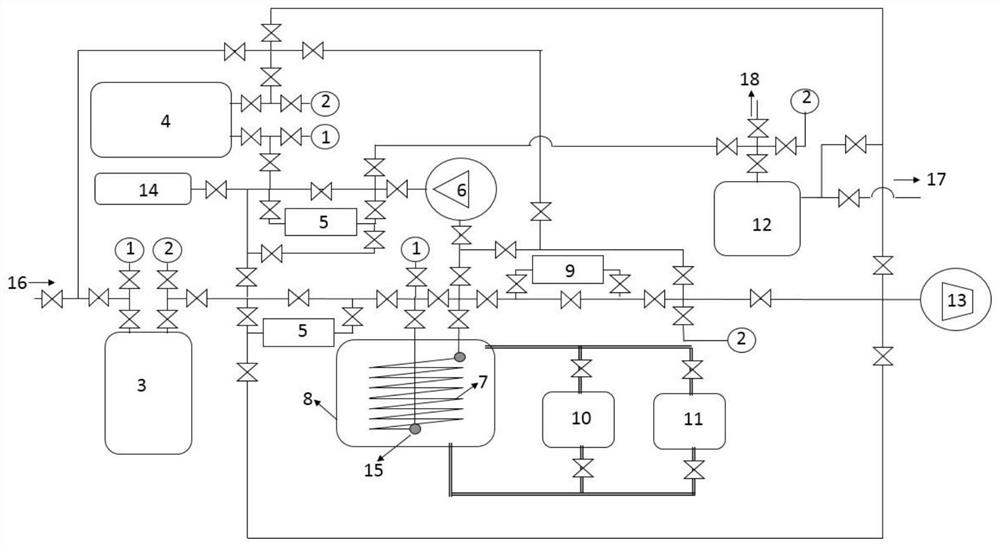

[0099] The separation shape column in this example is a spiral tube made of Ф12×2 stainless steel pipe, the length of the separation column is 10 m, and the middle diameter of the spiral tube is 0.25 m. The separation column is heated by a closed nitrogen heating system loop, and cooled by injecting liquid nitrogen into the separation column jacket. The separation column is filled with 5A molecular sieve particles with an average diameter of 2.17 mm, and the molecular sieve particle materials in the separation column are fixed by means of welded filters at both ends as shown in the attached figure.

[0100] The piping connection mode and valve position of the separation system are as follows: figure 1 shown;

[0101] The abundance of deuterium in the feed gas is 0.015%;

[0102] The separation process mainly includes the following steps:

[0103] (1) Connect the separation column fil...

Embodiment 2

[0113] The gas in the product tank of Example 1 is further enriched, and the steps are as follows:

[0114] Heat the hydrogen storage bed to 650°C, connect the product gas tank, hydrogen storage bed and raw material tank at the same time, the gas in the product gas will transfer to the raw material gas spontaneously; when the gas pressure in the product gas tank and the raw material tank are equal, the product gas tank, The gas in the hydrogen storage bed is transferred to the raw material tank through the transfer pump until the pressure in the product gas tank is lower than 100Pa. Close all valves of above-mentioned pipeline subsequently; Repeat step (2)~(8) among the embodiment 1, until the remaining raw material gas in the raw material tank is lower than 100kPa.

[0115] After repeated enrichment once, the deuterium abundance in the product gas was 0.029%, the enrichment factor was 1.4, and the deuterium recovery rate reached 99.0%;

[0116] After repeated enrichment twic...

Embodiment 3

[0118] On-line enrichment and separation of trace tritium in protium-tritium mixed gas

[0119]This example demonstrates the process of online enrichment of low-content tritium in protium-tritium mixed gas, and the tritium production system in this example can be used for, but not limited to, ITER-TBM cladding, tritium containment system of tritium-related laboratories, etc. Tritium-related facilities. The experimental device and the structure of the separation column are the same as in Example 1, and the raw gas is a protium-tritium mixed gas containing low content of tritium (the abundance of tritium is 1000ppm).

[0120] (1) Heat the separation column to 300°C under the heating of a nitrogen heating system, and at the same time use a vacuum pump to evacuate the separation column; maintain the above operation for more than 10 hours to ensure that impurities such as adsorbed water on the separation material in the separation column are completely removed attached. Then stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com