Patents

Literature

41results about How to "Sensitive temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

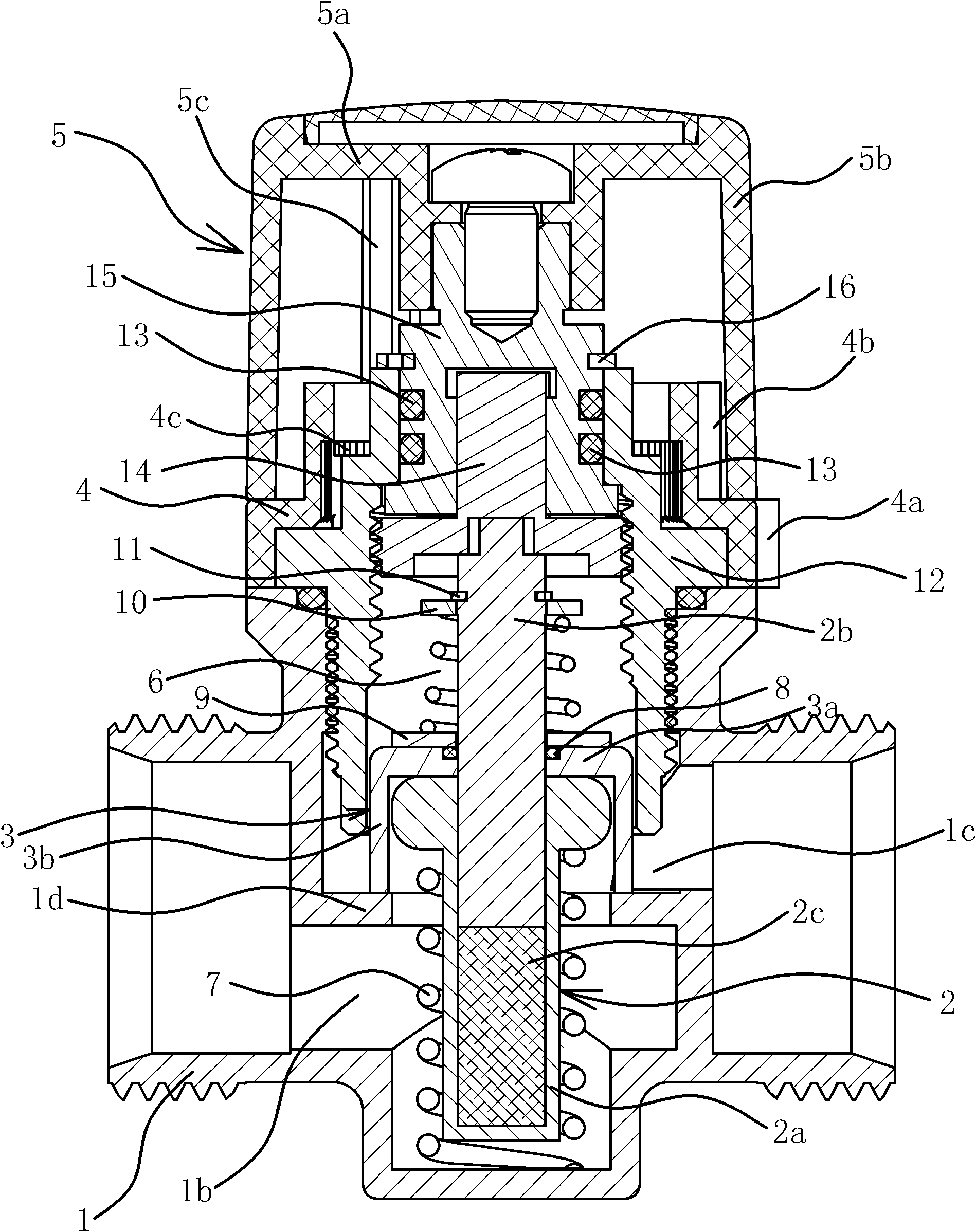

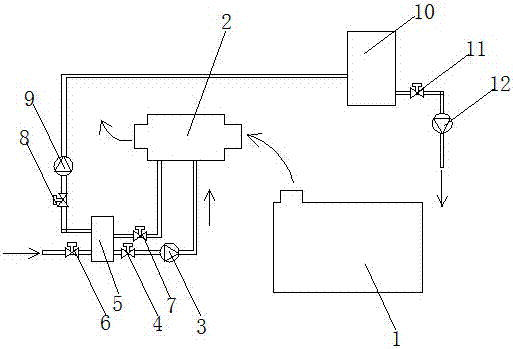

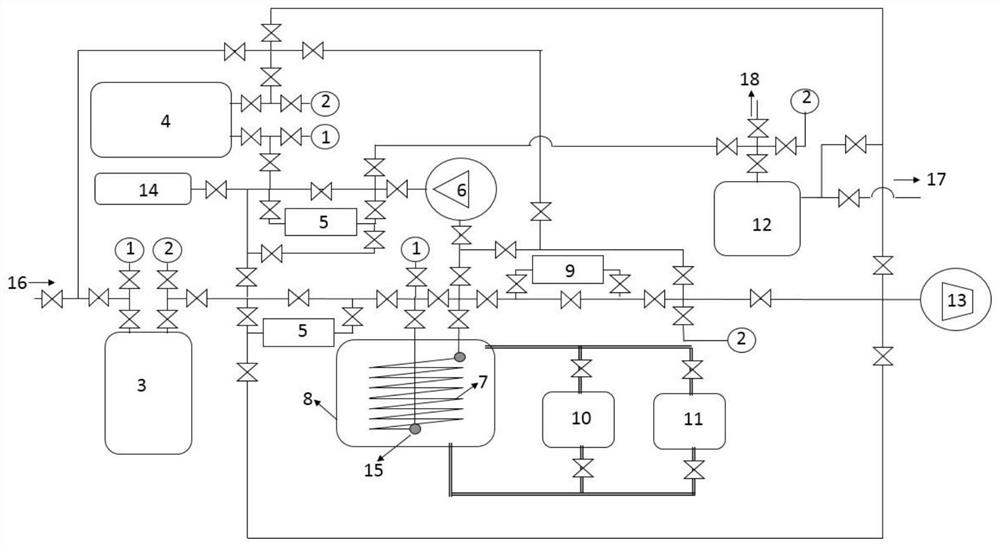

Stepless temperature control system

ActiveCN104199479AAvoid mutual contaminationAvoid corrosionTemperature control using electric meansTemperature controlThermal state

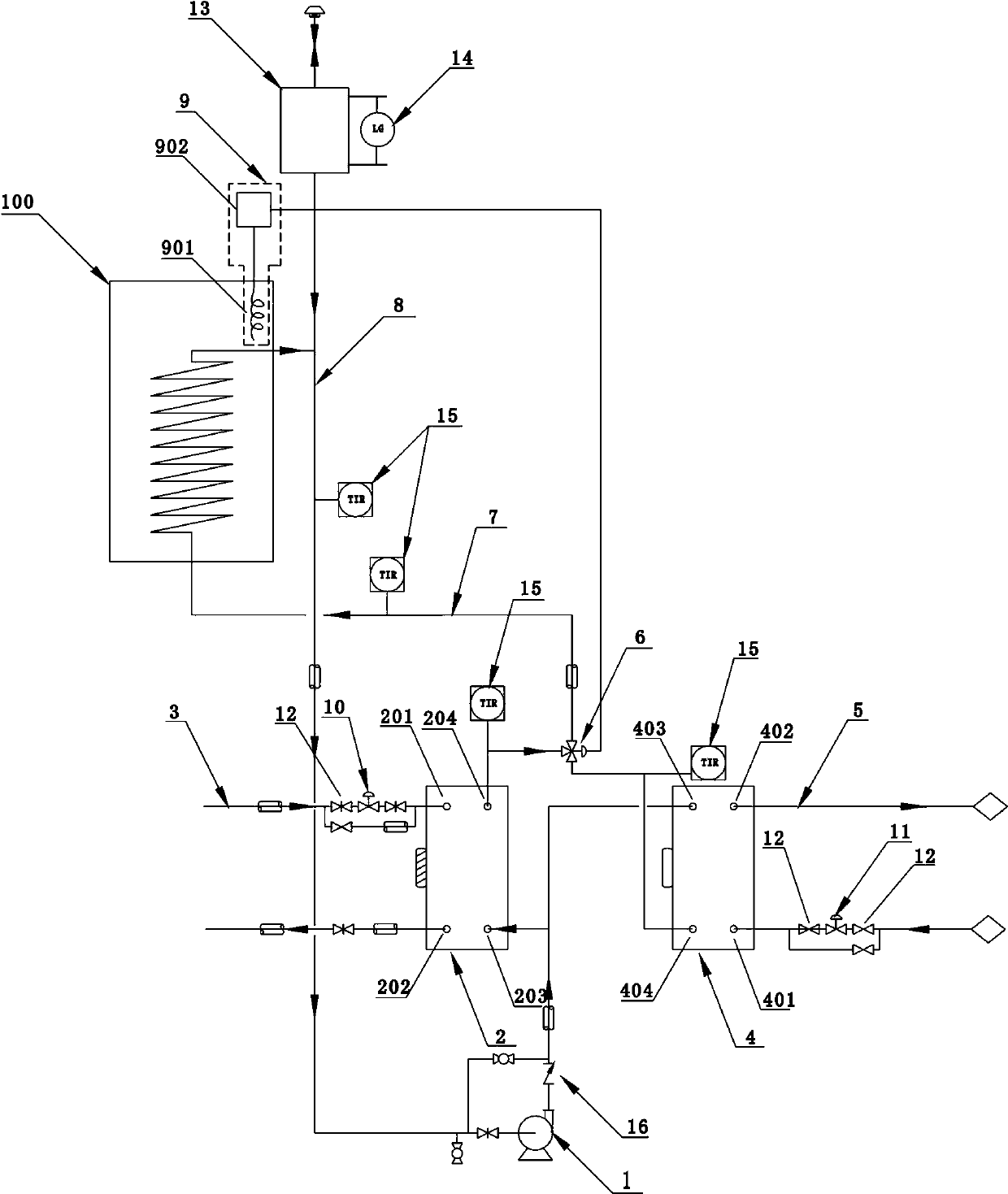

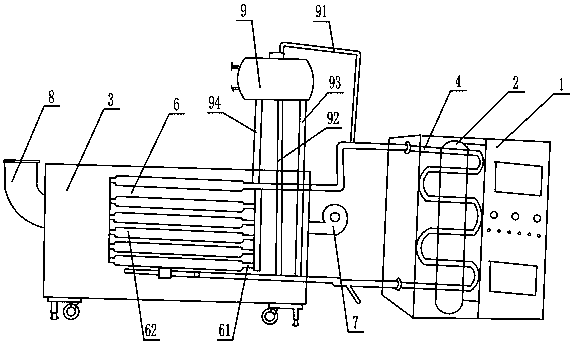

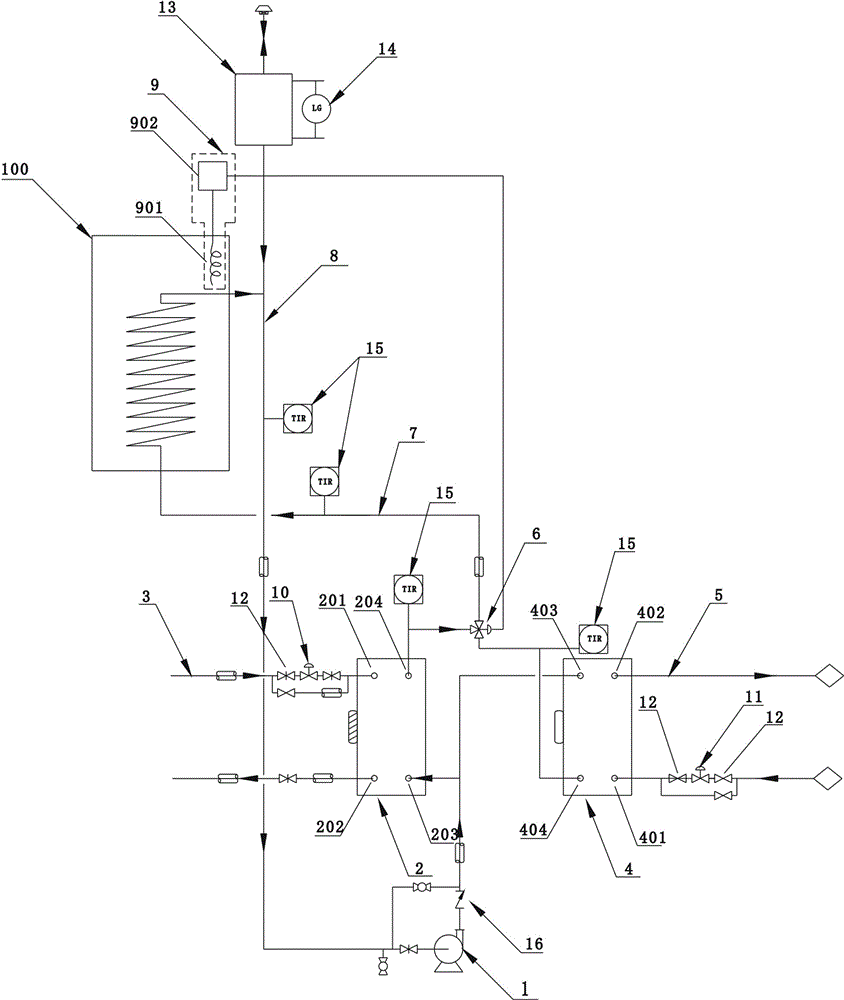

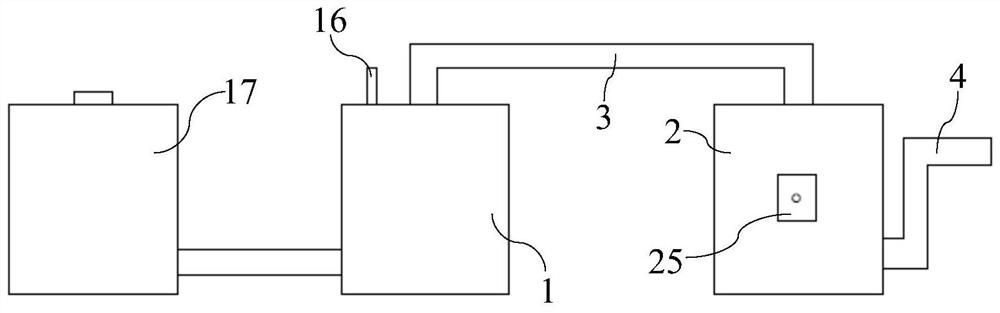

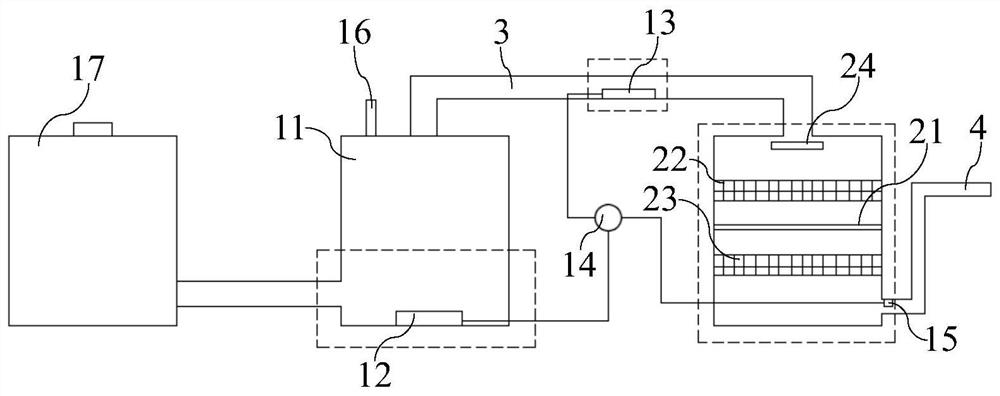

The invention provides a stepless temperature control system. The stepless temperature control system comprises a circulating pump, a thermal state heat exchanger, a heating medium delivering tube, a cold state heat exchanger, a refrigerant delivering tube, a proportioning valve, an oil supply main tube, an oil return main tube and a temperature controlling device. The thermal state heat exchanger comprises a heating medium inlet, a heating medium outlet, a heat-transfer medium first inlet and a heat-transfer medium first outlet, and the heat-transfer medium first inlet is connected with the circulating pump. The cold state heat exchanger comprises a refrigerant inlet, a refrigerant outlet, a heat-transfer medium second inlet and a heat-transfer medium second outlet, and the heat-transfer medium second inlet is connected with the circulating pump. Two inlet ends of the proportioning valve are connected with the heat-transfer medium first outlet and the heat-transfer medium second outlet respectively, and an outlet end of the proportioning valve is connected with one end of the oil supply main tube. The other end of the oil supply main tube is connected with an inlet of a temperature controlled device. The oil return main tube is connected with an outlet of the temperature controlled device and the circulating pump. The temperature controlling device controls the valve opening degree of the proportioning valve according to the temperature of the temperature controlled device.

Owner:ZHEJIANG HUAYI ENG DESIGN

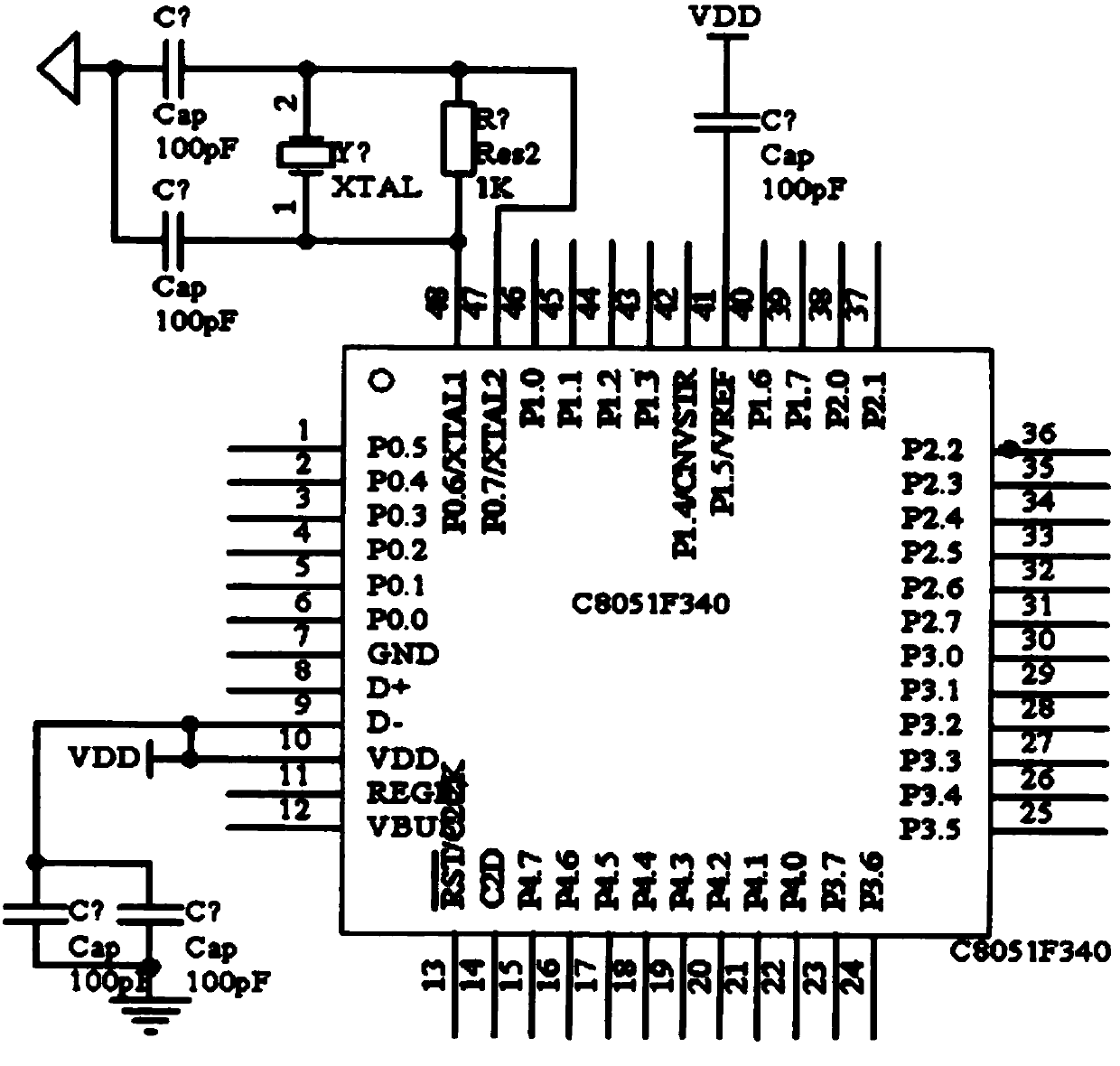

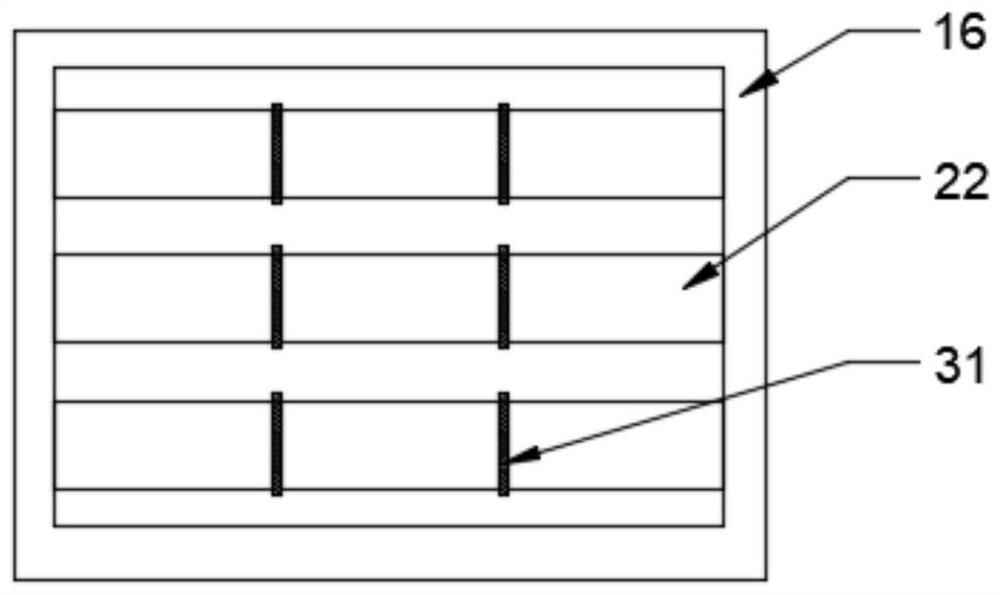

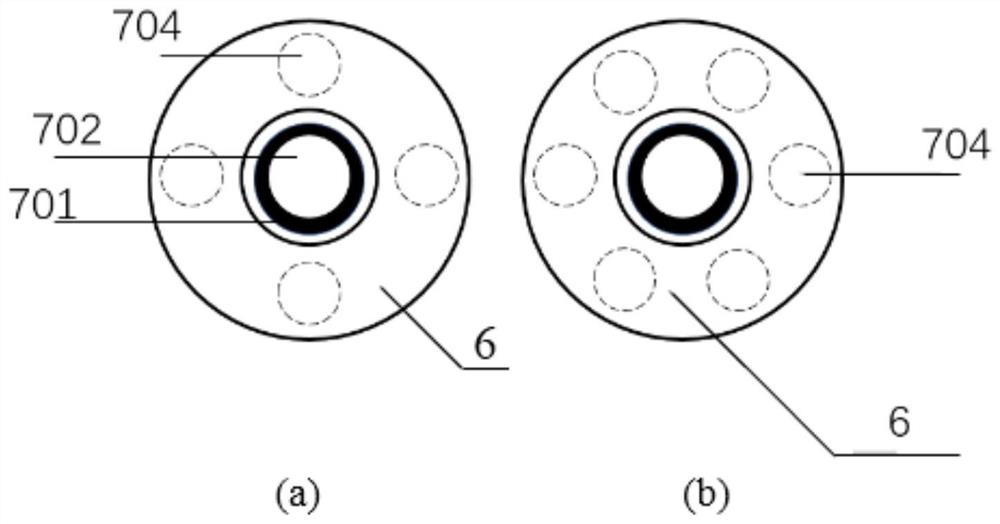

Magnetic fluid micro-channel thermal control system of microsatellite standalone

InactiveCN105578850AImprove heat transfer efficiencyReduce energy consumptionCooling/ventilation/heating modificationsTemperature controlActive cooling

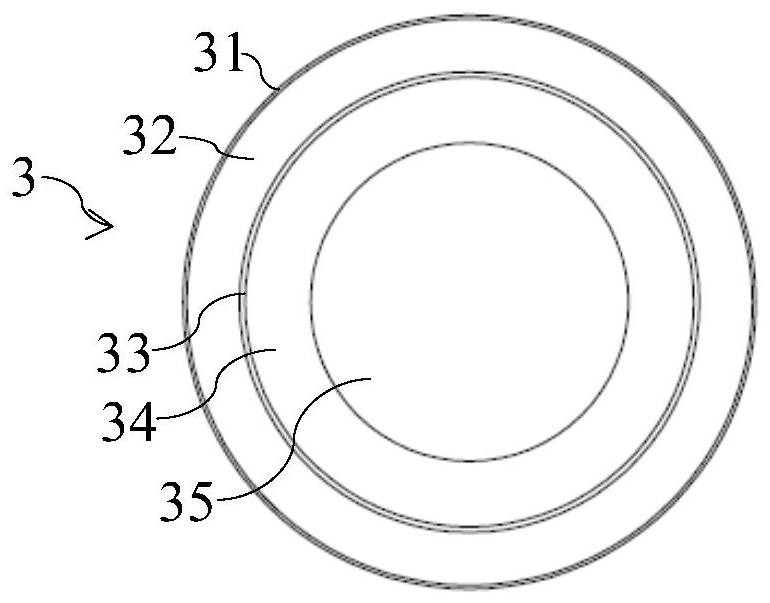

The invention provides a magnetic fluid micro-channel thermal control system of a microsatellite standalone, relates to a micro-channel-based thermal control system applied to a microsatellite, and solves the problems that existing microsatellite thermal control systems are poor in temperature control performance and poor in standalone active cooling and cannot realize effective thermal utilization in the microsatellite. The magnetic fluid micro-channel thermal control system of the microsatellite standalone comprises an electromagnetic pump, magnetic fluid pipelines, a hot-end magnetic fluid micro-channel and a cold-end magnetic fluid micro-channel. The outlet of the electromagnetic pump is communicated with the inlet of the hot-end magnetic fluid micro-channel through the magnetic fluid pipeline. The inlet of the electromagnetic pump is communicated with the outlet of the cold-end magnetic fluid micro-channel through the magnetic fluid pipeline. The outlet of the hot-end magnetic fluid micro-channel is communicated with the inlet of the cold-end magnetic fluid micro-channel through the magnetic fluid pipeline. The magnetic fluid micro-channel thermal control system of the microsatellite standalone is used for spacecrafts.

Owner:HARBIN INST OF TECH

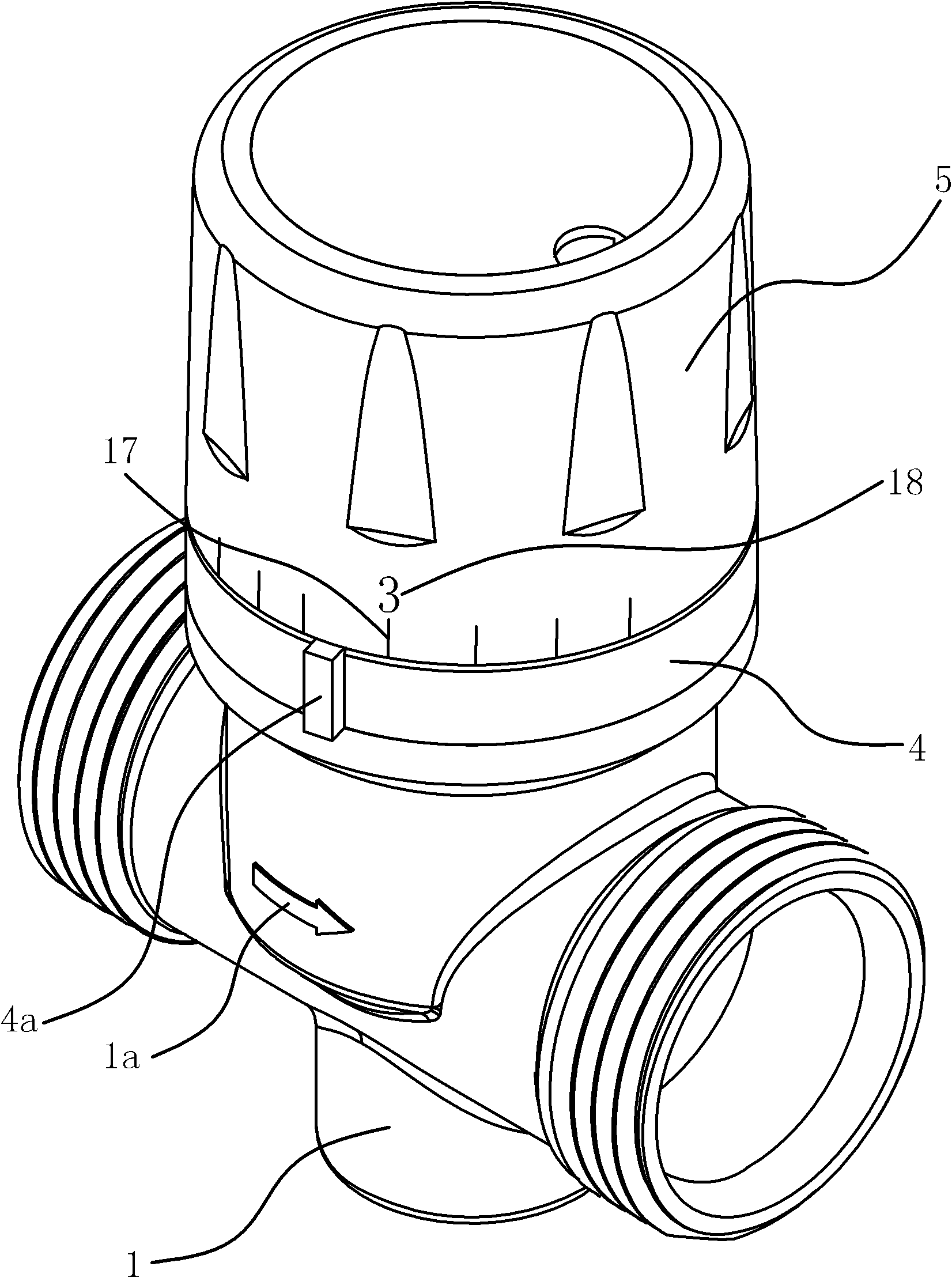

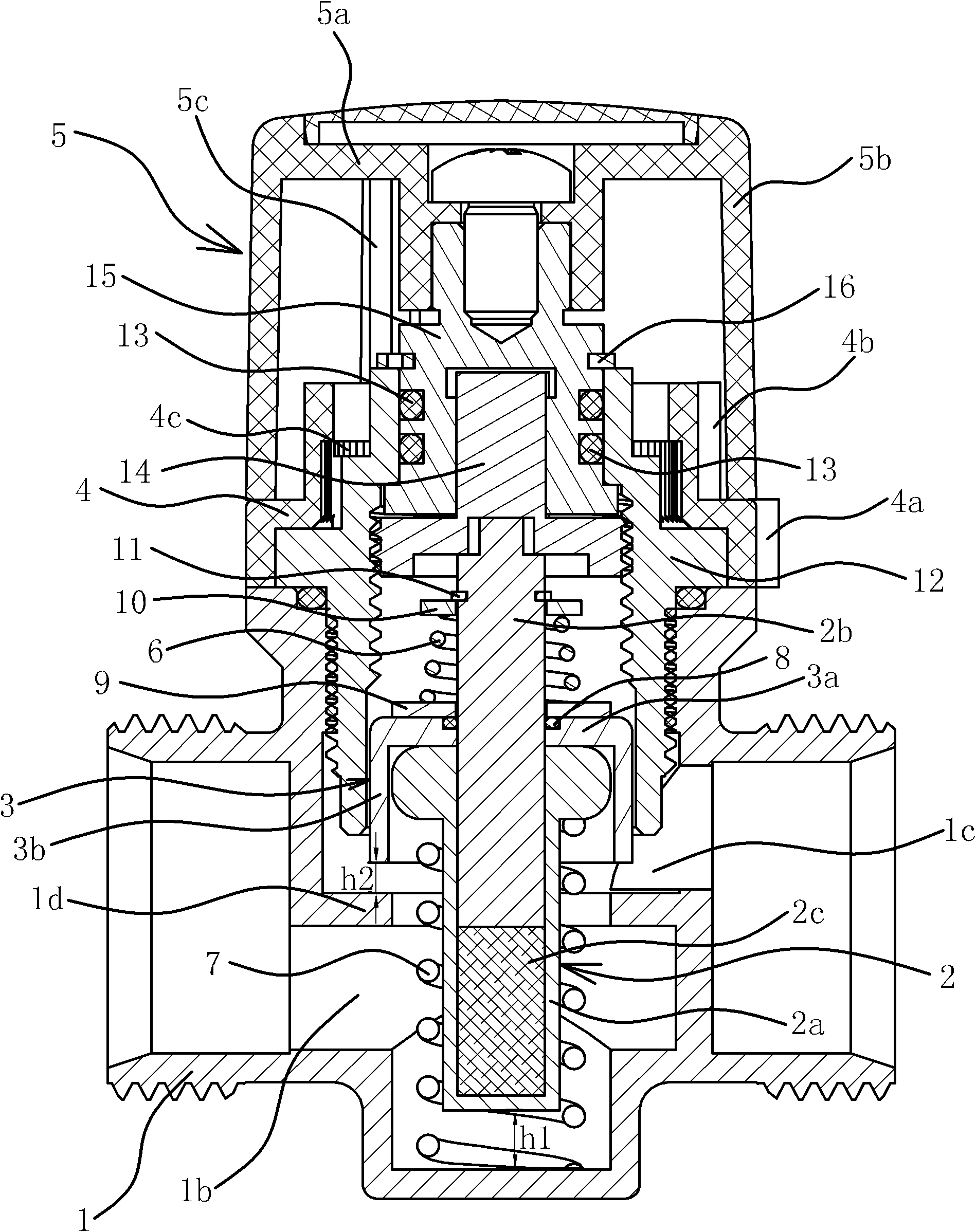

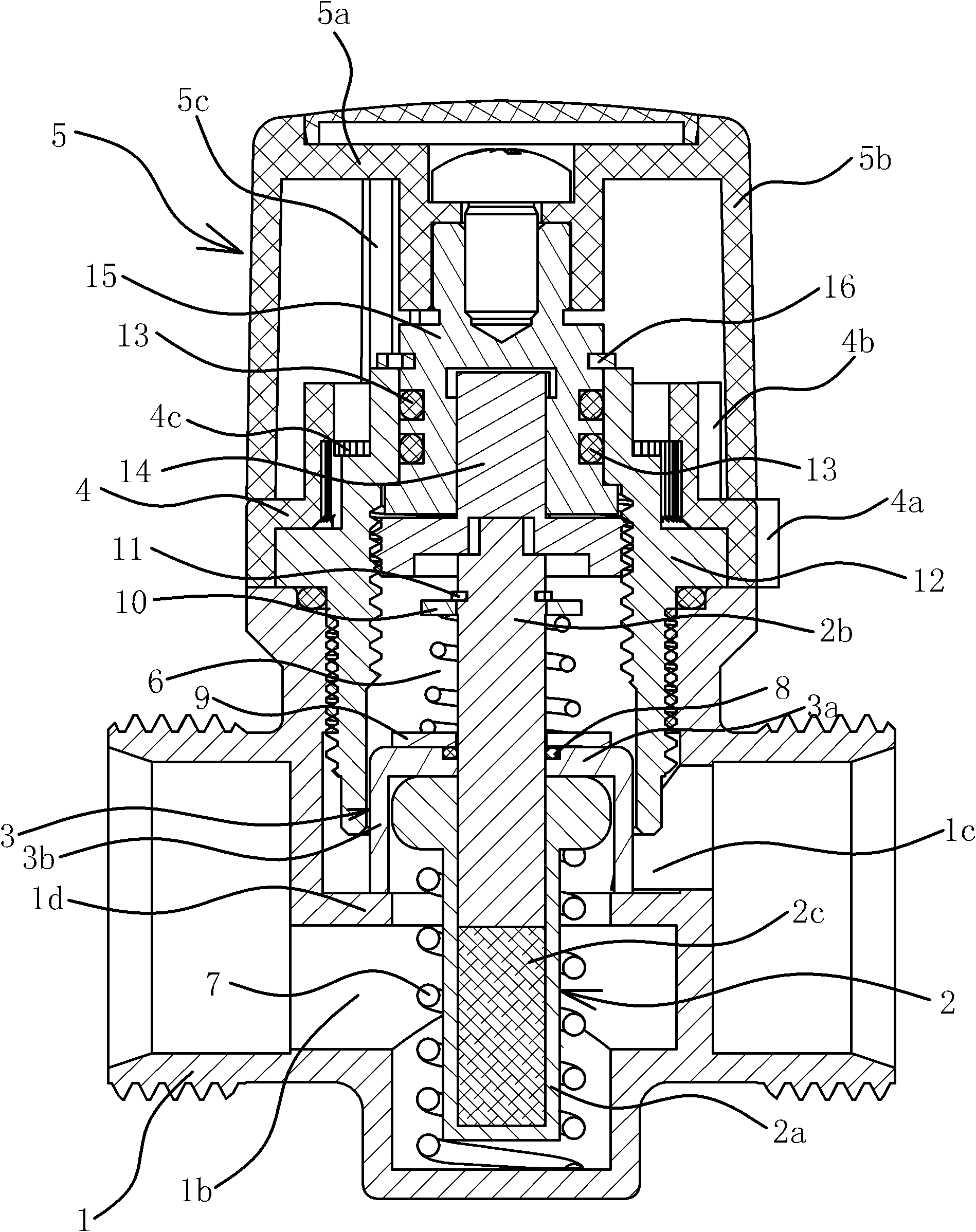

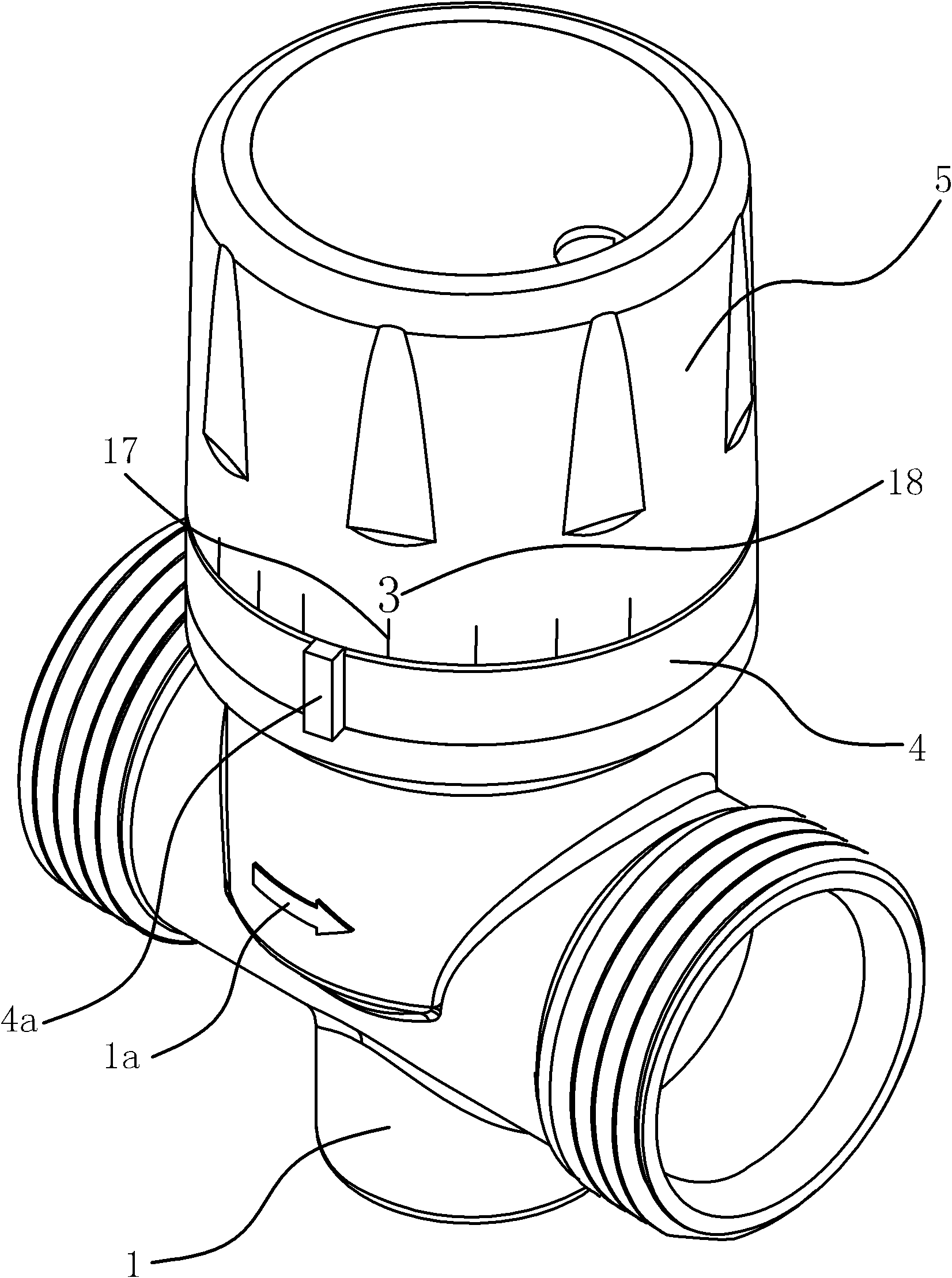

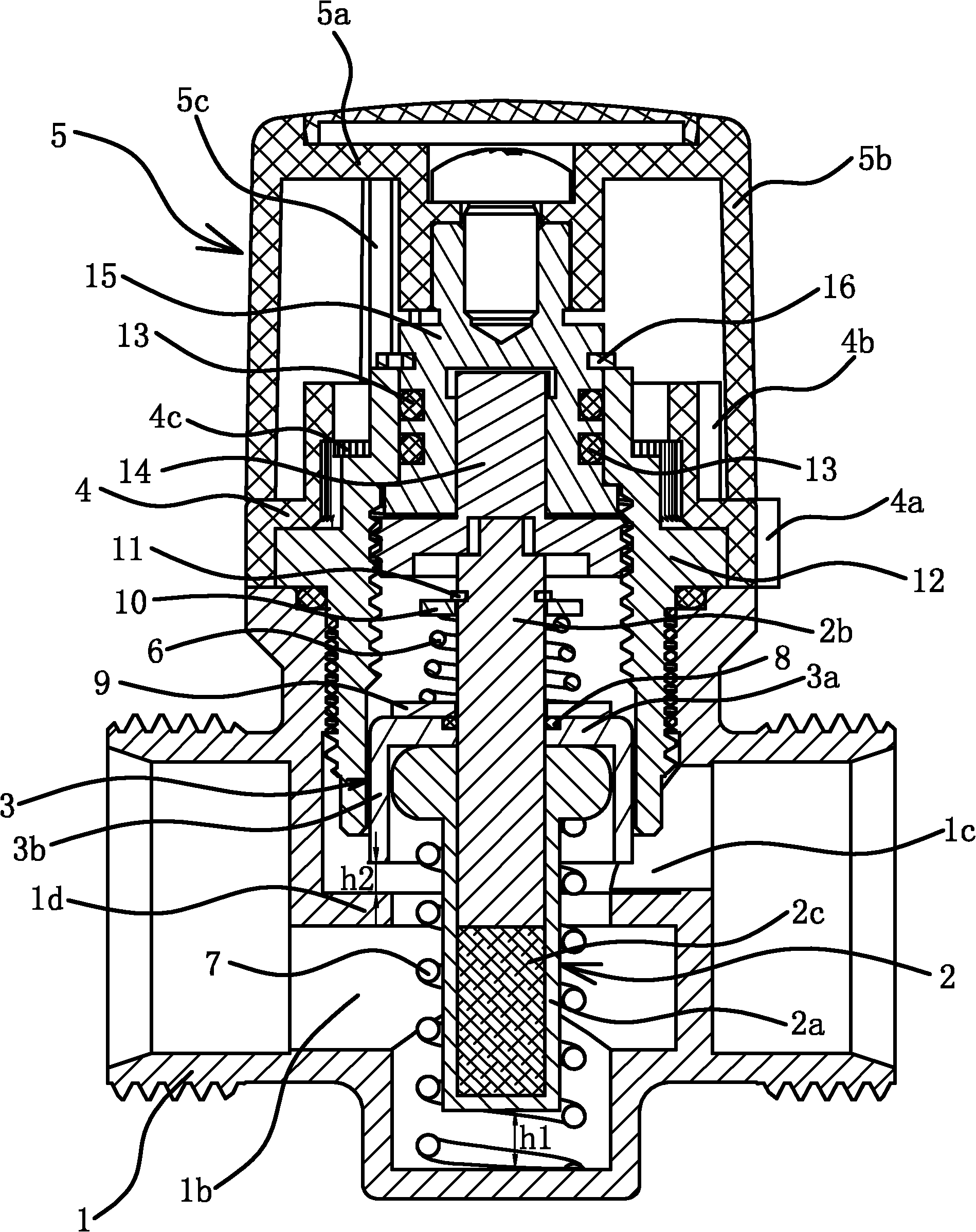

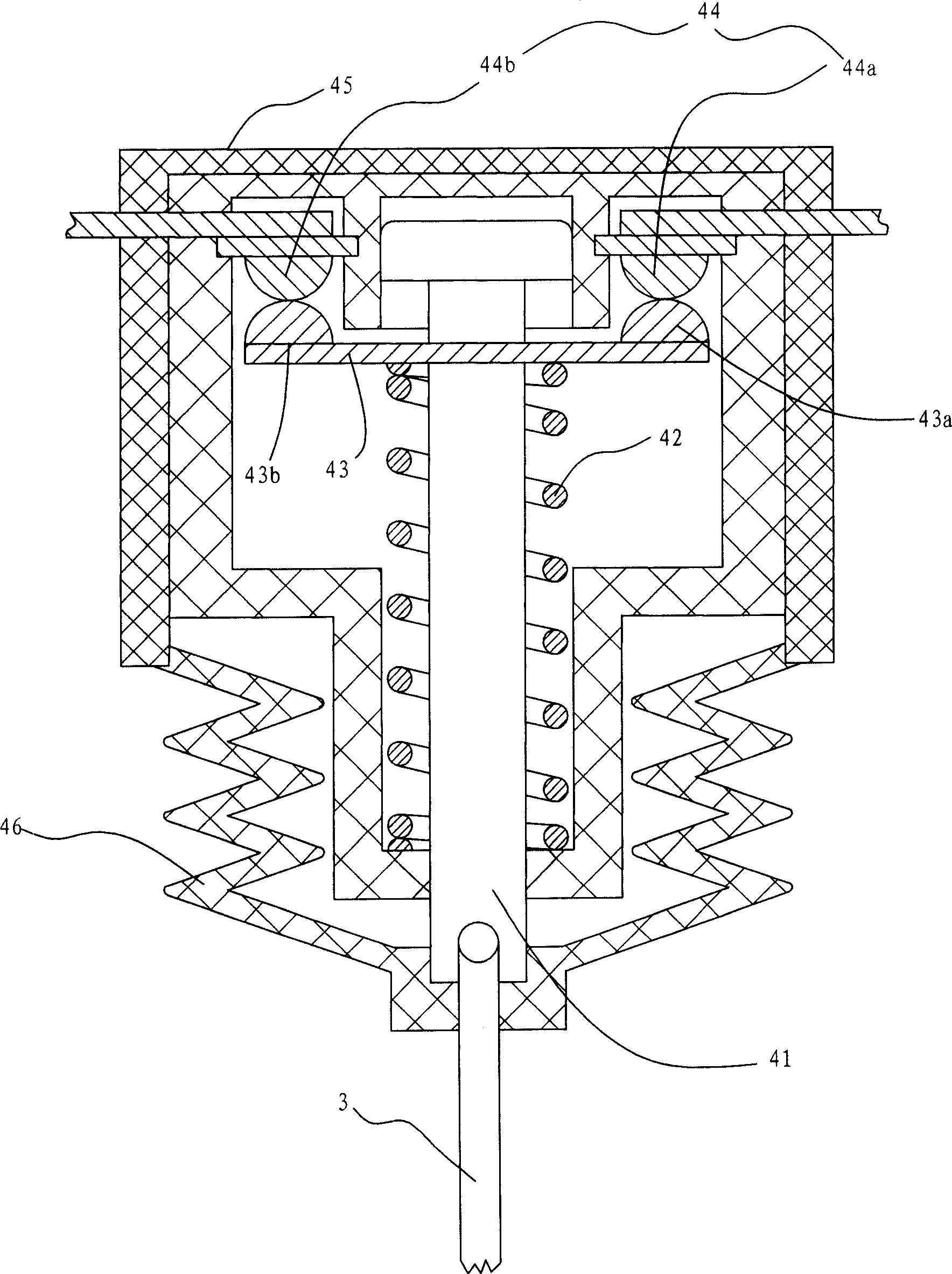

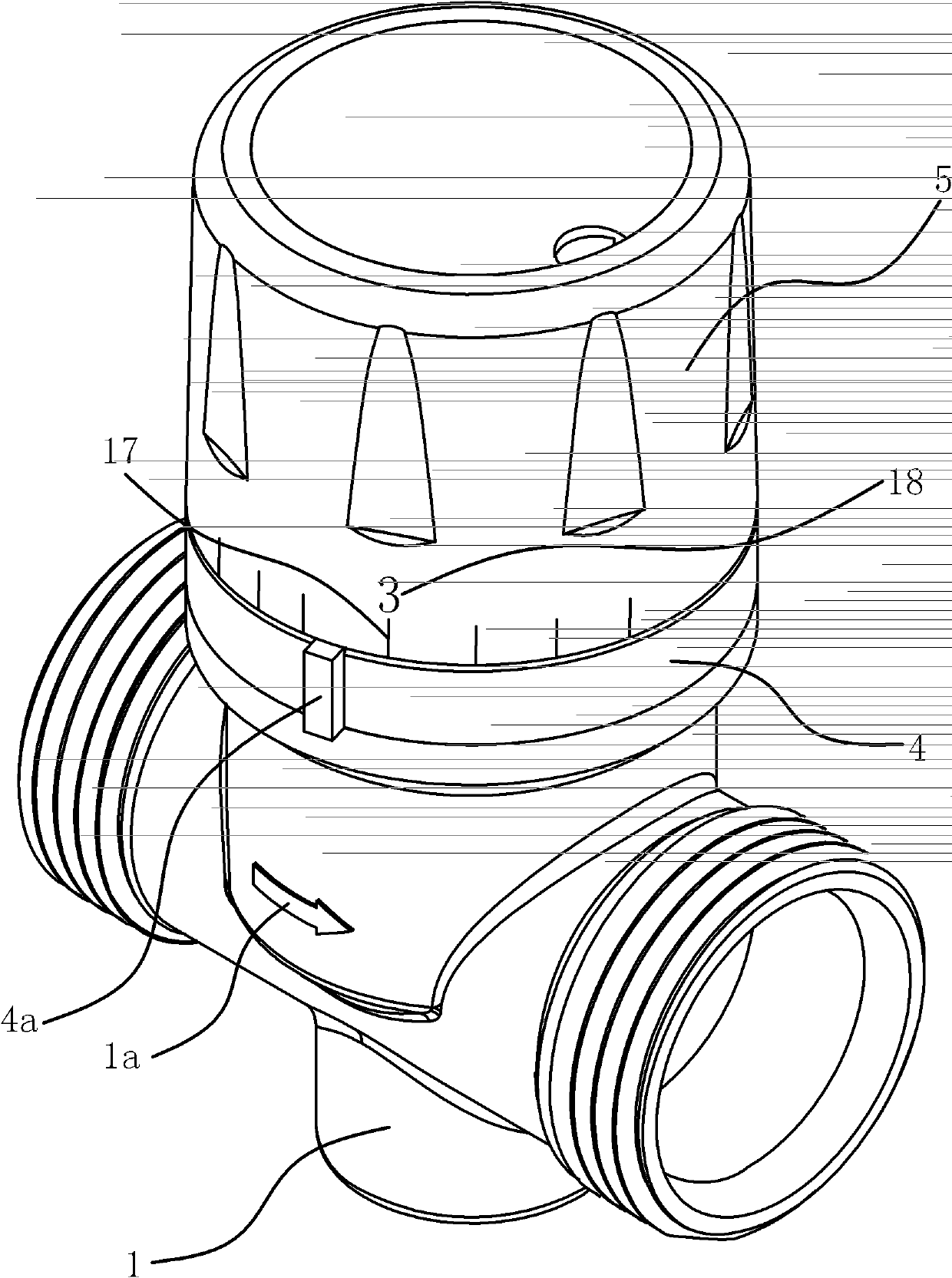

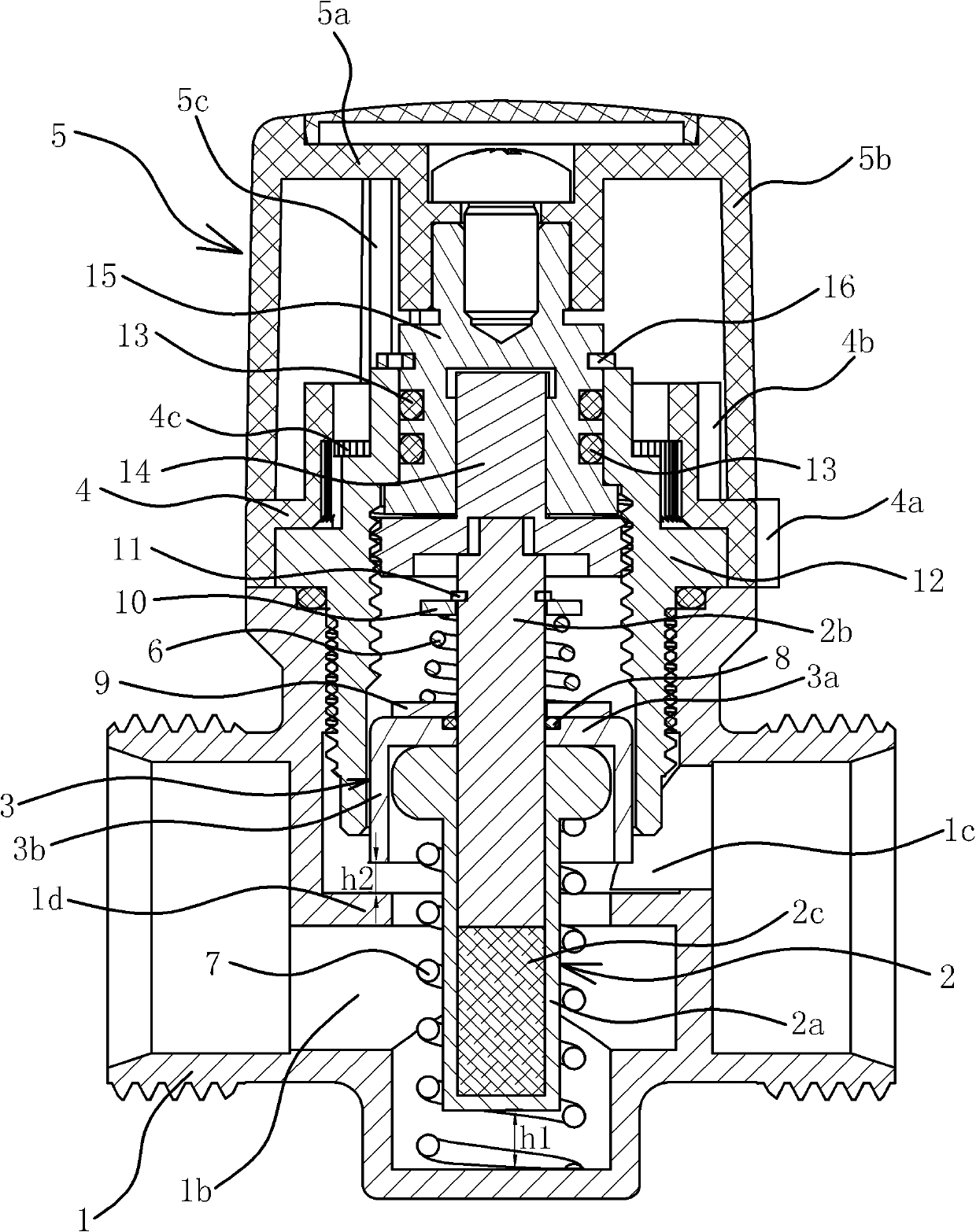

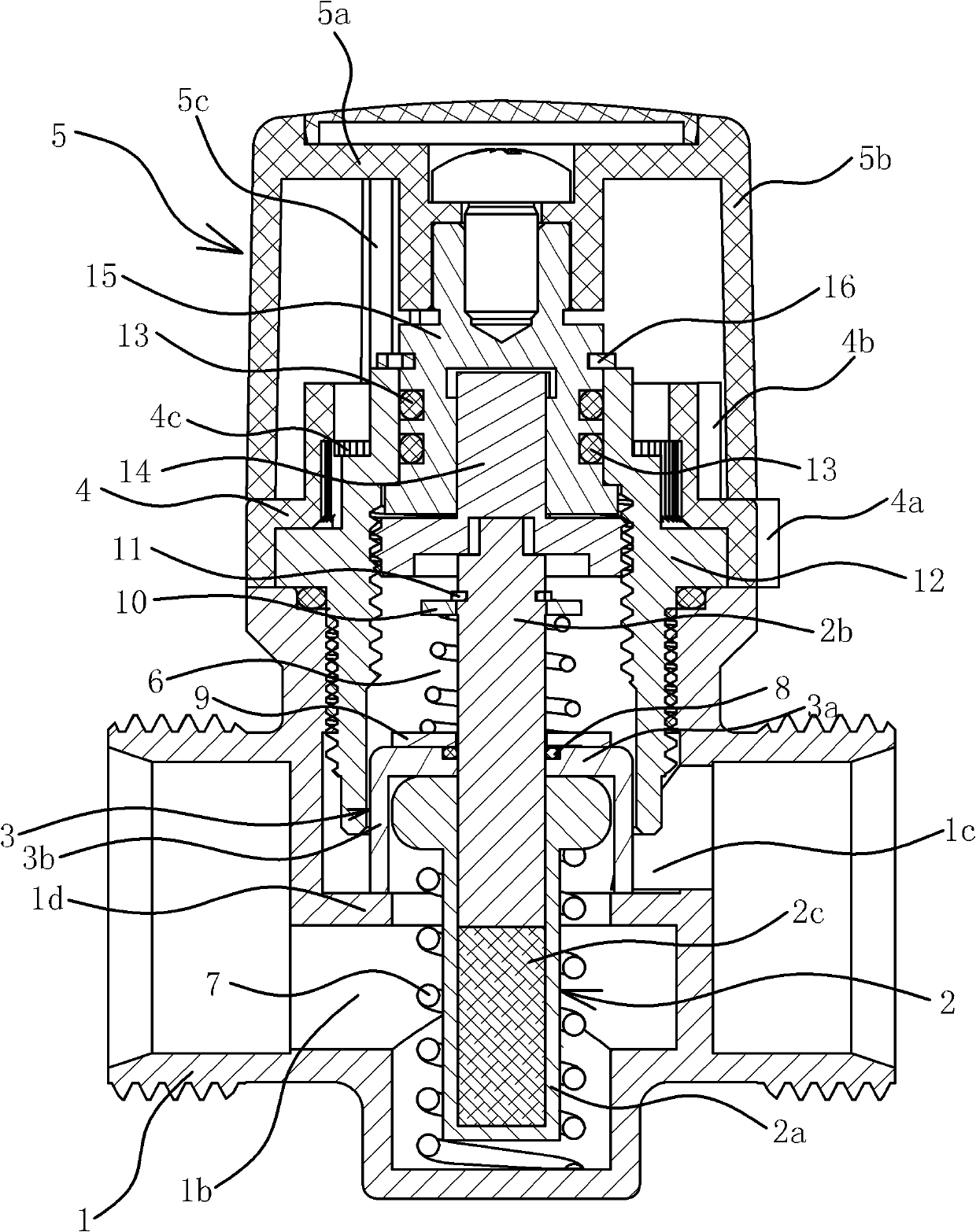

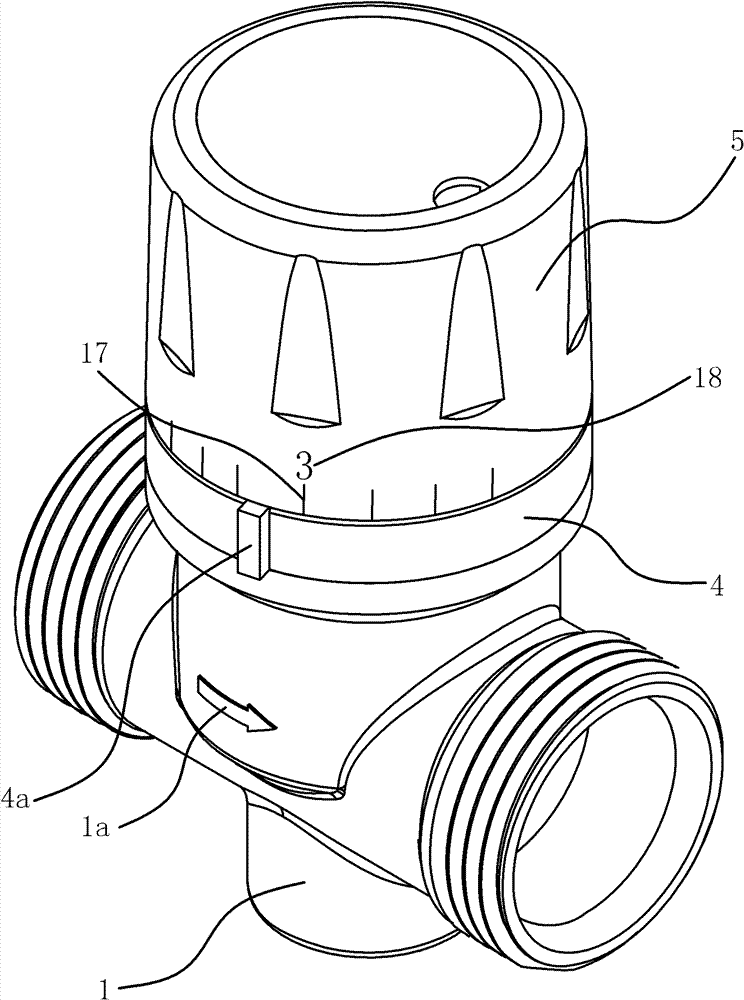

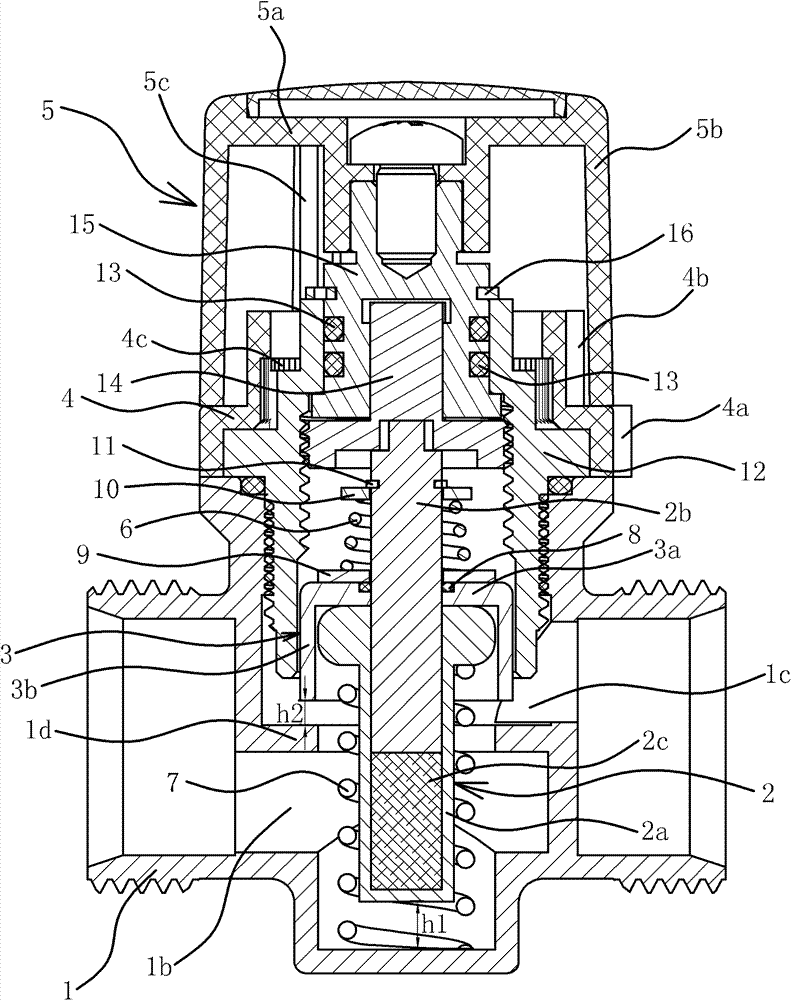

Floor heating thermostatic valve

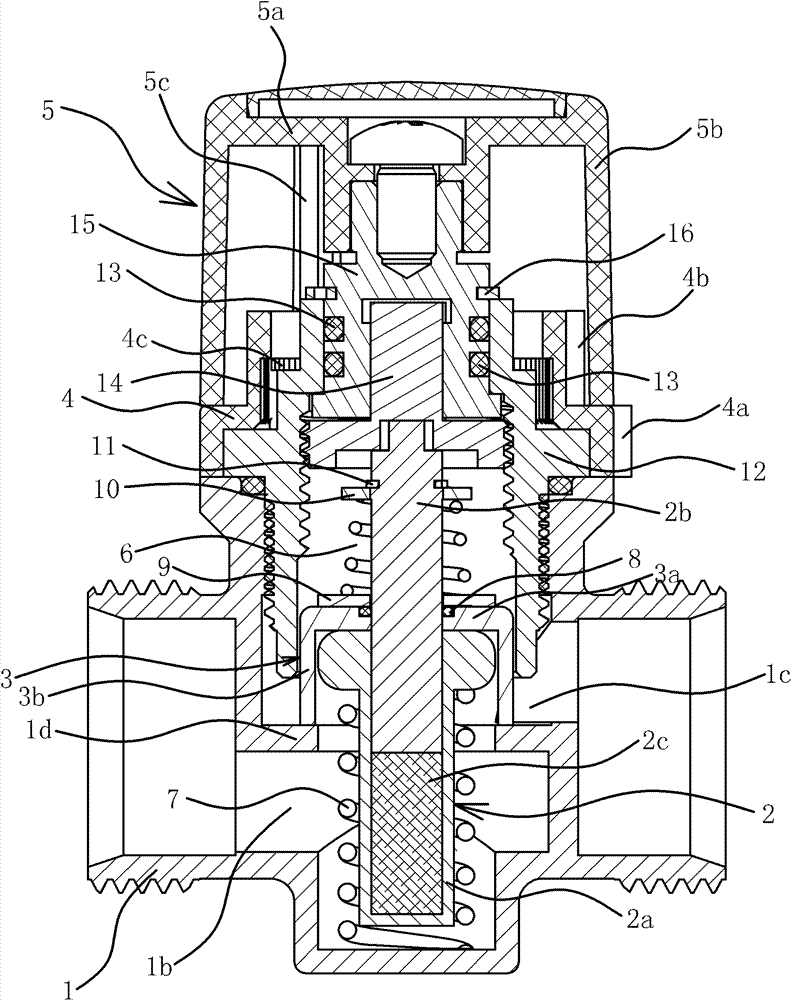

InactiveCN102062256AAccurate temperature controlSensitive temperature controlOperating means/releasing devices for valvesEqualizing valvesTemperature controlEngineering

The invention provides a floor heating thermostatic valve, belonging to the technical field of engineering components. The floor heating thermostatic valve solves problems that the traditional temperature control valve opens up only when the water temperature in the water inlet rises and the set temperature value cannot be adjusted. The floor heating thermostatic valve comprises a valve body, wherein the valve body is provided with a sealing part; an inner cavity of the valve body is divided into a water inlet cavity and a water outlet cavity; a temperature bulb and a valve core are arranged in the valve body; the body of the temperature bulb is arranged in the water inlet cavity; an ejector pin of the temperature bulb penetrates into the water outlet cavity; the valve core is hermetically connected with the temperature bulb; a spring 1 is arranged between the valve core and the side wall of the water outlet cavity of the valve body; a spring 2 is arranged between the body of the temperature bulb and the side wall of the water inlet cavity of the valve body; the elastic force of the spring 2 is bigger than that of the spring 1; when the water temperature in the water inlet cavity rises, the valve core moves towards the direction of the sealing part; and when the valve core leans on the sealing part, the body of the temperature bulb moves far away from the direction of the valve core and compresses the spring 2. The floor heating thermostatic valve has the advantages of accuracy and sensitiveness on temperature control, convenience in use and high operation safety.

Owner:卓旦春

Floor heating thermostatic valve

InactiveCN102135207AAccurate temperature controlSensitive temperature controlOperating means/releasing devices for valvesEngineeringWater temperature

The invention provides a floor heating thermostatic valve, which belongs to the technical field of engineering components, and solves the problem that the set temperature value cannot be adjusted along with the temperature increasing of water at a water inlet in the conventional thermostat valve. The floor heating thermostatic valve comprises a valve body with a sealing part; the inner cavity of the valve body is divided into a water inlet cavity and a water outlet cavity; a thermal bulb and a valve plug are arranged in the valve body; a thermal bulb body is positioned in the water inlet cavity; the thermal bulb is connected with the valve plug, when water temperature in the water inlet cavity is increased, the thermal bulb can drive the valve plug to move close to the sealing part; an elastic piece which ensures that an ejector rod of the thermal bulb can be contracted into the thermal bulb body when the water temperature in the water inlet cavity is reduced is arranged between the thermal bulb and the valve body; and an adjustment mechanism for adjusting the length of the ejector rod penetrating through the body is arranged between the side wall of the water outlet cavity of thevalve body and the thermal bulb. The floor heating thermostatic valve has the advantages of high running safety performance, wider application range and accurate adjustment, can control the temperature accurately and sensitively, and is convenient to use.

Owner:卓旦春

System and method for gathering trace heavy-nucleus hydrogen isotopes in hydrogen isotopes by hydrogen replacement adsorption

ActiveCN109663456ASimple heatingConvenient temperature controlGas treatmentIsotope separationDesorptionChemical separation

The invention belongs to the field of chemical separation and provides a system and method for gathering trace heavy-nucleus hydrogen isotopes in hydrogen isotopes by hydrogen replacement adsorption.Firstly, a separation column is adopted for adsorbing pure protium until a saturated state is achieved; secondly, raw material gas is fed into the separation column to realize replacement adsorption;thirdly, desorption is performed by means of gas heating, so that separation of the trace heavy-nucleus hydrogen isotopes is realized. The method and the system have advantages that multistage separation columns and sectional heating are avoided, and short single-time separation time, desorption thoroughness, excellent gathering effects, high recovery rate and low cost are realized.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

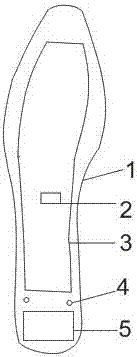

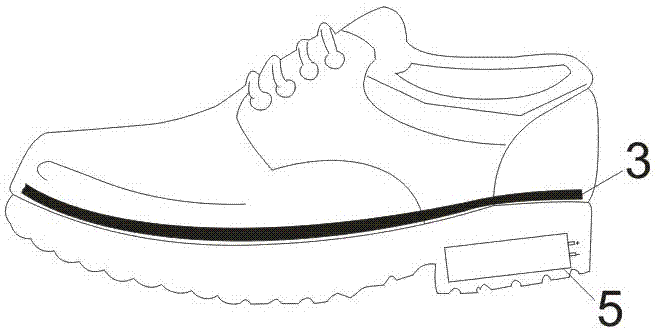

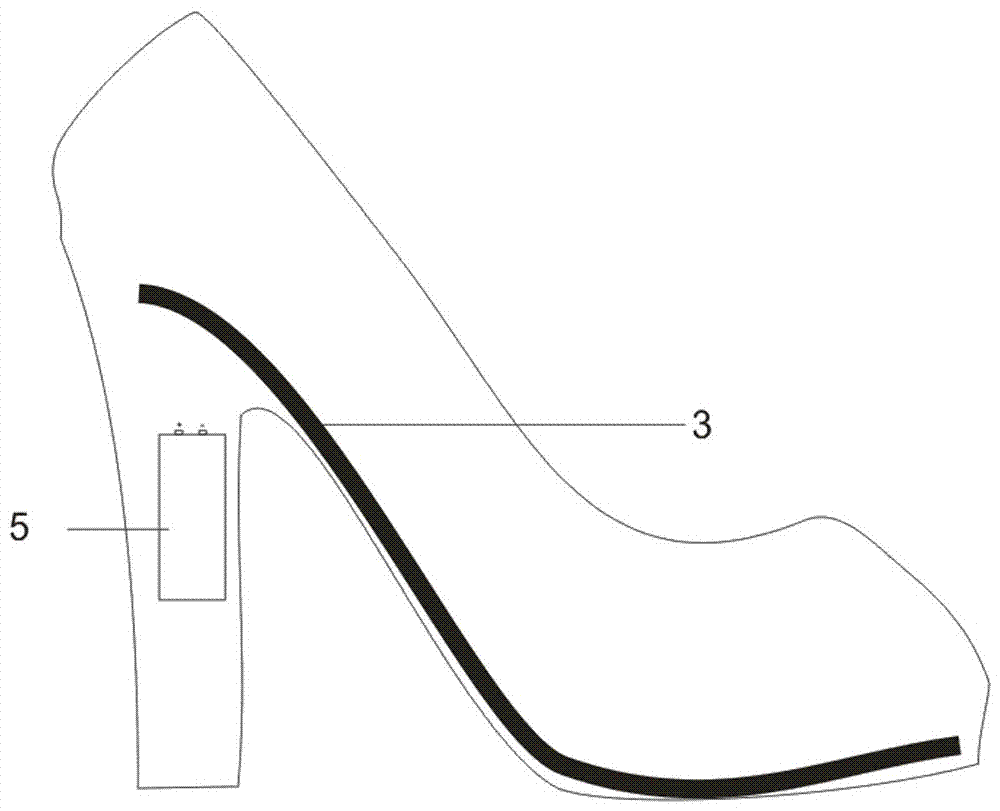

Graphene far-infrared heating shoes

PendingCN107157006APromote blood circulationHigh electrothermal conversion rateSolesSubstation equipmentLithium polymer cellAcupuncture point

The invention provides graphene far-infrared heating shoes. Each graphene far-infrared heating shoe comprises a heating chip carrier and modified graphene heating fiber cloth which are positioned at the bottom of each shoe body, wherein a heating main body is arranged at the bottom of the PET heating chip carrier, and a temperature control circuit is arranged inside the heating main body; the heating main body generates heat after a 3.7V DC lithium polymer battery is connected and conducted through a wiring port; the lithium polymer battery is positioned at the heel part of each shoe body. The scheme of the invention provides the graphene far-infrared heating shoes which are safe and reliable, are convenient to use, can improve the ice-cold feet, have the physical therapy effect, and can realize heating and thermal insulation on the human feet. The shoes have the physical therapy health care function, and can emit 8-14 [mu] m far-infrared rays while realizing the heating and thermal insulation effects, in use, the graphene far-infrared heating shoes carry out far-infrared physical therapy health care on the acupuncture points of the feet, so that the effects of heating the acupuncture points of the feet, as well as dredging the channels and promoting blood circulation are achieved, meanwhile, nano silver and volcanic rock powder are added on upper layer of the chip, so that the sterilizing effect can be achieved.

Owner:FOSHAN SHUNDE SANBEI ELECTRONICS CO LTD

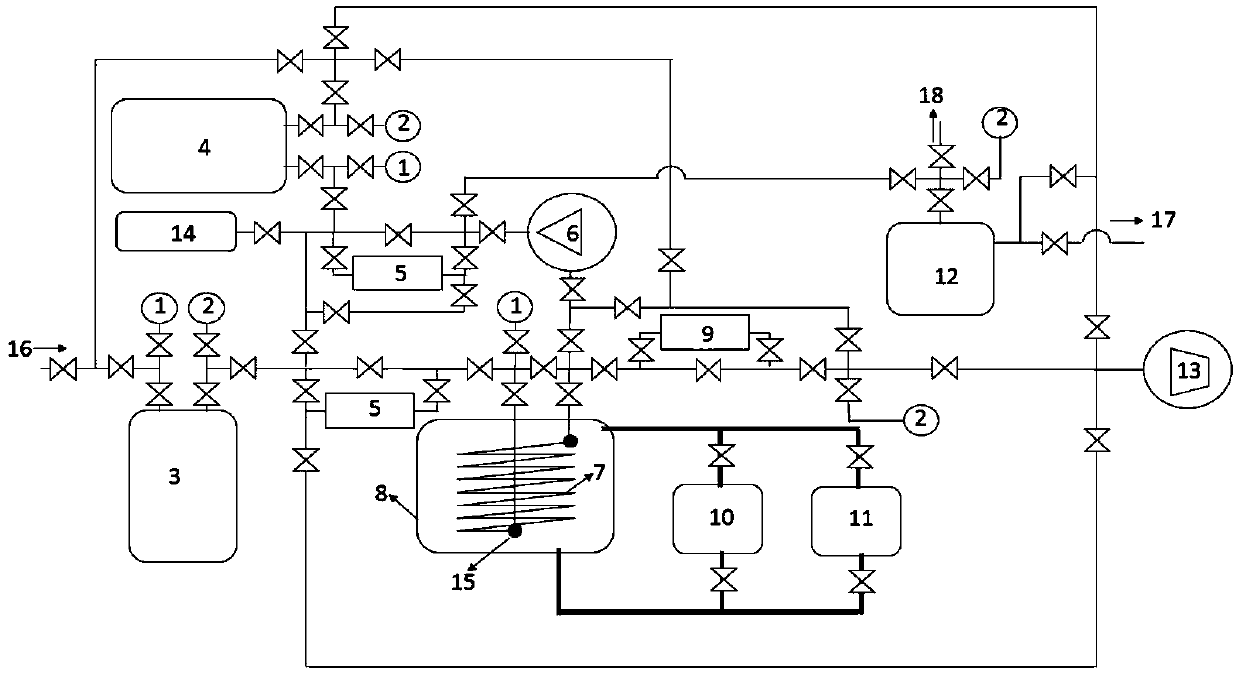

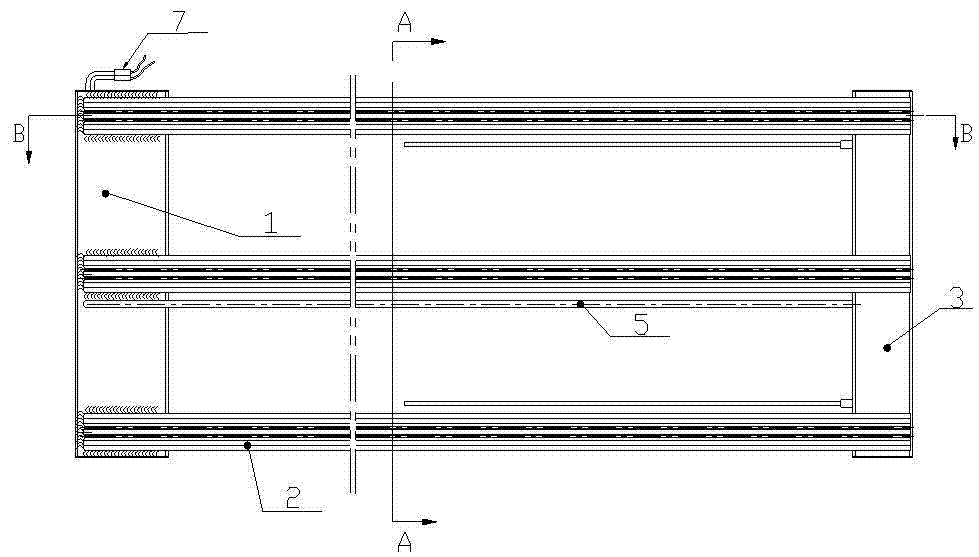

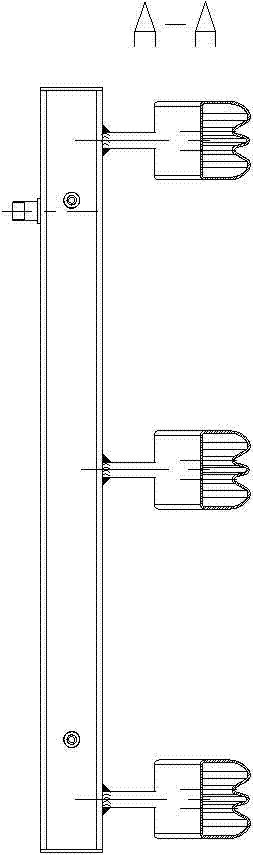

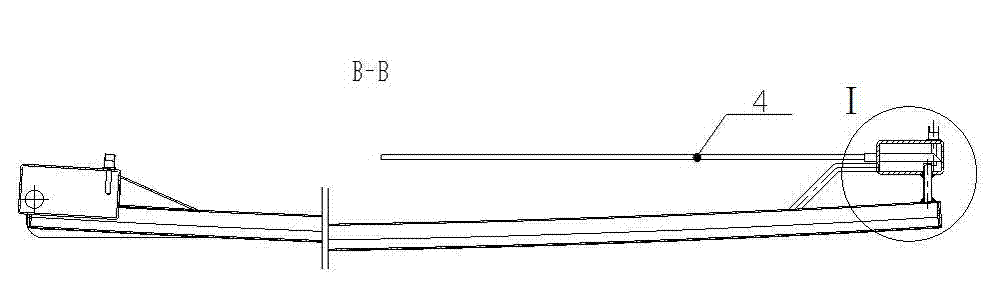

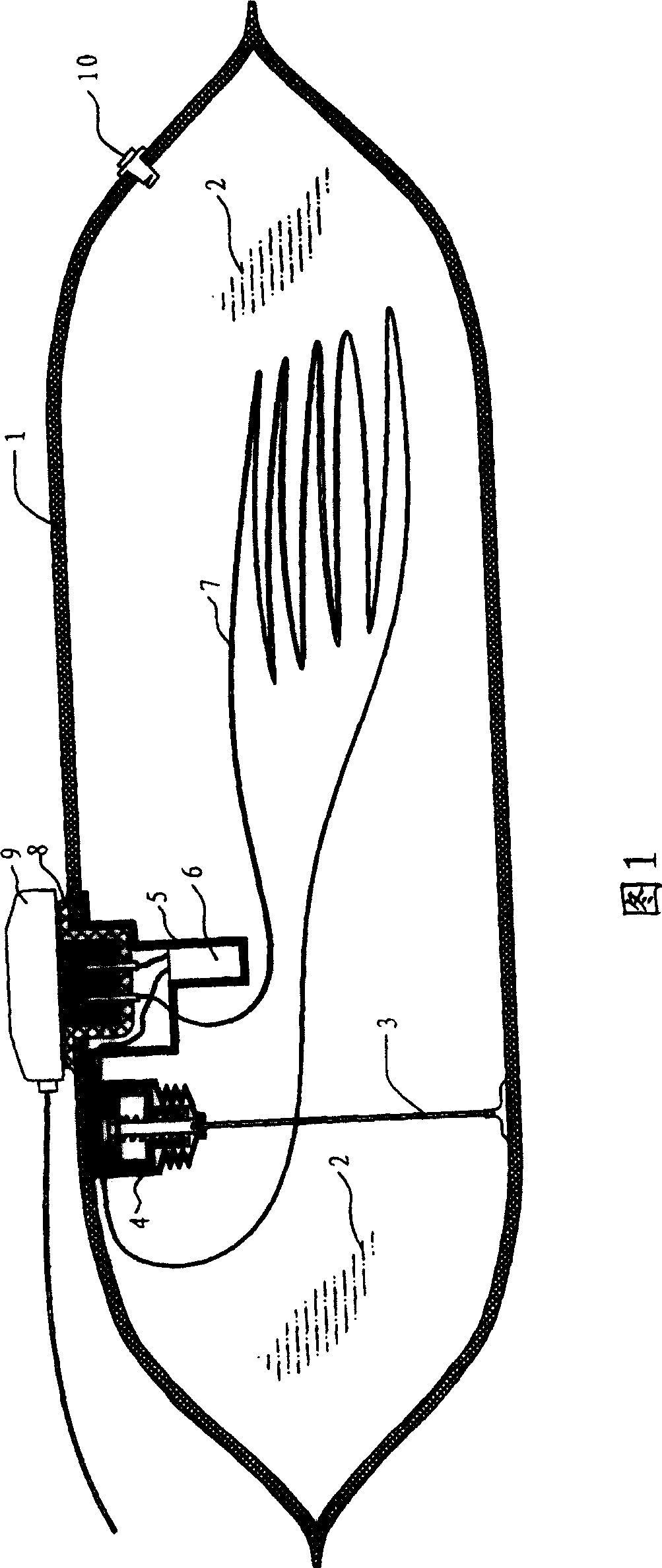

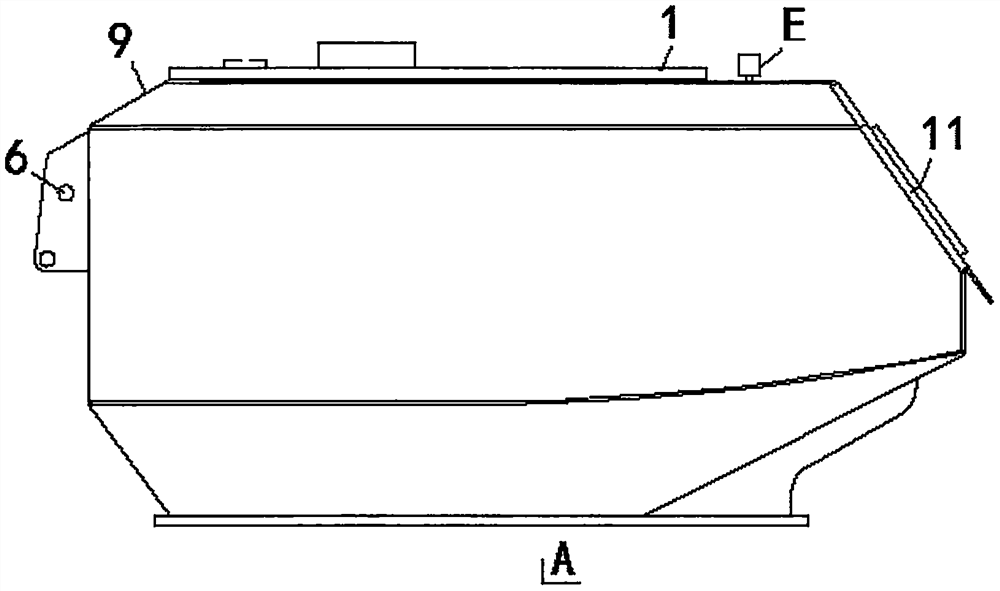

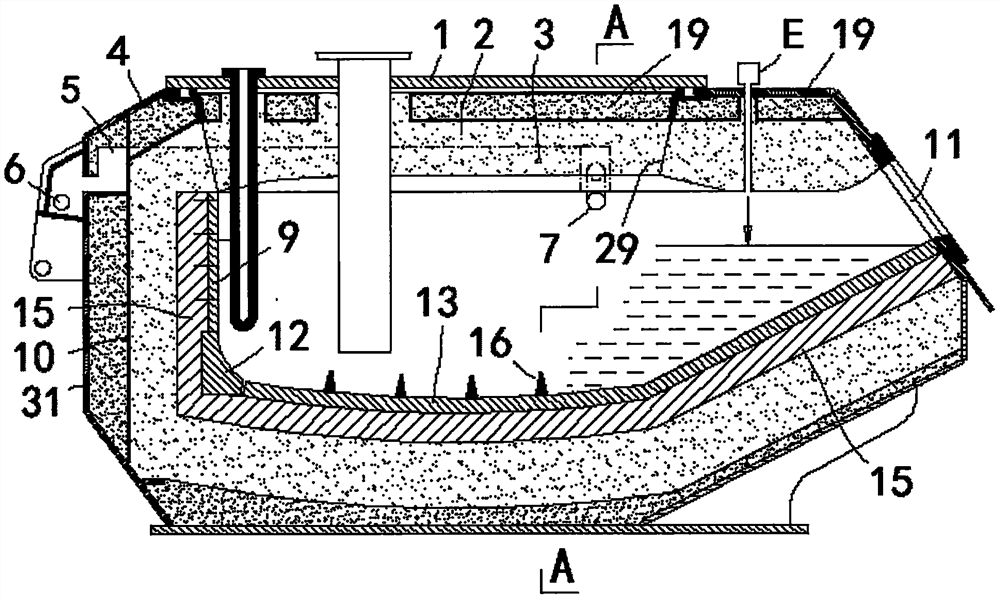

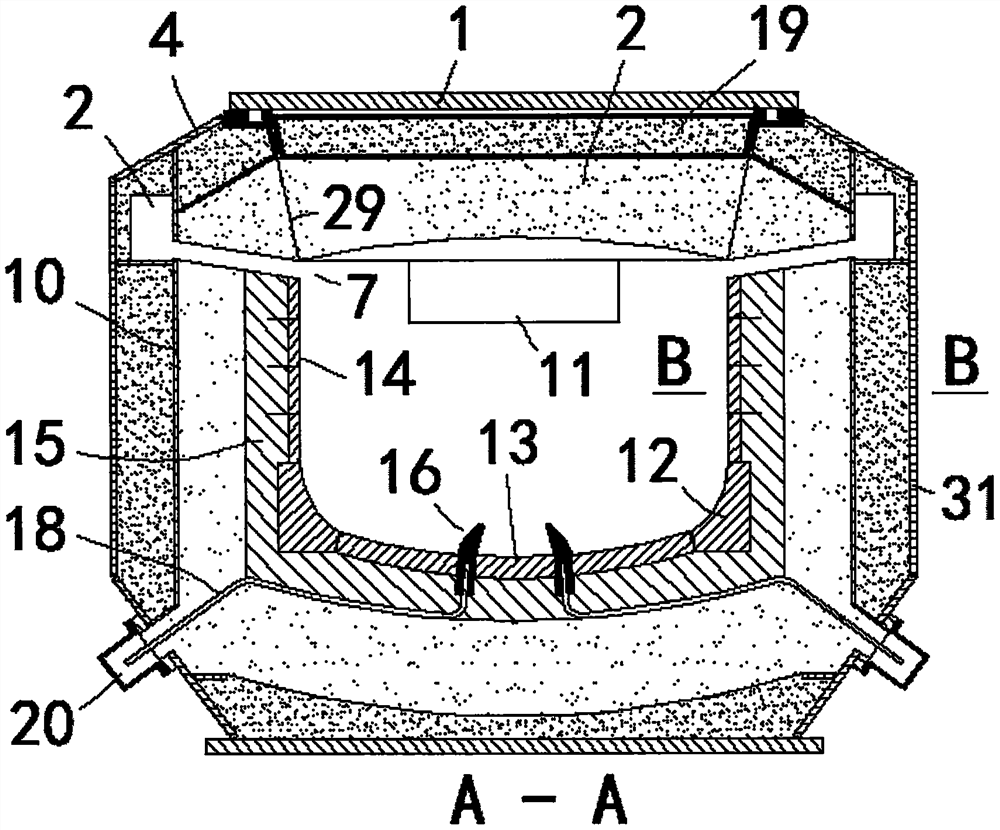

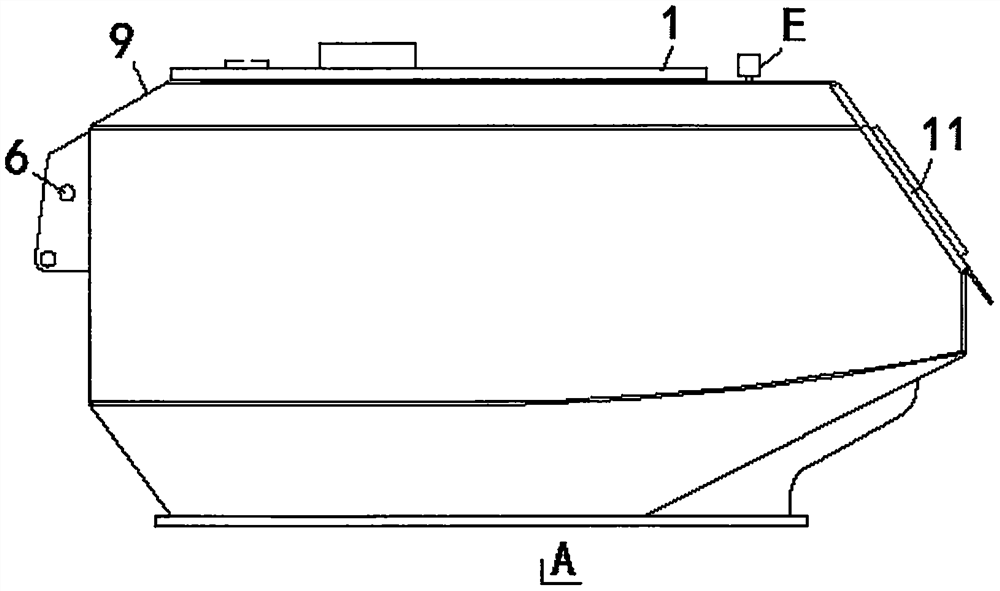

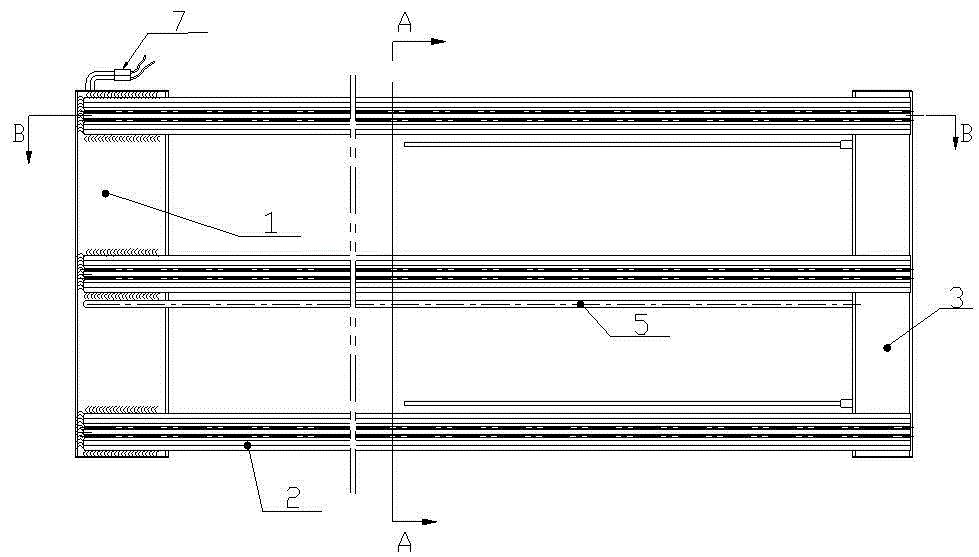

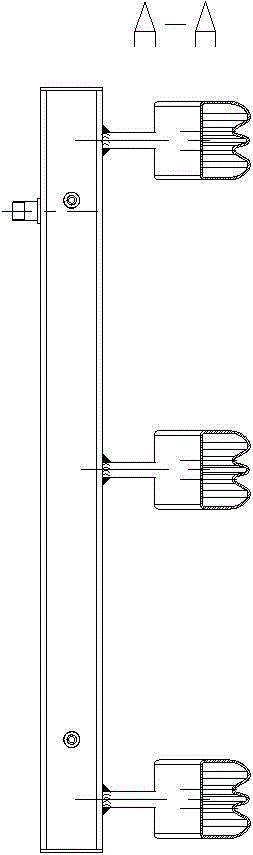

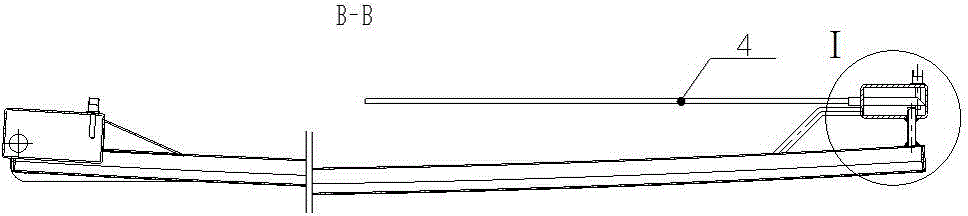

Hot box device of novel nylon yarn elasticizer

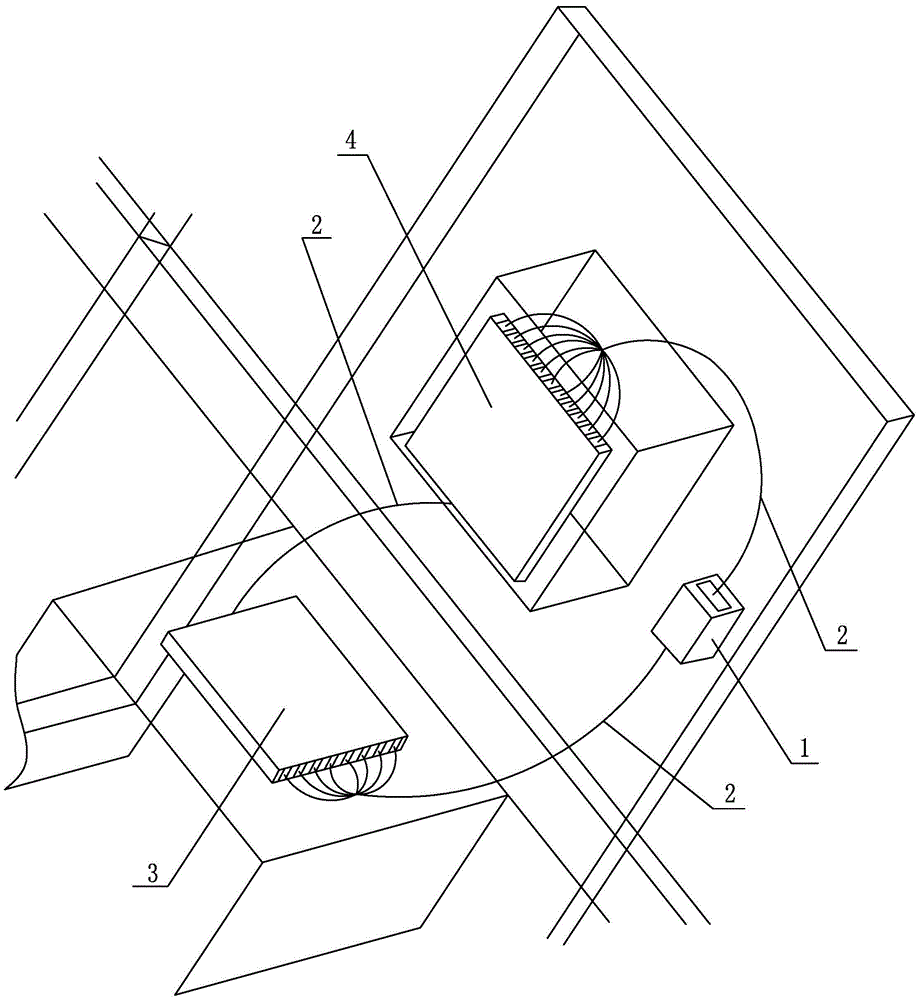

The invention relates to a hot box device of a novel nylon yarn elasticizer. The device is in such a structural mode that three rails, six spindles and three pipes are used, an evaporation pipe (1) is connected with a condensing pipe (3) through a return liquid pipe (5), an electric heating bar (7) is installed inside the evaporation pipe (1) and is directly immersed in heat-conduction oil inside the evaporation pipe (1), heating rails (2) are communicated with the condensing pipe (3) through a pipe (8), a throttler (6) is arranged at a top end position of the pipe (8), and two vent pipes (4) are arranged near heating rails (2) which are close to two ends of the condensing pipe (3). The throttler is arranged, the inside of heating rails is full of steam, and the steam inside a hot box is circulated compulsively, so that the normal usage time of the hot box is greatly prolonged; the TherminolVP-1 or DOWTHERNA type heat-conduction oil is used, so that the safety is greatly improved when the device works at 250 DEG C; and the heating method that the electric heating bar is directly immersed in heat-conduction oil is used, so that the temperature controlling is sensitive.

Owner:苏州旭鸣纺织有限公司

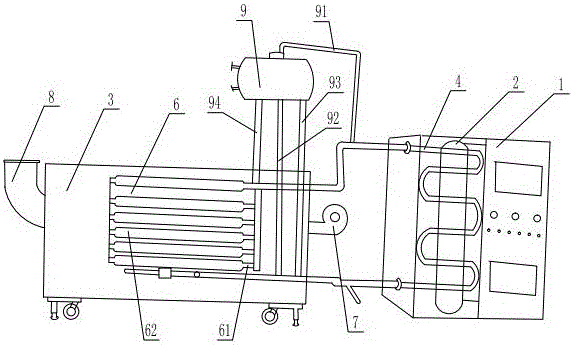

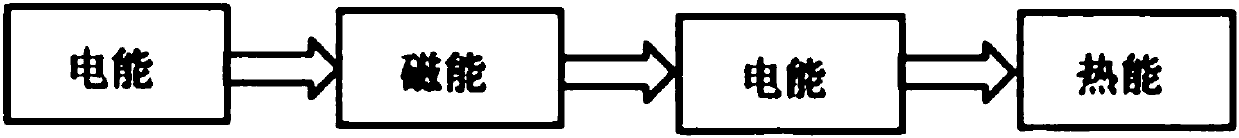

Control method for intelligent electromagnetic air heating machine

The invention discloses a control method for an intelligent electromagnetic air heating machine and belongs to the technical field of air heating equipment. The control method comprises the steps that the required heating time, the outlet temperature, the outlet air speed and the required room temperature are set, a preheating temperature rising mode is selected, after preheating is completed, indoor heating is conducted according to a heating mode corresponding to the selected temperature rising mode, the outlet temperature and the outlet air speed are monitored, adaptive adjustment is conducted, and heat storage and heat release use of a heat accumulator is achieved. The control method has the beneficial effects that the degree of intelligence is high, storage of heat energy is achieved effectively, and the heat utilization rate is high.

Owner:ZHANGJIAKOU RONGSHENG NEW ENERGY DEV CO LTD

Remote control intelligent family dining table system

InactiveCN107713358AStrong sense of experiencePrevent misoperation from causing dangerFurniture partsServing tablesTemperature controlCommunications system

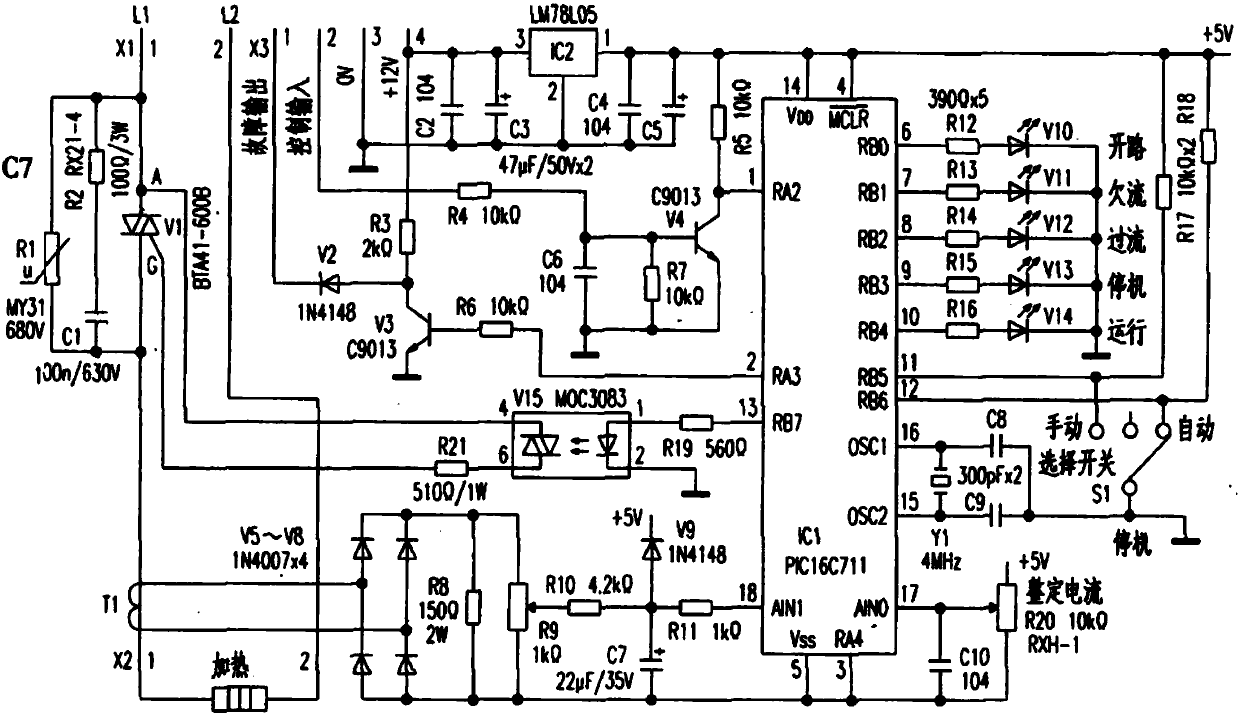

The invention relates to the technical field of intelligent homes, in particular to a remote control intelligent family dining table system which comprises a dining table, an electromagnetic heating system, a communication system and a central processing unit. The remote control intelligent family dining table system is characterized by comprising a semiconductor refrigeration system, a four-way temperature monitoring system, a can bus and a display system. The electromagnetic heating system comprises electromagnetic heating, manual working, automatic working and down states and has open-circuit, over-current and undercurrent detection functions and the like, the communication system is used for remote connection and can realize remote detection and control, danger caused by misoperation of children is prevented when parents are not around the dining table, the semiconductor refrigeration system can realize simple refrigeration and is used for cooling or used with cold food, the four-way temperature monitoring system can accurately monitor temperature values, user experience feeling is stronger, temperature control is more sensitive, and the remote control intelligent family diningtable system is more intelligent and has strong creativity.

Owner:陈乐晨

Boiler waste heat recycling system based on flue gas waste heat recovery boiler economizer

InactiveCN107543193AImprove corrosion resistanceImprove efficiencyCombustion technology mitigationWater heatersThermal energyEconomizer

The invention discloses a boiler waste heat recycling system based on a flue gas waste heat recovery boiler economizer. The boiler waste heat recycling system comprises a boiler and a flue gas waste heat recoverer; the flue gas waste heat recoverer is installed at an outlet of a flue of the boiler; one end of the flue gas waste heat recoverer is connected to tap water through a first heat recoverypump, a second stop valve, a heat preservation hot water tank and a first stop valve; the other end of the flue gas waste heat recoverer is connected to one end of a heat preservation water tank through a third stop valve, the heat preservation hot water tank, a fourth stop valve and a second heat recovery pump; and the other end of the heat preservation water tank is connected to a user througha fifth stop valve and a booster pump. The boiler waste heat recycling system based on the flue gas waste heat recovery boiler economizer is high in heat exchange efficiency, remarkable in energy saving effect and flexible in temperature control, and the flue gas waste heat recoverer has good corrosion resistance; the using efficiency of the boiler can be improved; and operation cost is not needed, a large amount of heat discharged to the atmosphere is recycled, and waste heat recycling is achieved.

Owner:HEILONGJIANG KANGGEER TECH

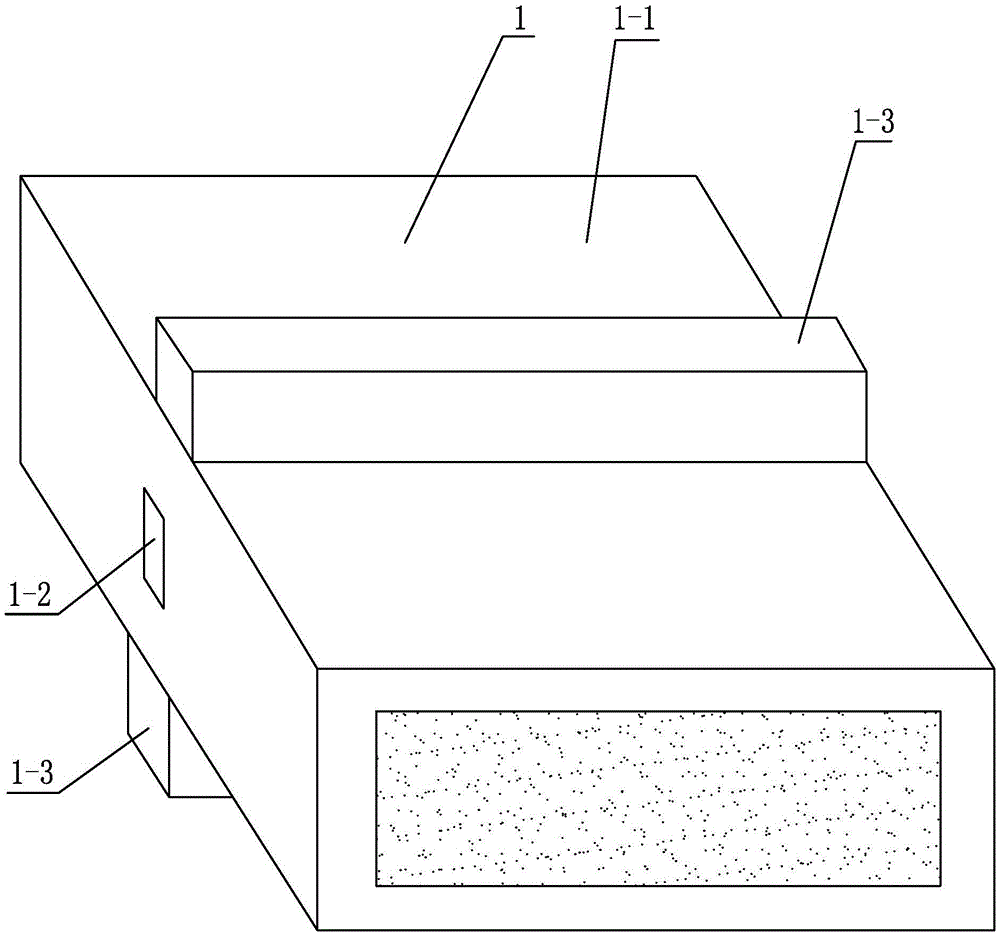

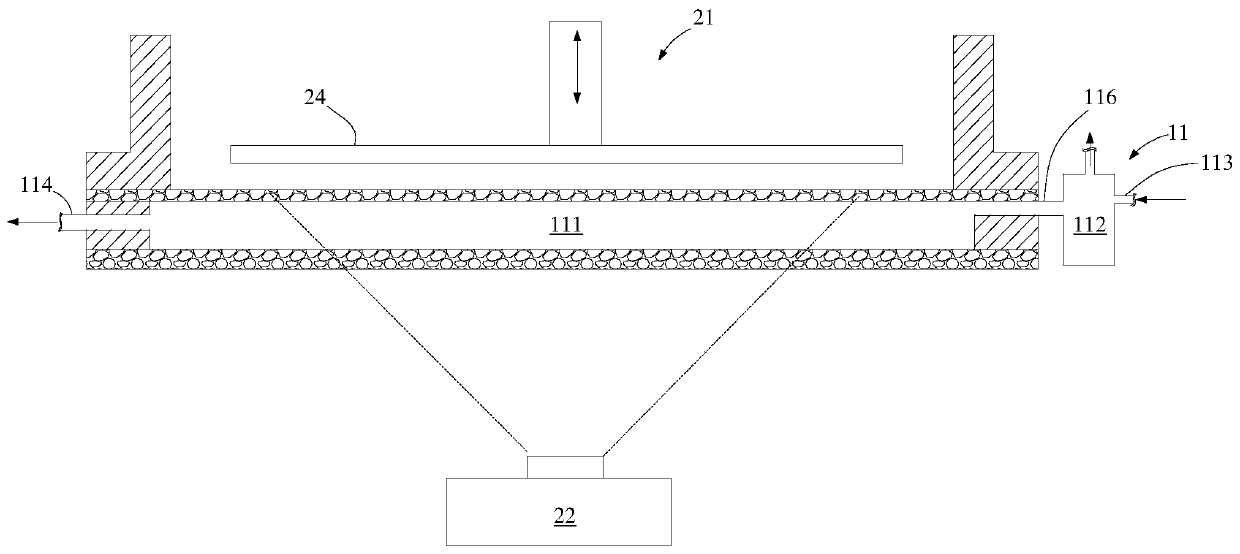

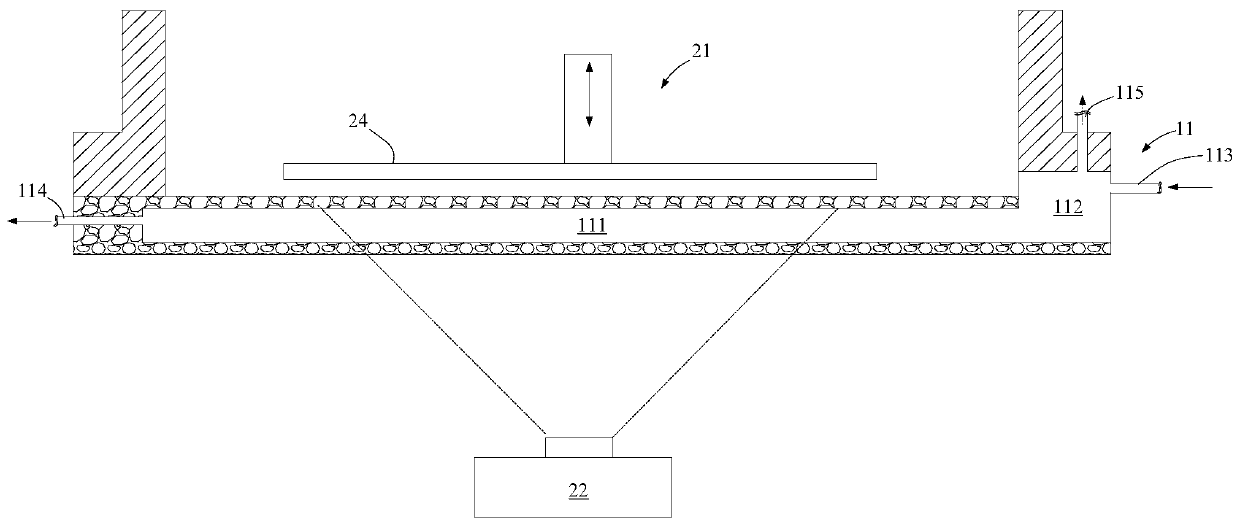

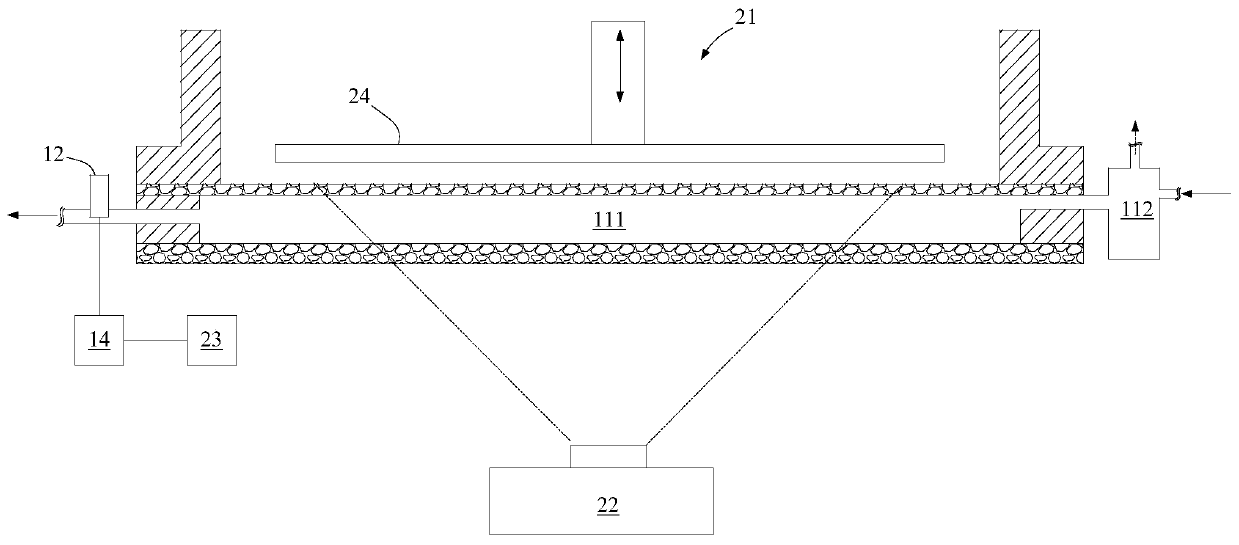

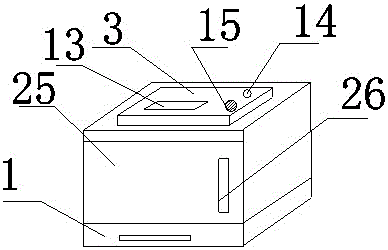

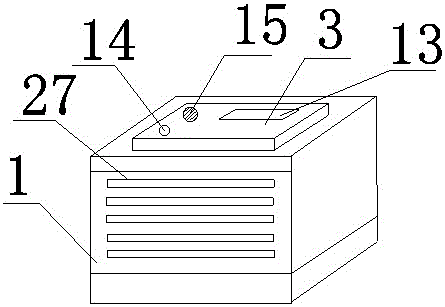

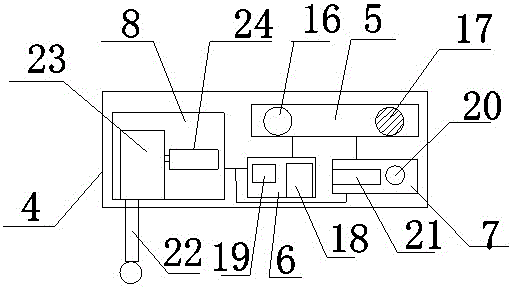

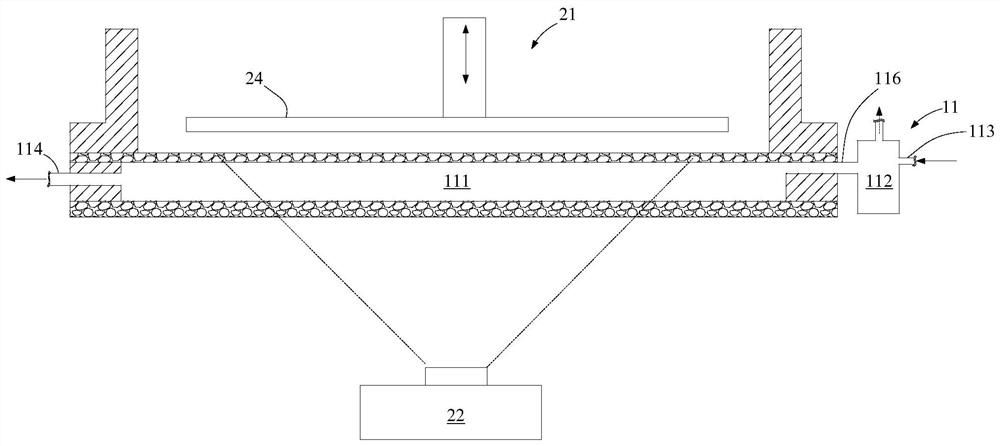

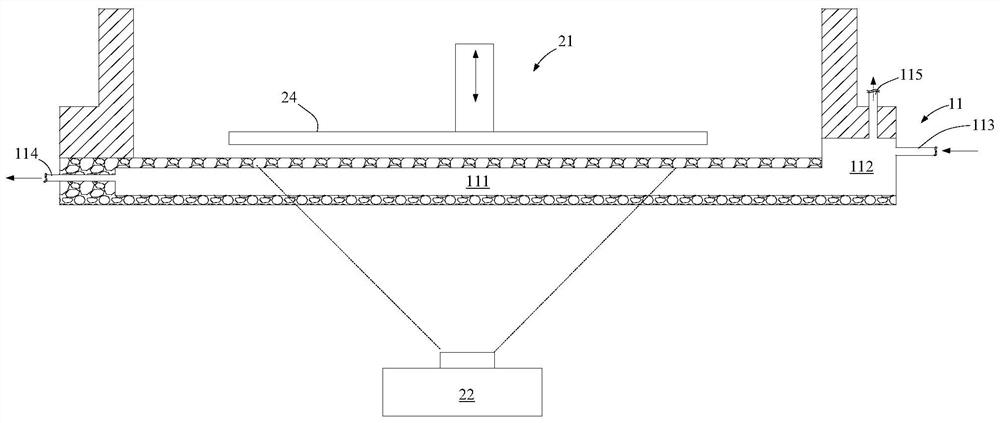

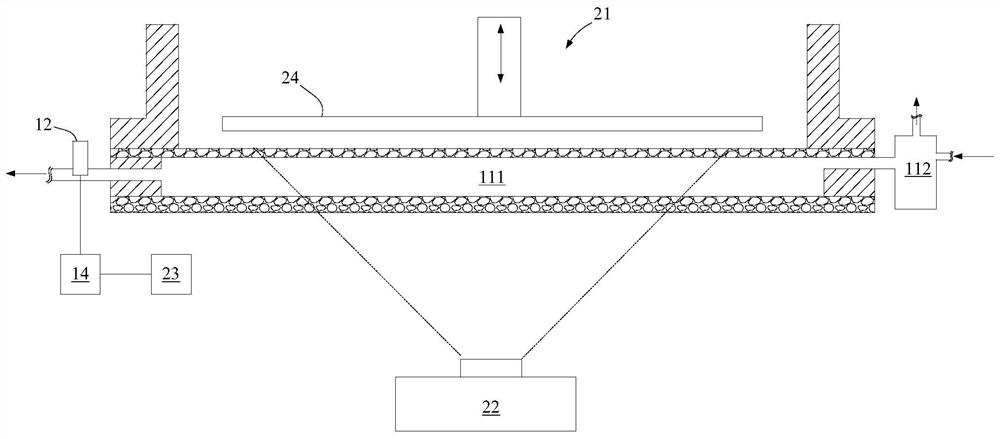

Container, temperature control mechanism of container as well as 3D printing equipment and method

ActiveCN111016163AReduce the impactReduce the risk of substandard qualityManufacturing enclosures3D object support structuresTemperature controlProcess engineering

The invention provides a container, a temperature control mechanism as well as 3D printing equipment and method. The temperature control mechanism of the container applied to the 3D printing equipmentcomprises a temperature control cavity attached to the bottom of the container and used for circulating a temperature control liquid, the temperature control liquid is subjected to heat-source heating treatment or cold-source refrigeration treatment, the temperature control cavity is provided with a liquid inlet and a liquid outlet, the temperature control cavity comprises a main cavity and an auxiliary cavity, the main cavity is attached to a radiation area at the bottom of the container and used for controlling temperature of the radiation area, the auxiliary cavity is adjacent to or away from the main cavity and used for collecting bubbles in the temperature control cavity, and the liquid level of the temperature control liquid in the auxiliary cavity is higher than that of the temperature control liquid in the main cavity. By real-time monitoring of the temperature of the bottom of the container, the temperature of the bottom of the container is always kept at a preset suitable temperature interval in a printing process, and the effects of temperature on the printing quality can be reduced.

Owner:SHANGHAI UNION TECH

Intelligent remote control dish heating device with timing function

InactiveCN106821043ASimple structureStable structureKitchen equipmentTemperature controlInsulation layer

The invention discloses an intelligent remote control cooking device with timing function, comprising an intelligent cooking device body, and a heating bin is arranged inside the intelligent cooking device body; The lower part of the control panel is electrically connected with an information processing component; the information processing component is provided with an information transceiver, an information storage processing module, a timing system and an automatic temperature adjustment system; a load-bearing push-pull plate is arranged in the heating chamber; The load-bearing push-pull plate is divided into upper, middle and lower layers, and each is provided with a rotating disk and a carbon crystal heating plate arranged in the center of the rotating disk; the outer side of the heating chamber is provided with a double-layer insulation layer; the control panel is powered on A timing input keyboard, a warning light and a work light are connected sexually. The invention has simple structure, stable structure, high heating efficiency, remote control, sensitive temperature control, good heat preservation effect, uniform heating, high safety performance and convenient operation.

Owner:安聪聪

Explosion-proof electric hot-water bottle

InactiveCN100482007CSimple structureLow costOhmic-resistance heatingTherapeutic coolingElectricityEngineering

This invention relates to anti-explosion electrical water bag, which comprises sealed soft bag, liquid as memory medium and heating element, wherein, the said bad is set with electrical socket with protection switch and ring; the protection switch is connected to the heating element; one end of string is fixed on bag inner wall with other end connected to second end of protection switch and push bar.

Owner:高国兴

5G energy-saving optimized crystallization furnace

PendingCN112781373ASave IoT sharingSaving and sharingMelt-holding vesselsFurnace componentsSingle crystalMaterials science

The invention discloses a 5G energy-saving optimized crystallization furnace and relates to a 5G energy-saving and optimized die-casting microstructure which is characterized in that a novel die-casting holding furnace is designed and manufactured by combining a practical structure on the basis of research and development of a non-sticky aluminum lining furnace material and a special soft heat-insulating casting material, a microstructure technology for optimizing die-casting crystals by an electric pulse is introduced into the novel holding furnace, the possibility of casting a single crystal or microcrystal microstructure in an existing die-casting machine is explored; and a smelting furnace, a transfer tank, a standing furnace, a casting ladle and a die-casting holding furnace of a 5G newest cellular mobile communication Internet-of-things die-casting system are applied to intelligently adjust and control temperatures of all links to be stable, a temperature fluctuation range is narrowed, the quantity of molten aluminum is allocated, heat energy carried by the molten aluminum is shared along with digital flowing, the molten aluminum with the accurate temperature is supplied to flow, the temperature of the molten aluminum is reduced to the maximum, and an existing die-casting machine is supported to popularize electric pulse die-casting to manufacture a single crystal or microcrystal microstructure technology upgraded finished product.

Owner:边仁杰

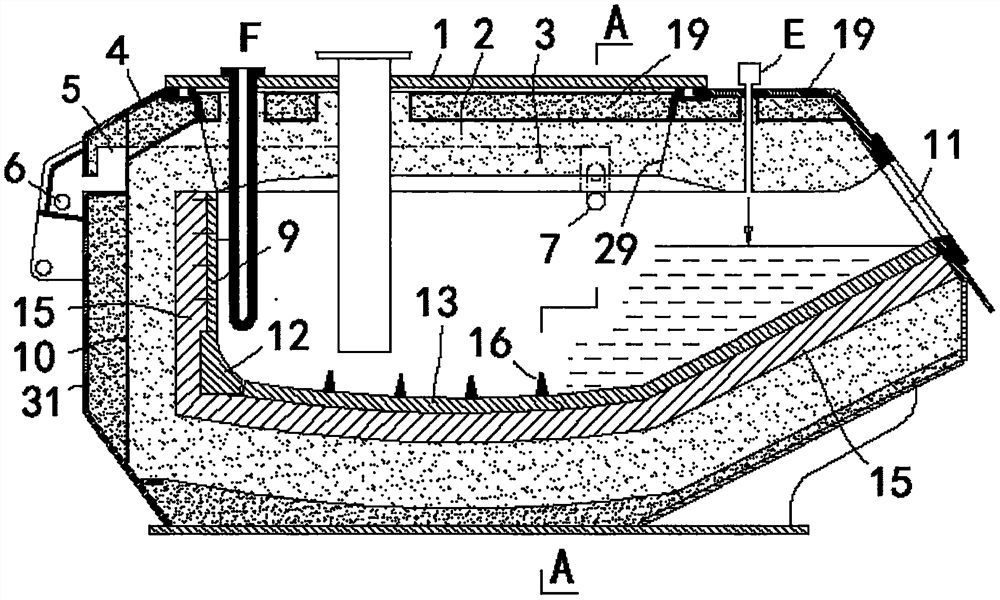

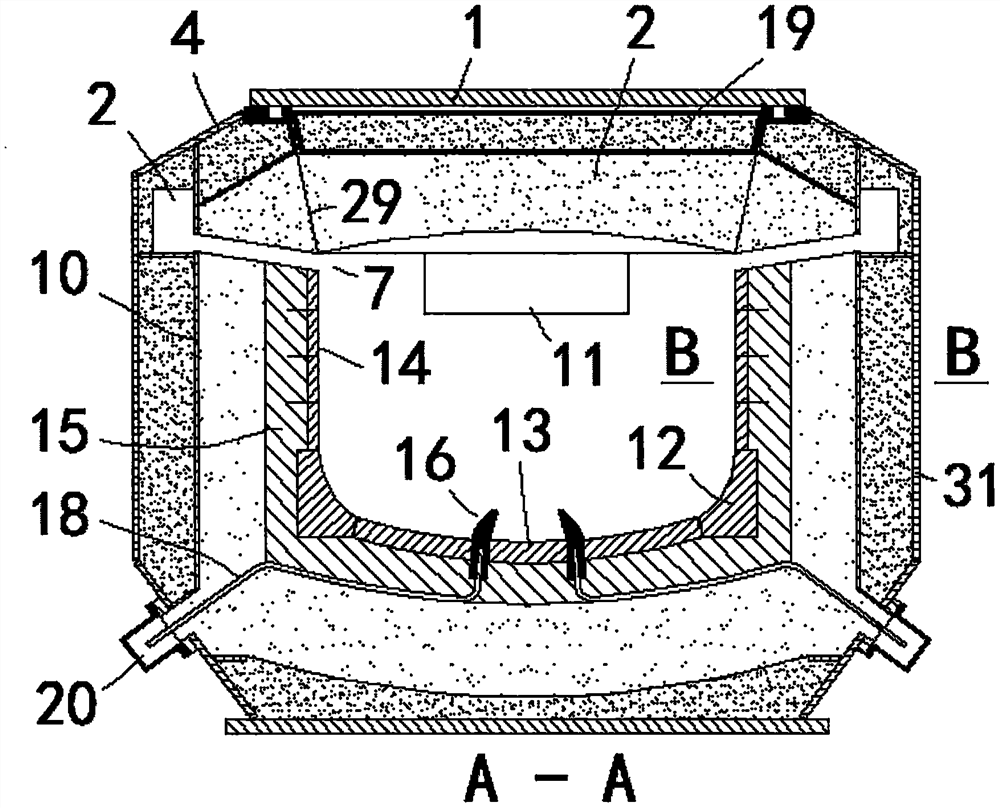

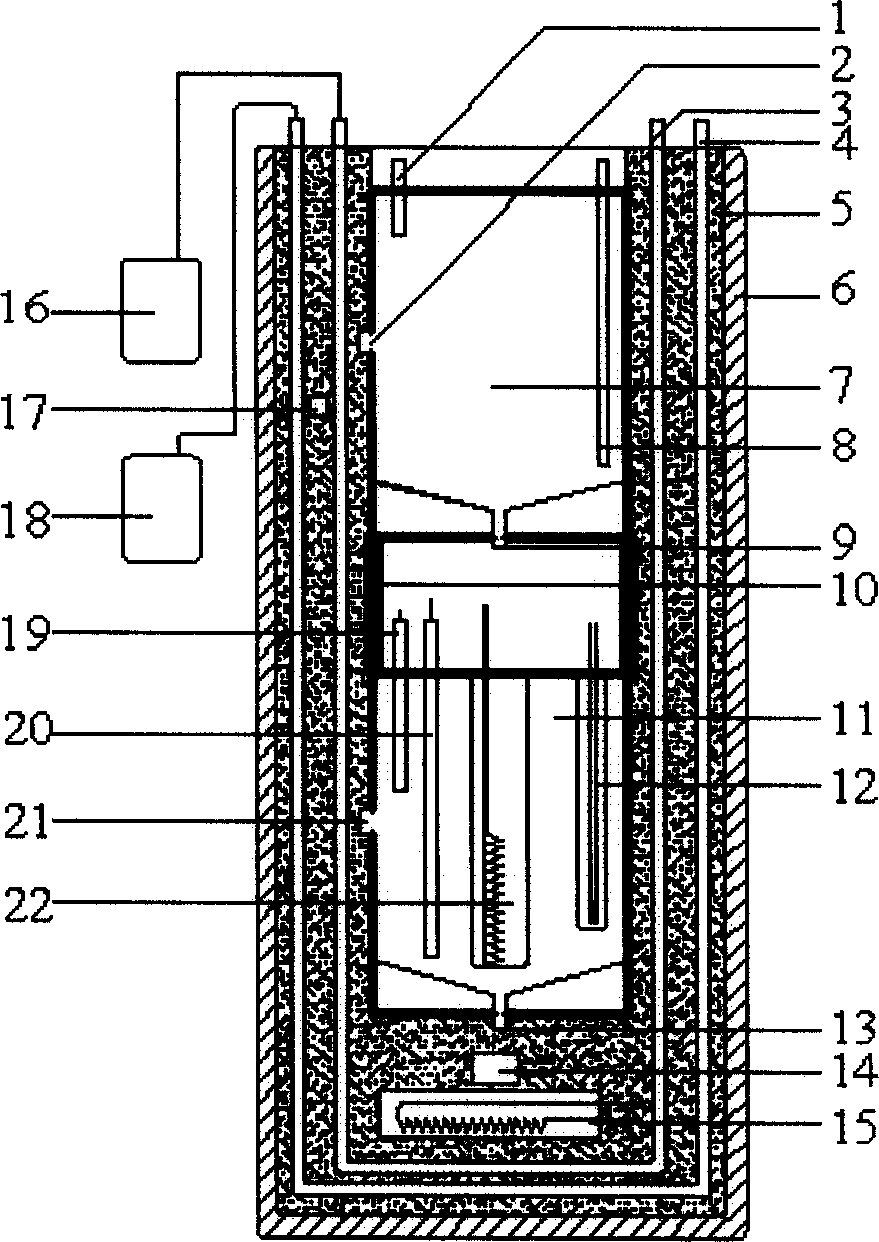

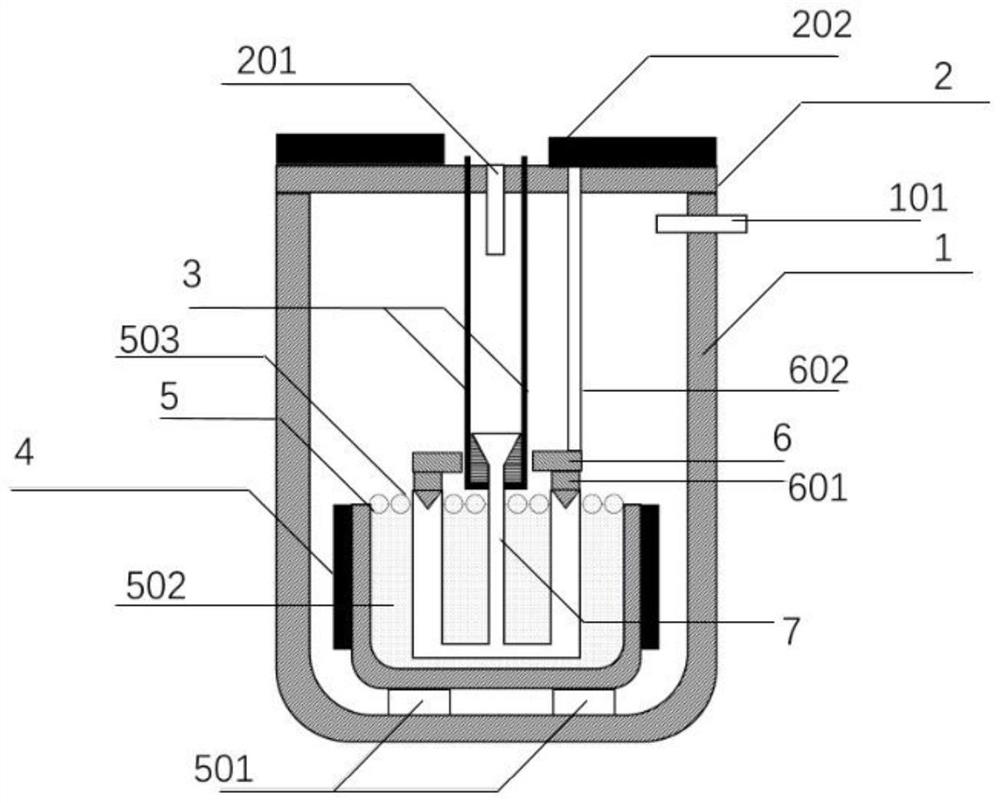

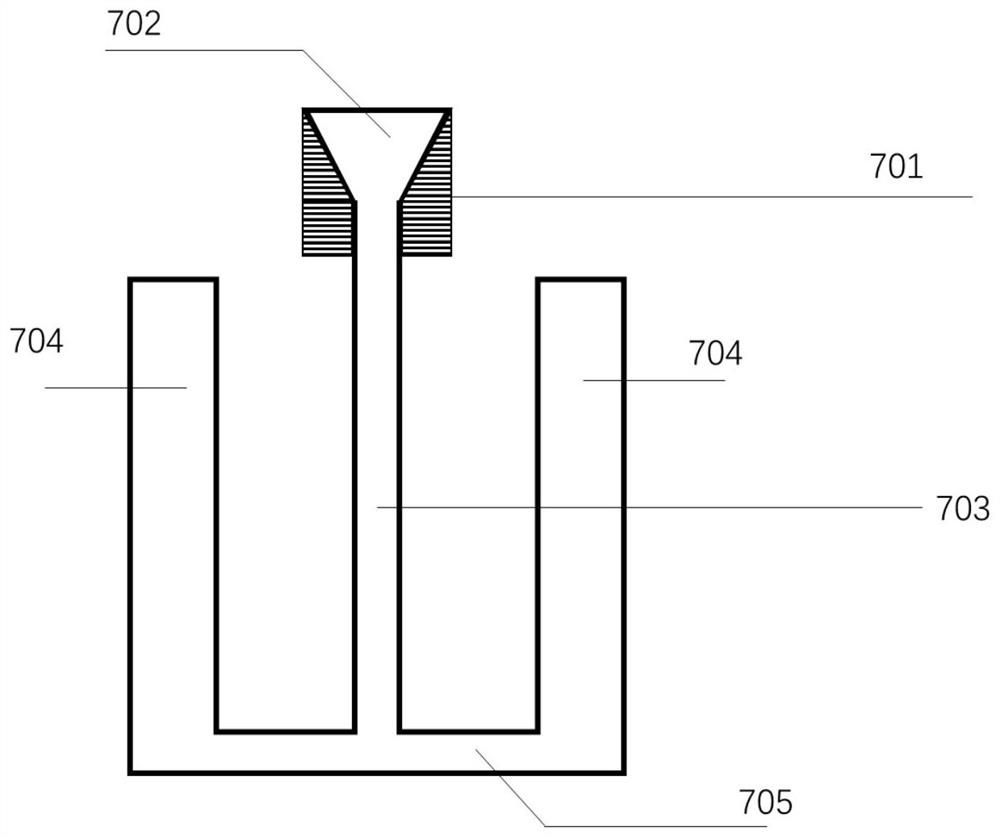

Constant tempeature reactor for reactor type biochemical oxygen-demand rapid measuring instrument

InactiveCN1709577ASensitive temperature controlHeating up fastHeating or cooling apparatusMeasuring instrumentAir pump

This invention refers to a constant temperature reactor that is used to fast mensurate the requirement of oxygen. In this invention, warim-up tin and retort are put in the constant temperature aluminous trough, and retort is up to warm-up tin between which there is the kickstand. There are liquid-in / out meatus and gas-in / out meatus in both warm-up tin and retort, electrical pipe and temperature transducer in warm-up tin. There are electrical pipe and temperature switch in the bottom of constant temperature aluminous trough, temperature transducer in the top, two U model unrubiginous steel tube inside one end connected to pump, the other connected to the gas-in meatus of warm-up tin and retort. The water in warm-up tin is heat and kept the constant temperature 30 degree C, then sent to retort. This constant temperature reactor completely appeases the specifically need of the temperature of water and air.

Owner:BEIJING TSINGNENG CHUANGXIN SCI & TECH CO LTD

Control method and controller for proportion integration differentiation (PID) control-based breathing machine heating and humidifying system

InactiveCN103235611BPrevent heating and thermal inertiaImprove heating efficiencyTemperature control using electric meansControllers with particular characteristicsTemperature controlProportion integration differentiation

The invention discloses a control method and a controller for a proportion integration differentiation (PID) control-based breathing machine heating and humidifying system and relates to a control method and a controller for the breathing machine heating and humidifying system. The invention comprises a step and a device for acquiring a real-time temperature value, a step and a device for obtaining a temperature departure value, a step and a device for carrying out PID calculations and a step and a device for outputting a PID calculating result to control heating. According to the control method disclosed by the invention, the heating temperature is controlled by adopting an improved PID control method, and the heating can be continuously performed by adding an external execution cycle, so that the heating efficiency is improved. Meanwhile, by the setting of the external execution cycle, the control precision can be improved, and the heating thermal inertia is prevented from being excessively high. An integration operation link is conditionally executed, so that the temperature control reaction is sensitive, the temperature control is stable, safe and reliable, and the operation is simple.

Owner:东莞市俊熙智能科技有限公司

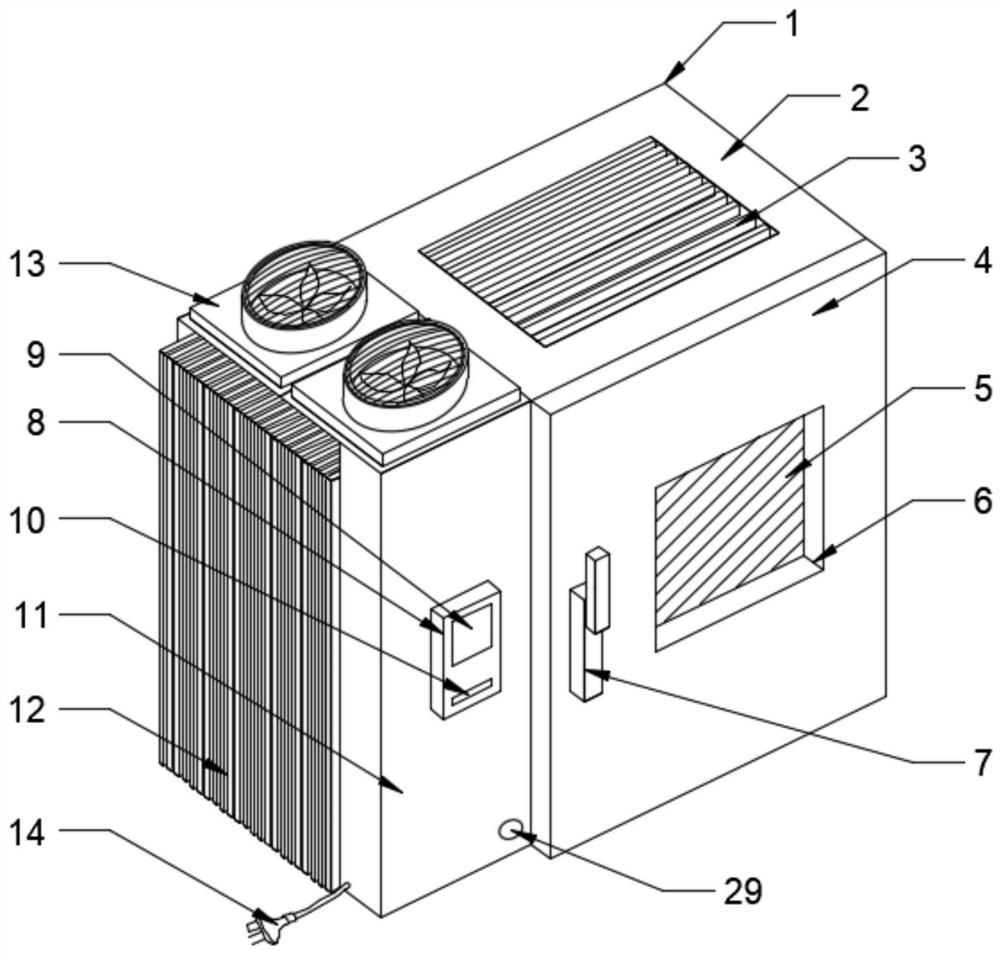

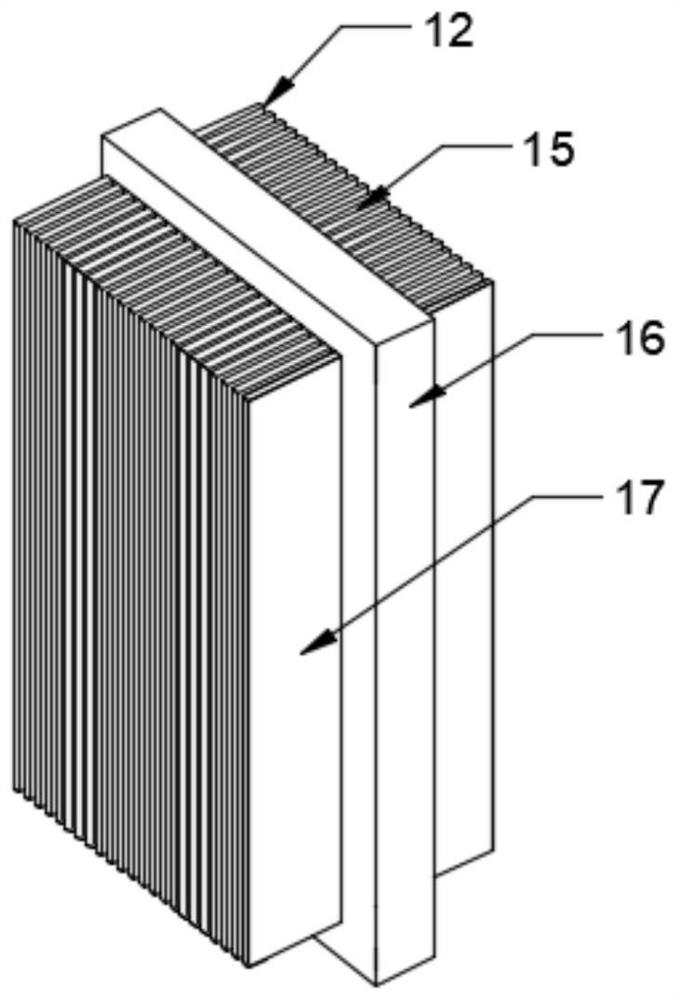

Refrigeration module with high safety performance

InactiveCN113237266ASolve pollutionEasy to condense and coolDomestic refrigeratorsMachines using electric/magnetic effectsTemperature controlCooling effect

The invention discloses a refrigeration module with high safety performance. The refrigeration module comprises a refrigeration module main body and a fuzzy PID controller, the refrigeration module main body comprises a refrigeration mother module and a refrigeration sub-module, the refrigeration mother module and the refrigeration sub-module are in through connection, the fuzzy PID controller is installed on the end face of the refrigeration sub-module, a touch screen is electrically arranged on the fuzzy PID controller, an alarm is electrically arranged below the touch screen, a semiconductor refrigeration structure is arranged in the refrigeration sub-module, an air blowing structure is arranged at the top of the refrigeration sub-module in a penetrating mode, and a condensate water outlet is formed in one corner of the lower end of the refrigeration sub-module. The refrigeration module is simple in design, and a control rule can be flexibly modified, so that the refrigeration module is more convenient and feasible, can completely meet the process requirements, is safe and efficient in control and high in practicability, has the advantages of low production cost, sensitive temperature control, obvious cooling effect and the like, saves energy, is green and environmentally friendly, and is suitable for popularization.

Owner:孙强

A method and system for enriching trace heavy nuclear hydrogen isotopes in hydrogen isotopes by hydrogen displacement adsorption

ActiveCN109663456BSimple heatingConvenient temperature controlGas treatmentIsotope separationChemical separationSeparation time

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Floor heating thermostatic valve

InactiveCN102062256BAccurate temperature controlSensitive temperature controlOperating means/releasing devices for valvesEqualizing valvesTemperature controlEngineering

The invention provides a floor heating thermostatic valve, belonging to the technical field of engineering components. The floor heating thermostatic valve solves problems that the traditional temperature control valve opens up only when the water temperature in the water inlet rises and the set temperature value cannot be adjusted. The floor heating thermostatic valve comprises a valve body, wherein the valve body is provided with a sealing part; an inner cavity of the valve body is divided into a water inlet cavity and a water outlet cavity; a temperature bulb and a valve core are arranged in the valve body; the body of the temperature bulb is arranged in the water inlet cavity; an ejector pin of the temperature bulb penetrates into the water outlet cavity; the valve core is hermetically connected with the temperature bulb; a spring 1 is arranged between the valve core and the side wall of the water outlet cavity of the valve body; a spring 2 is arranged between the body of the temperature bulb and the side wall of the water inlet cavity of the valve body; the elastic force of the spring 2 is bigger than that of the spring 1; when the water temperature in the water inlet cavity rises, the valve core moves towards the direction of the sealing part; and when the valve core leans on the sealing part, the body of the temperature bulb moves far away from the direction of the valve core and compresses the spring 2. The floor heating thermostatic valve has the advantages of accuracy and sensitiveness on temperature control, convenience in use and high operation safety.

Owner:卓旦春

Optimized crystallization heat preservation furnace

InactiveCN112393589APrevent oxidation and slaggingSolution to short lifeMelt-holding vesselsFurnace componentsPressure castingHeat conservation

The invention relates to an optimized crystallization heat preservation furnace, and relates to heat preservation and optimized casting microstructure. The optimized crystallization heat preservationfurnace is characterized in that a soft heat preservation pouring material and a hollow ball are used as a main body heat preservation furnace wall, a zirconium armor brick is anchored on the inner wall of the main body heat preservation furnace wall to be used as a non-stick aluminum lining layer, and the zirconium armor brick belongs to a permanent ultra-long service life die-casting furnace lining material. Therefore, the novel heat preservation furnace not only possesses better heat preservation performance, but also possesses an extraordinary service life, and is a heat preservation furnace which is not sticky to aluminum. On the basis of the advantages of being good in heat preservation, long in service life and non-sticky to aluminum, the optimized crystallization heat preservationfurnace is additionally provided with the molten aluminum self-resistance thermode, electric energy is converted into heat energy through the self-resistivity of molten aluminum, and therefore, the energy utilization efficiency is high, and the structure of the furnace body is very simple; the resistance thermode is also an electric pulse throwing electronic device, thrown electrons are beneficialto manufacturing a casting body with a finer microstructure through pressure casting, and therefore, the surface quality pass percent of a casting hub can be increased, and the mechanical performancecan be obviously improved.

Owner:边仁杰

Intelligent electromagnetic air heater control method

The invention discloses a control method for an intelligent electromagnetic air heater, which belongs to the technical field of hot air equipment. Including setting the time required for heating, outlet temperature, outlet wind speed and room temperature required temperature, select the preheating method, after preheating is completed, carry out indoor heating according to the heating method corresponding to the selected heating method, monitor the outlet temperature and outlet The wind speed is adjusted adaptively, and the heat accumulator is used for heat storage and heat release. The invention has the advantages of high intelligence degree, effective storage of heat energy and high heat utilization rate.

Owner:ZHANGJIAKOU RONGSHENG NEW ENERGY DEV CO LTD

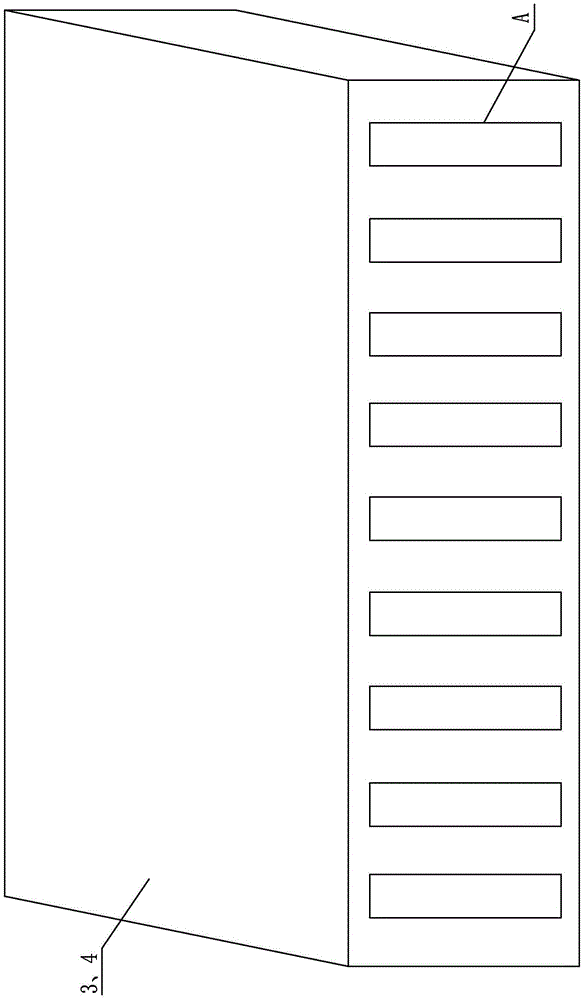

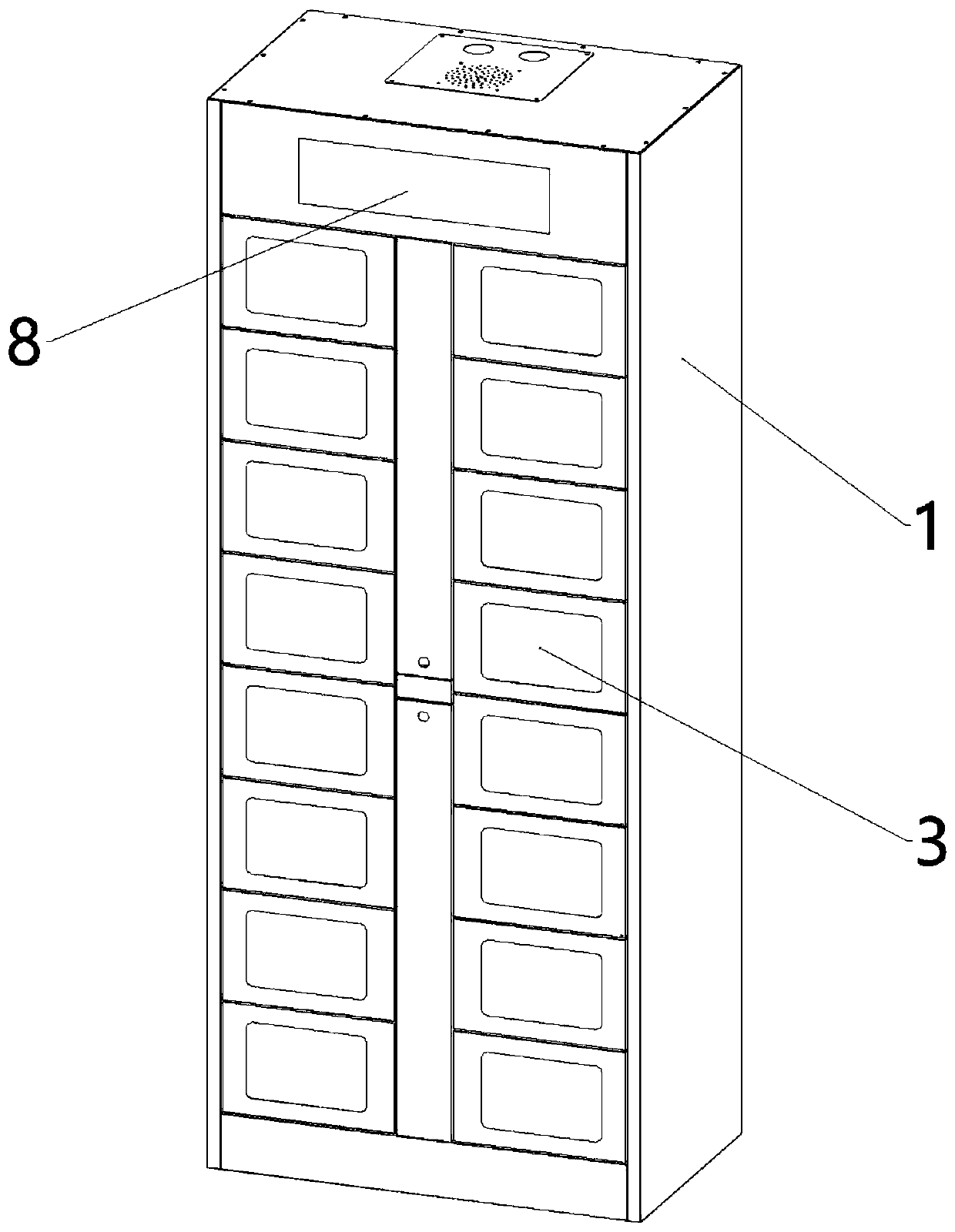

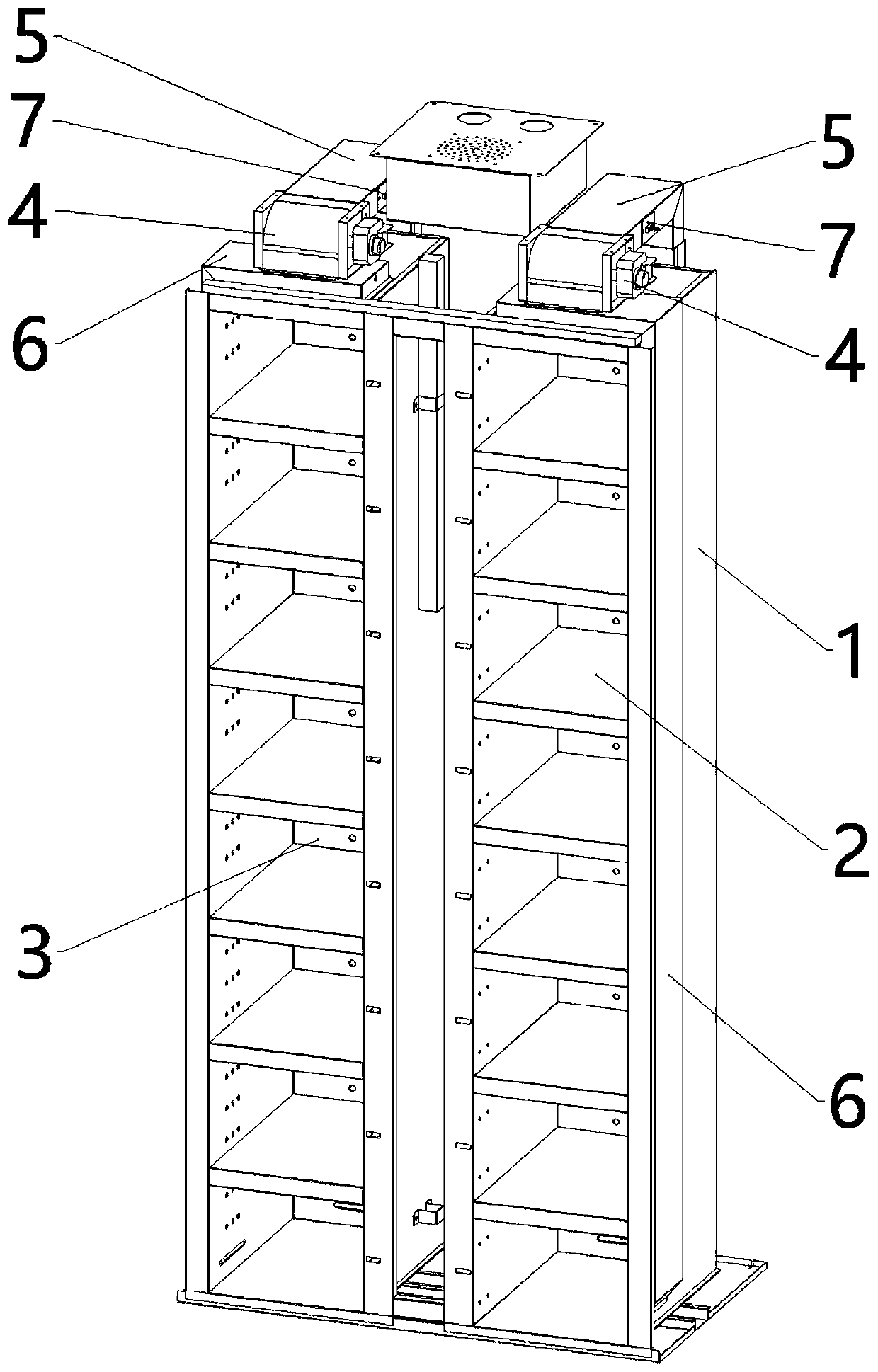

Heat insulation cabinet and temperature detection method thereof

PendingCN110558866AReduce the temperatureAutomatic adjustment of heating powerTemperatue controlTemperature measurement of flowing materialsEngineeringAirflow

The invention relates to the field of a heat insulation cabinet, in particular to a heat insulation cabinet and a temperature detection method thereof. The heat insulation cabinet comprises a cabinetbody, wherein a plurality of heat insulation lattices are arranged in the cabinet body; a fan is also arranged on the cabinet body; an air guide pipe and an air return pipe are connected between the heat insulation lattices and the fan; a heating device is connected between the air guide pipe and the fan; a controller and a temperature sensor arranged in the air return pipe are also arranged in the cabinet body; a temperature value is preset in the controller; and the controller is used for sending starting signals or stopping signals to the heating device. The airflow temperature in the air return pipe is used as a signal for controlling the on-off state of the heating device; the airflow temperature in the air return pipe needs to be lower than the temperature in the heat insulation lattices; the temperature in the air guide pipe is higher than the temperature of the heat insulation lattices; when the airflow temperature in the air return pipe reaches the preset stopping temperature,and after the heating device is turned off, the fan can continuously blow hot air in the air guide pipe into the heat insulation lattices; and the temperature of the heat insulation lattices far awayfrom the fan is prevented from being lower than the set temperature.

Owner:广州大学华软软件学院

Stepless temperature control system

ActiveCN104199479BFast temperature adjustmentAchieve coolingTemperature control using electric meansTemperature controlProportional control

The invention provides a stepless temperature control system, which includes a circulation pump, a hot heat exchanger, a heat medium transmission pipe, a cold heat exchanger, a refrigerant transmission pipe, a proportional regulating valve, an oil supply main pipe, an oil return main pipe and a temperature control system. device. The thermal heat exchanger includes a heat medium inlet, a heat medium outlet, a first heat transfer medium inlet and a heat transfer medium first outlet, and the heat transfer medium first inlet is connected to a circulation pump. The cold heat exchanger includes a refrigerant inlet, a refrigerant outlet, a second heat transfer medium inlet and a second heat transfer medium outlet, and the second heat transfer medium inlet is connected to a circulation pump. The two inlet ports of the proportional regulating valve are respectively connected to the first outlet of the heat transfer medium and the second outlet of the heat transfer medium, and the outlet end is connected to one end of the main oil supply pipe. The other end of the oil supply main pipe is connected to the inlet of the temperature-controlled equipment. The oil return main pipe is connected to the outlet of the temperature-controlled equipment and the circulation pump. The temperature control device controls the valve opening of the proportional regulating valve according to the temperature of the temperature-controlled equipment.

Owner:ZHEJIANG HUAYI ENG DESIGN

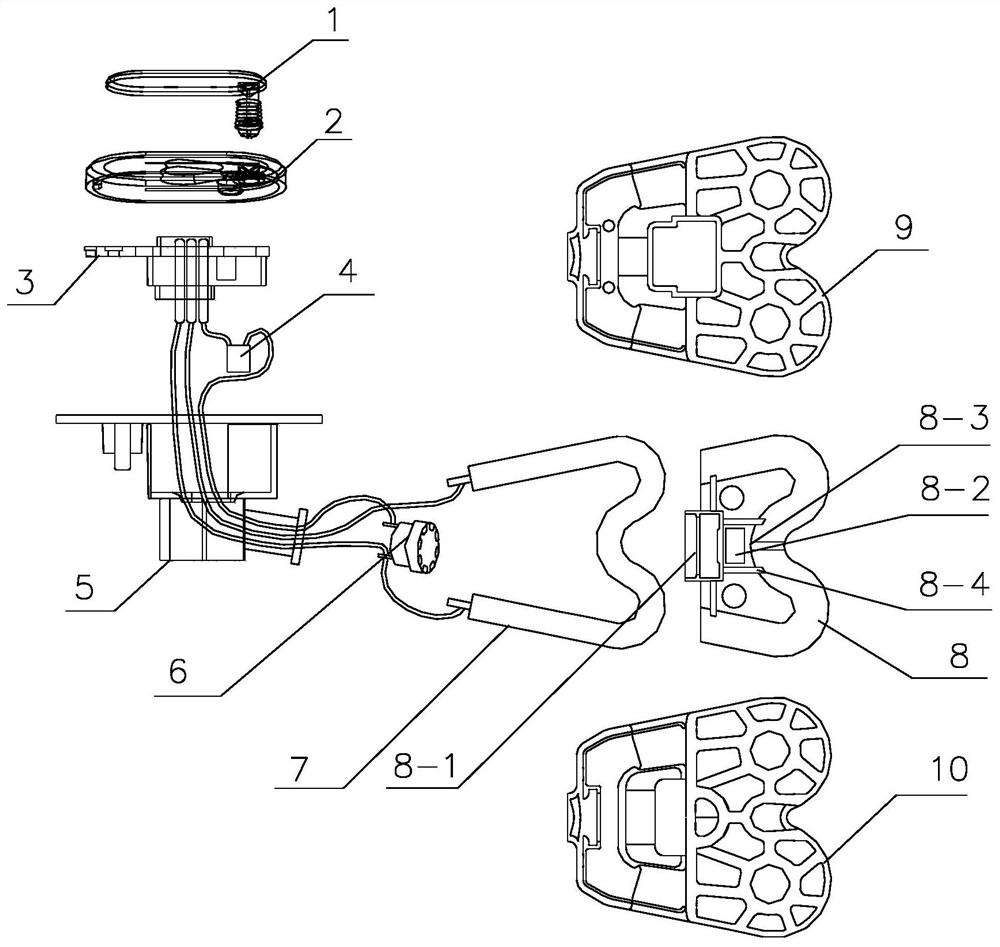

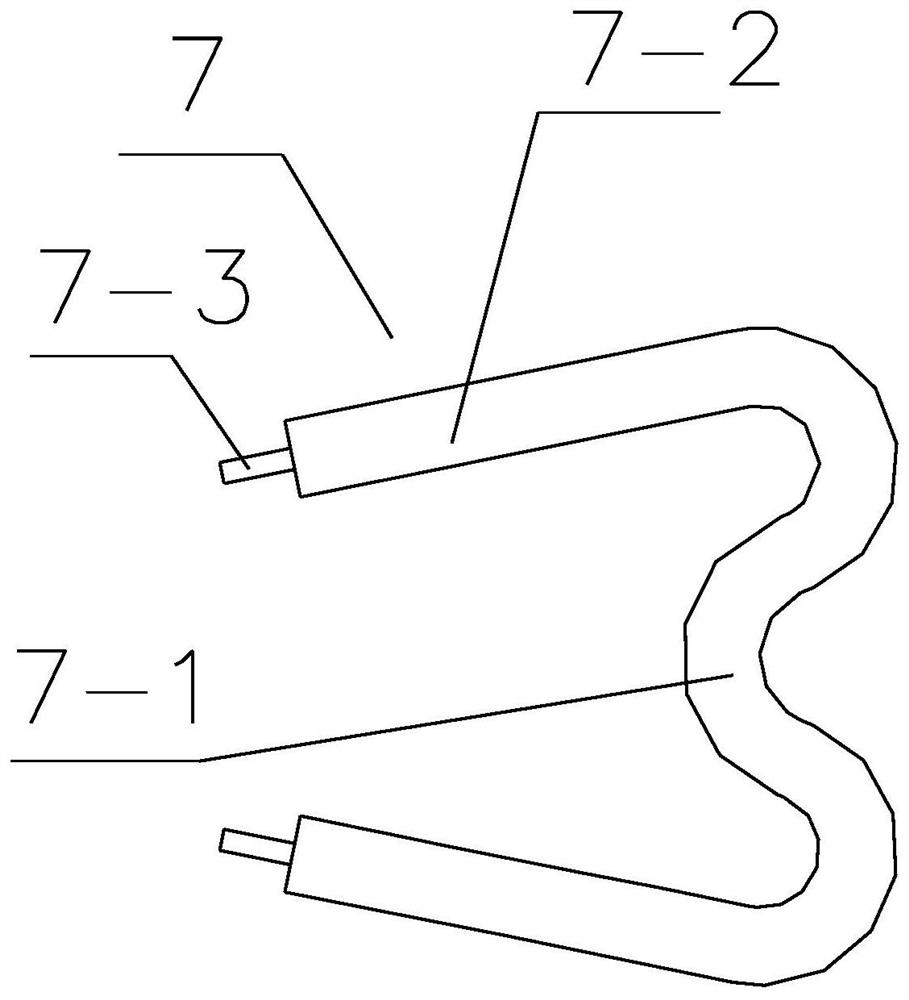

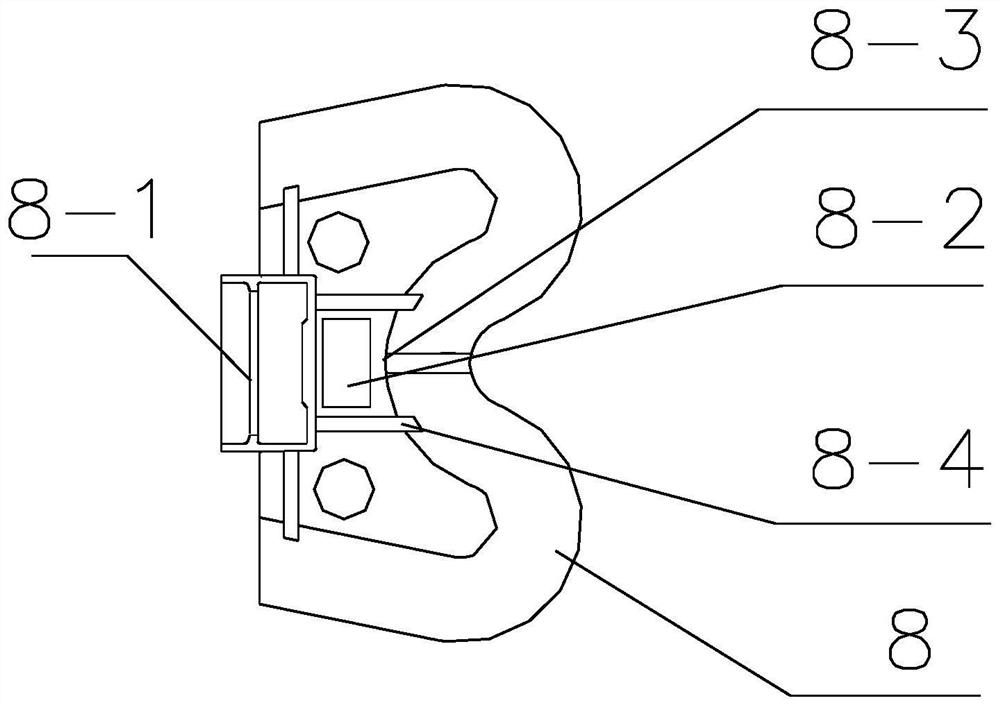

Anti-dry-burning heating body of electric hot-water bag

PendingCN113558854ABurn out preventionNovel structureHeating element shapesTherapeutic coolingTemperature controlHeat conducting

The invention discloses an anti-dry-burning heating body of an electric hot-water bag. The anti-dry-burning heating body comprises a heating tube, and a slurry wrapping layer is arranged outside the heating tube in an aluminum die casting mode; the heating tube is bent into a W-shaped structure; a temperature controller mounting seat is integrally formed on the slurry wrapping layer; a plurality of flow guide holes with two through surfaces are formed in the slurry wrapping layer; the temperature controller mounting seat is arranged close to a high-temperature point in the middle of the slurry wrapping layer; heat conducting ribs connected to the temperature controller mounting seat are arranged on the two sides of the high-temperature point in the middle of the slurry wrapping layer; the thickness of the slurry wrapping layer ranges from 1.2 mm to 1.35 mm; an outer housing consisting of an upper mesh enclosure and a lower mesh enclosure is buckled outside the heating tube. Thea anti-dry-burning heating body has the advantages that the structure is novel, the temperature of water in the hot-water bag rises better and more evenly, temperature control is more sensitive, the anti-dry-burning effect is better, the heating body is prevented from being burnt out, the outer layer of the electric hot-water bag is also prevented from being burnt out, the safety of products is improved, and the quality of the products is also improved.

Owner:罗长达

A hot box device for a nylon yarn texturing machine

The invention relates to a hot box device of a novel nylon yarn elasticizer. The device is in such a structural mode that three rails, six spindles and three pipes are used, an evaporation pipe (1) is connected with a condensing pipe (3) through a return liquid pipe (5), an electric heating bar (7) is installed inside the evaporation pipe (1) and is directly immersed in heat-conduction oil inside the evaporation pipe (1), heating rails (2) are communicated with the condensing pipe (3) through a pipe (8), a throttler (6) is arranged at a top end position of the pipe (8), and two vent pipes (4) are arranged near heating rails (2) which are close to two ends of the condensing pipe (3). The throttler is arranged, the inside of heating rails is full of steam, and the steam inside a hot box is circulated compulsively, so that the normal usage time of the hot box is greatly prolonged; the TherminolVP-1 or DOWTHERNA type heat-conduction oil is used, so that the safety is greatly improved when the device works at 250 DEG C; and the heating method that the electric heating bar is directly immersed in heat-conduction oil is used, so that the temperature controlling is sensitive.

Owner:苏州旭鸣纺织有限公司

Floor heating thermostatic valve

InactiveCN102135207BAccurate temperature controlSensitive temperature controlOperating means/releasing devices for valvesEngineeringThermostat

Owner:卓旦春

A container and its temperature control mechanism, 3D printing equipment and method

ActiveCN111016163BReduce the risk of substandard qualitySensitive temperature controlManufacturing enclosures3D object support structuresTemperature controlEngineering

Owner:SHANGHAI UNION TECH

Electromagnetic induction heating substrate and system thereof

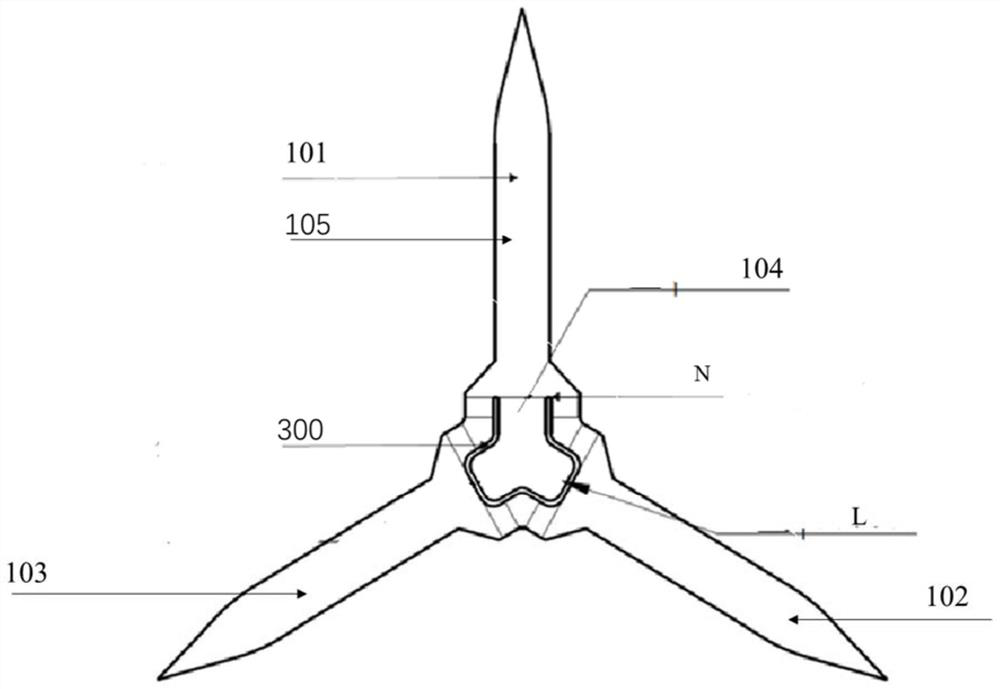

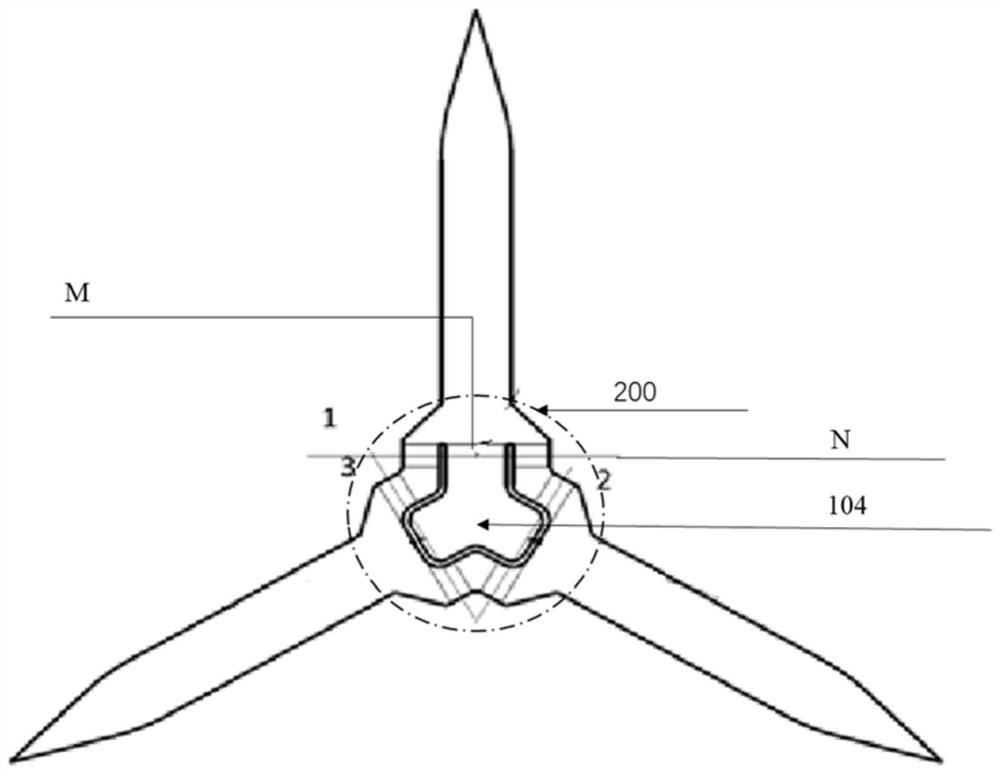

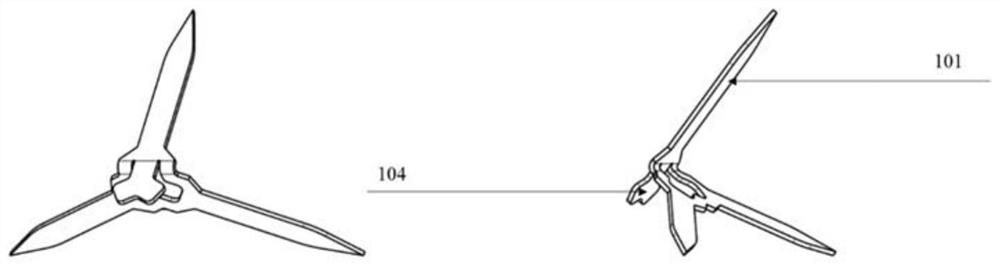

PendingCN114766719AIncrease the heating areaHeated evenly and fullyCigar manufactureEngineeringMechanical engineering

The invention discloses an electromagnetic induction heating substrate which is used for electromagnetic induction heating of an aerosol generating device and comprises a first sheet-shaped induction heating body and a second sheet-shaped induction heating body which are integrally formed, distributed in the circumferential direction and jointly connected to a center part, the first sheet-shaped induction heating body comprises a reverse extension part, and the second sheet-shaped induction heating body comprises a third sheet-shaped induction heating body and a fourth sheet-shaped induction heating body. The second sheet-shaped induction heating body is provided with a split line groove at a position close to the central part, the split line groove is not closed at a position close to the central part of the first sheet-shaped induction heating body, the split line groove forms an outline of a reverse extension part, and when the first sheet-shaped induction heating body is folded relative to the central part, the reverse extension part is reversely folded relative to the central part.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Sublimation dehydration device

InactiveCN111998616ASensitive temperature controlBarrier heat exchangeDrying solid materials without heatTemperature controlInsulation layer

The invention discloses a sublimation dehydration device. The sublimation dehydration device comprises a heating supply device, a sublimation work box, and a vacuum pipe which comprises an outer pipeand an inner pipe sleeved with the outer pipe, a vacuum layer is arranged between the outer pipe and the inner pipe, an inner cavity is formed in the inner pipe, and a heat insulation layer is arranged between the inner pipe and the inner cavity; two ends of the vacuum pipe respectively communicate with the heating supply device and the sublimation working box; wherein the heating supply device isused for heating gaseous nitrogen and conveying the heated gaseous nitrogen to the sublimation working box along the inner cavity, and the gaseous nitrogen flows in the sublimation working box and covers the surface of a freeze-thawed material; the pipe body structure of the vacuum pipe is provided with the outer pipe and the inner pipe, the vacuum layer is arranged between the outer pipe and theinner pipe, the inner cavity is formed in the inner pipe, the heat insulation layer is arranged in the inner cavity, heat exchange between gaseous nitrogen and the inner wall can be effectively blocked, and temperature control over the gaseous nitrogen is more sensitive.

Owner:广州蓝日生物科技有限公司

Directional solidification device and method for high-temperature alloy

ActiveCN113512763ASimple structureEasy to operatePolycrystalline material growthFrom frozen solutionsCrystal structureSingle crystal

The invention discloses a directional solidification device and method for high-temperature alloy, belonging to the technical field of metal casting. The invention aims to solve the defect problems of freckles and the like in a crystal structure caused by non-uniform heat dissipation of an anchor-shaped mold shell and the problem of crystal waste in the directional solidification process of the high-temperature alloy. According to the invention, the heat preservation or overheating state of alloy liquid can be achieved through a heater, the anchor-shaped mold shell is lifted upwards at a constant speed through a lifting rod, then a water cooling system is arranged on the anchor-shaped mold shell, and at the moment, a constant-temperature fluid gradually emerges from the anchor-shaped mold shell, so a part of heat of the liquid level is dissipated, a temperature gradient is generated, and the alloy liquid in contact with a sub-crystal is forced to directionally solidify downwards to form a single crystal; and therefore, the heat dissipation problem of the anchor-shaped mold shell can be effectively solved, the defect problems such as freckles in a crystal structure are also avoided, and crystal wasting in the directional solidification process is reduced.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com