Stepless temperature control system

A temperature control system, a stepless technology, applied in the direction of temperature control by electric means, can solve problems affecting the service life of pipes or equipment, pressure shocks of heat transfer medium pipes or equipment, etc., to facilitate hardware maintenance and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

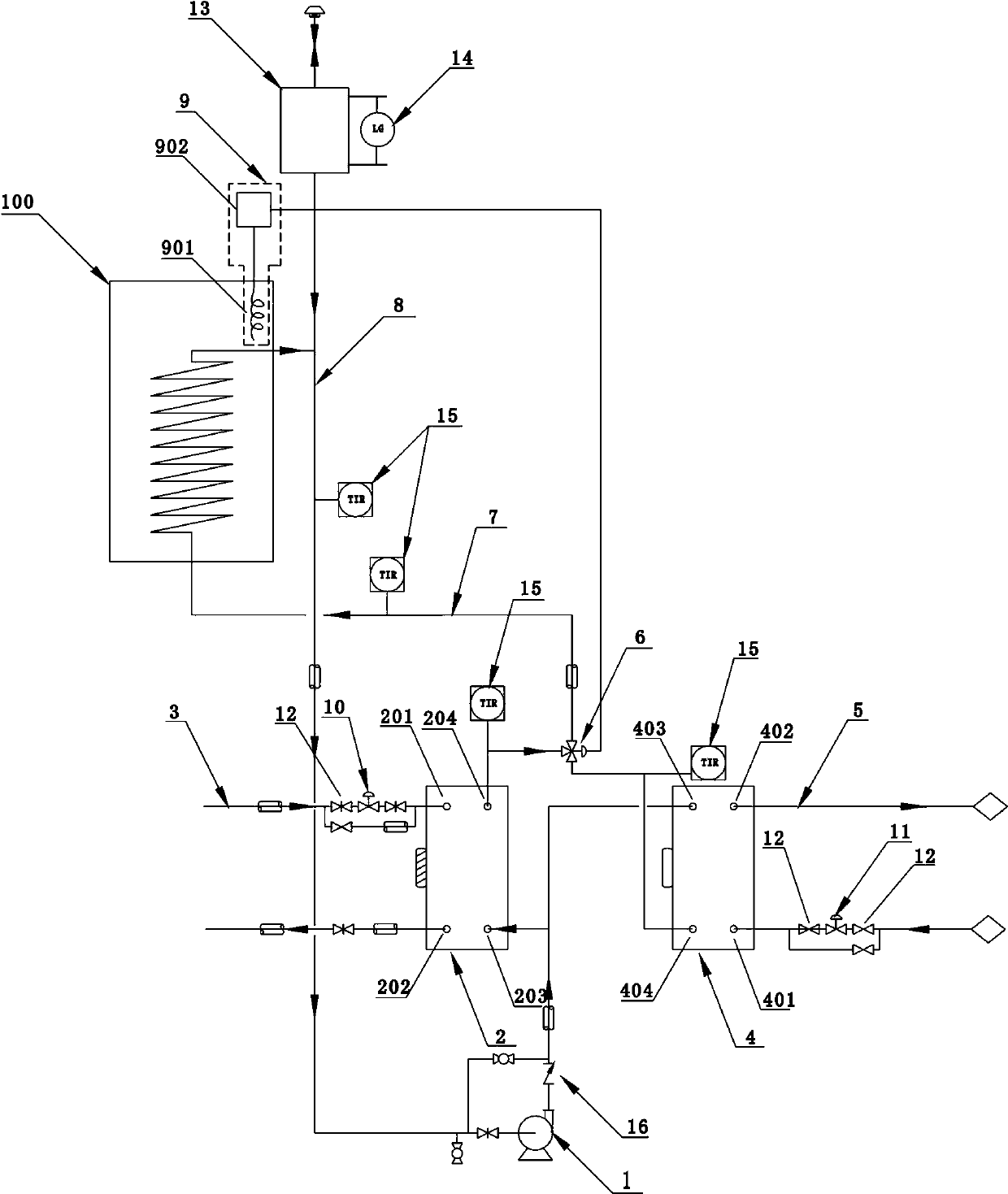

[0021] Such as figure 1 As shown, the stepless temperature control system provided by this embodiment includes a circulating pump 1, a hot heat exchanger 2, a heat medium transmission pipe 3, a cold heat exchanger 4, a refrigerant transmission pipe 5, a proportional regulating valve 6, an oil supply Main pipe 7, oil return main pipe 8 and temperature control device 9. The thermal heat exchanger 2 includes a heat medium inlet 201 , a heat medium outlet 202 , a first heat transfer medium inlet 203 and a first heat transfer medium outlet 204 , and the first heat transfer medium inlet 203 is connected to the circulating pump 1 . The heat medium transmission pipe 3 is connected to the heat medium inlet 201 and the heat medium outlet 202 . The cold heat exchanger 4 includes a refrigerant inlet 401 , a refrigerant outlet 402 , a second heat transfer medium inlet 403 and a heat transfer medium second outlet 404 . The second heat transfer medium inlet 403 is connected with the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com