5G energy-saving optimized crystallization furnace

A 5G, crystallization technology, applied in the field of energy saving and optimization of die-casting microstructure, can solve the problems of high space temperature, difficulty in constant temperature, long time, etc., and achieve the effect of reducing oven time, saving power consumption and time cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

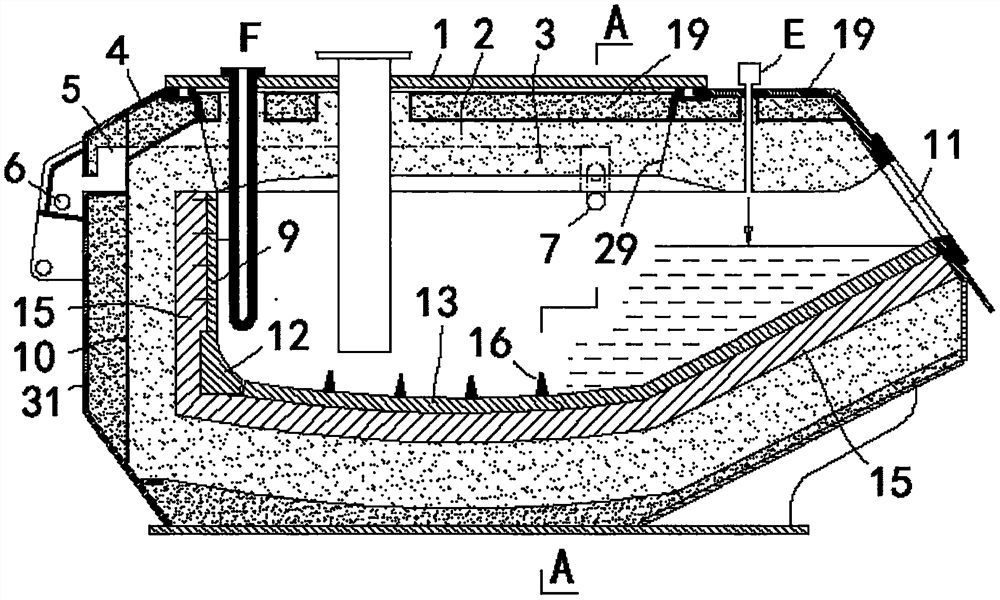

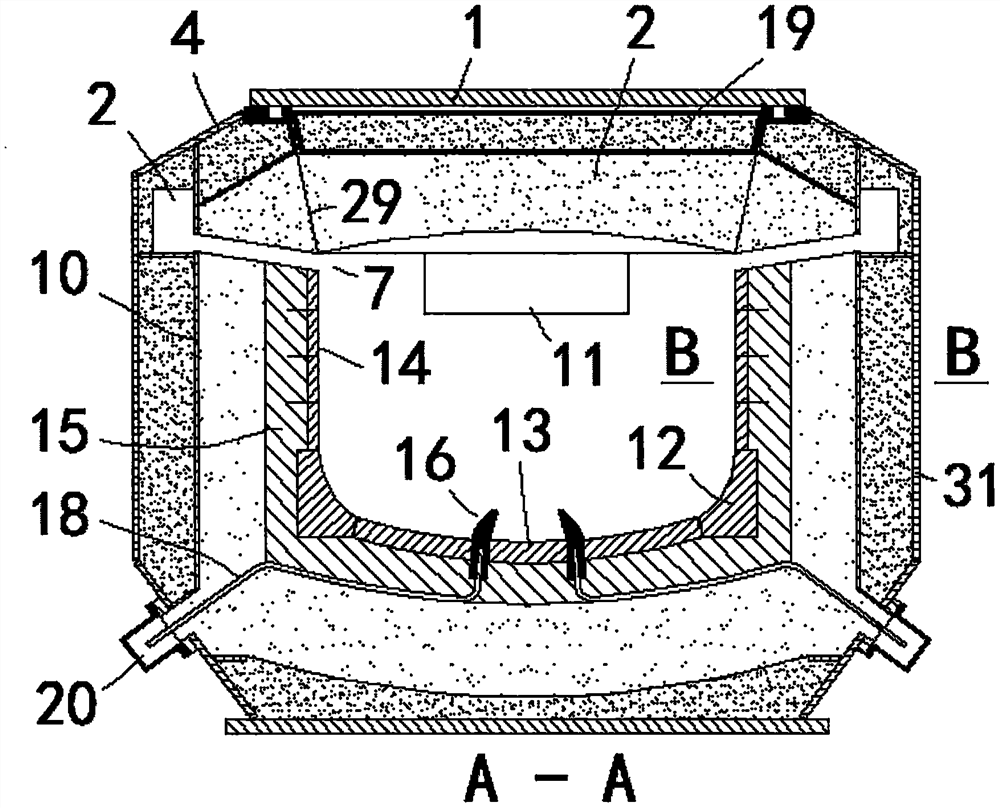

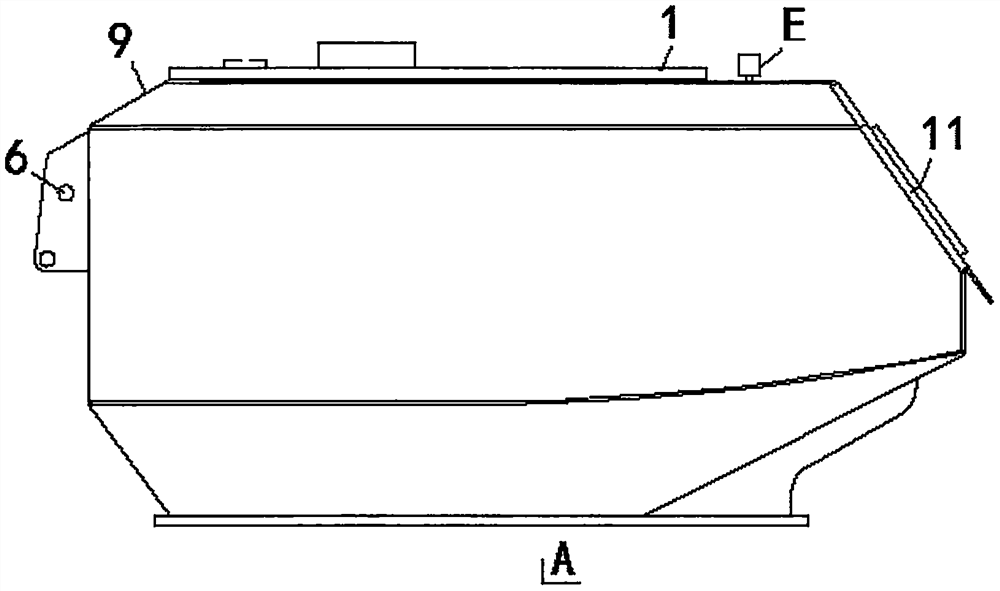

[0071] The utility model is described further with reference to accompanying drawing now.

[0072] attached Figure 1-15 What is shown is the general concept of the invention.

[0073] Figure 1-5 Shown is a 5G energy-saving optimized crystallization furnace, which has a main body, including: a PC, a laser rangefinder E, a temperature sensor F, and an image recognition device for the amount of aluminum stored in a ladle. The device is composed of a camera 52 and an operation program or Module CX-4 is composed of soft thermal insulation pouring material, air flow channel, hollow ball insulation layer, inner tank wall, armor bricks, and furnace shell. , the inner tank wall is formed by the tangent connection of the semi-circular arc plates 10 and the two side arc plates 17, and the curved liner wall formed by the tangent semi-circular arc plates 10 on both sides is connected to the furnace mouth plate, and the furnace mouth plate A furnace mouth 11 is provided, and a section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com