Directional solidification device and method for high-temperature alloy

A directional solidification, high temperature alloy technology, applied in the field of metal casting, can solve the problems of freckles of crystal structure, uneven heat dissipation of anchor-shaped mold shells, waste of crystals and miscellaneous crystal content, etc., to avoid freckles, simple structure, and solve the effect of heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

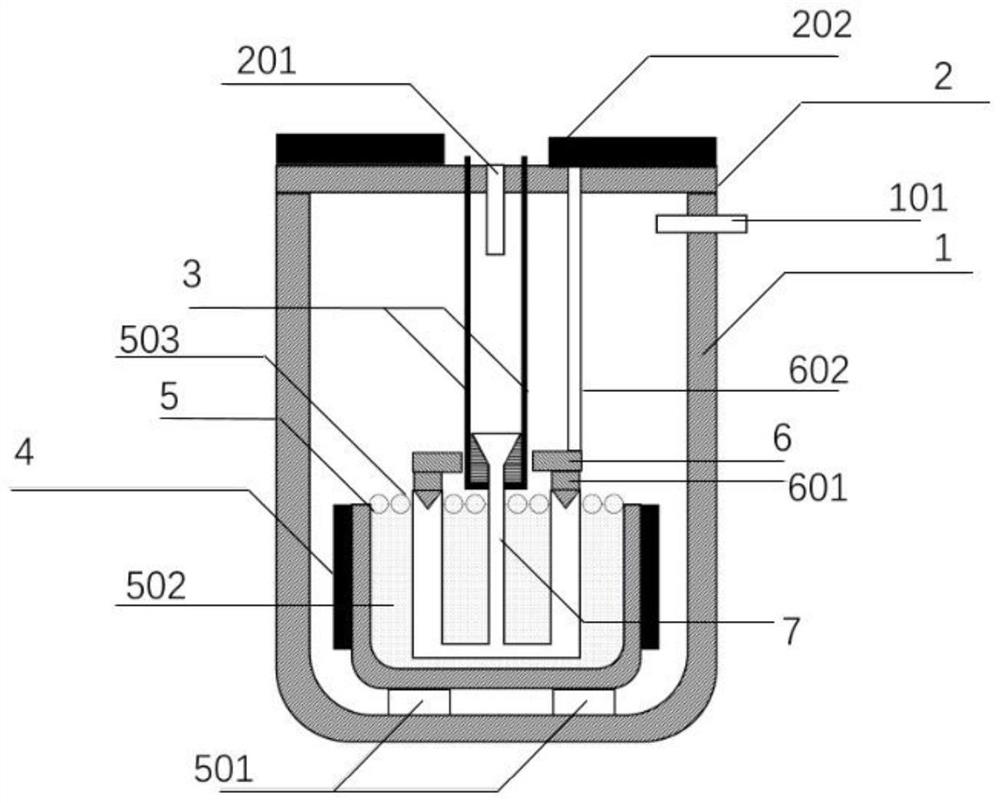

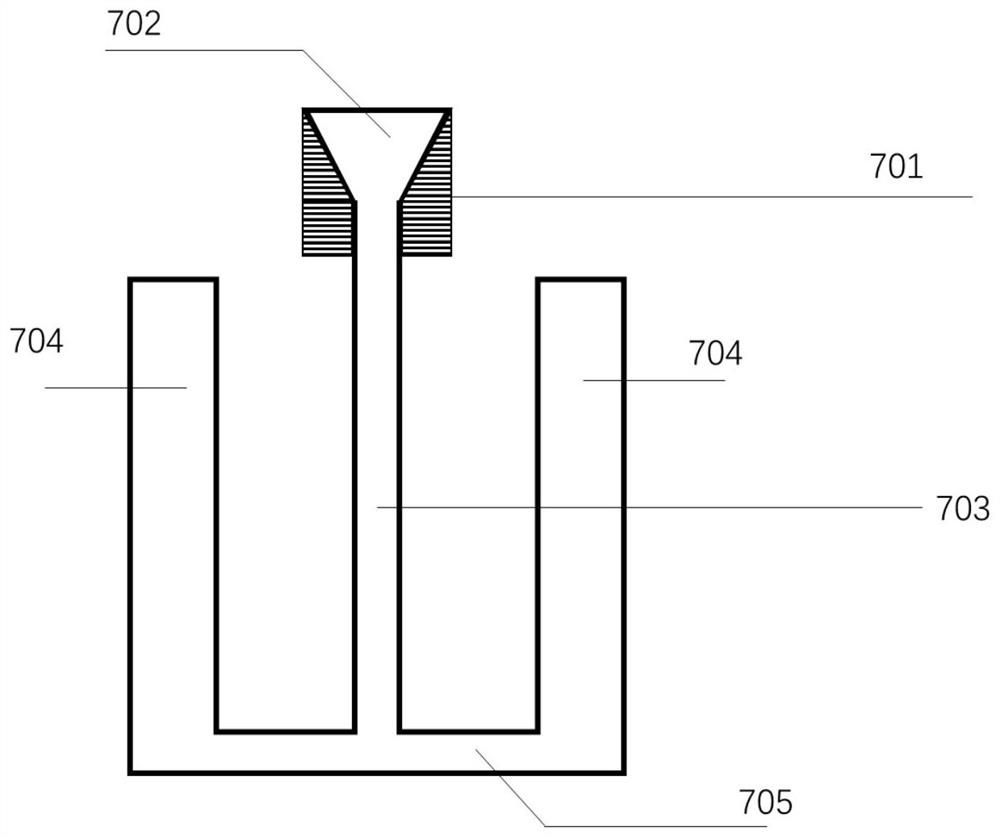

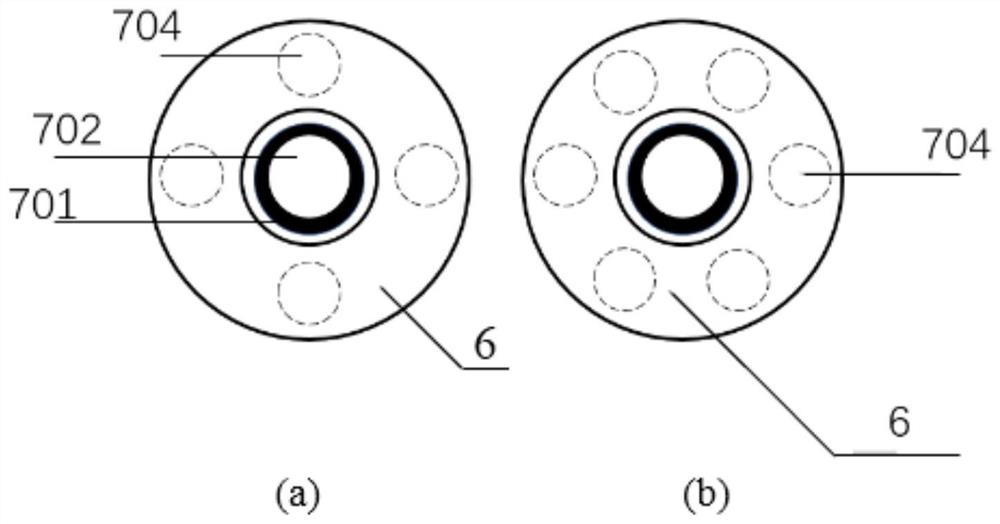

[0068] CMSX-4 alloy is selected as the experimental material, aluminum block is selected as constant temperature fluid 502, alumina ceramic sheet (10mm) is selected as thermal insulation float 503, alumina ceramic anchor mold shell 7 is selected, and 4 rows of alloy mold 704 are selected. Cloth, keep the constant temperature fluid 502 to 1450 ℃, and the alloy liquid casting temperature is 1500 ℃. After the alloy liquid is completely filled, the upward pulling speed is controlled to 1mm / min for upward solidification. The experiment shows that among the four alloy molds 704 A small amount of impurity crystals were found in the single crystal samples.

Embodiment 2

[0070] Choose CMSX-4 alloy as the experimental material, choose aluminum block as constant temperature fluid 502, choose alumina ceramic ball (10mm) as heat insulation float 503, choose alumina ceramic anchor mold shell 7, choose 6 rows of alloy mold 704 Cloth, keep the constant temperature fluid 502 to 1500 ℃, the alloy liquid casting temperature is 1500 ℃, after the alloy liquid is completely filled, the upward pulling speed is controlled to 2mm / min for upward solidification. The experiment shows that only one alloy mold 704 A small amount of impurity crystals were found in the single crystal samples.

Embodiment 3

[0072] CMSX-4 alloy is selected as the experimental material, copper block is selected as constant temperature fluid 502, alumina ceramic sheet (5mm) is selected as thermal insulation float 503, alumina ceramic anchor mold shell 7 is selected, and 4 rows of alloy mold 704 are selected. Cloth, the constant temperature fluid 502 is kept at 1500 ℃, and the alloy liquid casting temperature is 1550 ℃. After the alloy liquid is completely filled, the upward pulling speed is controlled to 3mm / min for upward solidification. The experiment shows that no miscellaneous crystals are found.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com