A hot box device for a nylon yarn texturing machine

A technology of silk texturing machine and hot box, which is applied in the direction of textiles and papermaking, etc. It can solve the problems of poor temperature uniformity of the heating rail wire path, large temperature fluctuation of the heating rail wire path, and affecting the normal spinning of users, so as to prolong the normal use time, reduced weight, ease of manufacture and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

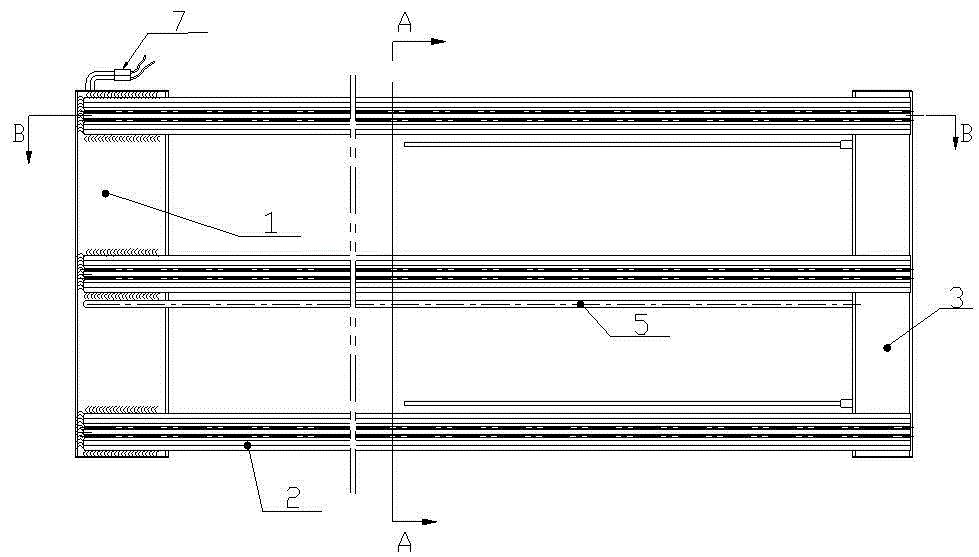

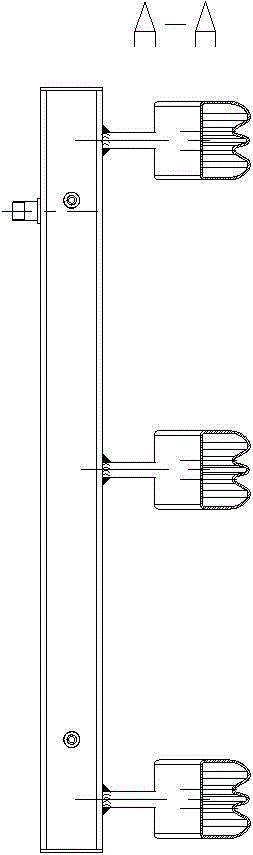

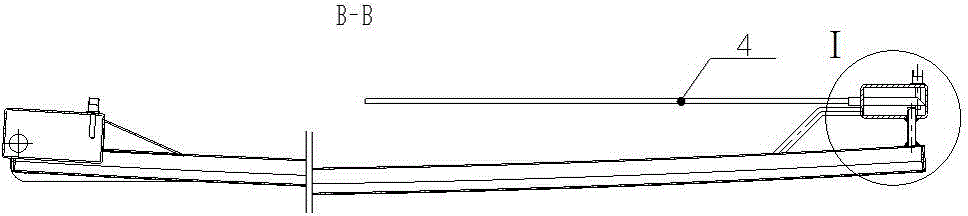

[0018] Such as figure 1 As shown: the present invention is based on the principle of gravity heat pipe, combined with the nylon filament texturizing process and equipment layout requirements, the overall structure of the heat box adopts the structural model of "three rails, six ingots, and three tubes", that is: the evaporation tube of the device 1 It communicates with the condensation pipe 3 with 3 evenly distributed heating guide rails 2, each heating guide rail 2 is equipped with 2 silk channels, and the entire hot box has six wire channels (that is, six ingots), and the heating guide rail 2 The cross-section is W-shaped (see figure 2 As shown), the lower part of the box is the evaporating tube 1, which is heated by an electric heating rod 7, and the temperature is detected by a platinum resistance. When working at 250°C, the internal pressure of the hot bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com