Production method of T2 copper strap used for automobile radiator

A technology for automobile water tank and copper strip is applied in the field of T2 copper strip preparation of automobile water tank, which can solve the problems of long process flow, expensive machinery and equipment, waste of manpower and material resources, etc., and achieves short process flow, fewer intermediate annealing times, and cold working rate. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

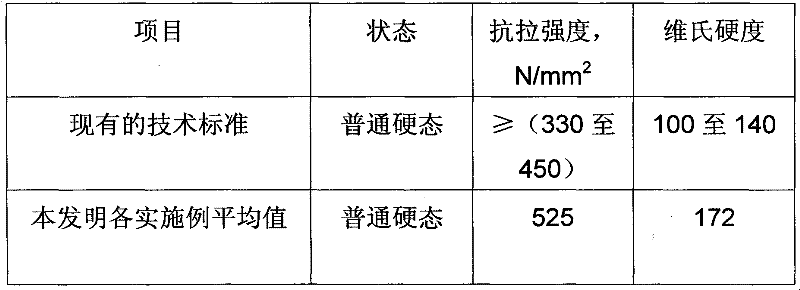

Examples

Embodiment 1

[0018] Firstly, the raw materials need to be proportioned. In this embodiment, the copper and silver content of the raw materials is 99.9%, the iron content is 0.002%, the bismuth content is 0.0003% to 0.0005%, and the zinc content is 0.001% to 0.005%.

[0019] After determining the ratio of raw materials, the raw materials are sent to the furnace for melting. The charge melting temperature is raised to 1160°C to 1250°C in the atmosphere. High-purity copper is easy to suck air into the raw material during the melting process, causing air bubbles to form inside the raw material. Therefore, in this embodiment, after the raw material is completely liquefied, a layer of dry charcoal is covered on the liquid surface, and then the slag is removed by stirring. Sampling, analysis, and composition adjustment. After the ingredients meet the formula requirements, transfer the raw materials covered with dry charcoal into the holding furnace. The temperature of the holding furnace is 1100°...

Embodiment 2

[0023] Proportioning raw materials, in this embodiment, the copper and silver content of the raw materials is 99.93%, the iron content is 0.003% to 0.004%, the bismuth content is 0.0004% to 0.0008%, and the zinc content is 0.001% to 0.002%.

[0024] After determining the ratio of raw materials, the raw materials are sent to the furnace for melting. The charge melting temperature is raised to 1150°C to 1280°C in the atmosphere. High-purity copper is easy to suck air into the raw material during the melting process, causing air bubbles to form inside the raw material. Therefore, in this embodiment, after the raw material is completely liquefied, a layer of dry charcoal is covered on the liquid surface, and then the slag is removed by stirring. Sampling, analysis, and composition adjustment. After the ingredients meet the formula requirements, transfer the raw materials covered with dry charcoal into the holding furnace. The temperature of the holding furnace is 1120°C to 1130°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com