Double-bladder type dyeing machine

A dyeing machine and double-tank technology, applied in the field of dyeing machines, can solve the problems of large volume, inconvenient operation and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

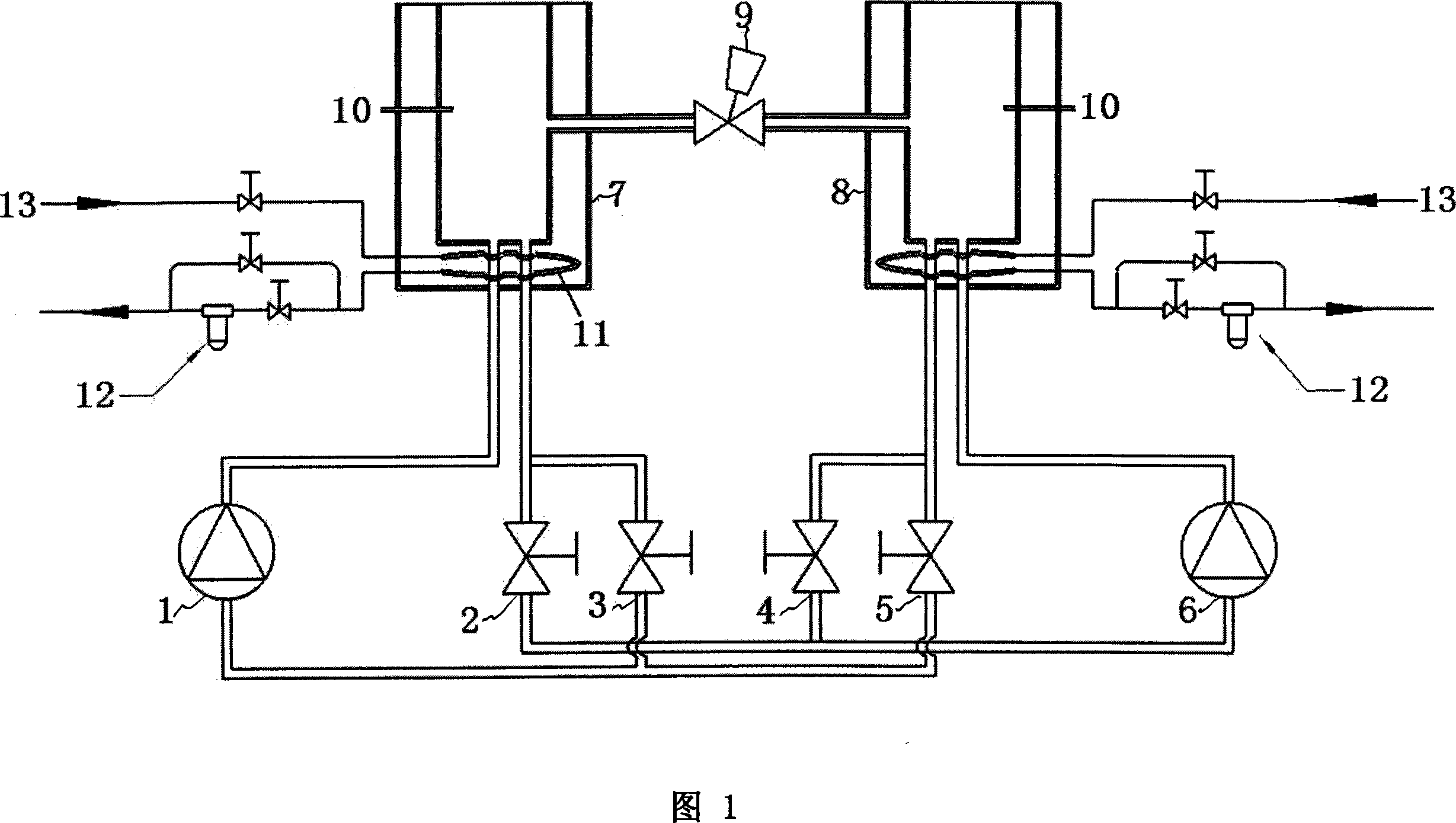

Examples

Embodiment Construction

[0010] According to the technical requirements, the height and diameter of the inner tank can be designed by dyeing up to three cheeses;

[0011] The inner tank is made of 2mm stainless steel plate, a hole with a diameter of 25mm is opened in the center of the bottom to connect with the outlet of the circulation pump, and a hole of the same size is opened in the center between the side of the inner hole and the inner tank wall to connect with the pump inlet, and the temperature probe is installed on the top of the tank; There is a connecting pipe in the middle of the two cylinders, which can balance the water levels on both sides when the two cylinders are dyed together; a stainless steel circular pipe with a diameter of 20mm is installed at the bottom between the inner tank and the outer tank as a heater.

[0012] The temperature control is controlled by calculus proportional (PID).

[0013] The two circulation pumps are controlled by frequency converters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com