Methods for processing titanium aluminide intermetallic compositions

a technology of titanium aluminide and intermetallic composition, which is applied in the field of titanium aluminide intermetallic composition processing, can solve the problems aluminum to be lost from casting surface, etc., and achieve the effect of additional cost and cycle tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

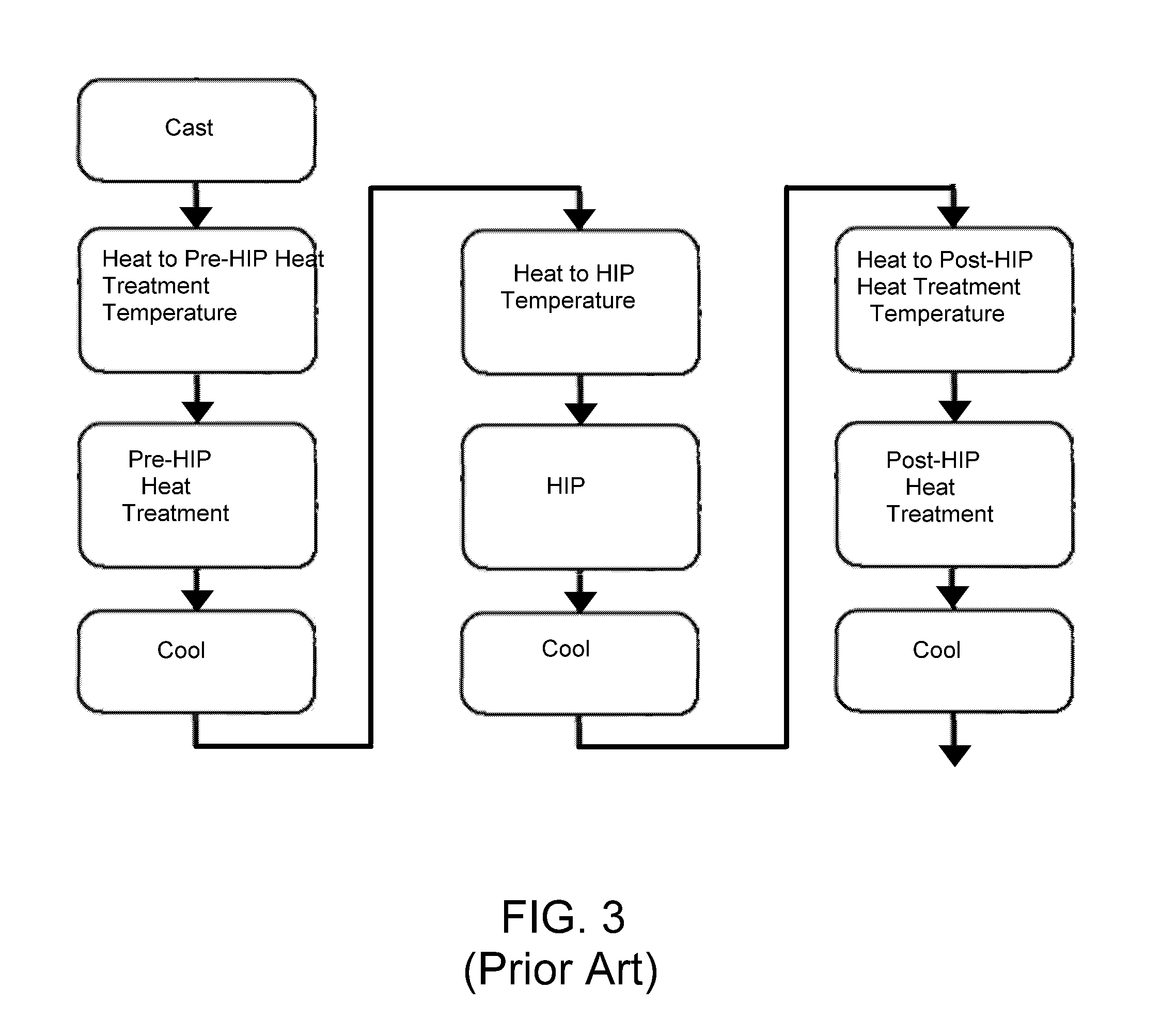

Embodiment Construction

[0017]FIGS. 4 and 5 contain flow charts that represent two related methods by which TiAl intermetallic compositions, including but not limited to the 48-2-2 alloy, can be processed to yield a desirable duplex microstructure, with the additional benefit of avoiding the disadvantages of the prior art process summarized in FIG. 3. In particular, the methods of FIGS. 4 and 5 avoid the pre- and post-HIP vacuum heat treatments that are believed to promote the loss of aluminum in TiAl intermetallic compositions. The invention also takes advantage of the high gas pressures and protective (inert) atmospheres used during HIP, the combination of which is believed to be capable of reducing the loss of aluminum in a TiAl intermetallic composition. Furthermore, each of the methods summarized in FIGS. 4 and 5 provide for interrupted cooling from a HIP step (FIG. 4) or a temperature that is believed to take advantage of the non-equilibrium phase distribution in TiAl intermetallic compositions follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com