New rapid proofing method for cold pad batch dyeing

The invention relates to a technology of cold pad-piling dyeing and a new method, which is applied to the field of cold pad-piling dyeing with reactive dyes mixed with alkaline agent, and achieves the effects of uniform color, simple process equipment requirements and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Experimental material: cotton fabric mercerized and bleached semi-finished product (30cm×10cm)

[0028] Dyeing chemicals: reactive dye EDB red 20g, penetrant JFC, reactive dye cold pad-batch alkali agent, soaping solution (1-5g / L soap flakes, 1-5g / L soda ash).

[0029] Equipment: beaker, electronic balance, graduated pipette, volumetric flask, glass rod (length 11cm), sealable plastic bag (20cm×14cm), clamp, rolling car, electric heating temperature control water bath, oven, electric iron, measuring color meter.

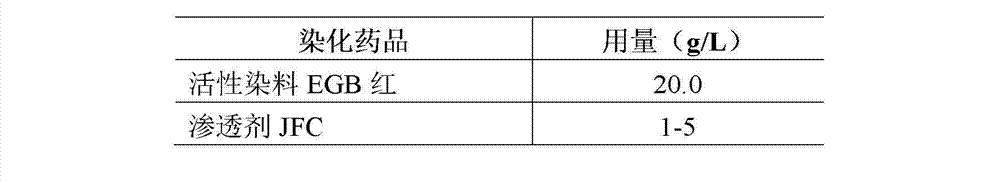

[0030] Table-1 Reactive dye cold pad-batch dye solution prescription

[0031]

[0032] Table-2 Prescription of Reactive Dye Cold Pad Batch Alkaline Solution

[0033]

[0034] Table-3 Reactive Dye Cold Pad Batch Alkali Agent Formula

[0035]

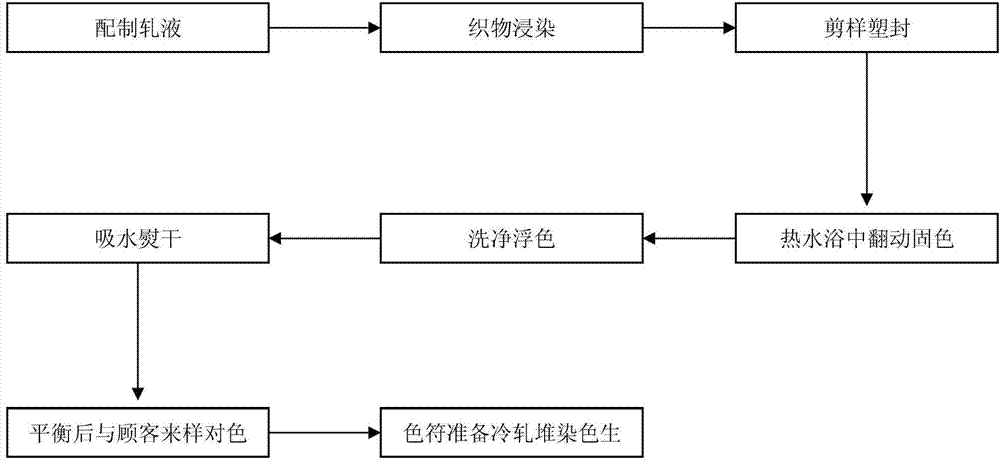

[0036] 1. Process flow and conditions

[0037] Before padding, mix the dyeing solution and lye in a ratio of 3-5:1-2, dip the fabric for 2-5 seconds, and roll it with a padding machine, with a pressure of 2-...

Embodiment 2

[0039] Experimental material: cotton fabric mercerized and bleached semi-finished product (30cm×10cm)

[0040] Dyeing chemicals: reactive dye EDB yellow 20g, penetrant JFC, reactive dye cold pad-batch alkali agent, soaping liquid (1-5g / L soap flakes, 1-5g / L soda ash).

[0041] Equipment: beaker, electronic balance, graduated pipette, volumetric flask, glass rod (length 11cm), sealable plastic bag (20cm×14cm), clamp, rolling car, electric heating temperature control water bath, oven, electric iron, measuring color meter.

[0042] 2. Dye Padding Solution Prescription

[0043] Table-1 Reactive dye cold pad-batch dye solution prescription

[0044]

[0045] Table-2 Prescription of Reactive Dye Cold Pad Batch Alkaline Solution

[0046]

[0047] Table-3 Reactive Dye Cold Pad Batch Alkali Agent Formula

[0048]

[0049] 3. Process flow and conditions

[0050] Before padding, mix the dyeing solution and lye in a ratio of 3-5:1-2, dip the fabric for 2-5 seconds, and roll i...

Embodiment 3

[0052] Experimental material: cotton fabric mercerized and bleached semi-finished product (30cm×10cm)

[0053] Dyeing chemicals: reactive dye EDB Zhangqing 20g, penetrant JFC, reactive dye cold pad-batch alkali agent, soaping solution (1-5g / L soap flakes, 1-5g / L soda ash).

[0054] Equipment: beaker, electronic balance, graduated pipette, volumetric flask, glass rod (length 11cm), sealable plastic bag (20cm×14cm), clamp, rolling car, electric heating temperature control water bath, oven, electric iron, measuring color meter.

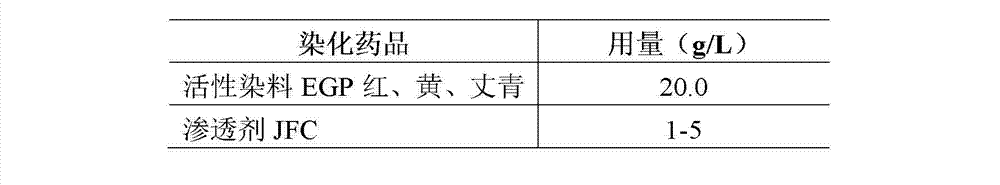

[0055] 4. Dye Padding Solution Prescription

[0056] Table-1 Reactive dye cold pad-batch dye solution prescription

[0057]

[0058] Table-2 Prescription of Reactive Dye Cold Pad Batch Alkaline Solution

[0059]

[0060] Table-3 Reactive Dye Cold Pad Batch Alkali Agent Formula

[0061]

[0062] 5. Process flow and conditions

[0063] Before padding, mix the dyeing solution and lye in a ratio of 3-5:1-2, dip the fabric for 2-5 seconds, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com