Wind-heat dyeing color tester

A dyeing color tester and air-heating technology, which is applied in the direction of processing textile material dyeing devices, processing textile material equipment configuration, etc., can solve the problems of increasing production costs of enterprises, and achieve the goals of saving production costs, reasonable design, and energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

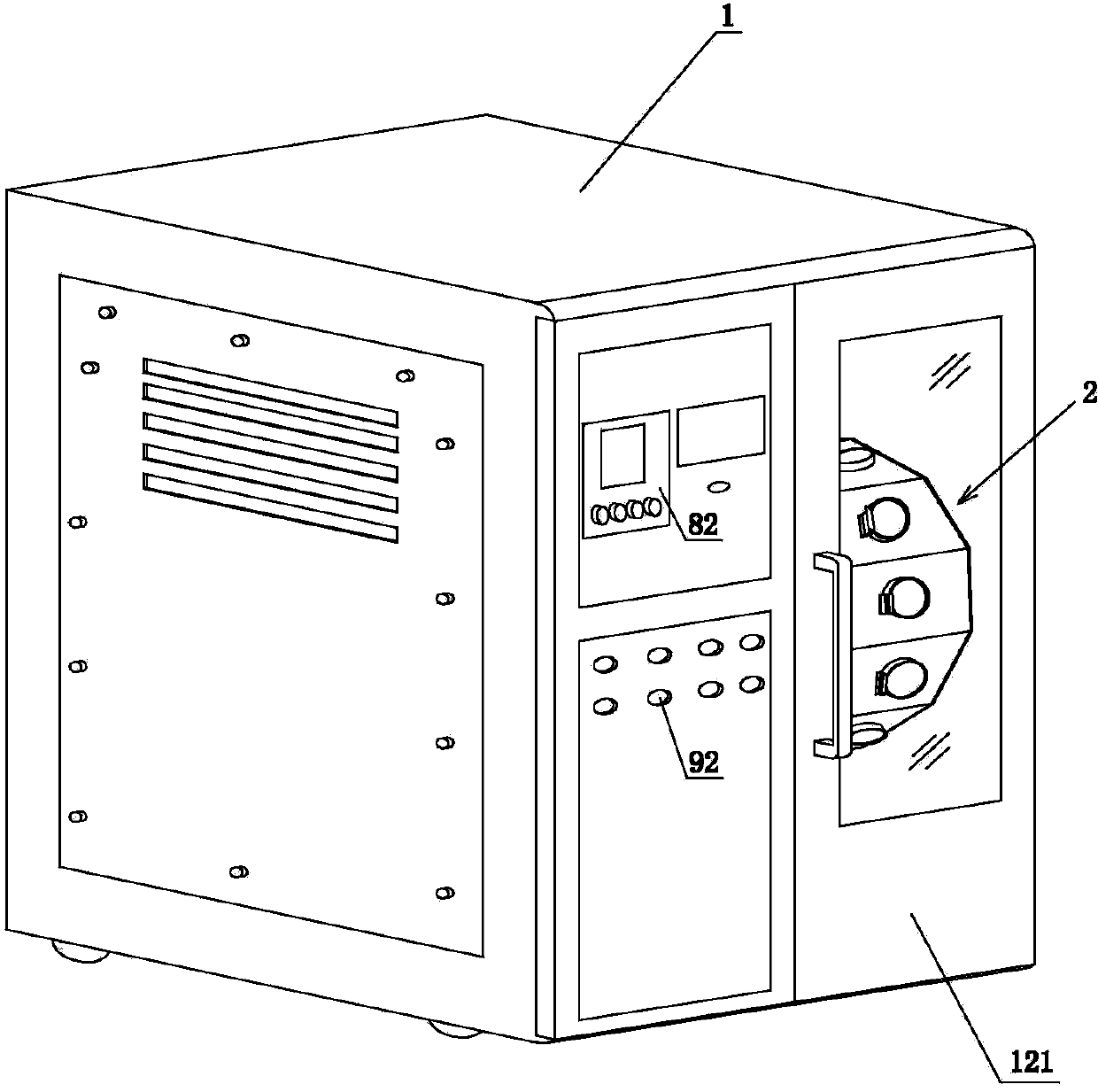

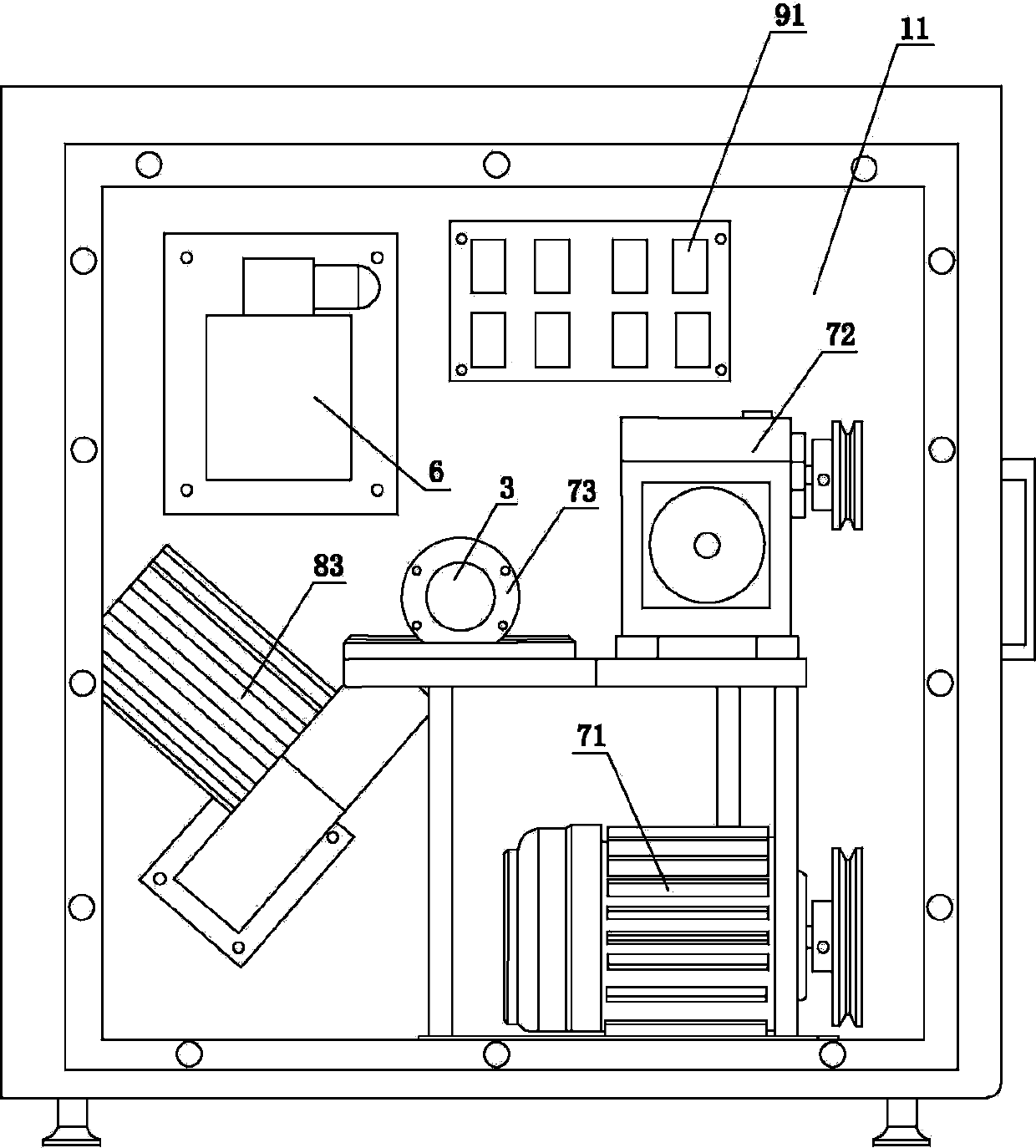

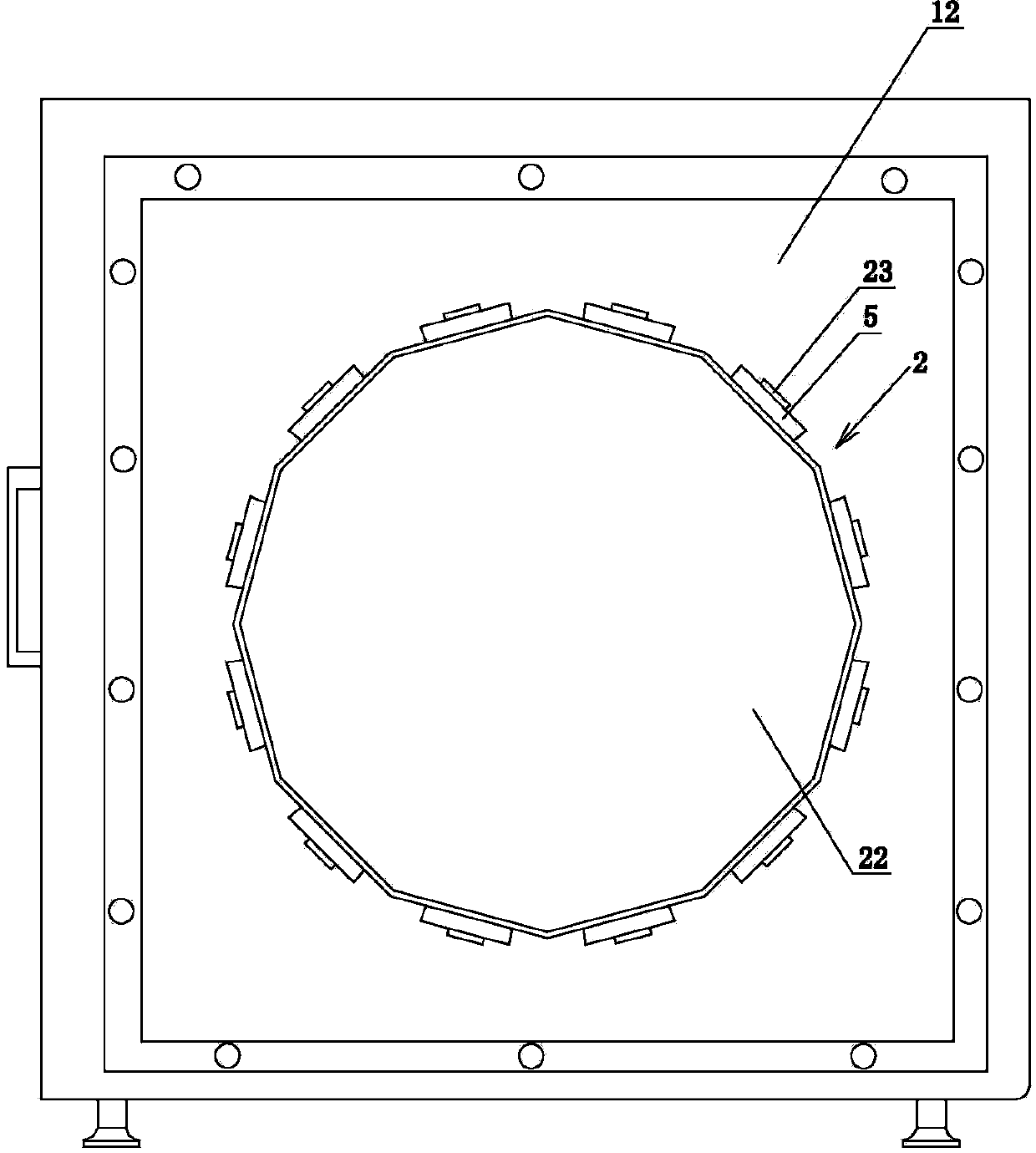

[0022] refer to figure 1 , figure 2 , Figure 4 and Figure 5 . An air-heat type dyeing color tester, comprising a box body 1, a rotating disk 2 which is arranged in the box body 1 and is hollow, and a rotating shaft 3 connected to the rotating disk 2, the outer peripheral surface of the rotating disk 2 is evenly distributed There are a plurality of dyeing cup sleeves 4, the opening of each dyeing cup sleeve 4 is exposed outside the rotating disk 2, and each dyeing cup sleeve 4 is provided with a dyeing cup 5. The left end surface of the rotating disk 2 is provided with a port 21, the right end surface of the rotating disk 2 is fixed with an end cover 22, one end of the rotating shaft 3 is connected to the end cover 22, and the other end of the rotating shaft 3 is connected to the end cover 22. Transmission mechanism is connected, and the left side of described rotating disk 2 is provided with hot air blower 6, and this hot air blower 6 is connected with hot air pipe 61, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com