Processing method of brittle material substrate

A technology of brittle material substrates and processing methods, applied in stone processing equipment, metal processing equipment, fine working devices, etc., can solve problems such as insufficient crack position control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

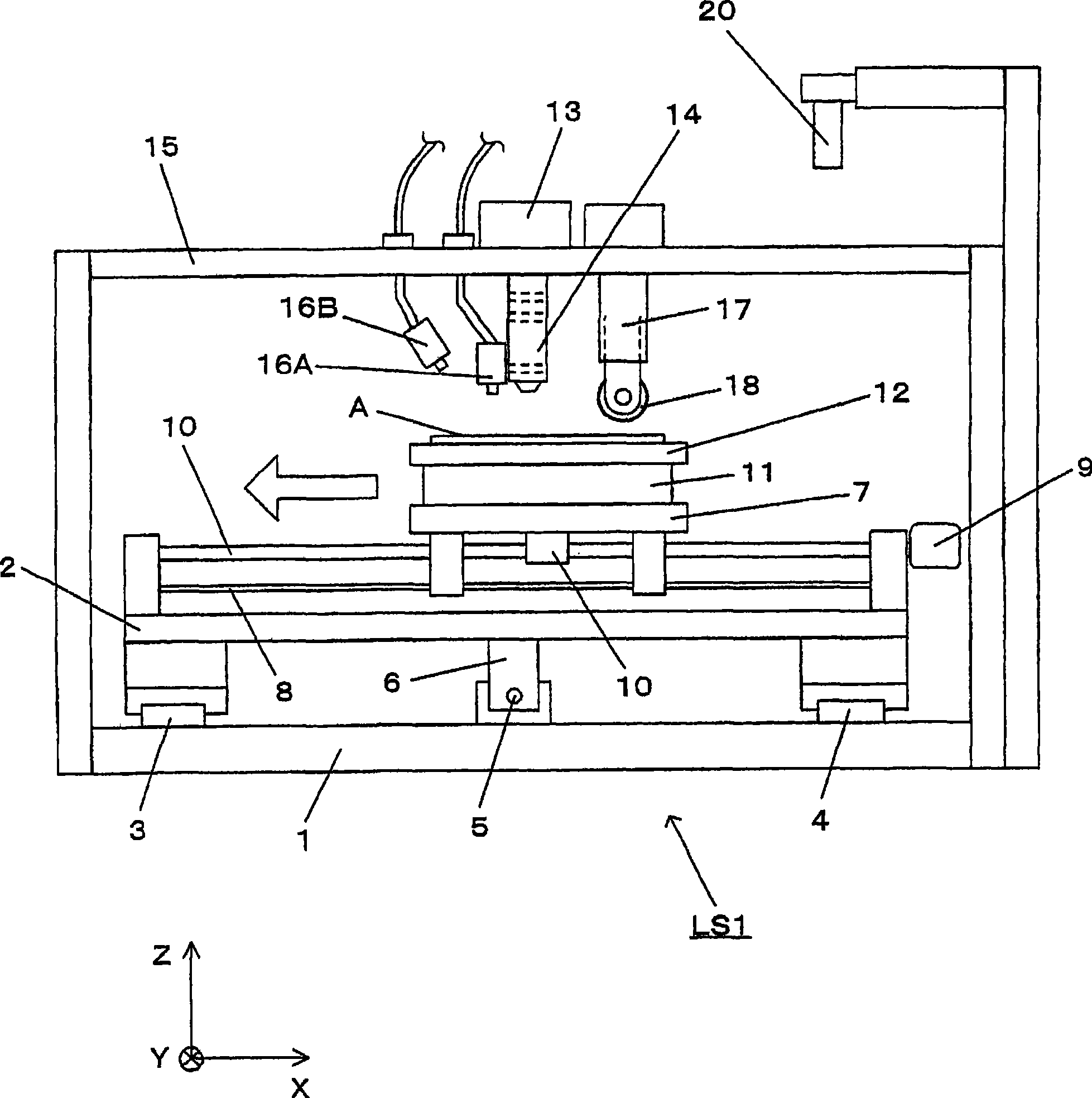

[0049] Embodiments of the present invention will be described below based on the drawings. figure 1 It is a structural schematic diagram of the substrate processing apparatus LS1 which is one embodiment of this invention. Here, the case of processing a glass substrate will be described as an example.

[0050] First, the overall configuration of the substrate processing apparatus LS1 will be described. The substrate processing apparatus LS1 is provided with a slide table 2 that is positioned along a pair of guide rails 3 and 4 arranged in parallel on the horizontal stage 1. figure 1 The front and rear direction of the paper (hereinafter referred to as the Y direction) reciprocates. A lead screw (skullu-neji) 5 is arranged between the two guide rails 3, 4 along the front-rear direction, and the strut 6 fixed on the above-mentioned sliding table 2 is screwed on the lead screw 5, and is driven by a motor (not shown). (shown) make the lead screw 5 forward and reverse, and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com