Wood cement board

A cement board and wood technology, applied in building components, molds, building materials, etc., can solve the problems of wood cement board strength, water resistance, frost resistance, weather resistance, poor workability, and uneven coating state. , to achieve the effect of good pattern effect, prevention strength and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

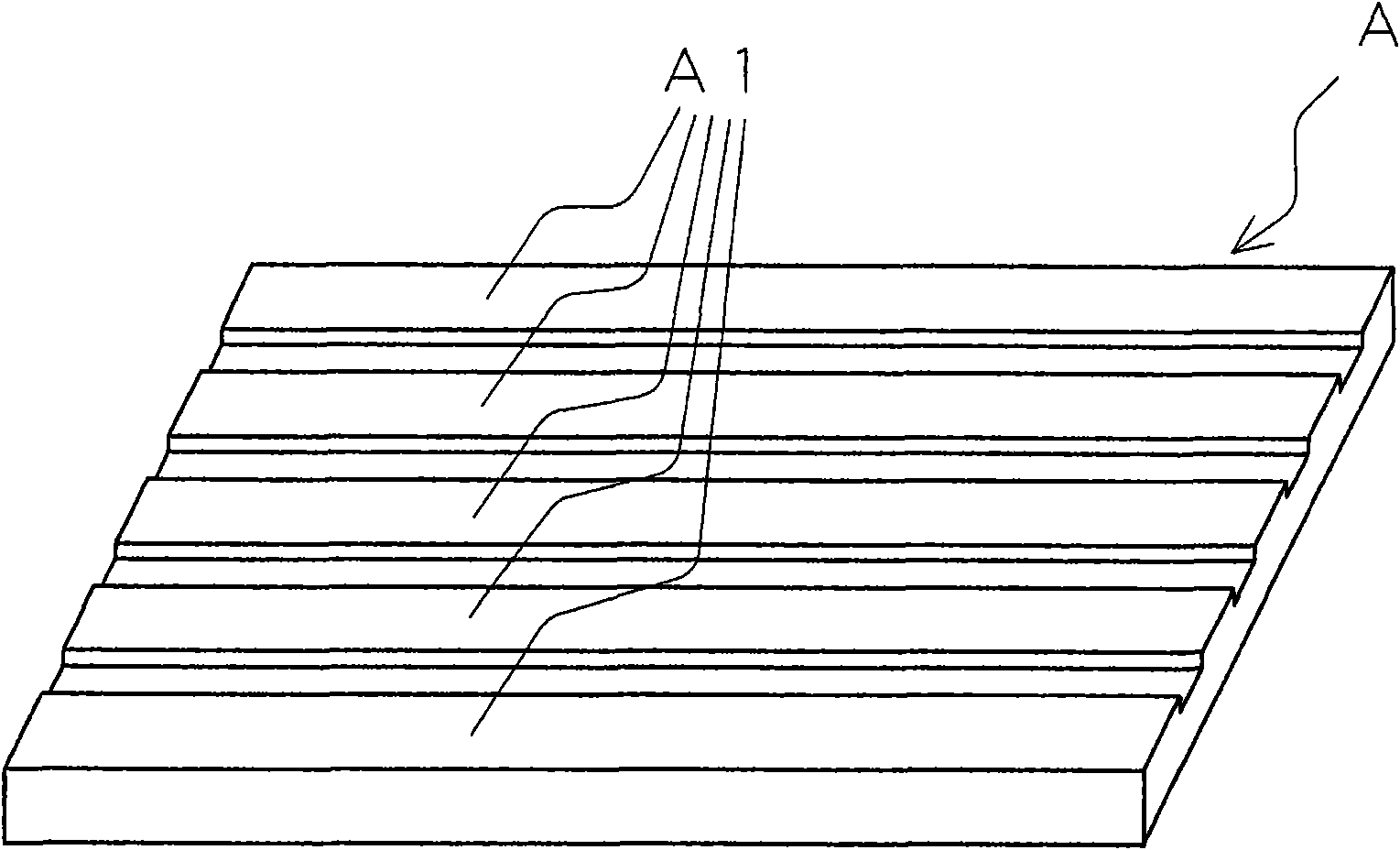

[0040] figure 1 It shows an example of the wood cement board A which has convex part A1 on the surface. Here, on the surface of the wood-cement board A, five protrusions A1 are formed in a straight line in the longitudinal direction.

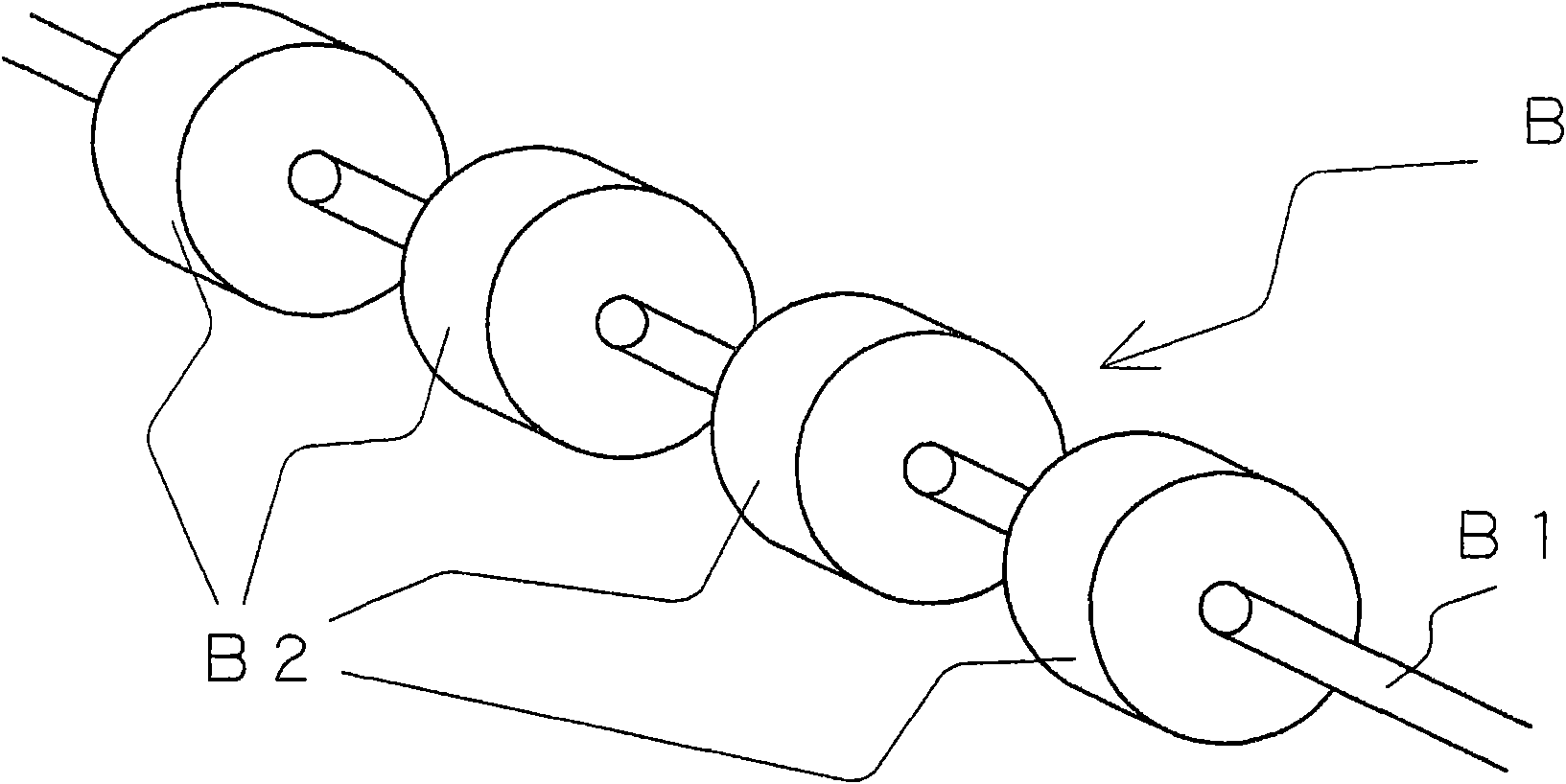

[0041] figure 2 means to manufacture figure 1 The apparatus used for the wood cement board A shown is a diagram of an example of the apparatus B that rotates and presses a part of the base material for forming the wood cement board A. The device B includes a rotating shaft B1 and a plurality of rollers B2 formed around it, and is arranged above a conveyor belt that conveys a base plate and in a direction perpendicular to the advancing direction of the base plate. When the rotation shaft B1 rotates, the roll portion B2 comes into pressure contact with a necessary portion of the raw material of the base plate, thereby pressurizing the base plate. In addition, the operation position and height of the roll portion B2 can be adjusted. In additi...

Embodiment 2

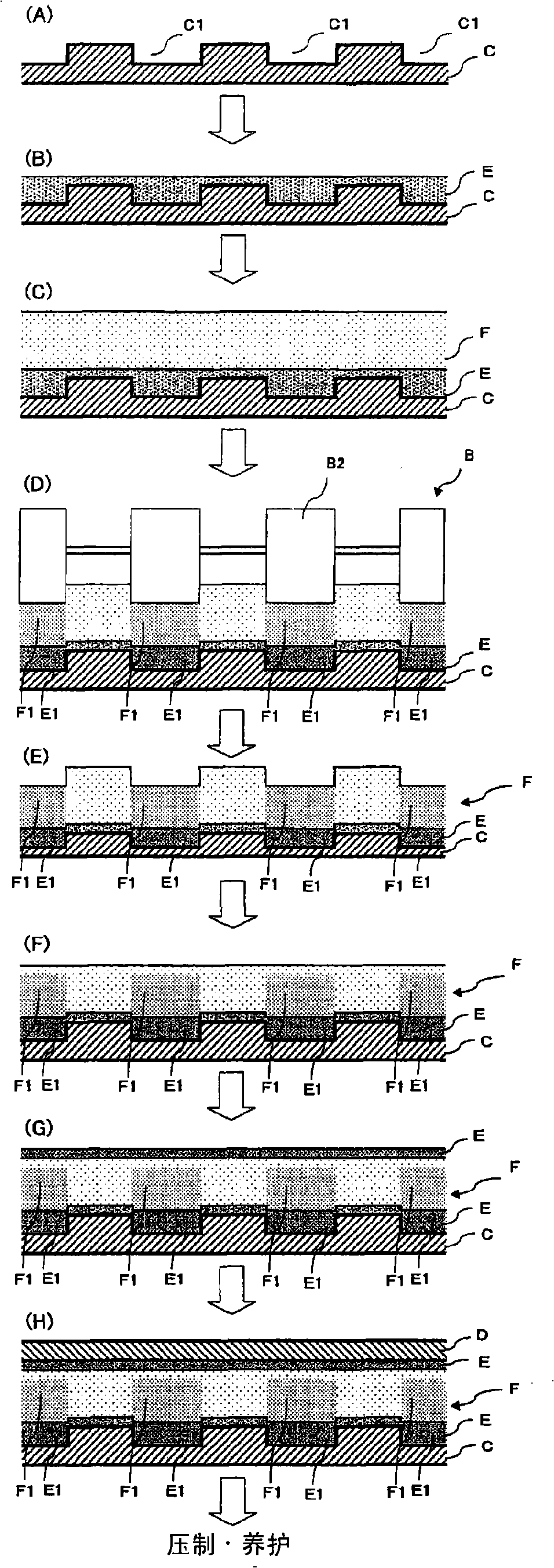

[0062] In addition, as another example, a raw material containing 38% by mass of Portland cement as a hydraulic material, 38% by mass of quartz sand as a silicic acid substance, and 24% by mass of pulp as a wooden reinforcement In the mixture, additionally add 5% by mass of aluminum sulfate as a solidification catalyst to make the raw material mixture of the surface layer, which contains 40% by mass of Portland cement as a hydraulic material, and 40% by mass of quartz as a silicic acid substance. Sand, in the raw material mixture that contains the wood chip of mass percentage 20% as wood reinforcement, add the aluminum sulfate of mass percentage 3% in addition as curing catalyst, make the raw material mixture of core layer, pass image 3 The manufacturing process of the wood cement board shown, manufacturing figure 1 Wooden cement board shown, at 165℃, 6kgf / cm 2 Under high pressure steam curing for 6 hours, to obtain Example 2 consisting of three layers and having a thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com