Method for detecting welding cracks of inclined Y-shaped groove

A groove welding and cracking technology is applied in the field of welding cracks to achieve the effect of reducing gap errors, reducing the risk of exceeding the standard, improving work efficiency and the success rate of tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

[0037] In this embodiment, NM500 wear-resistant steel plate is used, and the chemical composition is calculated by mass percentage as C: 0.20~0.30; Si: 0.20~0.40; Mn: 0.60~0.80; P≤0.012; S≤0.003; Cr: 0.60~0.90; Ni ≤0.30; Cu≤0.30; Mo: 0.10~0.30; the rest is Fe, the steel pipe wall thickness is 30mm. In this embodiment, the test steps of the reliable method for testing NM500 wear-resistant steel plate oblique Y groove welding crack are as follows:

[0038] 1. Choose the right welding consumables

[0039] The welding materials used in the test are imported Lincoln welding materials that match the base metal. The gas shielded welding is LA-100 with φ1.2mm, and the manual welding electrode is 11018MMR with φ4.0mm; the electrode must be dried strictly before welding.

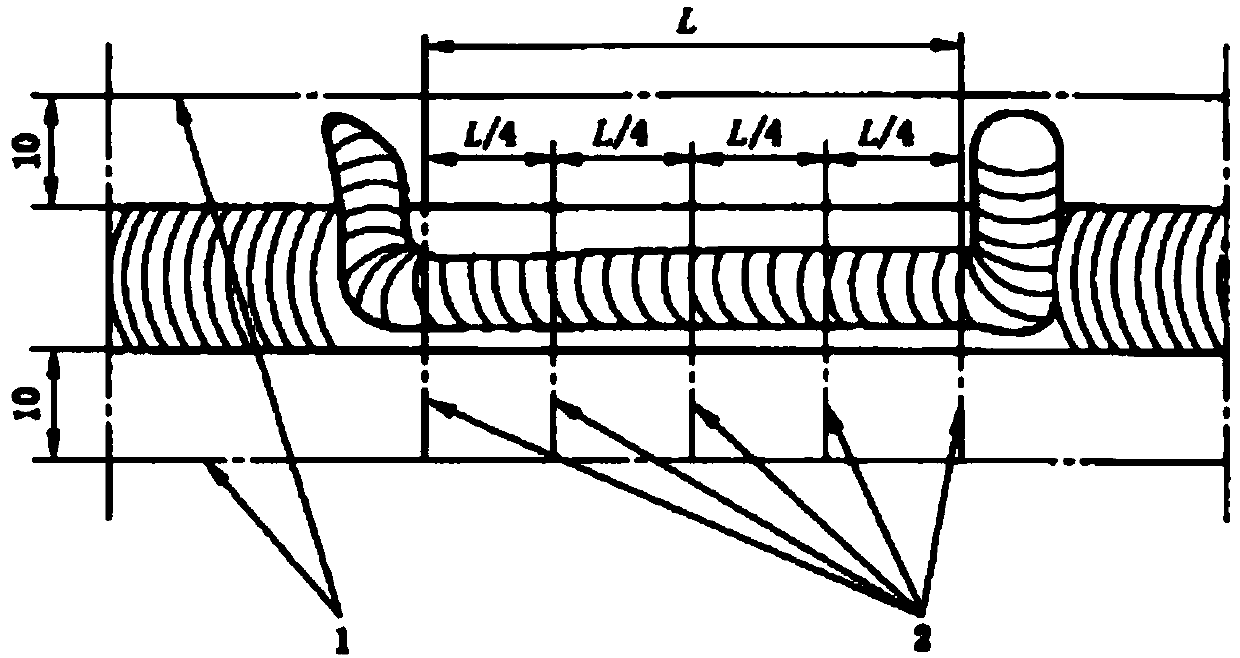

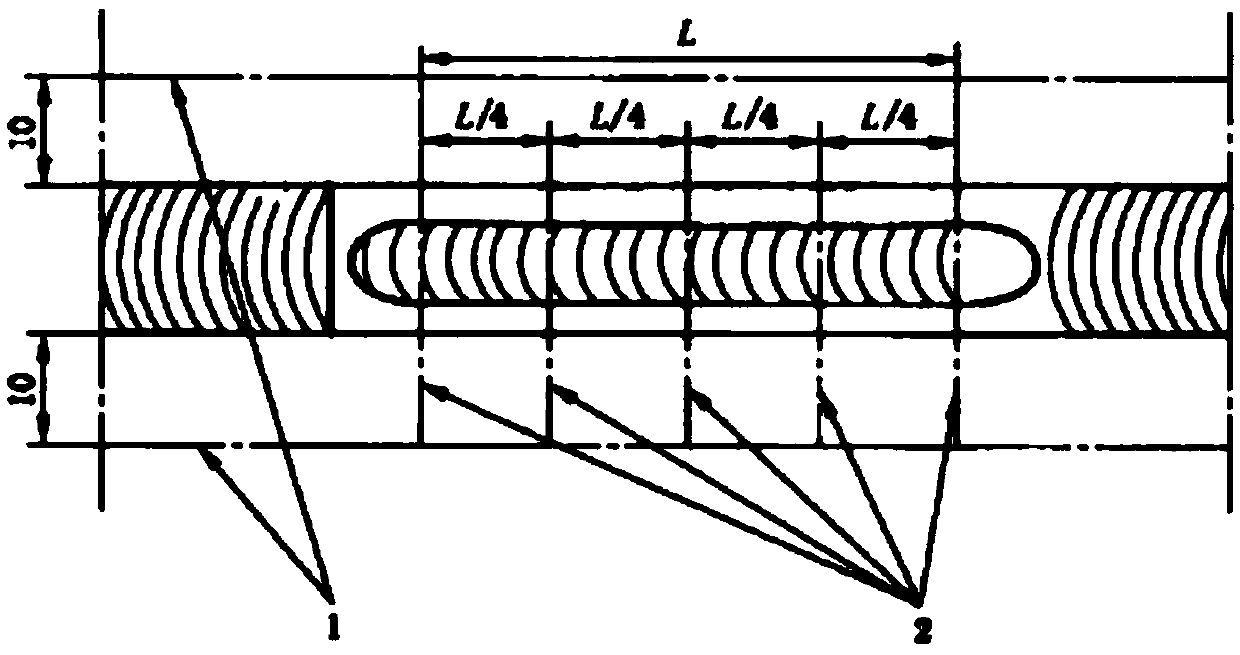

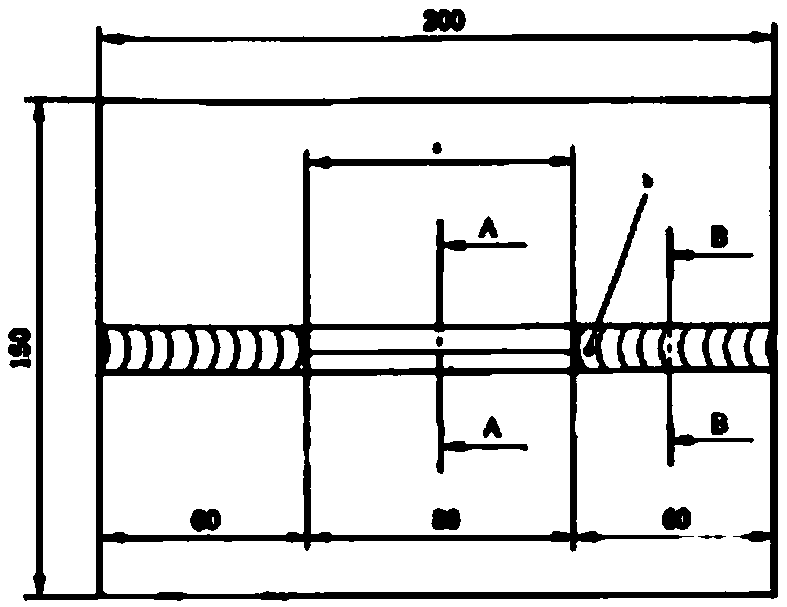

[0040] 2. Optimize the processing morphology of the groove, such as Figure 9-10 As shown,

[0041...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com