Titanium carbide metal ceramic powder and method for laser cladding of powder

A cermet and laser cladding technology, which is applied in the coating process and coating of metal materials, can solve the problems of pores and uneven structure, and achieve the effect of high hardness, dense and uniform structure, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

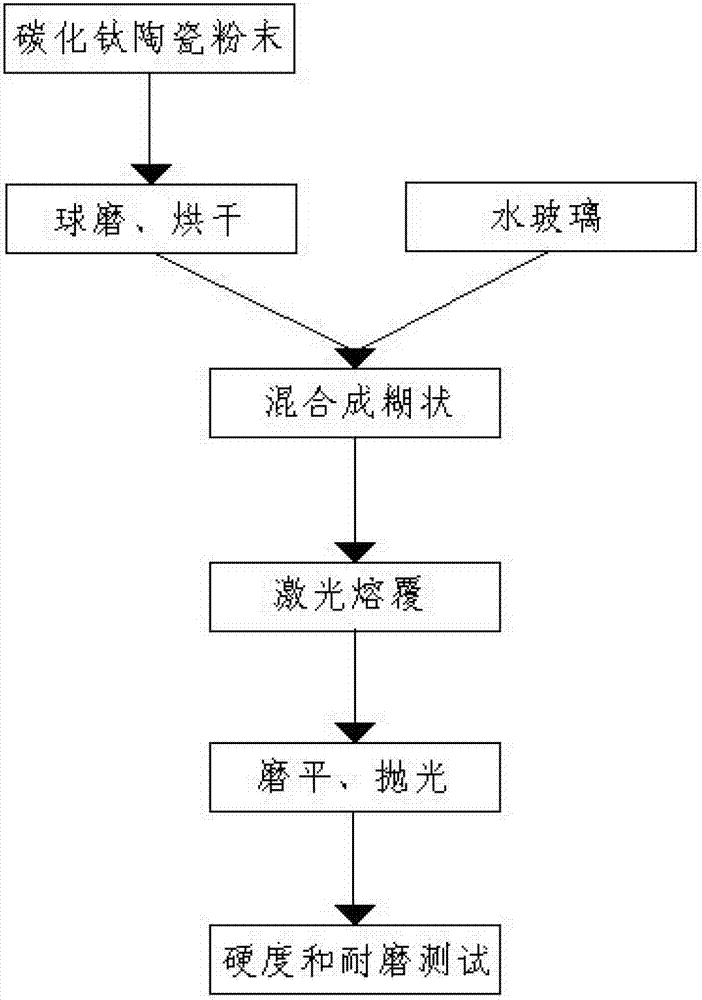

Method used

Image

Examples

Embodiment 1

[0033] The titanium carbide cermet powder of the present embodiment is composed of 30% titanium carbide, 2% lanthanum oxide and 68% nickel 60 by mass percentage, wherein nickel 60 is composed of 3% carbon, 19% chromium, 3% by mass fraction % boron, 2% silicon, 6% iron and 67% nickel.

Embodiment 2

[0035] The titanium carbide cermet powder of the present embodiment is composed of 28% titanium carbide, 1% lanthanum oxide and 71% nickel 60 by mass percentage, wherein nickel 60 is composed of 1% carbon, 12% chromium, 2% by mass fraction % boron, 1% silicon, 1% iron and 83% nickel.

Embodiment 3

[0037] The titanium carbide cermet powder of the present embodiment is composed of 29% titanium carbide, 2% lanthanum oxide and 69% nickel 60 by mass percentage, wherein nickel 60 is composed of 2% carbon, 16% chromium, 3% by mass fraction % boron, 1% silicon, 3% iron and 75% nickel.

[0038] The elements added in the titanium carbide cermet powder have their own functions. Nickel can dissolve a lot of alloying elements, and can maintain good structural stability. It can form coherent and ordered intermetallic compounds, making cladding The layer has higher high temperature strength; chromium element has solid solution strengthening and passivation effect, it can improve corrosion resistance and high temperature oxidation resistance, excess chromium is easy to form chromium carbide and chromium boride hard phase with carbon and boron, Thereby, the hardness and wear resistance of the cladding layer can be improved; a small amount of silicon and boron elements have the functions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com