Method and apparatus for continuous production of flexible micro-nano metal network transparent conductive film

A technology of transparent conductive film and metal network, applied in metal material coating process, ion implantation plating, coating, etc. The product is not easy to recycle and other problems, so as to achieve the effect of good product effect, shortened production cycle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

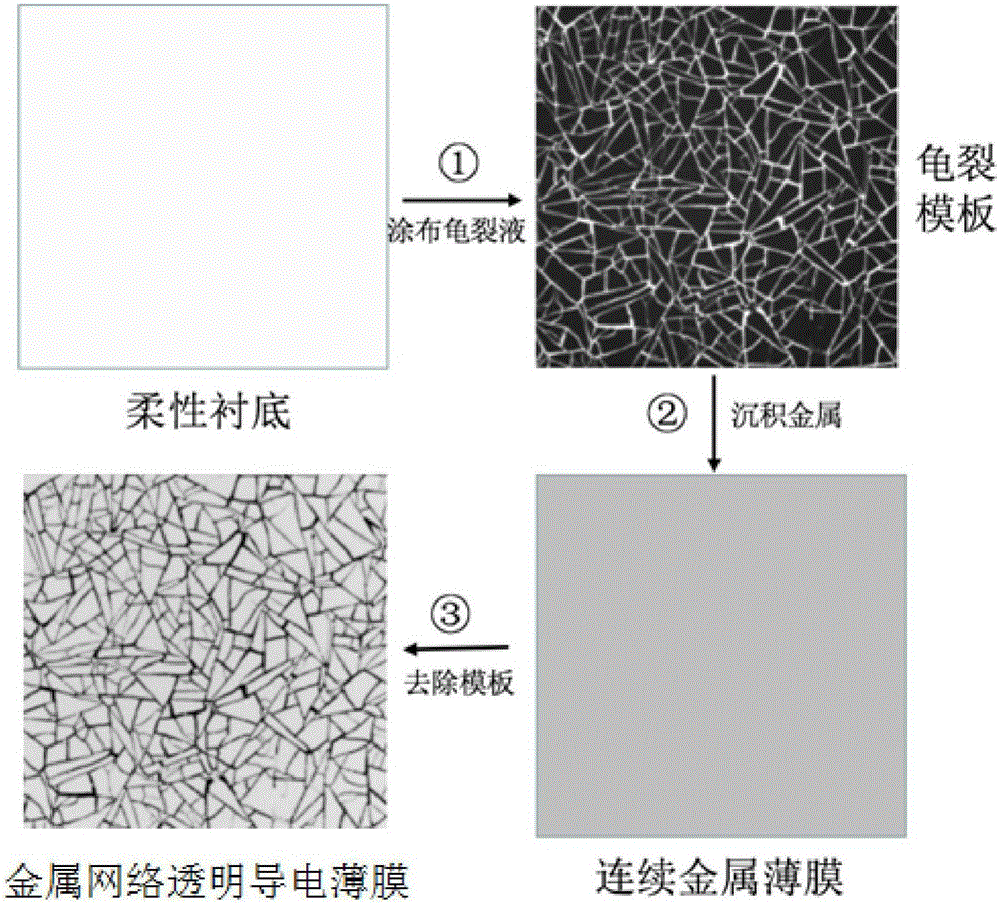

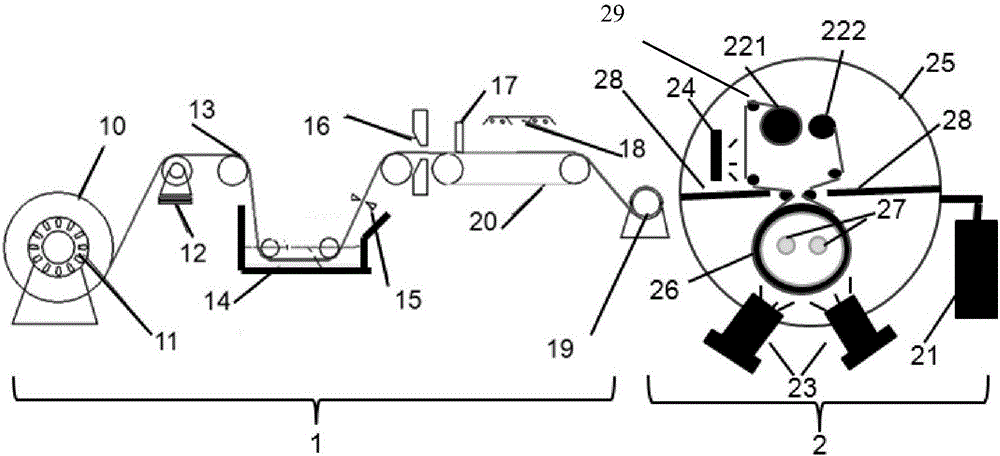

[0039] A method for continuously producing a flexible micro-nano metal network transparent conductive film, comprising the following steps:

[0040] ⑴Preparation of flexible substrates with cracked templates: rolls of flexible substrates are discharged, and the flexible substrates are continuously transported through pre-cleaning, air-drying, normal-pressure plasma cleaning, coating and heating of cracking liquids, and the selection of cracking liquids Polymer gels such as egg white and titanium dioxide. In this embodiment, egg white gel is used as the cracking fluid. A crack template is formed on the flexible substrate, that is, a flexible substrate with a crack template is produced, and the crack width on the crack template is 0.5-10 microns. During the conveying process, according to the tension of the flexible substrate, the tension and speed of the flexible substrate are adjusted to realize the constant speed and constant tension of the flexible substrate, and after the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com