Forming production process for whole-body ceramic polished tile

A production process, technology of polished tiles, applied in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve the problem that the surface wear resistance of glazed tiles is not as flat as polished tiles, and achieve the effect of bright texture and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

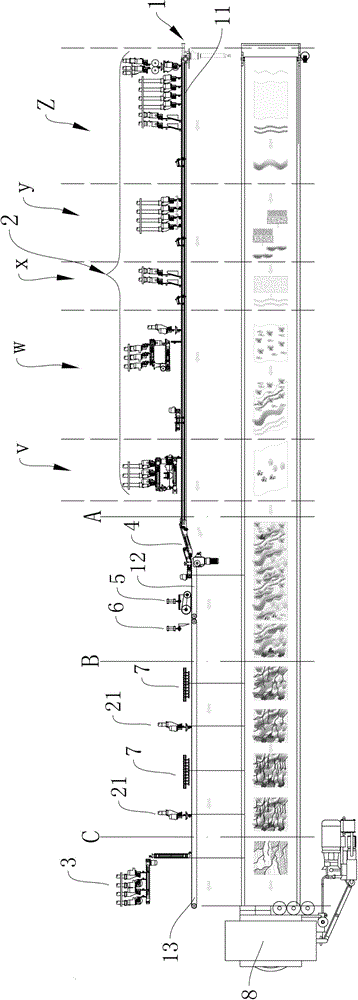

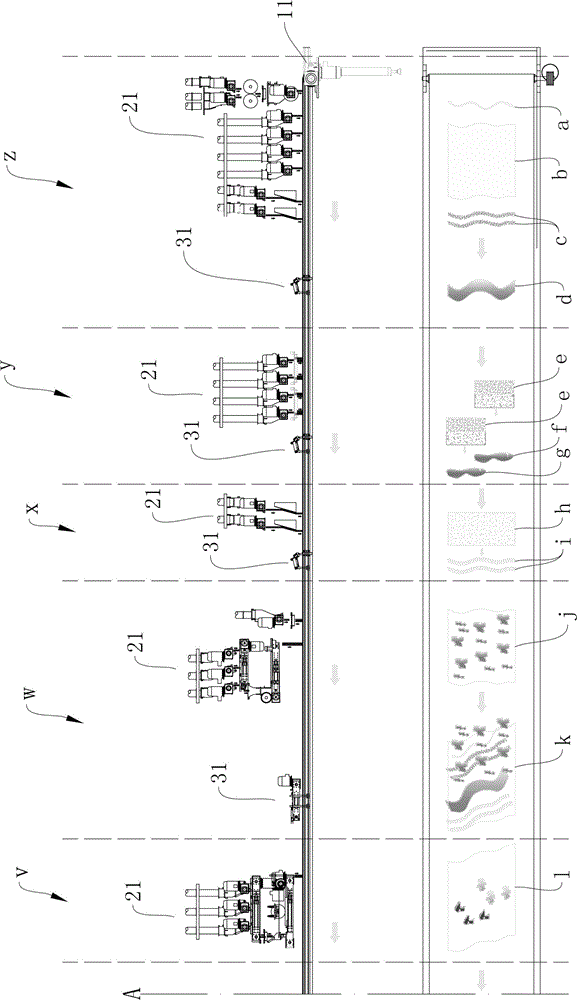

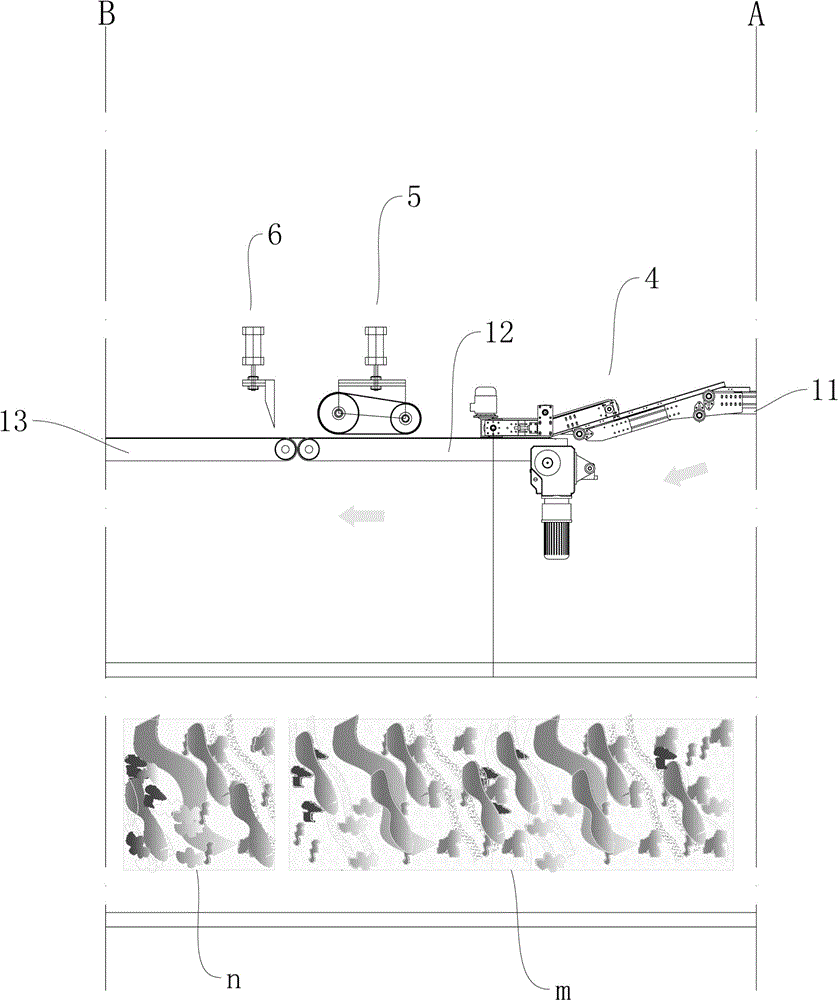

[0042] Such as figure 1As shown, a molding production process of whole-body porcelain polished tiles, the devices or mechanisms to be used in the production process include: a conveyor belt device 1 for receiving powder and conveying powder, a front distributing device 2, and four powder Shape correcting device 31, rear distributing device 3, stockpile slope arrangement device 4, rolling device 5, cutting device 6, two crevice generating devices 7, stamping forming device 8, wherein the conveyor belt device 1 consists of the front section The conveyor belt mechanism 11, the middle conveyor belt mechanism 12, and the rear conveyor belt mechanism 13 are composed of the front conveyor belt mechanism 11, the middle conveyor belt mechanism 12, and the rear conveyor belt mechanism 13. Composition, wherein the front conveyor belt mechanism 11 is further divided into five working zones, the five working zones are respectively the first zone z, the second zone y, the third zone x, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com