A kind of molding production process of whole body porcelain polished tile

A production process and technology of polished tiles, applied in ceramic molding machines, ceramic molding workshops, manufacturing tools, etc., can solve the problem that the surface wear resistance of glazed tiles is not as flat as polished tiles, and achieve the effect of bright texture and color

Active Publication Date: 2019-04-16

佛山市高明贝斯特陶瓷有限公司 +2

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because of the thin surface decorative layer, and due to factors such as color development and process limitations, the surface wear resistance and surface flatness of glazed tiles are not as good as polished tiles and whole body porcelain polished tiles.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

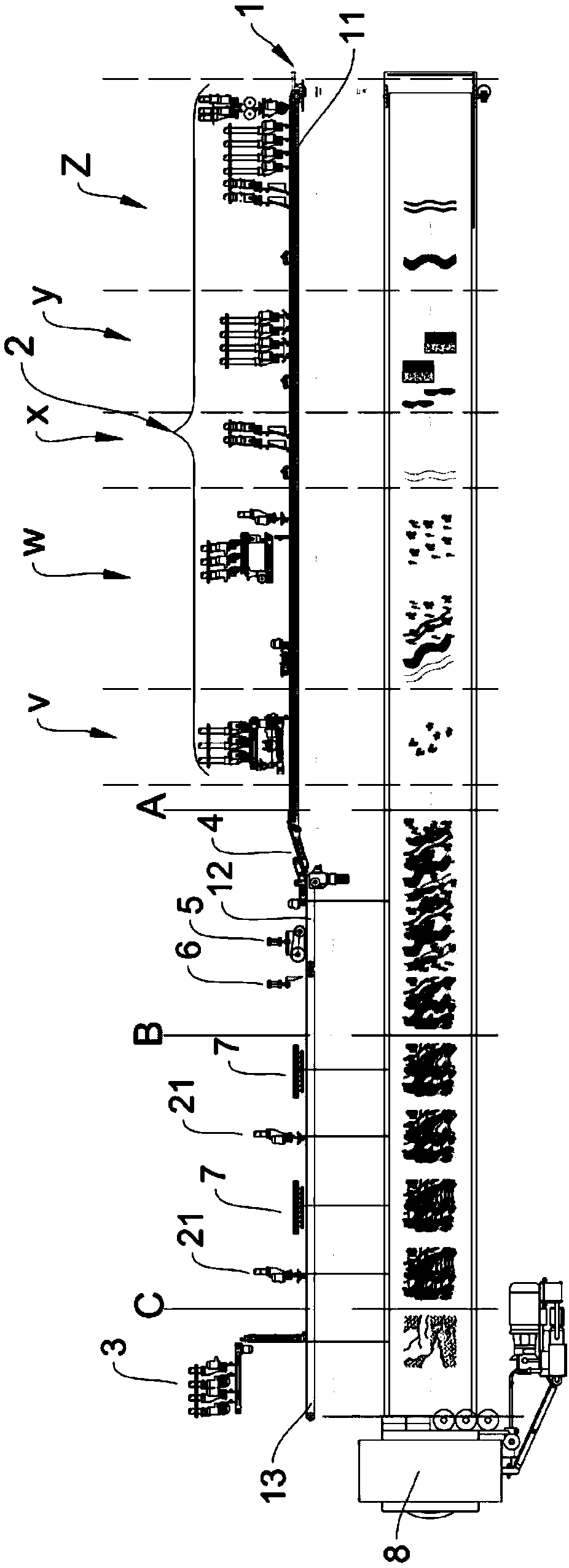

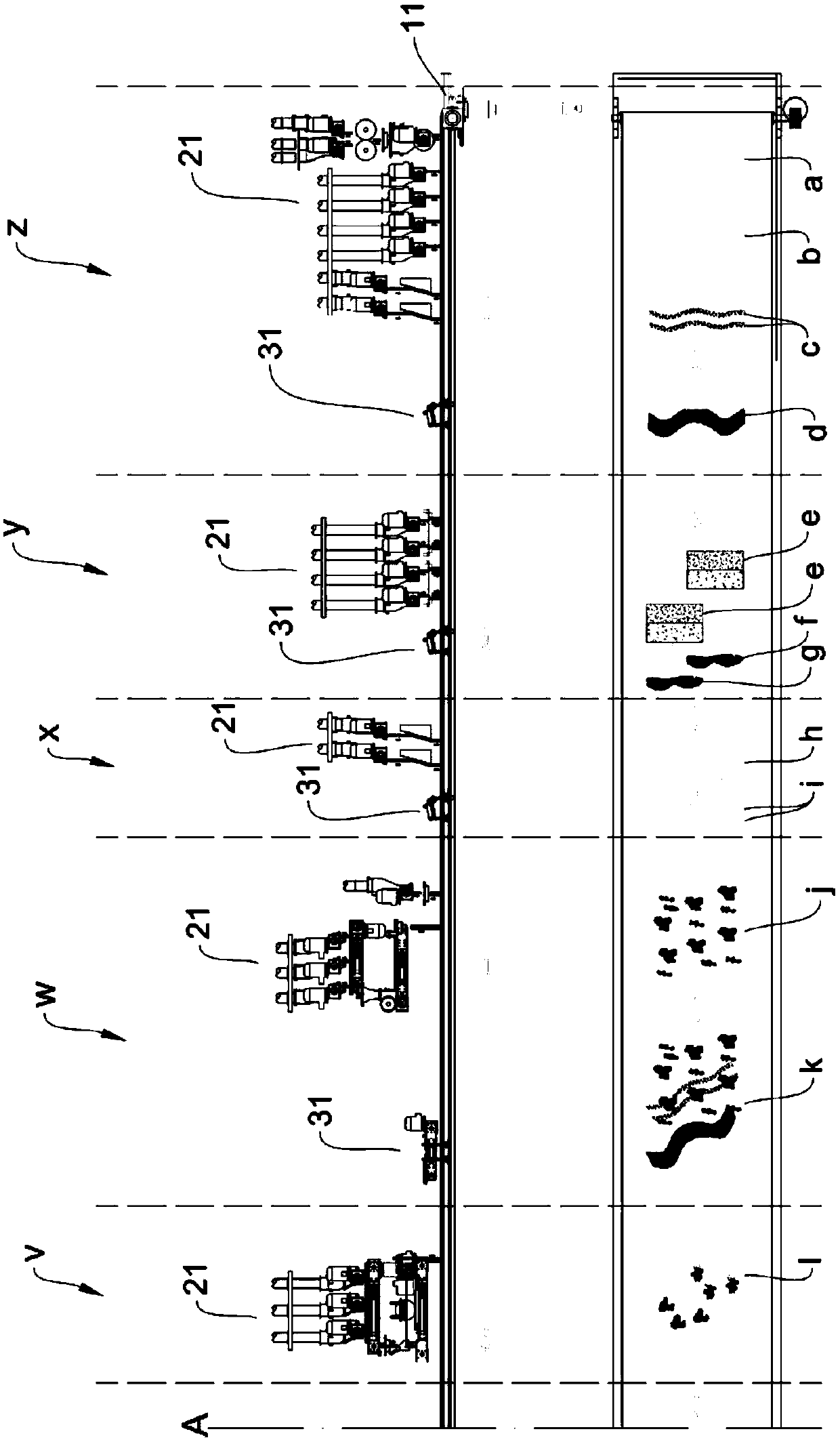

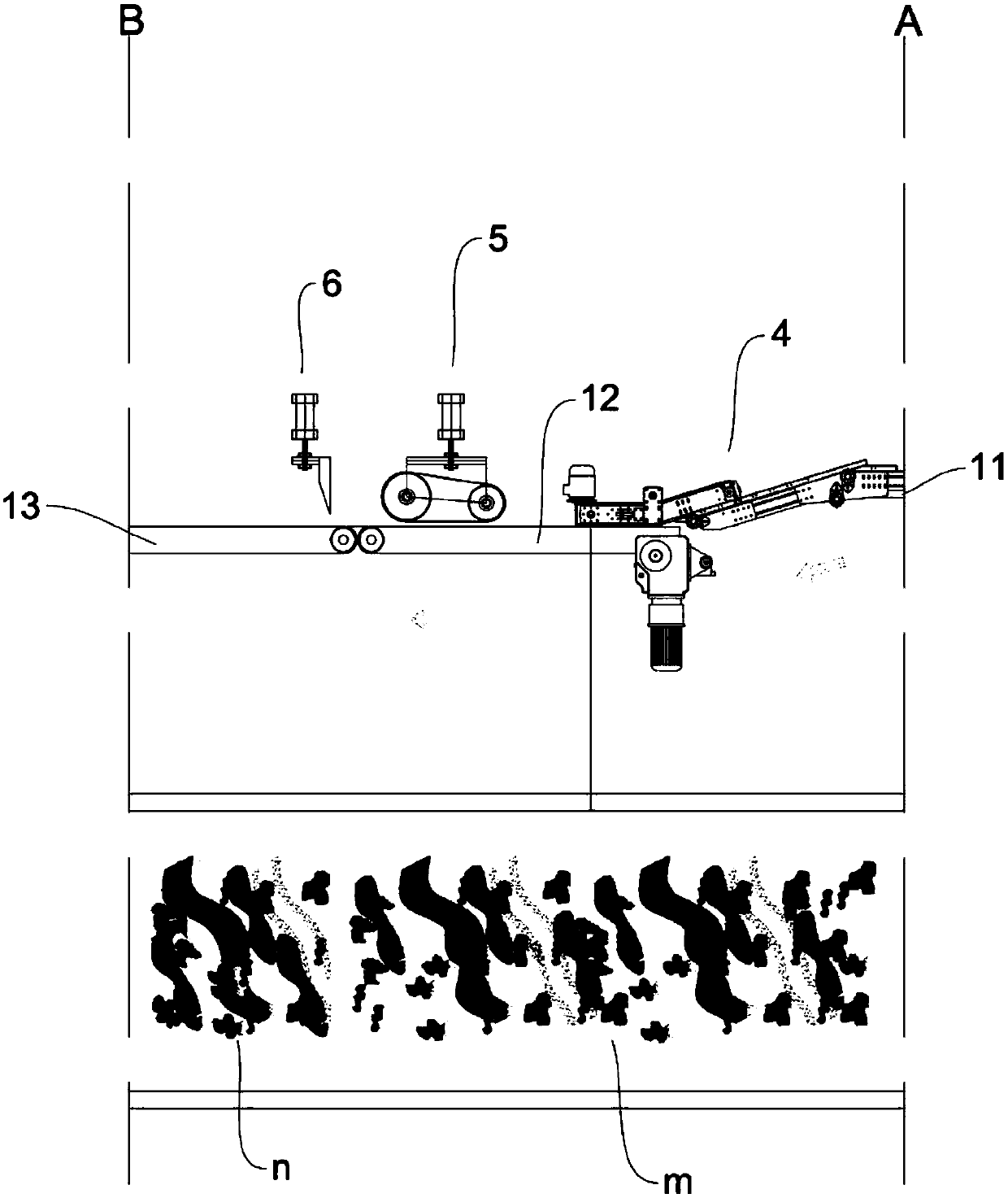

The invention relates to a forming production process for a whole-body ceramic polished tile. According to the forming production process, a conveyer belt device, a front distribution device, a powder shape correction device, a rear distribution device, a material pile slope arrangement device, a grinding device, a cutting device, a craquelure generation device, a stamping forming device and the like are scientifically, reasonably and orderly controlled to operate orderly and systematically according to well designed process steps, so that the produced tile product has the characteristics of hardness, abrasion resistance and durability of common whole-body ceramic polished tiles and has rich, realistic and bright textured patterns and colors of glazed tiles. The forming production process is a brand new and revolutionary production process which replaces a production process for existing polished tile and glazed tile products, meets increasingly high life quality requirements of people, and can be used for producing the ceramic polished tile product with the texture effect of natural stone and whole-body textures consistent from inside to outside.

Description

technical field The invention relates to the field of ceramic tile production technology, in particular to a production process method of a full-body porcelain polished tile and a porcelain polished tile prepared by the method. Background technique Whole body porcelain polished tile, referred to as "whole body brick", is a combination of carefully selected ceramic raw materials through scientific configuration into formula powder, and then through the process steps in the above production process method, high pressure pressing and molding, after high temperature (firing temperature 1210 ℃ - 1220 ℃) sintered, and then formed after surface polishing. Its various physical and chemical performance indicators are obviously better than natural stone, with lower water absorption, better wear resistance, higher hardness, better stain resistance, and product radiation reaching Class A standards. The surface of the whole body porcelain polished tile is not glazed, to achieve the ef...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B28B13/02B28B15/00

CPCB28B13/02B28B13/0205B28B13/027B28B15/00

Inventor 刘建新何国强吕仕康叶祥余东海余昌炽

Owner 佛山市高明贝斯特陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com